In the world of metal fabrication, where precision and efficiency converge, a welding technique has emerged to revolutionize the industry: Pulsed MIG Welding.

With the rhythmic dance of controlled energy pulses, this cutting-edge method has taken welding to new heights, defying conventional limitations.

Seamlessly blending the power of MIG welding with the finesse of TIG, Pulsed MIG Welding has unlocked a realm of possibilities. Imagine unparalleled control, reduced heat input, minimal spatter, and flawless welds on a wide range of materials. Join us as we delve into the captivating world of Pulsed MIG Welding, where craftsmanship meets innovation, and the boundaries of metal fusion are shattered.

What Is Pulsed MIG Welding?

Pulsed MIG (Metal Inert Gas) welding is an advanced welding technique that combines the benefits of both traditional MIG and TIG (Tungsten Inert Gas) welding processes. It involves the use of a power source that rapidly switches between a high peak current for melting the metal and a lower background current for cooling and solidifying the weld. This pulsing action allows for precise control over the heat input and weld pool, resulting in several advantages.

One of the key benefits of pulsed MIG welding is its ability to reduce heat input compared to traditional MIG welding. By pulsing the current, the welder can deliver short bursts of energy, allowing the metal to cool between pulses, resulting in a cooler weld puddle. This controlled heat input minimizes distortion and heat-affected zone (HAZ) while maintaining excellent fusion.

How Does Pulsed MIG Work?

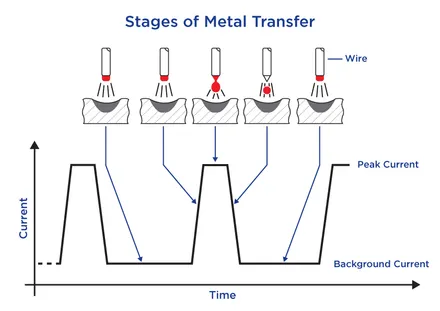

Simply put, pulsed MIG represents a modified spray transfer mode. This is a non-contact method, meaning that at no time does the electrode ever touch the weld puddle. The pulsed MIG process works by forming one droplet of molten metal at the end of the electrode per pulse.

Then, just the right amount of current is added to push that one droplet across the arc and into the weld puddle. The metal transfer of these droplets occurs through the arc, with one droplet per pulse.

During the process, the current rises to a peak when the droplet is formed. Then, in the background current phase, the current is lowered to reduce the overall heat input. It is the height and the width of the peak that is important for proper transfer.

Unlike CV (constant voltage), where current is represented by a straight line, pulsed MIG drops the current at times when extra power is not needed, therefore cooling off the process. It is this “cooling off” period that allows pulsed MIG to weld better on thin materials, control distortion, and run at lower wire feed speeds.

Why Welders Use Pulsed MIG Welding

Pulsed MIG (Metal Inert Gas) welding offers several advantages over traditional welding techniques. Most notable advantages of pulsed MIG welding:

- Lower Heat Input: Pulsed MIG welding allows for precise control over the heat input. By pulsing the current, the welder can deliver short bursts of energy, followed by cooling periods. This controlled heat input minimizes distortion, heat-affected zone (HAZ), and the risk of material warping. It is particularly beneficial when working with heat-sensitive materials like aluminum.

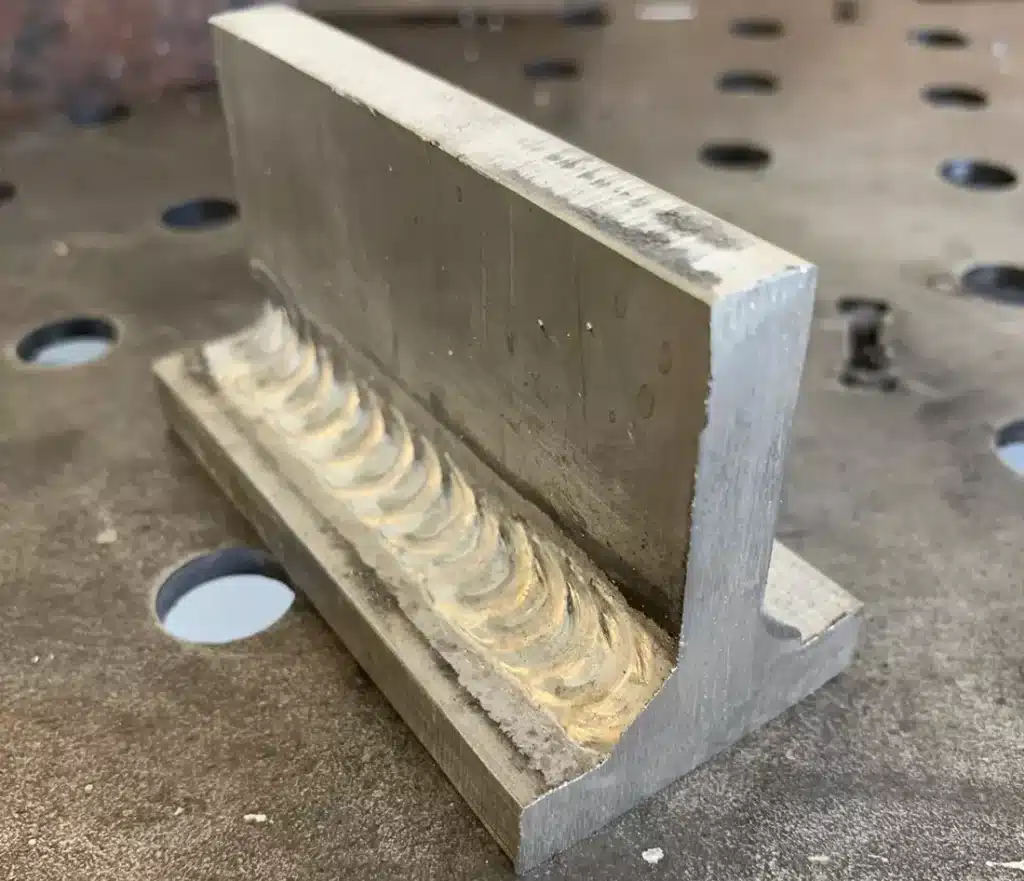

- Enhanced Control and Precision: Pulsed MIG welding provides superior control over the weld pool and allows for precise bead placement. The pulsing action creates a “stacked dimes” appearance, where each pulse creates a small, controlled weld deposit. This level of control is desirable in industries where aesthetics and precise weld profiles are crucial.

- Minimized Spatter: The lower background current in pulsed MIG welding reduces the risk of spatter formation. Spatter, which is the unwanted metal splatter that can occur during welding, is minimized in pulsed MIG welding due to the controlled heat input and shorter arc-on time. This results in cleaner welds, reducing the need for post-weld cleanup and saving time and effort. Additionally, there is a significant reduction in the welding fumes creates.

- Improved Arc Stability: Pulsed MIG welding offers excellent arc stability, even at low amperage settings. The controlled pulsing action ensures a stable arc throughout the welding process, reducing the likelihood of arc outages or arc wandering. This stability contributes to consistent and high-quality welds.

- Versatility: Pulsed MIG welding can be applied to a wide range of materials, including carbon steel, stainless steel, aluminum, and other non-ferrous metals. It is suitable for various thicknesses and can accommodate different weld joint configurations. Its versatility makes it a preferred choice in industries such as automotive manufacturing, aerospace, construction, and more.

- Increased Welding Speed: Pulsed MIG welding can result in faster wire feed speed compared to traditional MIG. The controlled pulsing action allows for higher travel speeds while maintaining excellent MIG weld quality. This increased productivity is advantageous in high-volume production environments.

- Improved Weld Quality: The combination of reduced heat input, precise control, minimized spatter, and superior arc stability in pulsed MIG welding contributes to improved weld quality. The welds produced with this technique often exhibit excellent fusion, minimal weld defects, and enhanced mechanical properties.

What Materials And Sizes Can Be Welded MIG Pulse Welding?

Pulse MIG is ideal for metals and applications where controlling heat is difficult when using conventional MIG welders. As a result, pulsed MIG (Metal Inert Gas) welding can be used to weld a wide range of metals, including aluminum, non-ferrous metals, stainless steel, and mild steel. Pulsed MIG welding offers versatility in welding various metals and can accommodate different thicknesses, making it suitable for a wide range of applications in industries such as automotive, manufacturing, construction, and more.

The specific size or thickness that can be welded using pulsed MIG welding depends on various factors, including the equipment used, welding parameters, joint design, and material characteristics. However, pulsed MIG welding is commonly employed to deal with delicate and thinner metals of 5/32 inch or up to 1/4 inch.

MIG Welding Aluminum With Pulse

Pulsed MIG (Metal Inert Gas) welding is a highly advantageous option for aluminum welding. Aluminum has high thermal conductivity, which makes it sensitive to excessive heat. Pulsed MIG welding allows for precise control over the heat input. This controlled heat input minimizes the risk of distortion, burn-through, and heat-affected zone (HAZ) issues commonly associated with aluminum welding.

Aluminum welding can produce more spatter compared to other metals. Pulsed MIG welding helps in reducing spatter formation.

Pulsed MIG welding creates a visually appealing weld bead profile known as the “stacked dimes” appearance. This is particularly desirable in applications where the weld appearance plays a significant role, such as architectural structures or automotive components.

Pulsed MIG welding can improve productivity in aluminum welding. The controlled heat input and reduced spatter minimize the need for extensive post-weld cleanup, saving time and effort.

MIG Welding Stainless Steel With Pulse

Stainless steel is sensitive to overheating, which can lead to issues such as distortion, grain growth, and reduced corrosion resistance. Pulsed MIG welding provides precise control over the heat input. The pulsed current alternates between high peak currents and lower background currents, allowing the stainless steel to cool between pulses. This controlled heat input helps prevent overheating and minimizes the risk of detrimental effects on the material.

Pulsed MIG welding is versatile and suitable for various stainless steel grades, including austenitic, ferritic, and duplex stainless steels. It can be applied to different thicknesses and joint designs, making it a preferred choice in industries such as automotive, food processing, pharmaceuticals, and construction.

MIG Welding Non-ferrous Metals With Pulse

Bronze wires, typically composed of copper and tin or other alloying elements, are commonly used in pulsed MIG welding for applications where properties such as high strength, corrosion resistance, and thermal conductivity are required. Bronze wires are available in various compositions to suit specific welding needs.

Pulsed MIG is used on thin materials (eg car body panels) where low-temperature welding is essential to avoid distortion. Also commonly used on galvanized or zinc-coated steels because the weld metal does not rust, and the lower application temperature prevents disturbance (evaporation) of the zinc coating. The ability to control and reduce heat makes pulse an ideal process for brazing wires.

Can you MIG Weld Mild Steel With Pulse?

Mild steel does not present the same “thermal challenges” as other metals like aluminum or stainless, and therefore pulse does not necessarily offer the same advantages. For this reason, conventional MIG (rather than pulse MIG) is still the best process for welding mild steel in many applications – especially in the material thickness range that is achievable with single-phase machines.

Double Pulse MIG (Pulse-on-pulse)

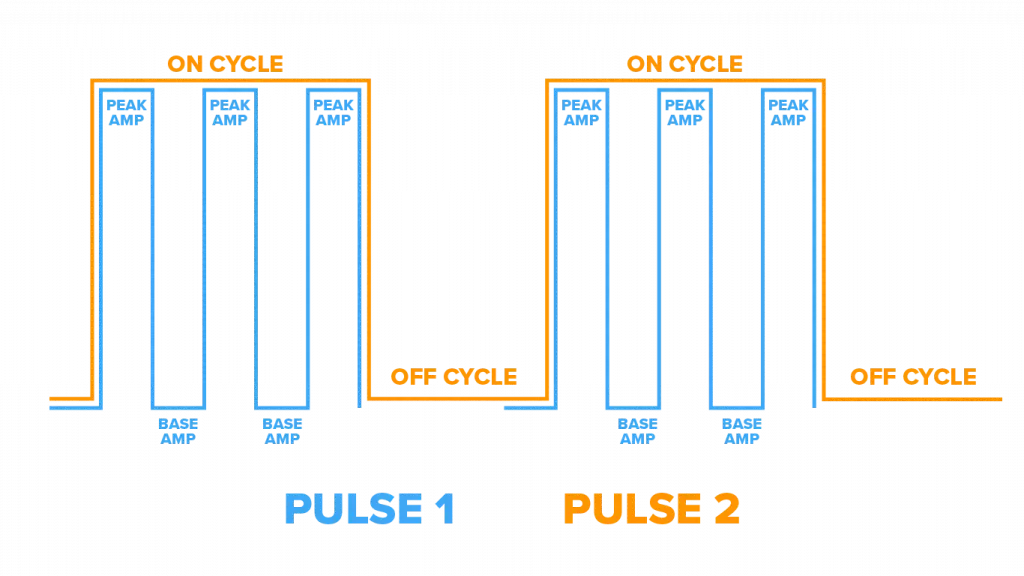

Double pulse MIG welding, also known as pulse-on-pulse MIG welding, is an advanced welding technique that involves the use of two pulses during the welding process. Here’s an explanation of how double-pulse MIG works:

Initial Pulse: The first pulse, known as the initial pulse, is a relatively high current pulse that creates a deep penetration into the base metal. This pulse provides the necessary energy to melt the base metal and initiate the formation of the weld pool.

Background Current: After the initial pulse, a lower background current is applied. This background current maintains the arc and allows the weld pool to partially solidify. It also helps in controlling the heat input and reducing the overall heat-affected zone (HAZ).

Interpulse Time: Between the initial pulse and the second pulse, there is a brief interval called the interpulse time. During this time, the weld pool solidifies to a certain extent, ensuring stability and preventing excessive melting or distortion.

Second Pulse: The second pulse, also known as the fill pulse, follows the interpulse time. It has a lower current compared to the initial pulse and is aimed at completing the fusion of the weld pool. The fill pulse adds additional metal to the weld pool, allowing for better sidewall fusion and overall weld bead shape.

The advanced welders with douple pulse or pulse can help you with advanced settings. These pulsed MIG power sources are capable of adjusting primary and background amps, voltage, and wire feeding speed, pulse frequency, pulse balance, arc length, start and ending current, and other settings.

MIG vs TIG Pulsed Welding

Pulse welding can be used in both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding processes, but there are some key differences in how it is applied in each method. Even though the base of the pulse is the same in both processes, in MIG welding, the pulse is just a modified spray transfer process, that compliments other welding transfer modes.

TIG welding is traditionally the go-to process when there is a need to weld materials to a higher standard (quality and/or appearance) than conventional MIG. Aluminum and stainless steel are commonly welded with TIG, as these materials are often used in projects where the finish of the final product is critical

Compared to TIG, MIG pulse typically requires less skill and is easier to learn, which reduces training time. The weld quality and finish are comparable or very close to TIG in many applications.

Conclusion

Overall, pulsed MIG welding has revolutionized the welding industry by providing welders with greater control, improved efficiency, and high-quality results. Pulsed MIG machines have advantages in heat control, reduced distortion, minimized spatter, deep penetration, versatility, and aesthetics, making them a preferred choice for many welding applications. As technology continues to advance, pulsed MIG welding techniques are likely to evolve further, offering even greater capabilities and expanding their applications in the field of welding.

Resources

- https://www.lincolnelectric.com/en/Welding-and-Cutting-Resource-Center/Process-and-Theory/Pulsed-MIG-Welding

- https://www.twi-global.com/technical-knowledge/faqs/faq-what-is-pulsed-mig-mag-welding-and-what-are-its-advantages-over-conventional-mig-mag-processes

- https://www.weldclass.com.au/blog/94-what-is-a-pulse-mig-a-how-why-guide-to-pulse-mig-welding

- https://www.millerwelds.com/resources/article-library/an-introduction-to-pulsed-gmaw

- https://www.jasic.co.uk/post/what-is-pulsed-mig-welding