DC TIG welding is a precise and versatile welding technique that uses direct current to produce a clean, high-quality weld. You can successfully use this method to weld a range of materials, including steel, stainless steel, and titanium.

However, the key to achieving a successful DC TIG weld is precise control of the heat input and a steady hand.

In this article, we will provide a detailed explanaion of the fundamentals of DC TIG welding, including the equipment you need, how to set up your welder, and tips for getting the best results.

What is DC TIG Welding, And When Is It Used?

TIG (Gas Tungsten Arc Welding) with direct current (DC) TIG welder settings is a welding process that utilizes an electric arc between a non-consumable tungsten electrode and the metal being welded. The arc is created by passing an electric current through the electrode, which then generates heat. This heat is used to melt the metal and fuse it together.

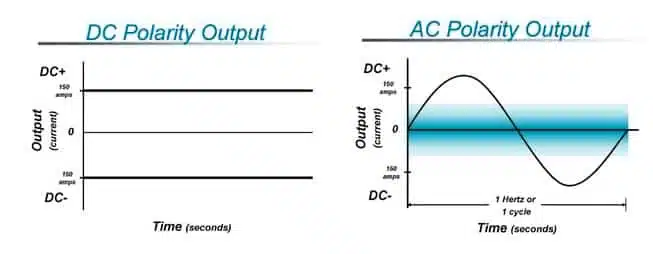

DC welding in GTAW uses DC output to pass electricity through the tungsten electrode. This means that the current flows in one direction only, from the positive (+) terminal of the power source to the negative (-) terminal.

The DC current is commonly used for welding thicker materials, as it provides a more concentrated heat source, allowing for deeper penetration into thicker metals.

What Metals Can I Weld With DC TIG?

DC TIG welding is an effective way to join a variety of “ferrous metals,” including mild steel & stainless steel, and also copper and chrome moly. Due to better control, precision welds, and minimal distortion, DC TIG welding works great with stainless steel (such as 304 and 316), which is often used in food processing equipment due to its resistance to heat, pressure, and oxidation. Additionally, i is more successful than MIG welding on copper alloys (such as bronze and brass) which are widely used in plumbing due to their excellent corrosion resistance properties.

There is an everlasting debate on the internet that concerns TIG aluminum welding with direct current. Aluminum has a low melting point and tends to cool rapidly after being melted, making it difficult to maintain adequate temperatures for welding. In addition, there is an aluminum oxide layer on top, which has a higher melting point. This can lead to porosity and cracking in the weld, causing the finished product to be weaker than desired. That’s why nearly all welders will tell you to switch to AC TIG welder settings if you want o weld aluminum.

Despite these challenges, DC TIG welding aluminum is possible. The most common reason to try DC power on Aluminum is a situation when the metal is thick, usually thicker than 1/2”. Experienced welders should have no problem achieving quality results when DC TIG welding aluminum. However, as a beginner welder, I don’t recommend trying it before understanding the basics. DC TIG welding aluminum isn’t a process to dive into if you’re just getting the hang of TIG welding

What Are The Differences Between AC and DC current in TIG Welding?

AC current is constantly switching between positive and negative charges, while DC current remains consistent with either a positive or negative charge. The major difference between AC and DC TIG welding lies in the heat intensity and penetration of the weld. For thin sheet metal, DC current tends to provide higher heat intensity than AC current.

This same heat intensity allows DC current to penetrate deeper into thicker metals, making it a better choice for welding thicker materials. Alternating current, on the other hand, tends to provide better control over the weld and better great cleaning action than DC current.

This makes it ideal for precision and exacting welds, where consistent heat levels are required. It is also more suitable for materials that are sensitive to high temperatures and can be easily distorted by intense heat.

Polarity Of DC TIG Welding

DC GTAW welding can be done on two polarities, DC positive and negative. To switch your TIG welder settings, you will have to switch the places of your TIG torch and clamp. If your torch is connected to the negative side of the terminal, you get DC-, Direct Current Electrode Negative, or DCEN polarity. Meanwhile, if your TIG torch with tungsten electrode is connected to the positive side of the terminal, you get DC+, Direct Current Electrode Positive, or DCEP polarity.

So let’s see how and when each polarity is used and what are the advantages and drawbacks.

Direct Current Electrode Negative – DCEN TIG Welding

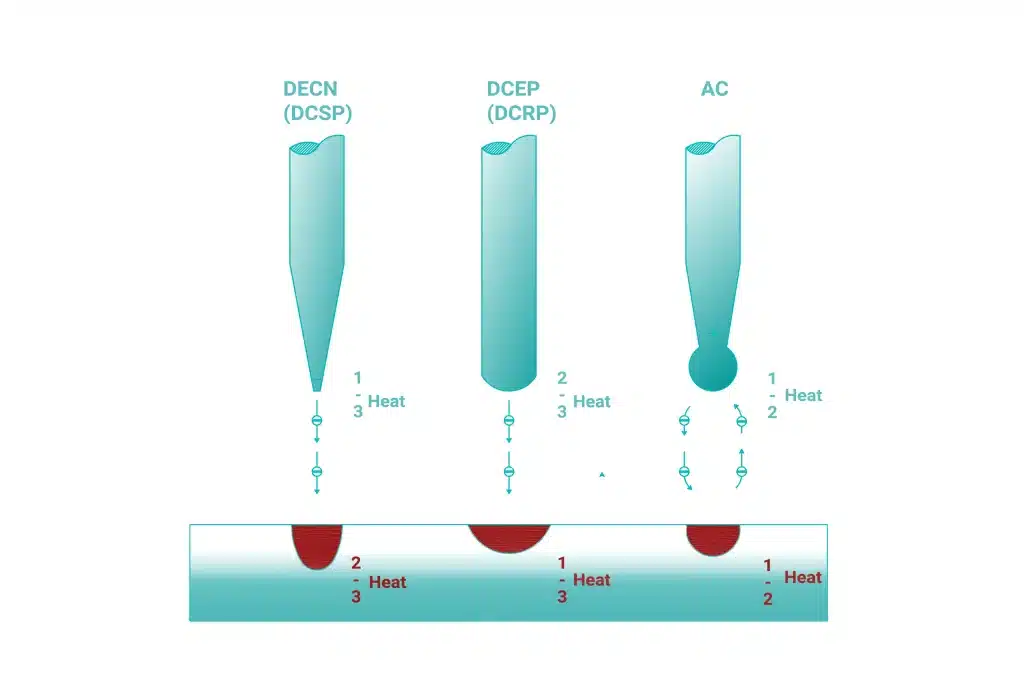

In DCEN TIG welding, the torch is connected to the negative output of the TIG welder and is often referred to as straight polarity. The heat distribution in the arc is around 33% in the negative side of the arc (the welding torch) and 67% on the positive side of the arc (the workpiece). As more heat is concentrated at the weld puddle, this results in maximum penetration into thicker metals and allows for stronger welds with the better overall quality.

The increased heat concentration afforded by this method results in a more stable arc and helps improve penetration and weld strength while producing less spatter than other types of welding processes, making it easier to clean up afterward. This reduced heat in the electrode allows more current to be carried by smaller electrodes compared to other polarity connections.

As a result, DCEN is one of the most commonly used TIG welder settings for common mild steel and stainless steel. Nearly 90% of all TIG welding is carried out at straight polarity, and your TIG welder is usually set for it by default.

Direct Current Electrode Positive – DCEP TIG welding

Direct current electrode positive (DCEP) polarity is also referred to as “reverse polarity” since the torch is connected to the positive side of the TIG welder. The heat distribution in the arc is around 33% on the negative side of the arc (the workpiece connected with the ground clamp) and 67% on the positive side of the arc (the welding torch). As a result, there is significantly lower penetration compared to DCEN polarity in TIG.

This kind of distribution results in high heat build-up on the electrode and TIG welding torch. Therefore, you must use larger diameter tungsten which is capable of withstanding high heat. High heat on the torch means you should consider using a water-cooling system to avoid failure. Additionally, DCEP has issues with arc blow more often. Even though this phenomenon can occur with DCEN due to the magnetic or thermal properties of base metal, it is more commonly associated with DCEP TIG welding.

Even though it is not capable as DCEN, DCEP has its advantages. The most significant one is the cleaning action. As the current flows towards the electrode, the electrons remove the oxide layer from the surface of the base metal. These oxides are usually found in metals such as aluminum or stainless steel, and they offer unique properties such as corrosion resistance.

However, they have different melting points than the base material, so you must remove them before welding. Nonetheless, they start forming once the surface is exposed to air, so you have to weld them quickly after grinding and removing them. With DCEP, this is much easier, as the current itself removes and prevents oxide formations.

Still, there are more drawbacks than advantages of DCEP, so that’s why it is usually used only occasionally and in specific applications. Additionally, welders pay more attention to the positive side when setting up the balance control on AC TIG welders. As the AC welding current oscillates, with the AC balance TIG setting, you can adjust how much time the AC cycle spends on the positive side of the current to provide more cleaning or the negative side of the AC waveform square wave to produce more penetration in the weld area.

DC TIG Welding Machines

DC TIG welder is your go-to choice if you are looking for an affordable TIG machine, and most welding jobs include joining mild steel and stainless steel. They are available as a transformer or inverter power sources, but inverter TIG DC welders are more common today due to higher versatility, power and welding efficiency, and lower price. You won’t have to break the bank to buy DC equipment, but you will still get enough for the money spent.

However, if your welding projects include welding aluminum or non-ferrous metals, you will need to choose an AC/DC TIG welder. This welder will operate similarly at DC current, but you get an AC TIG welding option when welding aluminum or other non-ferrous metals. However, they are pricier, so you’ll have to set your goals straight before purchasing. Still, if you are just learning how to TIG weld, you will be more than fine with a simple DC TIG machine.

Advantages and Drawbacks of DC TIG Welding

The DC TIG welding process has many advantages over other arc welding processes, such as MIG welding or Stick welding, including its ability to weld a variety of metals, the precise control that it offers the welder, and its low spatter production.

The process is much less likely to produce undercuts or burn-throughs than other welding processes. It also allows for a wide range of weld joint designs and provides a clean, aesthetically pleasing finish.

Compared to alternating current, DC TIG offers higher penetration, resulting in stronger and more reliable welds. However, once the base metal has an oxide layer on the surface, you will need a cleaning action of the positive side. Since DCEP has many issues, welders usually turn to alternating current welding for perfect balance over weld penetration of the negative and cleaning of the positive side of the current.

Additionally, the DC TIG welding process requires a higher level of skill than other arc welding processes since it demands precision in controlling the arc and heat input. It is also slower than other welding processes since it involves multiple passes with small amounts of filler material added each time. Finally, the equipment used for TIG welding is more expensive than other types of welding equipment and requires more maintenance.

Conclusion

DC TIG welding is a precise and versatile welding technique that is ideal for welding a wide range of materials. With the right equipment, techniques, and practice, anyone can achieve a high-quality weld with DC TIG welding jobs and better weld quality than Stick welding.

Whether you’re a professional welder or a DIY enthusiast, mastering DC TIG welding will give you the confidence and ability to tackle a wide range of welding projects with ease. By understanding the basics of DC TIG welding, you’ll be able to produce strong, precise, and cleaner welds and choose between AC/DC welding with ease.

Resources

- https://www.jasic.co.uk/differences-between-tig-dc-and-ac

- https://bakersgas.com/blogs/weld-my-world/tips-for-tig-welding-aluminum-on-dc-power

- https://www.weldclass.com.au/blog/39-the-tig-welding-process-your-questions-answered

- https://blog.thepipingmart.com/metals/dc-tig-welding-stainless-steel-an-overview/

- https://www.twi-global.com/technical-knowledge/faqs/faq-when-manual-metal-arc-welding-which-electrode-polarity-should-i-use

- ·https://www.thefabricator.com/thewelder/article/aluminumwelding/aluminum-workshop-aluminum-tig-with-dcen

- https://bakersgas.com/blogs/weld-my-world/tips-for-tig-welding-aluminum-on-dc-power