Lift arc TIG start is a welding technique that provides several benefits over the traditional scratch start method TIG welding, including reduced contamination, improved arc starting and stability, and the ability to start the arc on thin or delicate materials.

However, it requires specialized equipment and a good understanding of the technique to achieve a consistent and reliable start.

In this article, we will take you through the basics of the lift TIG arc initiation method, including the equipment you need, how to set up your welder, and tips for getting the best results.

What Is The Lift TIG Start

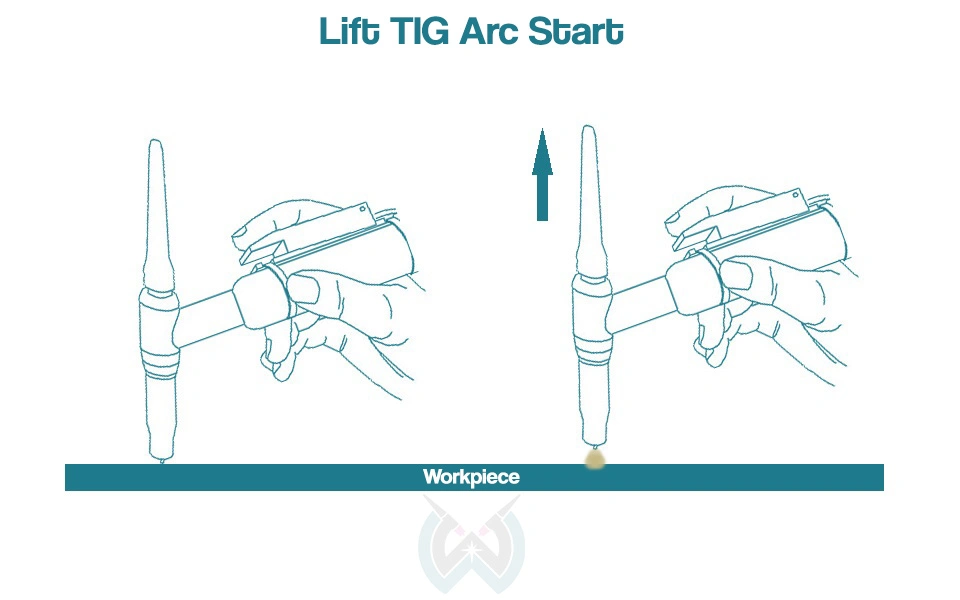

The Lift TIG start is an advanced starting technique in Tungsten Inert Gas (TIG) welding that is used to improve the quality of welds and reduce the risk of errors. This technique involves using a minimum-contact arc start, where the welding operator starts by touching the surface, but since the start-up current is very low, there is no risk of contamination. Once the welder lifts the tungsten electrode away from the workpiece, The machine senses that the contact is broken and begins supplying full welding current.

The Lift TIG start is considered superior to traditional arc starting methods (Scratch start TIG) because it reduces the risk of contamination, provides more consistent welds, and makes it easier to control the heat input during welding. Today, Lift start is found in nearly all budget-friendly TIG welders. This starting method has completely replaced scratch start due to ease of use and better performance, but it still can’t surpass the advantages of high-frequency TIG welder settings.

How To Initiate Lift TIG Start

The Lift TIG begins by setting up a proper gas flow and selecting an appropriate tungsten size and shape for the job. It’s important to ensure that proper shielding gas coverage is achieved during welding, as this will help to prevent oxidation of the weld pool and don’t forget to sharpen the tungsten.

Once these steps are completed, you can get back to the start. This involves starting the current on the TIG torch or foot control, lifting the tungsten electrode away from the workpiece at a distance of 1-2 millimeters, and then lowering it back into place. It’s important to ensure that there is no contact between the tungsten electrode and the workpiece during this process, as this could create a short circuit which could damage both pieces of equipment, leading to contamination and extinguishing the arc.

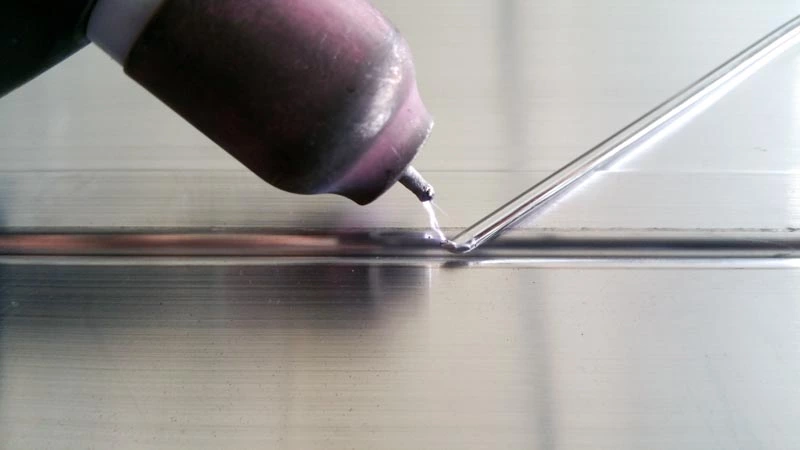

Once an arc has been established using this method, it’s important for welding operators to maintain a consistent arc length and travel speed in order to achieve optimal results. Maintaining a consistent arc length helps to ensure that there is enough energy being transferred into the weld pool while also helping to prevent excessive spatter or increased levels of porosity in the weld joint. Additionally, maintaining a consistent travel speed helps to ensure that all parts of a weld joint are receiving an even amount of heat input during welding.

Lift TIG Start Applications

Lift TIG arc starts are increasingly popular due to their ease of use and improved weld quality over the traditional Scratch start. The lift TIG starting technique offers several benefits over other methods, including improved weld starts and increased safety.

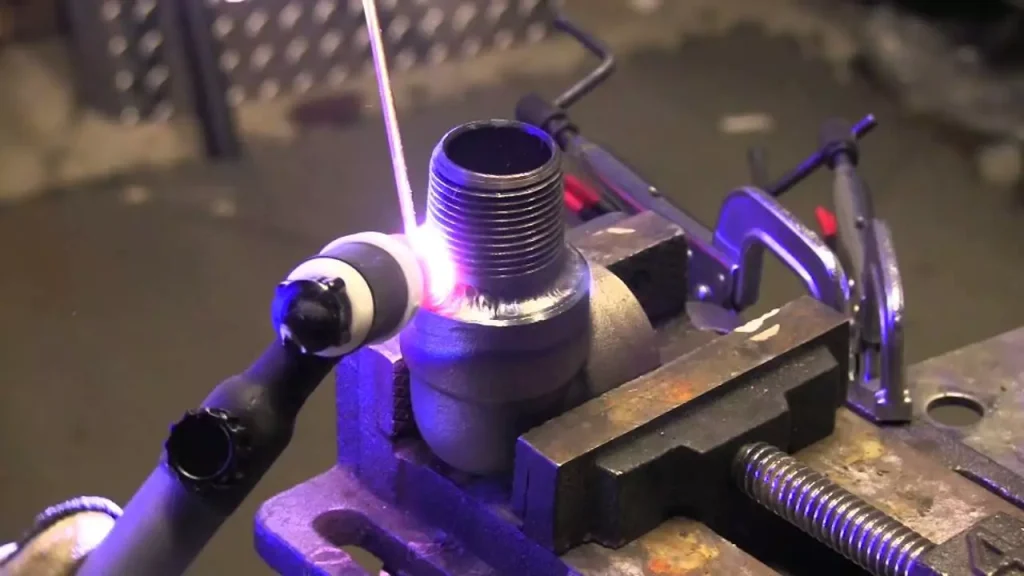

Lift TIG starting can be used on carbon steels and other ferrous materials.

Welding carbon steels require high levels of skill and precision due to their susceptibility to cracking if heat input is too high or if they are cooled too quickly after welding. With the lift TIG start method, welders can achieve higher levels of accuracy and control when welding carbon steels which leads to improved weld integrity and reduced chances of cracking or warping in thin gauges.

The lift TIG start eliminates issues with excessive spatter and poor-quality welds by creating a stable arc at the beginning of the weld, which helps to keep the spatter to a minimum while also providing excellent penetration in thin gauge aluminum materials. Additionally, this method allows for more precise control over heat input during welding, which helps to ensure good quality welds with minimal distortion in thin stainless steel materials.

Differences Between Lift TIG and High Frequency

One of the most notable differences between Lift TIG and High-Frequency start is the way in which they initiate the arc. With Lift TIG, the welder touches the workpiece, then lifts the TIG torch.

The machine senses the difference and initiates an arc. The HF start, however, uses a signal that creates an electrical current which then flows through both electrodes, igniting an arc without touching the base metal.

As a result, high-frequency is the crucial method when cleanliness is essential. Since there is no contact between tungsten and base metal, there is no risk of tungsten inclusions and contamination. Meanwhile, Lift TIG requires a brief contact at the start of the arc initiation. If your starting current is slightly higher, tungsten can stick to the surface, causing defects. Therefore, Lift TIG is considered to be slightly more demanding and difficult to use.

The prices of TIG welders are these days somewhat similar. Still, most TIG welding machines with lift TIG are cheaper than ones with HF start. The reason is special equipment that provides high-frequency starting, so if you are on a tight budget, these are the suitable choice.

Is Lift TIG Better Than Scratch Start Method?

Lift TIG was developed as a solution to drawbacks of scratch start, which include higher skill requirements, higher consumption of tungsten electrode and risks of contamination of the weld.

Lift arc start allows welders to more accurately control weld pool size and shape of TIG weld due to its ability to start at low amps and then quickly ramp up to higher amps as necessary, which is why it eventually replaced scratch start.

Scratch-Start is not a user-friendly and clean process: the tungsten must be very quickly touched on the job and can easily stick (which means the tungsten electrode must be removed and re-sharpened each time this occurs). If you are new to TIG welding, machines utilizing scratch start will be difficult and frustrating to learn. On the other hand, Lift TIG will help you a lot get into the world of the TIG process, but it still isn’t easier than HF ignition.

When Should You Choose Lift TIG Over High Frequency

High-frequency offers a number of advantages over the Lift TIG, but it comes short in specific applications. The high-frequency emits “electrical noise” that interferes with electronically sensitive devices such as phones, radios, computers or CNC tables, or signal amplifiers. Therefore, you should go for Lift TIG over a High-frequency start if you are welding in these conditions.

Additionally, you can choose Lift TIG if you are on a tighter budget. TIG welders with Lift start are usually cheaper, so if you are a hobbyist or occasional welder and your applications don’t require critical cleanliness, you can settle for Lift TIG. Overall, Lift TIG completely eliminates issue associated with HF and, when executed properly, almost entirely eliminates the risk of tungsten inclusions.

Advantages of Lift Start In TIG Welding

- Improved weld quality: Lift TIG starting can result in improved weld quality, as it helps prevent the formation of start defects like a cold lap, undercut and lack of fusion.

- Faster start-up: Lift TIG starting is faster to set up than traditional TIG starts, allowing for more efficient welding processes.

- Greater control: The Lift TIG starting method gives the welder greater control over the arc, resulting in a smoother transition from start to finish.

- Reduced risk of contamination: Lift TIG starting reduces the risk of contamination and improves weld penetration.

- Increased travel speed: Compared to other TIG starts, Lift TIG starting allows for high travel speeds without sacrificing quality or productivity.

- Improved safety: Lift TIG starting eliminates the risk of sparks or fumes that can be associated with traditional welding processes.

- Cost savings: The reduced setup time and increased productivity associated with Lift TIG starting can result in significant cost savings over time.

Conclusion

Lift TIG start is a valuable welding technique that offers several advantages over traditional TIG welding. This method provides improved arc starting and stability, reduced contamination, and the ability to start the arc on thin or delicate materials.

However, achieving a consistent and reliable lift TIG start requires specialized equipment and a good understanding of the technique. Whether you’re a professional welder or a DIY enthusiast, by understanding the basics of lift TIG start, you’ll be able to produce clean, strong, and precise welds every time. So, invest in the right equipment and take the time to master the technique, and you’ll soon be able to tackle even the most challenging welding projects with ease.

Resources:

- https://www.weldclass.com.au/blog/40-tig-welding-what-is-scratch-start-lift-arc-and-hf-ignition-

- https://americantorchtip.com/blog/tig-welding-scratch-start-lift-start-or-high-frequency/

- https://allweldsupplies.com/tig-lift-arc-ignition

- https://industrialmachinerydigest.com/industrial-news/features/understanding-tig-arc-starting-techniques/

- https://kevincaron.com/2015/08/19/what-is-the-difference-between-tig-lift-start-and-high-frequency-start/

- https://bakersgas.com/blogs/weld-my-world/how-and-when-to-use-scratch-start-tig-welding