Stainless steel is one of the greatest things ever made by man’s hands. It’s a type of metal that is irreplaceable in today’s industry.

It’s a technological marvel that is used in everything from aerospace and automotive applications to medicine and surgical tools.

![MIG Welding Stainless Steel - [Welder Settings, & Common Problems 2023] 1 Feature image for MIG Welding Stainless Steel article](https://weldingpros.net/wp-content/uploads/2021/01/MIG-Welding-Stainless-Steel.jpg)

The best cookware is made of stainless steel and many other types of products. Its main characteristics are durability and substantial corrosion resistance. The latter is the most important one and is the main point why the majority of products are made using stainless steel.

But you are not here to learn its merits you are here to learn how to MIG weld stainless steel…

Well, there is more than one way to skin a cat but you are probably here for MIG welding stainless steel, so let’s go into it…

Welding Methods

There are three main welding processes that welders use when working on stainless steel:

- TIG welding (gas tungsten arc welding) – slow but mostly used method.

- Resistance welding (spot welding) – used for thin metal sheets in industrial production.

- Stainless steel MIG welding – the fastest method.

- Stick Welding – used mostly for filing and finish passes on thick-walled stainless pipes and on hard-to-reach places.

![MIG Welding Stainless Steel - [Welder Settings, & Common Problems 2023] 2 image of a MIG welding process using a CO2 gas](https://weldingpros.net/wp-content/uploads/2021/06/MIG-welding-using-CO2-gas.jpg)

Using one of the mentioned processes will draw different results. When choosing the process that you need a welder will have to consider the bead appearance and the aesthetics of the piece they are working on, the thickness of the metal and the added costs to work on it, the time it takes to finish the project, and your own skill level.

Cost-Effective Way to Weld Stainless – MIG Welding Stainless Steel

Many people resort to shielded metal arc welding, or MIG welding when it comes to working on stainless steel. Stainless steel MIG welding is a great method when you don’t need your work to be aesthetically pleasing. Instead, this method bourns efficiency and cost-effectiveness.

MIG weld stainless steel is a method that does not require overly complicated pieces of equipment nor ones that are difficult to move. Another advantage is that MIG welding is a very easy process to learn and allows you to do your work fast. It is ideal for home repairs and DIY projects.

MIG Welder Settings For Stainless Steel – Set Up Your Machine

First, If your machine can weld steel it can weld stainless also.

Using a MIG Welder for stainless steel requires you to set your welding machine properly before you start. The majority of them come with an instruction manual chart of recommended settings. However, if they don’t, you have to know how to set your welder.

First of all, MIG welders should be set at DC+ polarity. The wire feed speed and voltage should be set based on the thickness of the stainless steel sheet metal that you are working on. In most cases, you will have to run a bit higher wire speed feed than you would with mild steel. This will result in a lesser current level. Additionally, higher voltage settings need to be used as it will wet out the puddle a bit more and allow a flatter face and better wash-in at the toes of the weld.

First – Choosing the MIG Welding Wire Wire

It is best that you use a stainless steel MIG wire as that way the end product will keep the corrosion-resistance properties that you would want it to have. The grade wire that you need to use will depend on the type of stainless steel base material you plan to work on.

308L is the wire that welders mostly use. It can be used on austenitic stainless steels like 301, 302, 304, 305 as well as CF-8 and CF-3 alloys.

316L filler wire is good for 316L and 316 base metals while 309L filler metal is used when joining mild steel or low alloy steel to stainless steels.

Second – Choosing a Shielding Gas

An important factor (or the most important!) when choosing the correct shielding gas mix is that stainless steel has a sluggish weld bead. Thus, when using the short circuit transfer method a tri-mix shielding gas of 90%He/7.5%Ar/2.5%CO2 is recommended. Another acceptable mixture is 98%Ar/2%O2 or an equivalent of 98%Ar/2%CO2.

Be advised that a completely inert shielding gas like 100% helium or 100% argon could result in poor arc characteristics.

Metal Transfer Mode

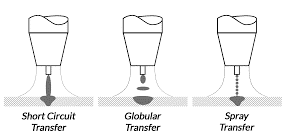

There are three main metal transfer options when welding stainless steel – spray-arc transfer, short-circuiting transfer, and globular metal transfer.

1. Spray Arc

The spray transfer method involves spraying small droplets of molten metal from the electrode into the weld joint. It is a pure constant voltage process that sends a stream of weld metal across the arc and to the base metal. However, this process uses a high-heat input and the danger of a burn through is high.

2. Short-Circuit Transfer

The short-circuit transfer method uses low voltage and is in fact the coldest form of MIG welding. Basically, the electrode comes into contact with the base metal and short circuits. The short circuit causes the wire to reach its melting point and create a weld puddle.

3. Globular Metal Transfer

The globular metal transfer is actually very similar to short-circuit transfer. The main difference is in how long the consumable electrode needs to melt. The wire is heated longer which creates a “glob” that drops from the base metal and creates a joint.

Potential Issues and Problems With MIG/MAG Welding Stainless Alloy

Welding stainless steel properly requires time and effort. You can’t expect to start to do it right off the bat. The practice is needed and certain problems may arise.

Overheating and Cracks

Unevenly distributed heat generated by the welding process used can create burns and cracks. Applying too much heat along the weld of a base metal can result in chrome carbide, which is not corrosion-resistant.

Choosing the Right Settings

An important part of arc welding processes is choosing the right settings. You have to pick the right gas for the material you plan to work on, the correct grade of wire, and set the amperage a bit higher as opposed to welding milder steel.

Weld Splatter

Weld splatter is one of the unwanted side-effects of using filler metal. The spatter may result in sharps or burrs on the weld joint that could lead to injuries of people that end up using the product.

Maintaining the CTDW

Welding stainless steel requires maintaining constant contact tip to work distance as opposed to working on other types of metal.

Frequently Asked Questions (F.A.Q)

Refer to these commonly asked questions for further insight.

Can you MIG weld steel to stainless steel?

Yes, you can. Stainless steel is usually welded with carbon steel, which is a far more economical choice. Carbon steel includes mild and low alloys and serves to reduce costs as making an entire construct from stainless steel could end up being far more expensive.

What is the best way to weld stainless steel?

There are various ways to weld stainless. The welding process you would want to use will depend on the results that you want to get. Each process comes with different properties and usage.

Can you wire feed weld stainless steel?

Yes, you can. Both stick and wire feed welders can be used when welding stainless steel.

Can I MIG weld stainless steel with 100 Argon?

Yes, you can but it is not advised to do it as you might wind up with poor arc characteristics.

Conclusion

Welding stainless steel can be challenging. However, using a MIG welding machine and a MIG process makes everything much easier as opposed when using other types of machines and processes. It does come with certain limitations, but if you factor them in before you start the benefits are much higher than the outtakes.

- Common stainless steel welding methods, by ATWF Inc,

- Pros, cons, and best ways of welding stainless steel, by American Torch Tip,

- Welder settings, wire and shielding gas options, by Lincoln electric,

- MIG welding metal transfer mods, by AED moto sport,

- Travel speed and contact to work distance, by EWI.