It is common knowledge that TIG welding (Tungsten Inert Gas) welding is one of the more complicated welding processes

as you probably already know.

You also know how hard it is to pull out a good TIG weld without a good welding machine,

and finding a fantastic TIG welder that also is not “over the roof” expensive is the hardest part. To shorten your search, We have prepared a list of the welders that I believe fall into the “Best TIG Welder” category!

There will be budget welders and semi-professional welders with AC/DC capability for aluminum welding and other machines that I consider worthy of mentioning.

We also updated our buyer’s guide for 2022 to fully cover every useful feature one should look at when purchasing a TIG welding machine. IF you give it a chance, the guide will help you to make the best choice in your budget range and for your needs exactly.

Please hop on, and let’s start…

Table of contents:

- Comparison table.

- Welder Reviews.

- Things to consider when selecting your welding machine.

Best TIG Welder Quick Comparison

| Welder Image | Name | Specials | Voltage inputs | Output Current Type | Amperage Output | Duty cycle | Dual Voltage | Check Price |

|---|---|---|---|---|---|---|---|---|

| YesWelder CT2050 7 in 1 Welder and Cutter | AC/DC Welder and Plasma Cutter Get 10% Off With Coupon: “-10% WELDPROS” | 96-265V | AC/DC | TIG: 5-200 A | 100% at 200 A | Yes | Check Current Price YesWelder |

| AHP AlphaTIG 203Xi 200Amp IGBT AC/DC TIG/Stick Welder with PULSE | Best Under $1000 | 110V or 220V | AC/DC | TIG 10-200A | TIG 60% at 200 amps | Yes | Check Current Price Amazon |

| Eastwood TIG 200 AC/DC | Best Entry-level Welder | 110V or 220V | AC/DC | TIG 10-190A | 60% at 190A | Yes | Check Current Price Eastwood |

| Everlast PowerTIG 200EXT | Best For Aluminum | 120/240V | AC/DC | TIG 5 A – 250 A | TIG 60% at 250 amps | Yes | Check Current Price Amazon |

| TIG Welder, Diversion 180, 120-240VAC | Brand-name Beginner Welder | 120V or 220V | AC/DC | 10 A – 180 A | 20% at 150 amps | Yes | Check Current Price Amazon |

| Lincoln Electric Square Wave TIG 200 | Great "Red" TIG Welder | 120/230V | AC/DC | TIG 10 A - 200 A | 60% at 130 A | Yes | Check Current Price Amazon |

Best TIG Welders Reviews

Let’s take a look at a selection of TIG machines that can be utilized for various uses of TIG welding.

1. YesWelder TIG 250P ACDC – Best TIG Welder For The Money

The YesWelder Firstess CT2050 is a fantastic 7-in-1 welder that combines AC/DC TIG, Pulsed TIG, Stick, and Plasma cutting. Even though there is no MIG welding, AC TIG, pulse, and cutting features make this machine an all-around welder for exotic and thin metals, such as aluminum, magnesium, brass, and also steel.

CT2050 is a dual voltage welder, and there is a built-in PFC technology. Power Factor Correction (PFC) technology allows the welder to work with 96-265V input.

When it comes to power, YesWelder CT2050 is quite a capable AC/DC TIG welder rated at 5-200 amps at 220V and 5-160 amps at 110V. I was surprised with the 100% duty cycle rated at the maximum power output of 200 amps for TIG welding. The power is backed up by fine features and controls, such as an AC input and pulse, which will help you weld delicate metals.

I really like the smart AC control, which will make AC TIG welding aluminum easier than ever for beginners. By selecting aluminum thickness and welding position, the machine will recommend the ideal parameters, such as amperage, pulse, and gas flow, for suitable aluminum welding.

Besides TIG, this is also a suitable stick welder. Even though it utilizes IGBT inverter technology, you can use the notorious 6010 electrodes, and there are decent features such as hot start, arc force, or anti-stick.

What you rarely see is a plasma cutter combined with a TIG welder. You can use CT2050 to cut up to 1 3/16″ thick metal. The torch features a blowback start and pilot arc. Blowback start works well with a CNC table, while pilot arc allows you to cut through paint, rust, or dirt.

I was not too fond of the bulky WP-26 TIG torch, which feels heavy and oversized. However, the torch features remote amperage control, but you don’t get a TIG pedal, which is rare today.

Read the extended review of this welder.

Pros & Cons Summarized

Pros

- 7-in-1 TIG welder and plasma cutter

- PFC power technology offers a wide input

- Smart AC aluminum welding controls

- Fine controls over the welding process

- 100% duty cycle at maximum amps

- Can work with 6010 electrodes

- Capable plasma cutting

Cons

- TIG torch is bulky

- Pedal not included

- Can be heavy to move around

Specifications

- Processes: TIG (GTAW), Stick arc welder (SMAW), Plasma Cutter

- Weld Thickness Range: Down to 1/25”

- Weldable Materials: Steel, Stainless Steel, Aluminum.

- Input Power: 96-265V, 50-60 Hz.

- Input Phase: 1-Phase.

- Current Type: alternating/direct current.

- Rated Output: 200 A @ duty cycle 100%

- Amperage Output Range: TIG 5 A – 200 A.

- Weight: 61 lbs.

2. AHP Alpha TIG 203Xi 110v 220v IGBT TIG/Stick – Best TIG Welder Under 1000

The AHP Alpha TIG 203Xi welder is a machine that includes superior inverter technology. Combine it with PWM technology (Pulse Width Modulation) and you get a good welder that can weld metal and aluminum with great success.

Besides being a reliable machine, the Alphatig 200x price is its greatest advantage. This is an affordable TIG welder capable of welding 1/4″ aluminum and 3/8″ mild steel.

Thanks to the added technology, the AHP Alphatig 200X TIG welder can provide unprecedented performances among its peers. This is an improved version of the 2018 AHP AlphaTIG that is more versatile, lighter, and better looking.

Besides the TIG process, this is an excellent dual voltage Stick welder. Stick welding arc starts easily, but as with other inverters, you shouldn’t try the notorious 6010’s. The front panel features a large LCD display that sha

AHP Alphatig 203Xi is a great machine you can use for welding stainless steel, aluminum, steel, alloy steel, and thin gauge materials. However, with a 5 amp lower start at DC and 20 at AC, welding extremely delicate metals might be challenging.

Depending on the needed work, you can use it both in DC and AC current. The pulse feature is more than useful as it allows you to adjust the amount of heat generated. Another thing that I need to compliment is versatility. This unit ensures smooth welding, and it will increase the quality of the weld.

It comes with a foot pedal which increases productivity and enables better welding control and operation. Even though MIG welders help you master aluminum quickly, the TIG welding process results in clean and beautiful welds.

You should pay attention to the poor clamp, which may break quickly. Provided TIG torch is decent, and flex head helps you get in tight places. However, there is no hose protection. In addition, when working at 110V, you shouldn’t turn the heat all the way up, as it might kick out the circuit breaker.

Pros & Cons Summarized

Pros

- A lot of control options

- High-Frequency start

- Foot pedal included

- Surprising stick welding capabilities

- Dual voltage 120 and 220v power source

- AC/DC TIG welder

- 3 year warranty

Cons

- Poor ground clamp

- 20 amp low AC TIG start

Specifications

- Processes: TIG (GTAW) Stick (SMAW).

- Weld Thickness Range: Plain steel – 24 ga. – 3/8 in.

- Weldable Materials: Steel, Stainless, Aluminum

- Input Power: 110/220 V, 60 Hz.

- Input Phase: 1-Phase.

- Current Type: alternating/direct current.

- Rated Output: 200 A @ 60% duty cycle.

- Amperage Output Range: TIG 10 A – 200 A.

- Weight: 40 lbs.

3. Arccaptain TIG200 – Best Beginner-friendly Welder

If you are a beginner, hobbyist, or occasional welder willing to try TIG welding, you don’t have to spend a fortune on advanced Miller, Lincoln, or Everlast machines. Instead, I suggest Arccaptain TIG200, a compact beginner-friendly TIG welder that offers decent features at a reasonable price.

TIG200 is the latest addition to Arccaptain’s lineup of modern and well-built machines. Each machine is tested in harsh environments, so there is no doubt it will last and perform.

In addition, the entire build is dedicated to ease of use, which is one of the biggest reasons to put it on our list. The control panel is relatively straightforward, and I liked the large LED digital display that shows precise values

However, a straightforward design means you get fewer control options than with AHP AlphaTIG or YesWelder CT2050. For example, you can only adjust downslope, post/pre-flow, or opt for 2T/4T mode. That shouldn’t be a surprise since TIG200 is a DC-only machine, so there are no AC squarewave or balance controls.

Besides fewer controls, DC-only means you cannot TIG weld aluminum with it. At 300 ish bucks price range, you shouldn’t expect the AC/DC machine. However, Arccaptain TIG200 is capable of welding medium-thickness steel and stainless steel, which you are likely to deal with in your garage or small fabrication shop.

Meanwhile, TIG welding performance is consistent and reliable. In addition, this welder utilizes a high-frequency start, which provides a smooth arc starting without contaminating the tungsten. With an amperage output of 5-200 amps, you are set to weld thin sheets and thicker plates. In addition, the welder supports a remote amperage control by a foot pedal which, surprisingly, isn’t supplied in the box. I say surprisingly because more budget manufacturers like YesWelder started introducing pedals with their budget machines.

TIG200 also supports Stick welding, which is pretty advanced, and you get features such as arc force, hot start, and anti-stick. With everything said, this seems like a pretty versatile machine. Your investment is even well protected by safety features such as overload or over-temperature protection, and you get an excellent 3-year warranty which is scarce with affordable TIG welders.

Check the full review here.

5% Discount Code: “WELDPROS”

Pros & Cons Summarized

Pros

- Good value for the money spent

- IGBT inverter technology

- High-frequency start

- Easy to use and setup

- Consistent and reliable results

- Suitable for everyday home or DIY projects and repairs

- Safety features

- 3-year warranty

Cons

- DC-only, meaning you cannot TIG weld aluminum

- No advanced controls

- Foot pedal not included

Specifications

- Welding process: GTAW, MMA,

- Weldable Materials: Steel, Stainless-Steel

- Input Voltage: 110/220V.

- Input Phase: 1-Phase.

- Current Type: DC.

- Rated Output: 240v: 60% at 200 amps; 120v 60% at 135 amps

- Amperage Range: 5-200 amps

- Max OCV: 48 VDC

- Welding Thickness Range: 0.020 in. (0.5 mm) – 13/64 in. (5mm)

- Start Type: High-frequency

- Weight: 12 lbs

3. Eastwood TIG 200 AC/DC – Beginner-Friendly Welder

Eastwood TIG 200 is a reliable but cheap TIG welder that is easy to use and set up. While most TIG welders offer latest features like pulse and squarewave AC, this is rather a simple machine.

You can only adjust post-flow and pre-flow, amperage, and clearance effect.

That is why we recommend TIG200 AC/DC as the first TIG welder you can use to practice and learn. WIth provided accessories, you can start TIG welding straight out of the box. You get a flex head TIG torch, improved rocker-style pedal, gas lens kit, and even tungsten electrodes.

Even though TIG 200 is also a Stick welder, you don’t get an electrode holder to do it. Nonetheless, the overall value for the money spent is amazing, and that’s one of the reasons we included this device on our list.

With a power output of 10-190 amps and a dual voltage option, you can use Eastwood TIG 200 AC/DC welder to join thin gauges up to 1/4″ thick materials. AC welding will allow you to practice working with aluminum. DC TIG makes welding mild steel simple.

Overall, Eastwood 200 AC/DC TIG is a decent and capable welder that uses inverter technology. You can use it to weld thin metals, but if you opt for 220V, you will need a 30-amp circuit breaker. Some welders find the 6″ power chord too short.

Price-wise, you get an excellent value for the money spent. Even though Eastwood TIG welder 200 AC/DC is not one of the cheapest units, investing won’t break your bank. If you are looking for more advanced settings, you should consider Eastwood TIG200 Digital, which features pulse width moderation, 2T/4T controls, and a squarewave inverter.

Read the full review here.

Pros & Cons Summarized

Pros

- Dual voltage machine

- High duty cycle 60% at 190 amps

- Simplistic control panel design

- Easy to use and set up

- 3-year regular warranty

- High-frequency start which is a must-have for aluminum

- Excellent value package content

Cons

- Lacks advanced settings

- Leads might be short

- No holder for stick welds

Specifications

- Welding process: GTAW, MMA

- Weldable Materials: Aluminum, Steel, Stainless-Steel.

- Input Voltage: 110/220V.

- Input Phase: 1-Phase.

- Current Type: DC.

- Rated Output: 240v: 60% at 190 amps; 120v 60% at 100 amps

- Amperage Range: 10-190 amps

- Weight: 38 lbs

4. Everlast POWERTIG 210EXT GTAW-P/SMAW – Best TIG Welder For Aluminum

The Everlast PowerTIG-210EXT is both an economic and versatile machine. It is more than suitable for professionals tackling heavy-duty projects and novice welders. The Everlast PowerTIG provides versatile solutions when it comes to welding which is backed up by performance.

It is capable of outputting 210 amps of TIG weld power on a single-phase at 240V. It also comes with a 60% duty cycle while doing it, meaning you can use it to weld steel a maximum of 5/16″ single pass. Overall this is the right TIG welder for 1/2″ aluminum, but the advanced options let you work around thin sheet without bending.

Keep in mind that Everlast welder comes with numerous features that include AC balance control, adjustable AC frequency, a fully adjustable pulse, stick function with stick options like power arc, arc force control, and surprisingly enough, a 2T 4T switch for remote control.

If you are a professional, you will love all the fine controls, while beginners find the flow chart easy to understand. Still, it might take you some time to work around it if this is your first welder. Some welders even compare fine controls to the legendary unit Miller Dynasty.

The Everlast Powertig welder operates efficiently on both 120/240V input voltage single-phase. With given features, this welder is not that light with 62 lbs. Alongside it, you will get 26 series and 9 series Everlast TIG torch with 12 ft. leads. In addition, package content includes an argon gas regulator, meaning you can start welding straight out of the box.

Read more here.

Pros & Cons Summarized

Pros

- Perfectly suitable for experienced welders and professional precision welding jobs

- Low 5 amp Start feature

- Packed with adjustable settings from amp start to features like spot weld timer

- Easy to set up and use

- It comes with two torches, and everything you need to weld straight away

- High-Frequency start

- Programmable memory

- 5-year warranty

Cons

- Might take some time to get used to settings

- Might be hard to move around

Specifications

- Processes: TIG (GTAW) Stick (SMAW).

- Weld Thickness Range: Plain Steel – 24 ga. – 1/2 in.

- Weldable Materials: Steel, Stainless Steel, Aluminum

- Input Power: 120/240 60 Hz.

- Input Phase: 1-Phase.

- Current Type: Alternating/Direct Current.

- Rated Output: TIG 250A @ 60% duty cycle.

- Minimum AC/DC current start: 5 amps

- Start: HF/Lift

- Amperage Output Range: TIG 5 A – 210 A.

- AC SquareWave: Advanced; Soft Square Wave; Triangular

- Weight: 62 lbs.

5. Miller Diversion 180 TIG Welder 120V/240V TIG Welder

The Miller Electric Diversion 180 TIG Welder is specifically made to cater to novice and everyday welder needs. High-end Miller products are designed to help people learn how to weld, but professionals won’t mind them either. However, since we are talking about brand-name units, you will have to be ready to pay more than quite a few bucks.

To use it, you will have to select material, choose a given thickness and the machine will do the rest.

That’s it! You might have noticed Millermatic MIG welder also features an Auto set option, but you don’t see it that often in TIG machines. With a given output of 10-180 amps, you can use Diversion 180 to weld 22 ga. up to 3/16″ thick metals.

Besides ease of usage, with less than 50 lbs and built-in handles, this AC/DC TIG machine is relatively portable and easy to move. Some of the prime features include both 120V and 240V plug compatibility. Miller Diversion 180 uses an inverter-based technology, alternating/direct current power input, which results in a consistent source of power.

The Miller Diversion 180 comes with an HF arc start. The non-touch start helps with better arc control and stability while eliminating contamination of the weld pool, resulting in high welding quality. Finally, the Miller TIG machine comes with a post flow that automatically adjusts according to amperage output.

One of the biggest drawbacks in my opinion is the price. You can find entry-level, beginner-friendly machines with similar or better settings for a much more reasonable price. Nevertheless, when buying branded units, you really get what you pay for. Some buyers complained about the loud fan, so you might need to get used to it.

Read more on Miller Diversion on this page.

Pros & Cons Summarized

Pros

- Multivoltage TIG welder. Works on 120 and 220v power input

- Great for beginners and hobbyist welders

- High Frequency start

- Advanced AC squarewave

- Foot pedal included

- Fan on-demand feature (great to protect from dust and other containments)

- Compact machine

- Availability of spare parts

- USA brand product

- 3 Year warranty

Cons

- Expensive

- Low duty cycle

Specifications

- Processes: TIG (GTAW).

- Weld Thickness Range: Plain Steel – 24 ga. – 3/16 in.

- Weldable Materials: Steel, Stainless Steel, Aluminum

- Input Power: 120/220 V, 60 Hz.

- Input Phase: 1-Phase.

- Current Type: alternating/direct current.

- Rated Output: TIG 150 A @ 20% duty cycle.

- Amperage Output Range: 10 A – 180 A.

- Weight: 50 lbs.

6. Forney 220 AC/DC TIG Welder

The Forey 220 AC/DC is one of the great “green” TIG welders that will suit your everyday welding needs. With a dual voltage input, you can use 110V to weld thin materials at remote job site locations or home and garage, while 220V allows you to tackle up to 1/2″ steel. In addition, you can use AC current to weld aluminum and aluminum alloys with ease.

The controls are intuitive and the digital display helps you read the exact values. This machine is great for many applications including simple metal art projects and professional repairs.

With low 5 amps start and AC pulse width modulation, you can use Forney 220 AC/DC to weld significantly thin sheets without bending. In addition, a high-frequency start and wide amperage range help you achieve as clean a weld puddle as possible. However, you can always turn the non-touch start off.

To weld straight out of the box, you get 17 series TIG torch with a flexible neck and pedal with 12.5″ leads. In addition, the package features a holder, ground clamp, gas regulator with hose, and 15″ long power chord.

Price-wise, Forney 220 AC/DC combines features and high-quality build of rest made in the US welders, at a reasonable price. Still, it might be more expensive than budget options such as YesWeldedr and Eastwood machines we mentioned above. Nonetheless, buying this unit won’t break the bank.

Keep in mind that 222 AC/DC is a transformer-based machine, meaning it might be heavy to move with 54 lbs. In addition, the not so long duty cycle is limited to 35% at a max output of 220 amps, while most inverters rate it at 60%, offering more efficiency.

Pros & Cons Summarized

Pros

- Dual voltage increases versatility

- Simple design and easy to use settings

- Advanced features such as pulse ad optional non-touch start

- Decent accessories with long leads

- USA brand product

- Great value for money spent

Cons

- Low duty cycle

- A bit heavier

Specifications

- Processes: TIG (GTAW), Stick.

- Weld Thickness Range: Plain Steel – 24 ga. – 1/2 in.

- Weldable Materials: Steel, Stainless, Aluminum

- Input Power: 120V/240 V, 60 Hz.

- Input Phase: 1-Phase.

- Current Type: alternating/direct current.

- Rated Output: 220 A @ 35% duty cycle.

- Amperage Output Range: 5 A – 220 A.

- Weight: 54 lbs.

7. Lincoln Electric Square-Wave TIG 200 TIG Welder

The Lincoln Electric Square Wave is a perfect TIG/Stick machine for beginners, hobbyists, and small fabricators. It is more than easy to use and is perfect for people who are expanding their welding skills. Square Wave TIG might be a top 10 best welder for starters.

Besides TIG, this one is good for various other welding applications like stick welding.

In addition, it can be used to weld aluminum, steel, stainless steel, and chrome-alloy. Dual voltage power input will help you plug it almost anywhere. The user interface is easy to use as you just need to set the power input and weld.

This TIG machine is pretty lightweight. Portability is definitely its advantage as it weighs approximately 46 lbs. Power output is rated at 10-125A TIG and 10-110A Stick at 120V and 10-200A TIG and 10-170A Stick at 230V. Pulse welding is available at 0.1 – 20 pulses per second. However, 10 amp high-frequency start and low pulse options may cause issues on super-thin metals.

The Lincoln Electric K5126 can weld metals of up to 3/8″ steel thickness. In addition, AC output will help you work with 3/16″ aluminum, and balance achieves better penetration and cleanliness.

On the other hand, the duty cycle might not be that high. With 25% at the maximum output, you can weld continuously for two and a half minutes before making a break. In addition, Lincoln Square Wave is not a cheap welder, but for the money spent, you get a high-quality machine with outstanding accessories.

Pros & Cons Summarized

Pros

- Very easy to use with a simple display for reading

- This TIG welder is portable given its dimensions and weight

- Multi-voltage power input

- Sturdy case with a really nice appearance

- USA brand name TIG welder

- Superior torch and foot pedal quality and other components

- Provides a smooth arc

- Capable of doing TIG and Stick tasks

Cons

- Expensive

- Low Duty Cycle

Specifications

- Processes: TIG (GTAW) Stick (SMAW).

- Weld Thickness Range: Steel – 22 ga. – 3/16 in.

- Weldable Materials: Steel, Stainless, Aluminum

- Input Power: 120/220 V, 60 Hz.

- Input Phase: 1-Phase.

- Current Type: alternating/direct current.

- Rated Output: TIG 200 A @ 25% duty cycle.

- Amperage Range: TIG 10 A – 200 A.

- Weight: 46 lbs.

8. YesWelder TIG 250P ACDC – Best TIG Welder For The Money

YesWelder TIG 250P is an amazing AC/DC TIG machine that offers so much for so few bucks spent. It is the best TIG welder at its price point, which will provide you with the highest value for the money you invest in it.

This YesWelder machine is one of the TIG welders for professional work, but it is also very beginner-friendly. You will find it easy to set up and use, meaning you can smoothly perform almost any task with ease. With added electrode holder, you can also use it as a stick welding machine.

Rated power of 5-250A is more than enough for challenging projects and light-duty fabrication.

TIG 250P is an AC and DC TIG welder, meaning you can use it to join various metals and aluminum. The unit supports HF arc start, which is a must-have for clean TIG welds, and it has a bunch of professional features such as upslope and downslope settings, pre and post-flow controls. Welder supports a low 5 amp start which is crucial for thin metal.

In addition, it has a squarewave for AC TIG welding which makes the job heck of a lot easier and better. There is an AC balance setting that provides excellent control of cleaning and penetration, it can do both AC and DC pulsed TIG welding and a lot more.

Once you are done, the unit saves the last preset, meaning you can continue your work without remembering exact values.

One of the great things is you get a foot pedal and heavy-duty WP-26TIG torch. Even though some might find the pedal a bit stiff, you will get used to it quickly.

Overall, a great TIG machine with excellent build quality also does stick welding with a lot of features.

Extended review of this welder is here.

Pros & Cons Summarized

Pros

- Top pick TIG welder for the money.

- You can TIG weld with a fully adjustable pulse rate

- High-Frequency Start

- AC/DC TIG welder

- AC balance control

- Squarewave AC

- Easy to set up and use

- Very good Aluminum AC/DC TIG welder

- A brand with good customer service support

Cons

- Works only on 220 volts

- Pedal might be stiff at first

Specifications

- Processes: TIG (GTAW) and Stick arc welder (SMAW).

- Weld Thickness Range: Steel – 24 ga. – 3/8 in.

- Weldable Materials: Steel, Stainless Steel, Aluminum.

- Input Power: 220 V, 60 Hz.

- Input Phase: 1-Phase.

- Current Type: alternating/direct current.

- Rated Output: 250 A @ duty cycle 60%

- Amperage Output Range: TIG 5 A – 200 A.

- Weight: 35 lbs.

9. Lotos TIG200ACDC 200A 110/220V TIG Welder

The Lotos TIG200 offers a great starter kit for beginners. IGBT technology makes it efficient and versatile.

You would probably not see it as part of an experienced welder’s arsenal, but it is a good budget TIG welder that will help you learn and do some home repairs and other simple welding projects.

It does come with a square wave inverter technology, suitable for copper, tin, and aluminum.

This device also is pretty good for precise welding. It has a high-frequency start hand torch control combined with precise foot pedal heat control.

Dual input power at 110/120V 220/240V 50/60Hz. With an output range of 15-200 amps, you can weld various metal thicknesses, but you should try it on thin metals.

The price tag for the welder is pretty affordable, especially when you see that it comes with a power supply, TIG torch, foot pedal, MMA /Stick clamp and ground clamp, Argon regulator, and a 220V/110V converter pigtail. Keep in mind that this version doesn’t have a plasma cutter incorporated. This is a TIG-oriented machine, while multi-process Lotos LTPDC2000D combines TIG/Stick welder with a plasma cutter.

The biggest drawback of cheap welders such as Lotos TIG200 is you don’t find replacement parts. You are covered by a 1-year warranty, but after that, you are on your own. Nevertheless, most welders said they didn’t have any issues after long periods of welding.

Pros & Cons Summarized

Pros

- Affordable light-duty machine

- Multi voltage input support

- Lotos models are lightweight and portable

- High-Frequency start

- Pedals included

- This TIG welder does both TIG and Stick tasks

Cons

- Not for heavy work

- TIG pedal doesn’t allow for fine amp adjustments

- Spare parts are scarce

Specifications

- Processes: TIG (GTAW) Stick (SMAW).

- Weld Thickness Range: Plain Steel – 25 ga. – 3/8 in.

- Weldable Materials: Steel, Stainless Steel, Aluminum

- Input Power: 110/220 V, 60 Hz.

- Input Phase: 1-Phase.

- Current Type: alternating/direct current.

- Rated Output: TIG 190 A @ 60% duty cycle.

- Amperage Range: TIG 10 A – 200 A.

- Weight: 58 lbs.

10. YesWelder TIG-225P Review – 5 in 1 TIG/Stick Welder With Cold Spot TIG Welding

The latest addition to the YesWelder line-up, the YesWelder TIG-225P, is a suitable 5-in-1 TIG machine that offers Stick, Lift TIG, High-Frequency TIG, Pulse TIG, and Cold Spot TIG.

With YesWelder TIG-225P, you get quite a few things for the money spent. However, the biggest surprise is you get the two TIG torches with accessories. You rarely see manufacturers include two torches in this price range. Therefore, you can use WP-9 Torch to reduce hand fatigue when dealing with light-duty projects but also switch to WP-17 Torch when tackling more complex tasks.

The build combines the characteristics of the old machines such as TIG-250P and the latest welders such as YWM-200 or MP200. Therefore, the welder case has the shape of the old YesWelder welding machines we loved, but the latest welders’ black/red color theme.

YesWelder TIG-225P is a dual voltage machine that provides excellent versatility. As a result, you can use a 110V input with an output of 155 amps for light-duty tasks. With a simple 110/220V adapter, you get a maximum output of 225 amps which will help you tackle more complex projects and thicker steels. However, TIG-225P is a DC-only machine, meaning you cannot use it for TIG aluminum welding. Even though it offers a high-frequency start that prevents tungsten contamination or inclusion, you still won’t be able to tackle aluminum.

One of the features you don’t often see in today’s budget TIG welder market is the Cold Spot TIG welding. This type of welding limits the amount of heat and the time the heat is applied. As a result, there is a lower risk of deformation and discoloration when welding thin and delicate metals. In addition, there is also a TIG pulse welding option, and by setting pre flow, post flow, upslope, and downslope, you get perfect control over the welding process.

These features are usually found in significantly more expensive TIG welders such as Lincoln Square Wave 200 or Miller Dynasty 200. In addition, they are sometimes part of hobbyist machines such as Eastwood TIG Digital 200.

More on this welder here.

Pros & Cons Summarized

Pros

- 5 in 1 TIG and Stick welding options

- Cold Spot TIG and Pulse option

- Two TIG torches included

- Two-pin foot pedal included

- Dual voltage capability

- High-frequency start

- Sturdy and well-built

- You can adjust pre-flow, post-flow, upslope, downslope, pulse

- A high duty cycle of 60% at maximum output

Cons

- DC-only welder, meaning you cannot TIG weld aluminum

- A foot pedal is not so high-quality

Specifications

- Processes: TIG, Lift TIG, HF TIG, Cold Spot TIG, Stick (SMAW).

- Weldable Materials: Steel, Stainless Steel

- Input Power: 110/220 V, 50-60 Hz.

- Current Type: DC.

- Open Circuit Voltage (OCV): 60V

- Rated Output Power (220V): TIG 225 A @ 60% duty cycle.

- Rated Output Power (110V): 155 A @ 60% duty cycle

- Amperage Range (220V): TIG 5 A – 225 A; Stick 5-225

- Amperage Range (110V): 5-155

- Weight: 19 lbs (lightest in the review).

TIG Welder Buying Guide

So you can better understand what to look for in the TIG machine, here are some basic guidelines. Put on your gloves for safety, and let’s learn how to weld. And if you want to learn more about TIG welding, itself self check out this page.

TIG Welder Features to look for (TIG Arc Start Features)

The most important part and the first thing to look at when buying a TIG unit is of course the way it starts an arc. There are 3 ways this is done and some are better than the others (and also more expensive).

Scratch Start

Scratch start may be a basic process usually found on low-cost inverter welders or multiprocess welding machines where TIG is not a primary welding process. However, it is still not obsolete and is used for those welders that have been designed for Stick welding or MMA. What you need to do is to scratch gently the TIG tungsten electrode to initiate the arc and quickly lift it away so it doesn’t stick. At the same time, you shouldn’t lift it too far away as that may extinguish the arc.

Scratch start needs some low-cost equipment like a DC TIG welder, a cylinder of argon, an air-cooled TIG torch, and a flowmeter. The equipment is all basic stuff, but the process is not what you would describe as user-friendly. It’s harder to learn and requires more skill to operate, ergo more room to make a mistake and even small mistakes can cost a lot.

Now, this does not mean you should not use it. Skillful and professional welders can create wonders with scratch-start TIG welders. It’s a great way to learn TIG welding, with a low-cost machine that will allow you to skill-up to a level where lift start or high frequency will be a breeze for you.

Lift Start

The lift start feature involves touching the workpiece with the tungsten electrode and then pulling it upward and away to start the arc. The startup current is low, so there is no danger of the tungsten sticking to the workpiece. Because of the low current, the sharpened point will not get damaged.

As you gently lift the electrode away, the machine will sense that the contact is broken and will steadily start to supply a full welding current. As opposed to scratch start, lift start is more user-friendly and can be easily controlled. However, it could be challenging to manufacture as the electronic process must be carefully calibrated for the machine to work properly. So if the startup current is not minimized, it will cause the tungsten electrode to stick to the workpiece.

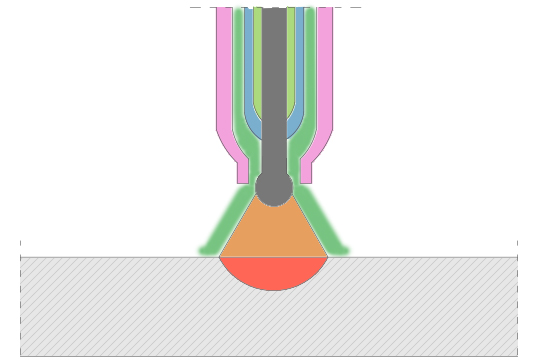

High-Frequency Start

The high-frequency start is probably the easiest process to start the arc. Pay attention if the machine is in your budget range and if it has a high-frequency start. All that you need to do is to position the tungsten electrode near the workpiece and press the trigger on the torch to start the arc. As simple as that.

However, HF start is usually found on some professional TIG welding machines, like AC DC TIG welders or a DC TIG unit. Additionally, these machines have a choice between an HF start or a lift start.

What is the 2T/4T Torch Control Feature on a Welder?

A digital TIG welder comes with some advanced features like the 2T and 4T modes. Welders are perhaps more used to a foot pedal for amperage control, but there are cases where you would want to use the trigger on the torch. The foot pedal allows you to control the amperage as you weld and the trigger is basically an ON and OFF switch. However, having the 2T and 4T mode allows you to control the amperage and the gas flow as you weld.

The T stands for Touches. With 2T, pressing the trigger will allow you to weld in the amperage you selected and continue doing so until releasing the trigger. There is even an option of setting the ramp-up time so you don’t get all the amperage at once, helping you to avoid burn-through.

With 4T mode, you have four touches to deal with. Pressing the trigger will start the gas flow and the arc at the predetermined start amperage. It will stay there until you release the trigger.

Once you release it, the machine will go to set working amperage and stay there while you weld. Pressing the trigger again will slop it to the ending amperage and terminate as you release the trigger.

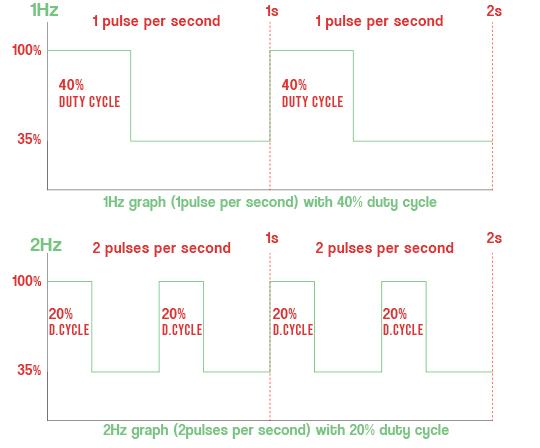

Pulse TIG Feature

The main benefit of using Pulse TIG is that it provides better results when working near an edge. It basically looks a lot better. It also helps for lowering heat input and for automated TIG welding applications.

However, it will mostly depend from person to person as some Pulse TIG settings are not going to be beneficial for everyone. It depends on the kind of work you are planning to do and the results that you want.

The Pulse TIG feature is not going to bring a significant upgrade to your work if you are a stay-at-home welder. But if you are looking for an edge compared to the opposition, it will do you good to have it with your TIG welding machine.

Multi-Process TIG Welding Machines

Why buy multiple machines and clog your workshops when you can get a single multi-process TIG welding machine that does all the work for you. Besides saving you on space, multi-process machines are labor-saving as you can switch to a needed process much faster than you would by setting up an entirely different machine.

Another important advantage, particularly for those on a budget, is that it will save you money as you are not going to need to buy more welders. You can invest in a single welder that does all the work for you.

They are perfect for smaller types of jobs, DIY projects, or stuff around the house. For those, you don’t really need a professional machine so a multi-process welder makes more sense if you are not planning welding career.

Output Current Type AC/DC And Aluminum Welding Capability for a TIG welder

When looking for a suitable TIG welder, there is a good possibility that you will be welding aluminum and magnesium at some point. Subsequently, you will need to be looking for a TIG welder that runs on both DC and AC current.

Most of the TIG welder reviews that I have on our list include machines with both AC and DC welding settings. However, picking a machine with suitable AC capability is important to weld aluminum and magnesium.

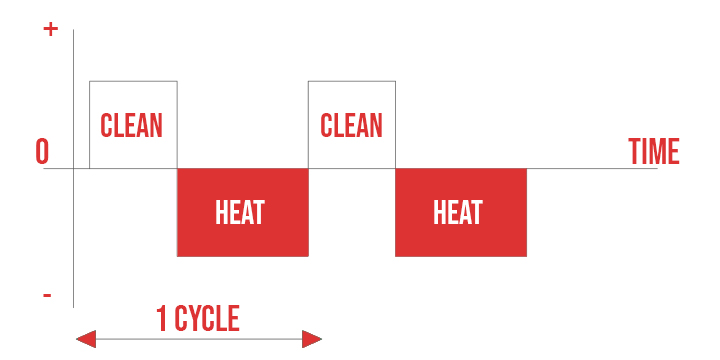

Using TIG Welder on Alternating Current (AC)

Alternating current (AC) TIG welding means that once flowing the current will not go down to zero until welding has ended. Most TIG inverters come with both AC DC settings, and there are only a few machines that have AC only.

Welding in AC current mode means that the current supplied by the inverter operates with either positive and negative elements or half-cycles. Simply saying, the current flows one way and then the other at different times.

The Square Wave

Square wave machines were created when more electronics were added to standard AC DC TIG welding inverters. Thanks to the advancements in electronics, the cross from positive to negative can happen instantaneously.

This allows for a more effective current in each half cycle due to a longer period at maximum.

The use of magnetic field energy stored in a machine creates waveforms that are very near square. This will allow the system to control both positive (cleaning) and negative (penetration) half-cycles.

Maximum Penetration or Maximum Cleaning

Maximum penetration is achieved when placing the control to the position that will enable it to spend more time in the negative half-cycle. This practice will allow you to use a higher current with smaller electrodes as more heat remains in the positive. The increase in heat will also allow deeper penetration when welding at the same travel speed and balanced conditions.

Maximum cleaning is the opposite – Allowing the control to remain more time in a position within the positive half-cycle. It results in an active cleaning current that can be used. However, there is an optimum cleaning time, after which more cleaning is not possible and there is a greater possibility of damaging the electrode.

TIG Welding with DC (Direct Current)

DC TIG welding current is when the current flows in one direction. DC is mainly used for TIG welding materials such as Mild Steel or Stainless Steel, as opposed to AC which is better for aluminum welding.

Direct Current TIG Welding – Electrode Positive (DCEP)

Welding in this mode means that the TIG welding torch is connected to the positive output of the inverter while the work return cable is connected to the negative output. After establishing the arc, the heat distribution in the arc is around 33% on the negative side and 67% on the positive side of the arc.

In this case, the electrode is subjected to the highest heat levels and must be much larger than with DCEN mode to prevent the electrode from overheating. The workpiece is subjected to lower heat, resulting in lesser weld penetration.

Direct Current TIG welding – Electrode Negative (DCEN)

Using this method, the TIG welding torch is attached to the negative output of the inverter while the return cable is connected to the positive output. After establishing the arc, the current will flow into the circuit while the heat distribution will be at around 33% on the negative side of the arc and 67% on the positive side.

Balancing it out this way will result in deeper penetration and the reduction of heat in the electrode. The heat reduction also allows the smaller electrodes to carry more current compared to other polarity connections.

TIG Welder Power and Metal Thickness

The main thing when choosing a welder is the thickness of the metals you will be working on. A machine with good capabilities will help you with precision work or any issues you may have with different thicknesses of materials.

However, if you are not really sure about the maximum thickness you will be working on, it is best to pick a TIG welder machine with a high amperage output. But besides a high amperage output, you also need a wide range as well.

Going with a machine with a power output of 200A doesn’t account for adjustability. You need a machine that can also offer a low amperage as a setting in addition to high output.

One of the best TIG welders offers the ability to work on both thin and thicker materials. TIG is usually used for thinner materials, like welding aluminum. So an amperage range rate of a minimum of 5 to 10 amps is more than suitable. But if you know the thickness of the material you will be working on, make sure to check the amperage range or see if it comes with amperage control.

Amperage Output –

Performance at Low Amperage or Low Amp TIG

Welding thin materials especially stainless steel and aluminum require good performance at low amperage. Simply having a welder with amperage specifications that go as low as 5 amps or 10 amps may not be enough. Welders with low amperages may also experience fluctuations or impairments and especially as the arc strikes. This means that the quality of the weld can be compromised.

Suppose you want to be sure that you don’t run into this problem. You need to get your hands on a good unit. The ones mentioned in our reviews are all stable and have amperage control. You won’t have to check gauges all the time. Accounting for a better weld. Brands like Miller don’t only offer precision with their units but stability as well. It allows users to have a sustainable amperage from start to finish of their welding jobs.

Duty Cycle With TIG Welders

The duty cycle is another important aspect of a welding unit. The duty cycle represents how much actual work your unit will be doing in a span of 10 minutes and how much it will rest. After rigorous work, each welder will require some time to cool down. This mostly depends on the quality of the machine and the cooling system it has or the cooling equipment you are using.

The duty cycle is measured in percentages. So you will often see labels that provide a duty cycle operation of 60% or 50%. So if the number on the label says 60%, this means that your device will be able to work for 6 minutes before rest.

Therefore, each machine has rates for specific amperages to determine their duty cycle. It also helps with determining the peak current that you will be using. This is one of the requirements you will need to look for before making your decision and purchasing your new unit.

Here is also a nice video by Weld.com explaining it.

Heating Protection

Heat protection is directly tied to a better duty cycle of your welding machine. More expensive welders plugged into 220v outlet frames or higher should have more than one fan to distribute the fresh air and remove heat from the machine more efficiently and reduce the dust and debris intake.

Having the duty cycle function protects the welder as well as your machine. Once thermal overload is reached, the protection will automatically switch on by switching your machine off. You don’t want your machine to overheat and burst into flames. You will save on expenses as you don’t need to get a new machine because of an unwanted accident.

Accessories: Foot Pedal

A good thing to have from the TIG welding accessories is a foot pedal. There are torches on which you can adjust to amperage setting and gas flow, but if you are sitting and working from your welding table, the solution is to have a foot pedal.

You don’t need to be an expert-level welder to operate the foot pedals. You will develop a skill quickly, and changing the heating input to a base metal will ease the job immensely, so check if your welder has a connection for a foot pedal.

Price, Quality, and Warranty

Even though some people like the YesWelder Digital TIG 200P, which offers the best value for the money, you still need to think carefully before making your final choice. You need to think about flexibility and versatility equally. But most importantly, you have to be sure that the machines will do everything you plan to use them for.

Determining the pros and cons is a good idea. But research says that more popular brands like Hobart, Miller, Lincoln, or Everlast provide more capabilities. The thing is that they are more than capable of allowing you to work all day.

However, if you just need a machine for regular work or as a hobby and don’t plan to do any entire-day welding, any of the mentioned units in this article is more than suitable. Always make sure to strive for quality fabrication in terms of your budget.

Another important aspect to consider is the warranty, More expensive machines come with an extended warranty. Extended hours of welding will accumulate a lot of wear and tear on your machine. It might affect the operating range of the machine and diminish its welding capacity in the long run. Five years of work can wreak havoc on your machines. So having a better warranty may be more favorable here.

Weight and Portability

This part is probably the easiest to understand; the weight of your machine can hamper and influence the quality of the work you are doing. It makes moving about the job site much more difficult (you may need a welding cart) and will strain the welder, especially if they are working long hours.

Therefore, if when you are picking your next welder, besides durability and the offered adjustments, be sure to consider the weight.

Lightweight products will make it a lot easier for you to finish the job well. You can even seek some with a shoulder strap to make it easier to move around. All in all, a lightweight welder will be easier for you and any kind of welding project you are working on.

Frequently Asked Questions [F.A.Q]

Why are TIG welders so expensive?

A: First of all, they are expensive because of the quality of the weld they deliver, then they use pure Argon as a protective gas to shield the arc and molten metal pool from contamination. Also, the technology of a TIG welder is much more complicated than, for example, on a simple inverter stick welder.

Is TIG stronger than MIG? (TIG vs MIG)

A: Yes in some applications, but both MIG and TIG have their own pros and cons and their own applications; the operations are completely different.

TIG welding is much more expensive than MIG. Much slower and handles dirt very purely but looks much better and gives the most quality welds possible. On the other hand, MIG welding is much faster, very easy to learn, and quite inexpensive.

With the TIG process, the heat input is done through the TIG torch ( electrode holder ) and an electrode made of tungsten alloy with 2% of a radioactive element called Thorium, and “add material” is done through a filler rod with your free hand.

With the MIG welding process, the welding gun’s consumable wire acts as an electrode and as a filler material that automatizes the process and speeds it up immensely.

Both use gas for shielding the arc and the welding pool from the oxidation of the weld. The shielding gas exposure to the weld will help in reducing the possibility of contamination. It is also important for the welded material not to come in contact with air before it cools off, so one has to check the flow meter of the gas cylinder and gas shutoff when working.

Can All TIG Welders weld aluminum?

A: Yes, TIG welding is a process primarily used to weld aluminum and stainless steel.

Do you TIG Weld Aluminum on AC or DC?

A: Welding aluminum is done by using AC. DC is usually used when welding steel. On the other hand, AC is the go-to method for welding aluminum. AC offers welders with the melting and cleaning option simultaneously and will resolve the problems that one usually comes when welding aluminum. With AC, the current switches by default and allows cleaning and melting to be balanced out just right.

Should I buy a TIG welder?

A: Buying a TIG welder is a good idea for many reasons. However, one should take into consideration the actual need for getting one first. TIG welders are useful for many things. They are necessary for working on thinner metals and can provide quality work. They allow consistency and are used for visually appealing welds.

If this is something that you strive for and will need to do at some point, the verdict is easy, and you should definitely get a TIG welder. But the process is hard for beginners, and it takes more time to master than with some other types of welders.

Conclusion

If you are on the hunt for a good TIG welder but don’t have the budget to spend on a costly one, check out the ones on the list above. I understand how hard it is to choose the right one as many of them are on the market. Each product here is a good option for inexperienced people without much expertise, but they also come with some major features that pros will enjoy.

There are various machines out there, and every person will eventually choose based on their own needs and preferences. Our reviews are here to help you better understand the choices in front of you and make a better decision. Spending more does not always have to mean good performance. Think economically and still get everything you need.