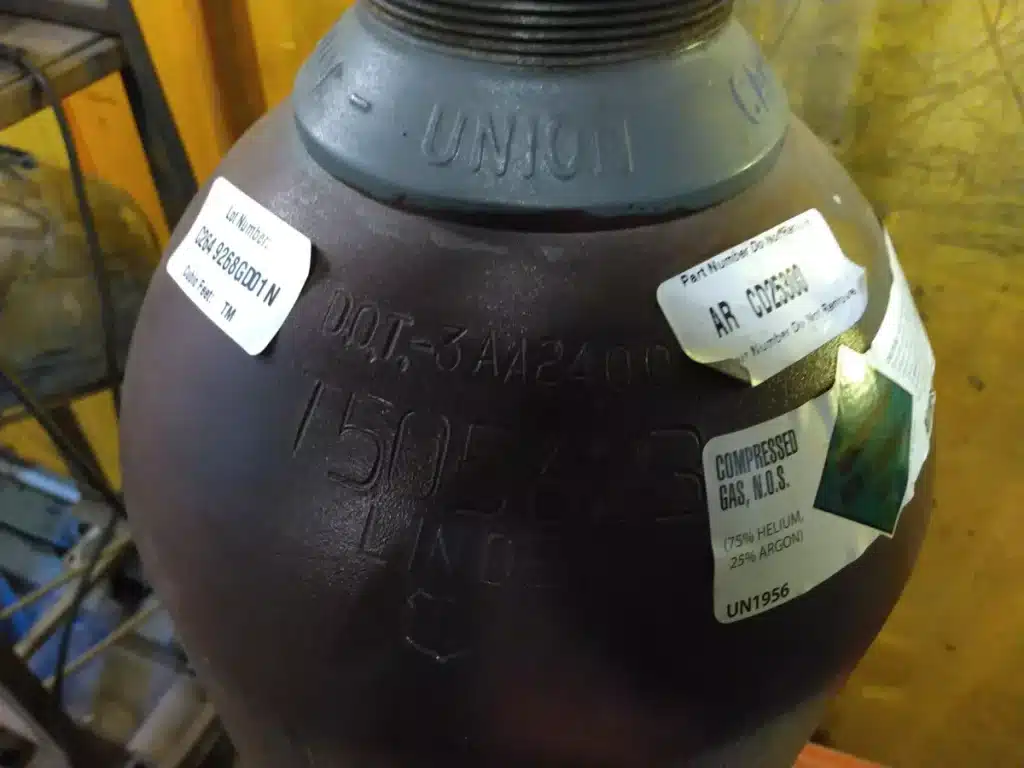

Metal Inert Gas (MIG) welding is a popular welding method that uses a shielding gas to protect the weld area from atmospheric contamination. Typically, pure argon or CO2 is used as a shielding gas in MIG welding.

However, when welding thicker metals or in specific environments, a mixture of argon and helium can be used to improve the welding process’s overall performance.

In this article, we’ll explore MIG welding with argon helium mix. The detailed overlook will show you why and when this MIG shielding mixture is used.

Role Of Inert Gases In MIG Welding?

In MIG welding, the role of shielding gas is crucial for achieving a successful weld. The primary purpose of the shielding gas is to protect the weld zone from the surrounding atmosphere, which contains oxygen, nitrogen, and other contaminants. These contaminants can react with the molten metal and cause defects, such as porosity, oxidation, or brittleness in the weld.

Shielding gas forms a protective atmosphere around the arc and weld pool, preventing atmospheric gases from entering and reacting with the metal.

It acts as a barrier, displacing the surrounding air and creating a stable environment for the arc to form and the metal to melt. By maintaining a controlled and inert environment, the shielding gas ensures a cleaner and more reliable weld with minimal defects, improved bead appearance, and increased weld strength.

MIG Welding With Pure Argon Inert Gas

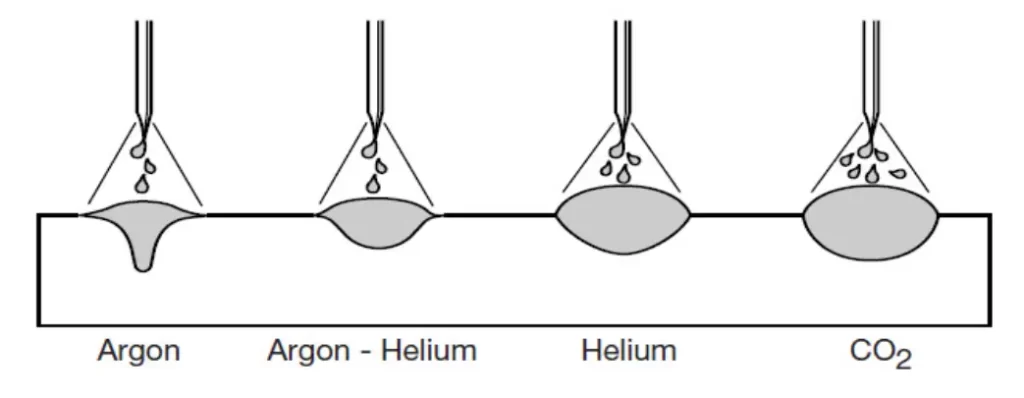

Pure argon is common gas for MIG that produces a smooth and gentle arc. The arc’s softness refers to its ease of control and reduced spatter, which is beneficial for welding thinner materials or when precise control is required. The arc cone, the shape formed between the electrode and the workpiece, tends to be wider when using pure argon. This wider arc cone can result in broader heat distribution, making it suitable for welding thicker materials.

Pure argon has a lower thermal conductivity compared to other gases like CO2. As a result, it generates less heat, which can be advantageous when welding heat-sensitive materials.

However, keep in mind that pure argon can also produce shallower penetration compared to gases like CO2 or argon/CO2 mixtures. This limitation may not be suitable for applications requiring stronger weld joints or when welding thicker sections.

MIG Welding With Pure Helium

Pure helium MIG welding gas produces an arc with high heat intensity. This characteristic makes it suitable for welding thicker materials, as it facilitates deep penetration and faster welding speeds. It can also be beneficial for welding high-conductivity materials like aluminum.

The high heat of the helium MIG gas enhances the fluidity of the weld pool, allowing for better control and bead appearance. This can result in improved fusion and a smoother, aesthetically pleasing weld.

The intense heat of pure helium minimizes the size of the heat-affected zone, which is the area surrounding the weld that experiences thermal changes. A smaller HAZ can help preserve the base material’s properties and reduce the risk of distortion or warping.

However, pure helium can be more expensive and less readily available than other shielding gases. This can increase the overall welding costs, especially for larger projects or continuous welding operations.

When And Why Welders Mix Argon And Helium?

Welders often mix argon and helium common shielding gases to create a gas blend that combines the benefits of both gases for specific welding applications.

Argon-helium mixtures are commonly used for MIG welding non-ferrous metals, such as aluminum, copper, or titanium.

These metals typically require higher heat input and better penetration, which can be achieved by using a blend of argon and helium.

The combination of argon and helium allows welders to optimize the welding process for specific applications, balancing penetration, heat input, and weld pool control to achieve high weld quality with improved efficiency.

Properties Of Argon/Helium Mix In MIG Welding

Helium has a higher thermal conductivity and heat transfer capability than argon. By adding helium to the shielding gas, you can enhance the arc’s energy and achieve deeper penetration into the base metal. This is particularly useful when welding thicker materials or when a stronger weld joint is required.

Helium’s higher heat input can help increase welding speed and deposition rates. This is advantageous for applications where productivity and efficiency are essential, such as high-volume production environments.

Argon, on the other hand, provides better arc stability and weld pool control. By mixing argon with helium, welders can balance the heat intensity of helium with the stability and control offered by argon. This combination improves the fluidity of the molten weld pool and enhances control over the welding process, resulting in better weld bead appearance and fusion.

It’s important to note that the specific ratio of argon to helium in the mixture can vary depending on the desired weld characteristics and the specific application. Welders may experiment with different ratios to achieve the desired results, considering factors such as the base metal thickness, joint configuration, and welding parameters.

Can You MIG Weld Steel With Argon/Helium Mix?

MIG welding with an Argon/Helium mixture can be used to join steel, but there are some things you can consider. The Argon/Helium mixture’s increased heat input and deeper penetration can help reduce the risk of solidification cracking in the weld, especially in thicker steel sections. The addition of helium to the shielding gas mixture enhances the arc’s energy and provides deeper penetration into the steel. This is particularly advantageous when welding thicker steel sections or when a stronger weld joint is required.

However, Argon/Helium mixtures tend to be more expensive than using pure argon or other shielding gas combinations like argon/CO2. The higher cost can impact overall welding expenses, particularly for larger projects or continuous welding operations. While the Argon/Helium mixture improves fluidity, excessive fluidity can also be a drawback. It requires careful control and technique, as excessive fluidity may lead to increased weld width or difficulties in achieving precise bead placement.

Overall, CO2 provides nearly similar results when MIG welding steel, but it is significantly more available and cheaper, so welders readily use it in these applications over Argon/Helium mixture.

Can You MIG Weld Stainless Steel With Argon/Helium Mixture?

MIG welding with an Argon/Helium mixture is commonly used for welding stainless steels. When welding thicker stainless steel sections, an Argon/Helium mixture can provide deeper penetration, which is essential for creating strong welds with good fusion. The increased heat input from the helium can also help to reduce the risk of weld defects such as incomplete fusion.

Using an Argon/Helium mixture for welding stainless steel can provide a balance of penetration, heat input, and weld pool control, resulting in strong and aesthetically pleasing welds. However, it’s essential to consider the specific requirements of the welding application, including the base metal thickness, joint configuration, and welding parameters, to determine the optimal shielding gas mixture.

Can You MIG Weld Aluminum With Argon/Helium Mixture?

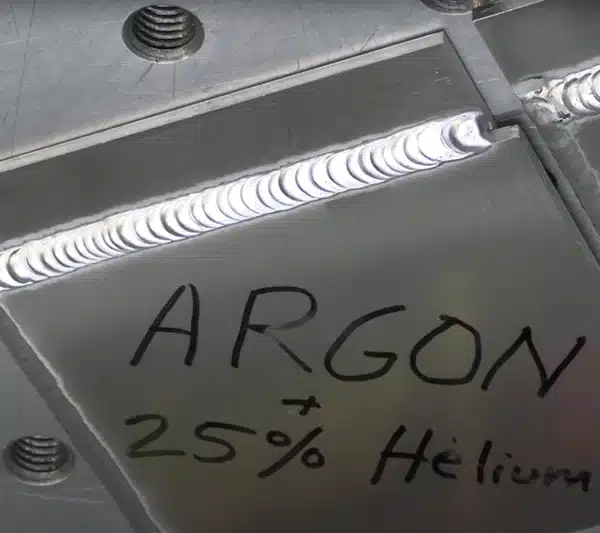

You can MIG weld aluminum with an Argon/Helium mixture, usually when dealing with thicker pieces. Aluminum has a high thermal conductivity and heat dissipation, which can make achieving sufficient penetration challenging. By using an Argon/Helium mixture, the higher heat input from helium can enhance the arc’s energy, resulting in improved penetration into the aluminum welds.

However, Argon/Helium mixture can be more expensive than pure argon as the shielding gas in MIG welding aluminum. Helium is typically more costly and less readily available compared to argon.

This higher cost can impact the overall welding expenses, especially for larger projects or continuous welding operations. That’s why this mixture is rarely used for hobby MIG welding aluminum, but it finds its way into industrial applications, and the same goes for TIG welding.

Should I MIG Weld Mild Steel With Argon/Helium or Argon/Carbon Dioxide mix?

The choice between using an Argon/Helium mixture or an Argon/Carbon dioxide mix for MIG welding mild or carbon steel depends on various factors and the specific requirements of your welding application. However, when we consider the arc characteristics of both mixtures, it is easy to say they provide somewhat similar results and arc impact.

Both Argon/CO2 and Argon/Helium provide highly stable results with good penetration and low spatter. Pure argon doesn’t show the best penetration and most stable arc when welding steel, so welders introduce CO2 or Helium to the mixture. These gases complement the arc and provide the best results on steel.

However, there is one crucial factor that affects the choice between welders, and that is costs. CO2 as a more widespread and reactive gas is significantly cheaper and more available on the market, so MIG welding steel with Argon/CO2 is the most popular among hobbyists across the globe.

Pros And Cons Of MIG Welding With Argon/Helium Mix?

Pros of MIG welding with an Argon/Helium mix:

- Improved Penetration: The addition of helium enhances the arc’s energy, allowing for deeper penetration into the base metal. This is beneficial for welding thicker sections or when stronger weld joints are required.

- Increased Heat Input: Helium’s higher heat input compared to pure argon can increase welding speed and deposition rates provided by the spray transfer process of MIG welding wire and weld metal. This can improve productivity, particularly in high-volume production environments.

- Better Control and Bead Appearance: The argon component provides better arc stability and weld pool control. It improves bead appearance, enhances weld pool fluidity, and allows for better control over the welding process.

- Reduced Heat-Affected Zone (HAZ): The Argon/Helium mixture helps minimize the size of the heat-affected zone, preserving the base material’s properties and reducing the risk of distortion or warping.

- Suitable for Non-Ferrous Metals: The Argon/Helium mix is commonly used for welding non-ferrous metals like aluminum, copper, or titanium. It provides the necessary heat input and deep weld penetration in these materials and finished weld.

Cons of MIG welding with an Argon/Helium mix:

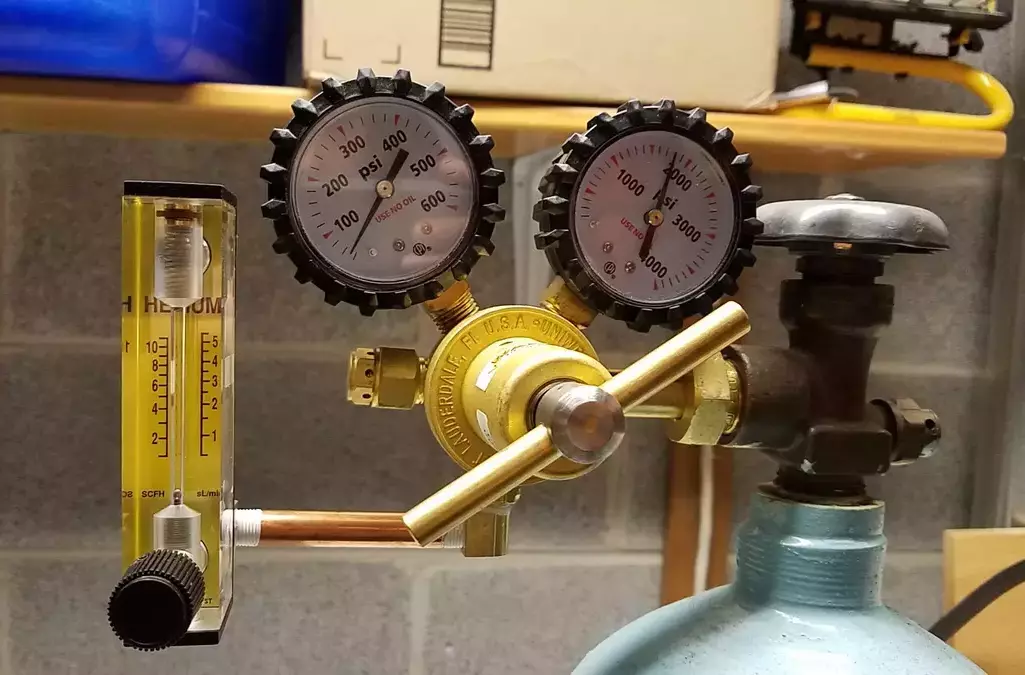

- Cost: Argon/Helium mixtures are generally more expensive compared to using pure argon or other gas mixtures. The higher cost can impact overall welding expenses, particularly for larger projects or continuous welding operations. It also requires higher flow rates, so you cannot get desired MIG welds with too little shielding gas.

- Challenging Bead Control: The increased heat input from helium can make bead control more challenging, especially for less experienced welders. It requires careful technique and control to achieve desired bead placement, appearance, and good shielding gas coverage.

- Limited Availability: Helium may not be as readily available as other shielding gases, making it more difficult to obtain or requiring additional logistical considerations.

Conclusion

MIG welding with an Argon/Helium gas mix offers several advantages and considerations. The addition of helium provides improved penetration, increased heat input, and enhanced control over the welding process.

This makes it particularly beneficial for welding thicker sections, non-ferrous metals like aluminum, and high-volume production environments. The argon component contributes to better arc stability, weld pool control, and bead appearance. However, there are drawbacks to consider, including the higher cost, sensitivity to wind, and the need for careful bead control.

Resources

- https://www.alleima.com/en/technical-center/shielding-the-weld/

- https://www.millerwelds.com/resources/article-library/what-gas-should-you-use-for-mig-welding-in-diy-applications

- https://www.tregaskiss.com/mig-welding-shielding-gas-basics/

- https://unimig.com.au/which-gas-do-you-need-for-your-mig-weld/

- https://americantorchtip.com/blog/the-fundamentals-of-mig-welding-gases/