It’s a no-brainer that you need welding safety equipment.

The question is what equipment you need, what are the non-negotiables of safety standards and what can you get by without if you are not into heavy-duty welding.

Not all welding safety equipment is made equal. There are many different materials that are used in protective clothing like safety gloves and there are many different features the personal protective equipment can offer.

TIG welding doesn’t require the same safety levels as stick arc welding.

Eye protection is a must in every possible scenario but depending on the frequency of your welding work you could get by with basic stuff and save some money or if you are a professional you will benefit much more from the professional gear.

You get the picture. There are a lot of things to discuss here in order to maximize your budget use for your particular case. You don’t need to have all of the equipment. What you need is to be protected from the dangers that YOU will face when welding.

That’s why this article will explain the personal protective equipment in detail. That way you can judge yourself which of the items you will need and what they are protecting against.

Welding safety equipment checklist

I will list everything in this checklist and explain what are the features, use cases and benefits of each protective equipment element.

You will also learn about the different grades of the equipment. Different materials and standards and what each is meant for. This will tell you if you can save some money or not. Don’t buy safety equipment that is underrated for your use case. Never put yourself in harm’s way when welding.

Welding is one of the most dangerous things you could do. Accidents happen all the time that results in serious injuries and even death. Use your best judgment when determining the safety gear you will need and abide by the codes and standards set in place in your work area.

Welding Helmet

A welding helmet provides you with face and eye protection.

I would always advise going with a quality auto-darkening welding helmet. However, if you are a hobbyist welder that will do a weld here and there you can also use a passive hood. Still, there are many cheap but decent-quality auto-darkening helmets meant for this kind of hobby welding work.

If you are planning to weld often or you are a professional then you need quality stuff.

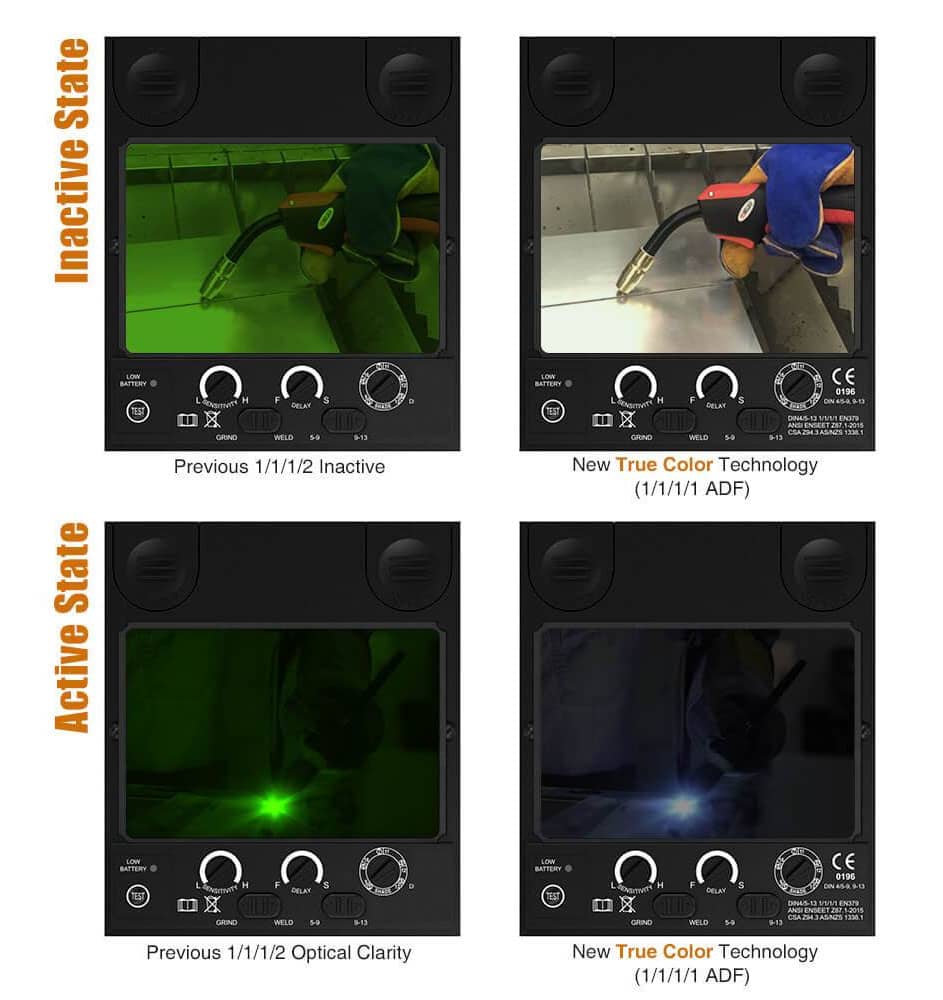

In an ideal world your auto-darkening welding helmet needs to have a fast response time to the welding arc, multiple high-quality sensors that never fail, as big a viewing area as you can get, the highest optical rating, and excellent light and color transmission.

On top of that, it needs to be comfortable to wear, have multiple adjusting points in its headgear, be of high durability because the welding sparks and molten pieces will make contact with it, and let’s face it you will drop it by accident occasionally. Maybe it just slips and falls from a high point or even worse some heavy piece of metal falls on it.

However, if you are a pipeline welder or you weld outside a lot for other reasons, you will probably want a passive welding helmet. That is because the rain and humidity can damage the auto-darkening electronics found in these welding helmets. If you are a pipeline worker then you will need side shields on your mask as well. That way you are will not be exposed to the nearby light originating from another welder’s activity.

Face protection and eye protection are non-negotiable in this line of work. Welding arc flash is not a game and can cause permanent eye injury. UV intense light radiation is dangerous for the skin on your face and your eyes. The hot slag, sparks and other flying objects can scar your face or worse.

Oftentimes when you buy a welder you will get a hand shield with it. Those are utterly useless so you should definitely upgrade from a hand held shield to an actual hood whether passive or autodarkening.

Never wear contact lenses underneath the hood. If you have vision problems, just add cheater lenses to the helmet. Using contact lenses can lead to eye irritation or worse.

Welding Gloves

Welding gloves are definitely something you shouldn’t skip.

You can get by with the cheaper gloves as long as they offer the needed protection.

But if you are a professional welder you will benefit from more durable and more expensive gloves.

Sparks and molten slag can burn your fingers, palm, or backhand area easily and those burns can be devastating.

A good pair of welding gloves will prevent that. Even a cheap pair will as long as it is meant for the type of work you will be doing.

The gloves should match these criteria:

- Provide strong physical protection of your hands

- Provide insulation and heat resistance

- Cover the hands and wrists

- Fit under or over the jacket’s arm cuff

- Provide enough dexterity of movement and comfort

- Be durable or have a very good price to quality ratio if you will change them often

There are various types of welding gloves. Generally speaking, they can be divided by the welding process to MIG, TIG and Stick. Their purpose is determined by the materials they are made of and the design.

Gloves used in stick welding need to be heavy-duty. They have to endure high heat and spatter. The best of them have heavy stitching, are flame-resistant, and have many layers of insulation. These can also be used for heavy-duty MIG work.

Regular MIG gloves offer more dexterity and are less insulated. They still need to be quite durable and resistant so they are usually made of leather.

TIG work gloves put much more emphasis on flexibility and dexterity. While they have to protect your hands, this is a fairly clean process, without many sparks and slag flying around. This means that they can be thinner and in turn give you the much-needed precision that the TIG welding requires. They are usually made of thin heat-resistant leather-like goat hide or from the deer.

Depending on the work you do your gloves may also need to protect you from chemical burns. Think hard about the entire work process before you decide which ones are for you.

Heat Resistant Welder’s Jacket

A welding jacket will protect your torso from sparks and slag. It does a similar job as the gloves do but on the torso area. Additionally, it helps in lessening ultraviolet radiation exposure.

If you are a hobbyist who will place a weld here and there you don’t necessarily need one. However, it is a practice to wear it and you will be much safer that way. If you don’t wear it and you get burned it is on you, so it’s always better to be safe than sorry. If you really want to save money and don’t get an official welding jacket, you can substitute it with a heavy, tightly woven clothing that is made from 100% wool or cotton. While this is already similar to the store-bought welding jackets, you might already have something like that at home.

Never wear clothes made from synthetics or any combustible materials. Synthetic clothes can catch fire easily and melt while getting your skin in the process as well.

If you are someone that does this for a living or you will be then you need an actual welding jacket. If you are careful with it, it will last long so it’s a nice investment. Plus they are often fairly cheap and good looking.

Basically, there three two types of welding jackets:

- Flame-resistant cotton: Jackets made from this material are affordable, light and your skin gets to breathe in them. The flame resistant material is actually chemically treated in order to be fire resistant. These materials “off-gas” when they come in contact with intense heat like flames. The released gas diminishes the supply of oxygen in the immediate vicinity and this prevents the combustion of the jacket’s material. Cotton based jackets are not meant for very intense work. They work well when you are exposed to low to medium amounts of sparks and slag. Even a medium amount of spatter is pushing it a little. If you are working in dangerous conditions, the heats are high and your work shed sparks a lot consider upgrading to more durable leather jackets.

- Leather welder jacket: Leather jackets are more durable thanks to the material’s density, durability and thickness. The combination of these factors results in a material that is difficult to penetrate with heat or force which makes them excellent for use by welders. However, it is a bit of a double edge sword because the skin can’t breathe, the material is heavy and the heat buildup inside of it can be troublesome. Still, if it is needed to get the job done it is a great option. There are many different grades, types and cuts of leather and they determine the cost and the purpose of it. Grain leather jackets are thinner, more comfortable and repel sparks at a better rate than split leather which is less expensive but heavier, thicker and more prone to oil absorption.

- Denim: Denim jackets are an excellent solution for light welding jobs or for TIG welders. TIG work doesn’t require thick clothing because there isn’t a lot of spatter associated with it. Denim however has decent protective abilities against spatter so it is fair to say that a good denim jacket can be a great substitute if you are careful and you don’t work with high heat in intensive work conditions where severe hot metal pieces flying around. A big plus for denim is that you can be much more flexible in it, it breathes well and it is lightweight.

There are a lot of brands that offer a lot of types of welding jackets. What I described above is simply the basis on which they build upon. There are innovative solutions that combine the benefits of one material and exclude its drawbacks with another. If you are a professional you will benefit greatly from a top quality jacket but if you are a hobbyist you should stick with the basics.

Welding Pants

Not many people talk about welding pants. Well, not many people but those that need to use them or have had bad experiences.

If you are a hobbyist or a small-time welder then you can use regular jeans. It is always better if they are a bit tougher and thicker.

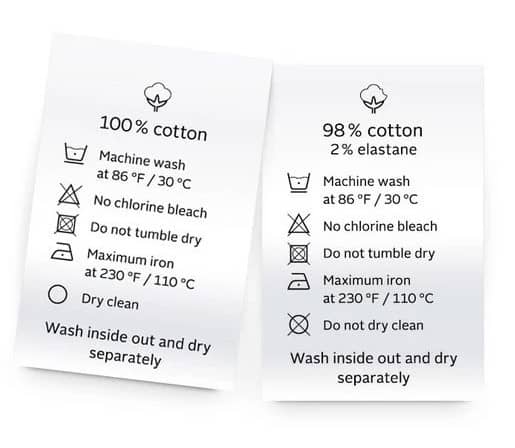

Make sure that you use only 100% cotton-made jeans. If they have synthetics just don’t use them. There are jeans that use elastane to make them more elastic. Check your jean’s fabric composition and if you see something like 97% cotton and 3% something else or similar numbers, don’t use them to weld.

If you are someone that does this for a living or you will weld on the ground, crouching and having your shins and thighs directly exposed to the hot metal then you will need flame-resistant actual welding pants.

Such pants are rated for FR and can even look like normal jeans so that you can even use them in everyday life.

There are so many different experiences so if one brand doesn’t work for you keep looking until you find pants that offer good protection, good price, and durability. You don’t want anything that won’t last at least 6 months.

Your pants shouldn’t have cuffs at the end of the leg holes or anything else where burning metal debris can get caught on. This is a recipe for a disaster so make sure that your pants are flat throughout their length.

Welding Work Boots

I say that a good pair of welding boots is nonnegotiable. People may disagree which is understandable but even a DIY hobbysit shouldn’t weld in their sneakers. At least get the cheapest shoes that can actually endure a molten piece of metal dropping on your toes. They may not last as long as the expensive shoes but will sure as hell last longer than summer sneakers and you also get to keep your toes intact which is a nice plus right?

It’s not just about the heat and physical protection. Good pair of welding boots need to protect you from electrical shocks and be slip-resistant.

Even a hobbyist or a small welding shop owner can get an electric shock in unfortunate scenarios. You can also step on a sharp piece of metal pointing upwards, twist your ankle in a bad position or have a burning debris land in the ankle opening.

Getting shoes that are not designed for welding work might not prevent all of these issues even if they are work boots and not some plain sneakers which are definitely a no in my book.

Proper welding boots should be electric shockproof, flame resistant or flame retardant, have a steel plate to protect the sole area (from molten slag or heavy objects), cover way past the ankle area, be slip resistant, have toe protection and be durable. The durability part is where you get to negotiate the pricing. If you get the cheaper shoes that fulfill the above criteria you will be safe but for how long is the question. Having it all and the durability will cost more and such shoes I would recommend for people doing this for a living.

Welding Respirator or Lung protection

You can’t overprotect your lungs when welding but you also don’t have to spend money on respirators if you don’t need to.

If you are working in a well-ventilated area or outside you are most likely not going to need any welding respirator and especially if you are a hobbyist. In these conditions, welding basic stuff like mild steel will not require a respirator. Just keep your head as far away from the welding fumes as possible and you will be fine.

However, if you are working in a closed area with no exit pathway for the welding fumes, you will need a good fume extraction system and possibly a respirator.

But if you working in a really tight area like inside a boiler or a pipe with little to no airflow then you definitely need a respirator.

In addition, professional respirators are comfortable, refreshing to work with, minimize re-breathing of used air and filter out almost 100% of the bad stuff you don’t want in your lungs. That way you can enjoy your work and live longer without the hassle of lung issues.

If you are working with hazardous metals like galvanized steel or you use electrodes that release dangerous fumes you must use a welding respirator.

Welding Apron

A welding apron is still often used as additional welding apparel for the legs and chest. While you don’t have to use it, it is very useful in a welding shop because you will also be using a grinder and plasma arc cutting.

Pair that with welding operations and as you can imagine welding shop workers are more often than not being bombarded with sparks, slag and spatter.

If you weld with high heat with a lot of slag flying around then it is a good idea to have that additional protection and especially if your pants are not up to the task.

Aprons are usually made of durable leather but you can also find cotton-made welding aprons which are meant for less intensive work.

Leather aprons are made from different leather sources and cuts which have various degrees of safety.

Welding Sleeves

Welding sleeves can be used as a substitute for the jacket in light to medium weld work but you will be at increased risk of burns in your torso area.

If you have a cotton jacket but want additional protective clothing because you need to do some more demanding work the welding sleeves can help provide protection.

They are also very useful when doing any kind of overhead work too. Especially the cape sleeves which cover the upper torso (upper back and chest), shoulders, and arms.

They are something like a half of a welding jacket and are put on like a shirt. They come in various degrees of protective abilities. This largely depends on the material. Cotton-made welding sleeves offer less protection while leather-made are more durable and offer more protection.

Ear Muff or Ear Plugs

If your helmet doesn’t cover the ears or if you are doing overhead work, it is a good idea to protect your ears as well.

Sparks and debris have their mysterious methods of finding a pathway to the unprotected part of your body and ears are not an exception.

If you are not doing overhead work and your helmet protects your ears then using earmuffs can be a bit of an overkill. Especially for hobbyists.

Basically, if you are in a position where the slag can fall in your ear, protect yourself. If not, don’t bother with this welding apparel.

If you do use ear protection make sure that it is rated for flame resistance. Never use anything synthetic because that would be a fast lane path to the emergency room.

Welding Goggles

Welding goggles are usually made for brazing and cutting and their shade level is DIN5. They are not meant for more serious work and they can’t protect your entire face from debris and radiation, just your eyes.

If your welding work comes down mostly to this kind of work then you can substitute the helmet with the goggles but I would always go with a helmet for any kind of arc welding.

Safety Glasses

Many welding helmet manufacturers recommend wearing safety glasses underneath the helmet to prevent eye injury. If you wear safety glasses you will have additional protection against physical injuries.

While you won’t necessarily need them it is still a good idea to have them. Additional eye protection is always a plus and they become handy when you do some other metal-related work around the shop that is not welding or plasma cutting.

I don’t know anyone who doesn’t own a pair of these so if you are thinking of doing stuff with metal you should definitely get them and even wear them under your hood. Especially if you will be working in more dangerous conditions.

Just make sure that the safety glasses you get meet the ANSI (American National Standards Institute) Z87.1 Standards.

When grinding you can also use face shields to protect against eye injury.

Conclusion

Welding work conditions are often unpredictable and especially out on site. Use your best judgment when determining what safety level of you need. The hazard assessment should be estimated prior to any work. Never use suboptimal protection just to save on a few bucks or even a few hundred dollars. Medical bills can be much more costly and not to mention reducing your ability to work or losing it completely. Money can be earned again if you are still able to.

Additional safety never hurts anyone but you should also not spend the money you really don’t have to. Take everything you read here into consideration and think about the level of your work. You also need to think about fire hazards and multiple types of hazards you could expose other people to, but that is a topic for another article.

Are you a hobbyist that welds in a garage in a standing position with the welded piece on a table so that your pants are unlikely to be hit with a lot of sparks and molten metal? Are you a professional or an apprentice out in the field where you are expected to weld in tight spots or in multiple positions including over head with high amps?

These questions are important. Assess your welding task and the dangers you will be exposed to in order to figure out the protective gear you will need.

Resources:

- Welding, Cutting, and Brazing by OSHA – Occupational Safety & Health Administration

- What are the causes of welding accidents? at www.ishn.com

- Welding – Personal Protective Equipment and Clothing at www.ccohs.ca

- Welding Safety Procedures at Thompson River University

- Safety in Welding, Cutting, and Allied Processes ANSI Z49.1:2012 An American National Standard