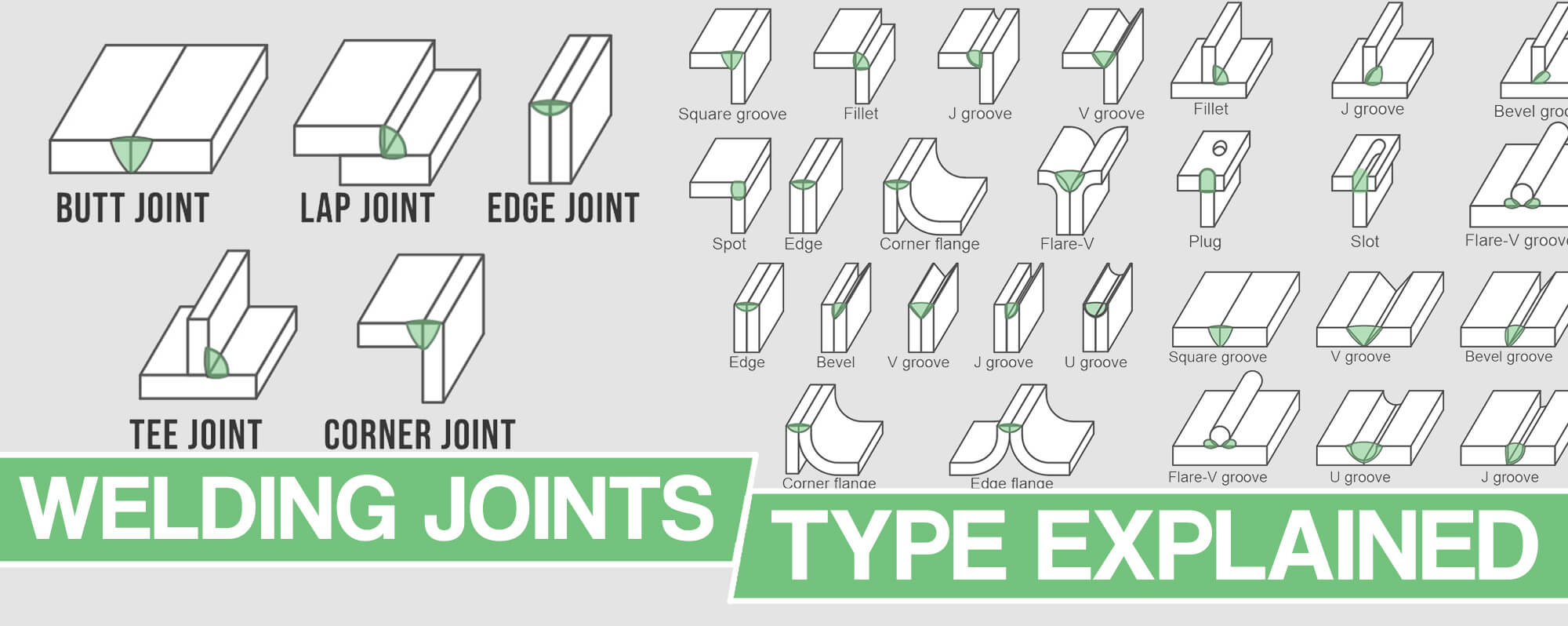

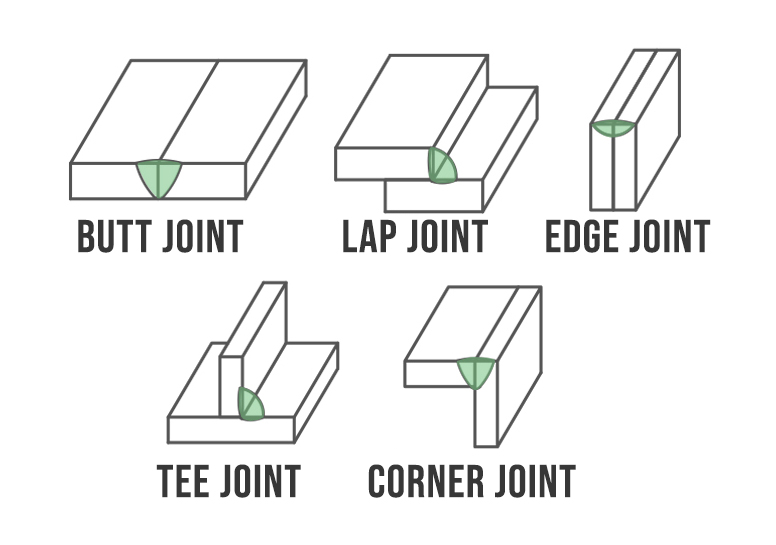

There are five major types of welding joints. You have to differentiate between a joint and a weld.

This article will teach you how to do that and how to easily recognize each welding joint type as soon as you see it. It’s rather simple really.

Especially when somebody gives it to you straight. Now let’s see these joint types in detail and on examples.

Different Welding Joint Types Explained

I love the definition of a joint by the American Welding Society the best. AWS says that a joint is simply “The manner in which materials fit together”. Therefore the five welding joint types are simply five different ways of fitting two pieces together.

However, each of the welding joint types can be welded in place using many different weld types.

That is why I said at the beginning that welding joint is not the same as weld type terminology-wise.

There are many different types of welds and some of them are fillet welds, groove welds, flange, bevel, surfacing, backing, plug, slot and etc.

I will show you how each of these looks when applied to each welding joint type. Basically, there are 5 major joint types and each can be welded with many different types of welds.

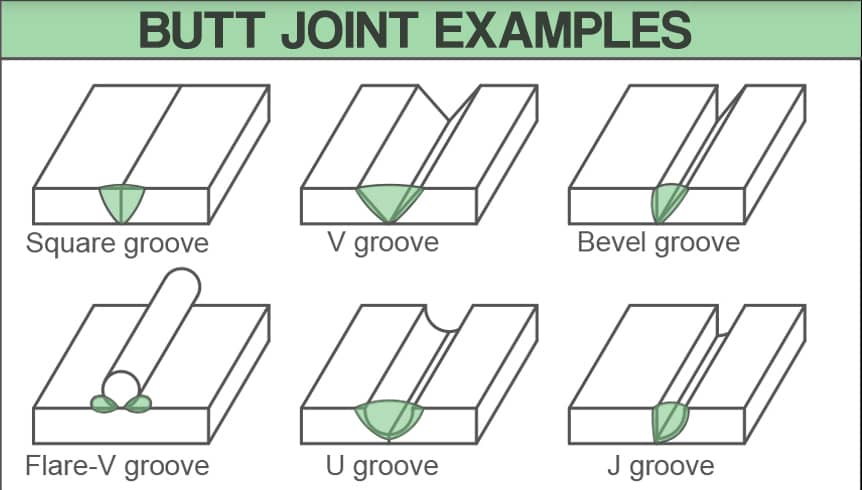

Butt Joint Welding

This is the most common and simplest welding joint type. It is as straightforward as putting two pieces of metal together in the same plane.

In a real scenario, this is often done by just placing two rectangular metal pieces together so that they are in contact with each other’s edge. They can have an opening in between or be in contact with one another.

The area between the pieces is prepared if necessary and welded. In the preparation phase, you will choose the weld type.

It will be either a simple square groove with or without a root opening between the pieces or you may shape the edges so that you get a V groove, J grove or similar (shown on image).

The most typical butt joint types of welds are:

- Square groove

- V groove

- Bevel (single and double)

- Flare V groove

- U groove (single and double)

- J groove (single and double)

The butt welds are used in hundreds of different industries from structural fabrication to pipeline. They are often irreplaceable and represent a very economical and simple weld joint.

You can modify each of the member pieces’ edges in the preparation phase differently if that is what the engineer specification requires. Or the faying surface (the melted area of the surface) can receive the same preparation.

This can get more complex depending on the weld specification. The size and angle of the groove can be specified which demands from the welder a higher degree of precision. If these are not specified then it is up to the welder to choose dimensions as long as the specified type of weld is achieved (i.e. V groove).

Thicker pieces require modifying a joint design so that a proper penetration can take place. Thin pieces on another hand are more likely to achieve full penetration with a simple square butt joint. Square groove type of weld is not usually used with anything on the thicker side. Adding a root opening and doing a double square groove can help in penetration but in practice, you would grind out the edges and make a V groove more often than not.

Achieving a 100% penetration without modifying the welded piece edges is almost impossible at very thick sections and that is why knowing both weld joint type and what weld types can be used with it is important. Incorrect preparation can lead to burn-through, poor penetration, cracking, or porosity as well.

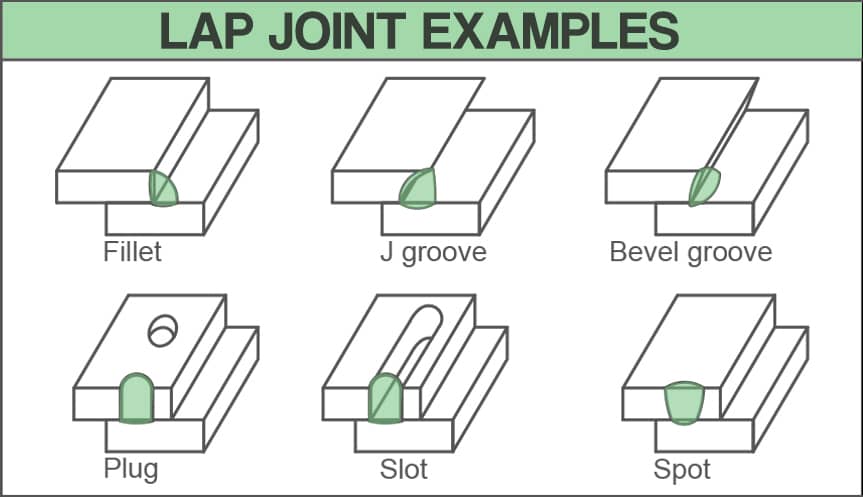

Lap Joint Welding

Lap joint is a second in line when it comes to complexity. It is as simple as a butt weld joint and functions as a bit of a modified version of it. To form a lap joint you would simply need to place two pieces of metal in an overlapping pattern. Afterward, you place your welds on one or both sides.

The lap joint is usually used to weld together two base metal pieces to each other of different cross-section thicknesses. This makes it difficult to achieve a proper butt joint which is why the lap joint makes a better choice.

There are other reasons why a lap joint may be preferred but this is the most common one. You can apply various types of welds to lap joint and commonly used are:

- Fillet weld

- J groove weld

- Bevel groove weld

- Plug welds

- Slot welds

- Spot weld

This type of welding joint is not often applied to thick materials. It is much more common in sheet metal parts welding work. In order to avoid problems like corrosion and lamellar tearing, it is necessary to follow the engineer’s notes that specify the details about the weld type. For example, if you need to perform a fillet weld on both sides and the weld dimensions are specified then you need to make it accordingly. Lap joints are notorious for issues if not done properly.

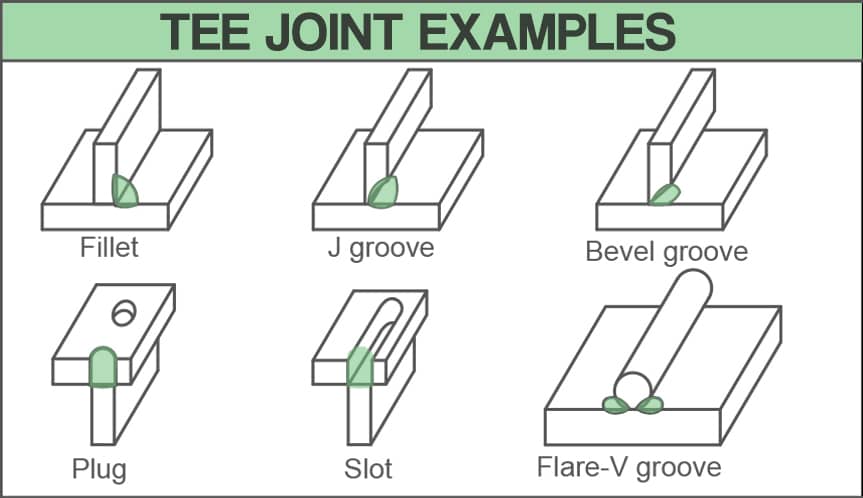

Tee Joint Type

Tee welding joints are shaped just what they should like. They have a “T” shape because the two base metals intersect at a 90° angle. Tee joints can also be formed from non-rectangular welding parts. A good example would be when circular sections like pipes and tubes are welded on a piece (see image).

When welding a T joint it is of utmost importance to make sure that the required penetration is achieved into the roof of the welded joint. It is naturally easier to achieve strong penetration with the bottom part of the T joint which is why welding the upper edge requires more focus.

T weld joints can be achieved with multiple welding styles and these are the commonly used:

- Fillet

- J groove type weld

- Bevel groove weld

- Plug weld

- Slot weld

- Flare V groove weld

The welding joints are not commonly prepared with groove before they are welded to each other. If the welding project consists of very thick base metal then joint preparation will definitely be necessary. Common welding practices require that the filler metal makes a strong connection with the base plate on both sides of the weld.

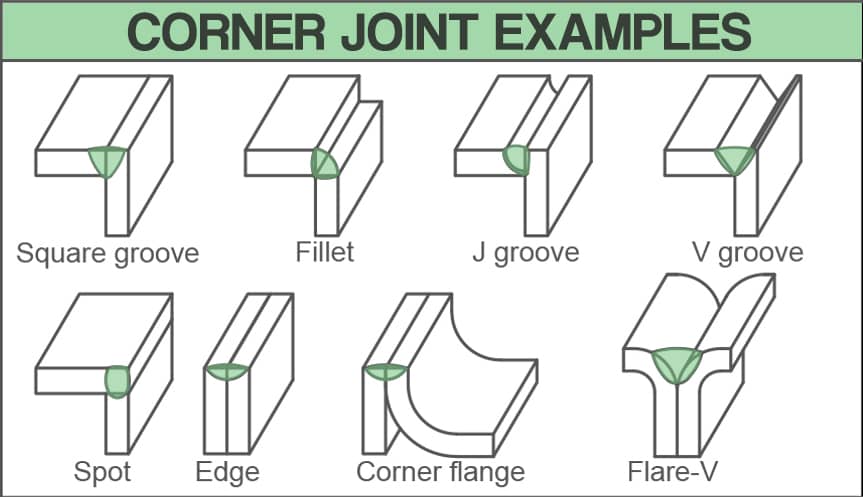

Corner Joint Welding

Corner joints are somewhat similar to the Tee joints that we discussed above. But you will always be able to easily differentiate between the two because the corner joints have their metal part connected in the corner while the Tee joints are welded in the middle.

The corner weld joints can be either in the open or closed state.

These weld joints are very common in sheet metal work and they are achieved with various welding processes.

If you are interested in welding jobs in the sheet metal industry then you should master corner joint welding. Commonly used weld types are:

- Square groove

- Fillet weld

- J groove weld

- V groove weld

- Flare V groove weld

- Spot weld

- Edge weld

- Corner flanging edges

Since corner joint welding is so used with sheet metal work, all of these weld types are used all the time. Construction of frames, boxes, various profiles and other shapes is quite demanding and requires thorough knowledge of types of welding joints.

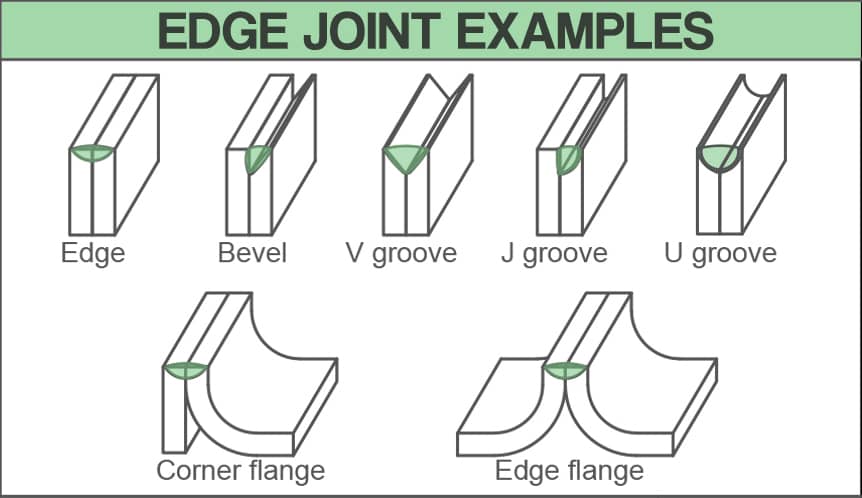

Edge welding joints

Of all different types of welding joints the edge welding joint may be the most difficult to master. This is however subjective as some people excel faster than others.

The biggest challenge is when welding thin sheets parts together and when the edge weld configuration is complex.

Edge joint is formed by the metal surfaces that are placed together so that their edges are even and in the same plane. The edge joint can have one or both plates bent at an angle (see image).

These welding joints are quite often used with flanged edges sheet metal parts or are used when a weld needs to be made that attaches adjacent edge joints sheet metal elements.

The edge joint joints the parts together in a way that the internal stresses get properly distributed. These internal stresses are tensile, compression, bending, shear and torsion. Some welding styles will achieve this better than others. There are a lot of factors at play here and if you are unsure it is best to consult the weld notes or talk to the engineer.

When working with edge welding joints it is important to note that everything will influence the final weld. The metal is usually thin and if the finished weld requires high quality then filler metal, welding process, joint design, penetration, rate of travel, deposition rate, heat input, rate of cooling and etc. will influence the final weld joint.

The common weld types:

- Edge welding joint

- Bevel groove weld

- V groove welds

- J groove weld

- U groove weld

- Corner flange

- Edge flange, flanging edges

Learn about different weld types and their symbols

I’ve shown you how each of the welds looks like when applied to these joints but there is so much more to it. Each of the welds can have its modifications and different preparations. I wrote an ultimate guide about welding symbols and all of the welding styles have been explained thereon over 50 cross-section images. We have also published a book about it and in it, you can find a chart that contains all of the welding joints displayed above and so much more than that.

Conclusion and summary

The reason why we have different types of welding joints is the different types of welding work. There are hundreds of different scenarios and these five types of welding joints will cover pretty much all of them. Mastering them will prove very beneficial in your career and will make you an exceptional welder.

To actually master each of the welding joint types you need to learn how to apply different weld types with each of them. Butt weld joint with square groove weld may be the easiest to start but that doesn’t mean that you will be limited to simple work only because it is used in so many applications. Simple doesn’t mean bad. We want things to be simple but sometimes that is not possible so we need to do things like flare bevel groove weld or more complex like tee joint arc welding.