Purchasing a wrong diving hat is an absolute disaster. The underwater diving helmet is one of those things that are so specialized that any mistake will significantly impair your workability.

If you are a diver, you know this already.

I won’t bother you with emphasizing the importance of matching the diving hat with your needs. What I will do is explain everything in detail so that you get a very clear picture of which diving hat is for what use and how to go about selecting your helmet. Let’s start with the different types and then see more details of the most commonly used hats.

What types of commercial diving welding helmets are there?

Fun little fact for you.

The first “diving” hats were made in the 1820s by Charles and John Deane brothers.

They were used to protect firemen from inhaling smoke during the fire because the hats were air-tight and had a steady supply of fresh air just like today’s diving hats do.

Anyway, long story short, the brothers had some funding issues and in the end, their invention was modified into the first commercial diving helmet.

Charles performed the first-ever dive with his helmet where he recovered 28 cannons from a sunken ship in 1834. No comms, no lights no established safety procedures.

The true pioneers of this industry. Later on, the brothers made the first-ever diving manual and established the industry itself.

There is more to the story but let’s keep our focus on what matters.

You are probably not here for the History lesson so, let’s see which diving hats are still in use today and for what purpose. Important stuff first!

What are Free-Flow Systems and Demand Systems in Diving Hats

The first diving hats used the free-flow system and the newer types use the demand system for supplying air. However, free flow is still used today because sometimes it offers more advantages.

Free flow diving helmet design – Hats have a constant supply of fresh air regardless if the diver is breathing in or out or not breathing at all (for example if the diver gets unconscious). The continuous flow of air is supplied through the umbilical and expelled through an exhaust valve against over-pressure.

Demand diving helmet design – These diving hats operate using a special demand regulator which only provides air when the diver inhales. These commercial diver helmets are a standard in the industry today but they are not always the best choice. These helmets are also referred to open circuit design hats.

The free flow design has logistical issues, increases the cost of air supply significantly and especially when the helium mixture is needed for a diver and compromise communication because of constant air noise.

But on the other hand, the free flow design is preferred when commercial diving in HAZMAT waters. The positive pressure inside the free flow hat makes it difficult for any toxic matter to penetrate the barriers if the suit or helmet gets compromised.

These helmets are also cheaper than the demand design types and using a hat in HAZMAT environments shortens its lifespan so the lower cost associated with free flow design is a plus. Now we can talk actual diving helmet types and models.

The Mark Five

If you are a new diver and you take a look at the Mark Five diving helmet, you would probably think that it’s some ancient piece that no one ever uses anymore.

It is ancient but commercial divers still use it. These hats are still handmade (breastplate) and in accordance with the design from 1942. This diving helmet originates from WWII and it was the U.S. Navy Bureau of Ships that made the drawings of it.

This is a free flow system hat and today it is used mostly in high current situations. These hats are very heavy.

Once you combine the hat, the breastplate and the rest of the suit you will easily put on another 200lb and sink to the bottom in a flash. The high currents are much easier to handle in the hostile marine environment if you are in one of these when you are performing underwater welding jobs.

The Mark Five’s weight rests upon your shoulders because the breastplate transfers the weight onto them. This is necessary because the helmet itself weighs about 80lb.

The DESCO

There are a few variants but generally speaking the DESCO’s are known as the free flow hats that are used in HAZMAT waters only. The design itself is very safe for the diver and they are best used with the full Vulcan drysuit to protect from the contaminated waters.

The DESCO is an underwater helmet that lasts a very long time and has been time tested. A lot of the old-timers swear by them and prefer to use them over other diving hats.

Commercial divers can disassemble the DESCO in the field using nothing but a simple screwdriver and a wrench.

The robust and simple design is what old-timers still love and use today. These have a two and four-wire communication option (more on this later), adjustable exhaust valves, stainless steel air control valve, double inlet valve and many other safety features.

The Kirby Morgan Hats

The Kirby Morgan hats revolutionized the commercial diver hat industry and especially for underwater welders because they have a very easy way of attaching a welding screen.

The Kirby Morgan’s come in many different models and weights. They are generally lighter than the DESCO and Mark models but there are also superlight Kirby Morgan series.

The weight of these commercial diving hats is carried by your head but they become positively buoyant once you are in the water.

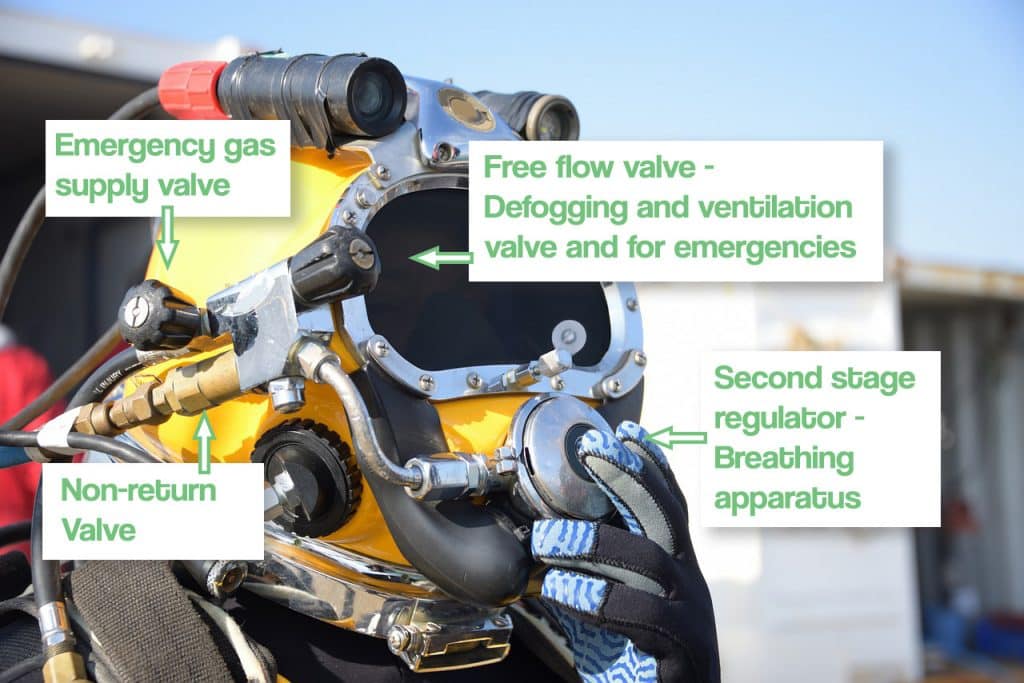

Almost all of these helmets have open circuit (demand air) supply systems. The Kirby Morgan is a standard today. You are most likely going to be using it if you are doing any underwater welding jobs. They are built on a fiberglass shell with chrome-plated brass fittings but they also come in a stainless steel form. Here is an excellent overview of every element of a Kirby Morgan hood.

Can You Just Use A Full Face Mask instead of a Helmet?

For light jobs in shallow water, yes you can. Will the safety instructors allow it? Most likely not. Sometimes if the job is not very dangerous it is possible to use a full face diving mask.

It would actually be best if you could use it all the time. It provides greater visibility, it’s lightweight and way less expensive.

But it also provides you with very low protection so unfortunately, for real underwater welding, you will need more than a full face mask or scuba diving gear. Using a face mask doesn’t provide clear communication, physical protection from metal impact, HAZMAT safety from toxic material and other dangers that could kill you on site.

How To Choose A Commercial Diving Helmet

Now that you know some history behind these models and how they work in principle it is time to discuss the specifics. First of all, if you are not a HAZMAT diver you are unlikely to need a DESCO model. Second, you will not need to own a Mark V, if you ever have a chance to use it, the company will provide it for you.

No one in their right mind would buy the Mark V today except the diving companies for rare jobs that require it. Third, you are most likely going to get a Kirby Morgan model. Almost everybody does. They are almost irreplaceable commercial diving equipment at this point.

But regardless of the type and model, you choose, here are some things to keep in mind when making your selection. It is important that you get a hat that fulfills your needs and doesn’t make your job difficult.

The Return Policy

Make sure that the place you are buying your new diving helmet has at least 2 weeks of a return policy. You must thoroughly test the hat. Try everything and see if it works for you. The commercial divers’ equipment is expensive and the hats are the most expensive element the underwater welders own.

This brings us to…

Price

The commercial diver hats’ price can range from $6,000-$10,000 dollars if you buy a new one. But it is also possible to get a used helmet thanks to its durability.

That way you could be looking at a $1,000-$3000 range. This may sound more approachable but you should only get a used helmet if you are positive that the previous owner took proper care of it. Make sure that you are ready for this type of investment. If you are a new diver, think about your work experience and future income.

Are you sure you are ready to start getting your own equipment?

Maybe you don’t really need your own helmet?

A lot of jobs will give you underwater welding equipment and this includes the hat. During the duration of the job, you will be responsible for it. You must treat it like your child and almost every job will have a policy on maintaining the hat.

Such a policy may state that every night after the job is done, you must clean the hat, check its conditions, feed it, love it, never let anything happen to it and such.

Using the company’s hood saves you money but it’s also a responsibility.

On top of that, you have to trust the employer that everything is in working order because someone else used that hat before and someone else before them and so on. So, you can evade buying the hat at first, if you find a job that provides it and you are ready for the responsibility and risks that come with it.

Breathing Function

Now let’s get started with technical aspects. The most important aspect of them all? How well you can breathe inside the helmet. You should test different helmets and find the one that allows you a high degree of breathing efficiency.

Your breathing needs to be effortless and easy to control. We talked about the open circuit aka on demand airflow helmets above and the free flow designs. You will use the on demand air hats most of the time so make sure that all of their regulators and valves are of extreme quality and that they allow for adjustments. Nothing will make your job difficult as having problems when breathing under the hood.

Regulators and Valves

The regulators on your helmet must be made of anti-corrosion materials. This is industry standard in modern helmets. You will be choosing between hard plastics and stainless steel but there are other materials that can be used.

Your regulator should have a high range of adjustments. This will help you fine tune the breathing settings according to your needs. Valves need to be in an easy to reach location but most designs have taken this into consideration already. Especially the emergency air valve.

As a welder diver, you will always have a backup tank with you. This tank is connected to your emergency valve on your helmet and if the umbilical were to sever or something else were to happen that would leave you without air, you would just open the emergency valve and breathe from your tank.

This tank usually has a very little amount of oxygen. Just enough to get you to the surface. Other valves your helmet needs are the gas supply non-return valve and a ventilation valve.

The ventilation valve is used to defog the viewing area and to ventilate the face. The non-return supply valve lets the breathing gas enter from the umbilical cord.

Communication abilities

Commercial diving requires a lot of communication. You will constantly be in direct communication with the topside team.

Your tender will constantly communicate with you, directing your workflow, paying attention to your breathing and be in a constant state of readiness if you were to call for help.

None of this is possible without clear communication. There are two methods of comms underwater welders use when wet welding.

- Two wire: This is a term used to describe a communication method where only one person can talk at a time. Radio-style comms system. This means that when you are underwater that only you or the person above can talk.

- Four wire: This is a more complicated system that allows everyone participating to talk at the same time. This can prove better or worse depending on the organization. Commercial diving is not a picnic so no unnecessary talk should happen.

The diving helmet is directly responsible for the quality of voice transfer. The acoustics of the hat plays a major role. Your helmet’s shell should be made of dense material and be elastic enough. Stainless steel is an excellent material for clear comms but bronze is also a great choice.

Weight of the diving helmet

Welder divers need balance and proper buoyancy when doing any underwater wet welding but even when doing hyperbaric welding you will need to get there first.

Your typical Kirby Morgan diving helmet will weigh about 28-35 pounds but there are even heavier models. The DESCO is much heavier and the Mark Five is the heaviest of them all. We will now talk only about Kirby Morgan because that’s what most of you will be buying.

The weight distribution must be even and your head shouldn’t be falling forward or backward. If this is happening then there is either some problem with the weight distribution or that specific model is not for you.

We are all built differently so you need to try multiple Kirby Morgan models to find what works for you.

Most driving schools will let you try many models in order to find what works the best for you. Spending some time in the water with your diving helmet is crucial.

That way you will be able to assess the weight distribution and buoyancy and see if there are any issues. You shouldn’t satisfy with a helmet if your workflow is impaired by it. Your work quality may suffer at best and it could be dangerous at worse.

Diving helmet size

The diving helmet must have a very nice fit with your head. It shouldn’t be tight but it must feel just right. This is something that only you can feel and know if everything is okay. The hat shouldn’t be bigger than what you need either.

Your face must have a comfortable area.

You could spend months or minutes working on a structure but either way, in order to do a good job your helmet needs to be tailored to your head.

Every expert takes sizing seriously and so should you. Almost every commercial diving helmet will let you substitute one foam padding with another so that you can achieve that proper fit so even if you are not satisfied with the model, it is possible to modify it.

The mobility you can exhibit

Imagine welder divers not being able to make a full range of motion. Unfortunately, some people don’t know that an improper setup of the helmet or just choosing the wrong helmet is the cause of this. This can lead you to working with reduced abilities and can stifle your career.

You will perform better if your mobility is similar to that when you don’t wear any commercial diving equipment. In order for this to be possible, your neck dam needs to have a proper fit with your neck. This may mean testing out different models and finding the one that works for you.

Depending on the diving suit you are using this could get a bit more complex too. For example, if the job characteristics require you to wear dry suit you will have impenetrable insulation from the HAZMAT particles but your mobility will suffer unless the material is right for your body and everything is sized properly.

The neck dam is usually made of neoprene (a synthetic rubber) or latex. The material characteristics can also play a role in both mobility and insulation you can exhibit. Next, the dam has to be properly secured to the helmet and the helmet needs to fit your head properly.

Before you set up everything, make sure to check your mobility during the various stages. For example, test your mobility after you put your neck dam and see if you have a full range of motion. Then secure the helmet on it and see if there is any difference.

The complexity of the diving helmet

Simple is always better. DESCO is way more simple to disassemble and maintain than Kirby Morgan for example but the Kirby Morgan offers many other benefits that make it an industry standard.

However, you should look for the diving helmet that you feel comfortable maintaining. If the helmet is easy to maintain it will also be easy to repair if it comes to it.

A helmet that has a complex design will have more elements that can break. I would always prefer purchasing versatile stuff with the capability I need and that is simple enough for maintenance. No overly complex stuff.

But with the helmets, it is not as simple because a project may force you to take on a more complex designed hat. A diving helmet that is made with durable materials and has a straightforward method for maintenance will save you a lot of time and trouble in your career.

Welding and other Accessories

Different commercial diving jobs may require different accessories. The more accessory friendly your diving hat is the better. For underwater welders, the number one thing is the ability to attach the welding lenses accessories.

The welding screens flip up and down easily on most helmets which is a big plus for welder divers. Kirby Morgan models are constructed with the special lens attachments capability on the shell. The lens shades will range anywhere from DIN 4 to DIN 12 but you are likely to need a few different pieces. I’ve seen some guys from the UK sporting auto-darkening shades.

There is a UK company selling what they claim to be the only one in the world, an auto-darkening shades kit fitting for Kirby Morgans so if that sounds interesting to you, you can check it out in the links section below.

But there are other things you may want to use like cameras, brackets and lights. Taking video footage or photographs can be a part of the commercial divers’ job and good cameras accessories can make this way easier.

Consider the type of jobs you will be doing the most and what accessories are needed. Then find a helmet that supports these characteristics and you are good to go.

Conclusion

I understand that a lot of what I wrote comes down to “you must test the hat because it’s subjective”, like weight distribution, size, fit and etc. But remember, the commercial diving industry doesn’t have hundreds of thousands of divers so that these things are perfectly solved.

It’s difficult to buy a proper welding machine and there are so many more surface welders than underwater welders. Of course that we are still somewhat limited in the commercial diving helmet design choices and they do have their issues. The Kirby Morgan diving helmet model is from the 60s and while it works the best, you have to take matters into your hands and test things out.

This article is meant to be a practical guide to help you in finding a commercial diving helmet model and to give you an idea of where you could make a mistake so that we can hopefully prevent that but in the end, it’s tough to just order your diving hat online as if its a surface welding helmet.

Resources:

- https://www.kirbymorgan.com/ – Kirby Morgan Offical Website

- https://www.divedesco.com/ – DESCO Official Website

- https://www.smp-ltd.com/shop/real-colour-auto-darkening-welding-filter-lens/ – Auto-darkening lens

- Underwater Welding techniques at www.academia.edu