Tungsten Inert Gas (TIG) welding is highly prized for its ability to produce clean, even, and aesthetically pleasing welds that don’t actually require any post-welding finishing.

The downside is that, on average, TIG welds are relatively wide, shallow welds because currently produced ferrous metals usually contain less sulfur as an impurity.

Making full-penetration welds on thicker base metals, therefore, requires multiple passes. Consequently, full-penetration TIG welds on these sorts of thick metals are time-consuming and costly.

As a result, a new type of TIG welding has been developed to overcome the drawbacks. This process is called advanced A-TIG Welding, offering an ultra-deep penetration. This article will overview the ideas and technology.

Overview of Active TIG Welding (A-TIG)

An Activated TIG welding process known as A-TIG offers an increase in productivity that can be achieved by increasing the penetration depth, as it helps reduce the number of welding passes.

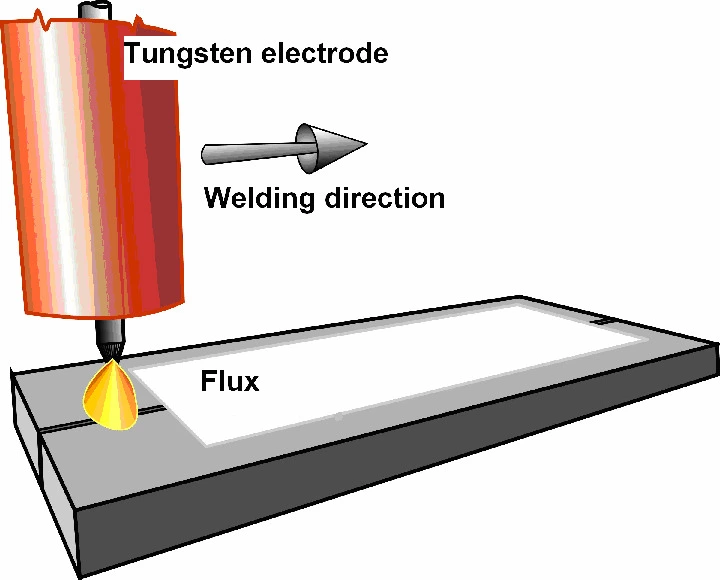

The A-TIG welding process involves increased penetration capability of the arc in traditional TIG welding. Increased penetration is achieved by applying a thin coating of activating flux material onto the workpiece surface prior to welding. The flux in this application constricts the arc, increasing the current density at the anode root and the arc force on the weld pool.

However, despite the productivity benefits of A-TIG welding, today’s industry has been slow in utilizing this process. Why? Mostly because the use of the flux is seen as an additional cost and its application an additional operation.

Furthermore, the commercial fluxes might produce an inferior surface finish compared to traditional TIG welding. In addition, welders have to deal with a surface slag residue, which requires post-weld cleaning, increasing the operation time and, yes, final costs. That’s why an idea for an even improved welding method emerged.

Introduction Of Advanced A-TIG Welding (AA-TIG Welding)

A group of Japanese inventors has developed and patented an Advanced A-TIG welding technology to overcome this problem by changing the characteristics of the puddle directly at the point of the weld.

The patent was actually issued in the United States on March 29, 2011. Still, the process took a full seven years to pass the US patent process, and logic would dictate that the inventors had the good judgment to file for a Japanese patent as well concurrently.

However, even before the patent was issued, inventors were already touting their process in esoteric scientific journals as a variant of A-TIG (active flux TIG) that has been dubbed AA-TIG (advanced A-TIG). The patent is actually for the practical application of this type of welding, not the underlying scientific principle itself.

According to Welding International, “This enhanced TIG welding effect was discovered at the Paton Research Institute, Ukraine, in the 1960s.” Apparently, it has taken fifty years for this science to be turned into a practical welding machine.

What Is Advanced A-TIG Welding?

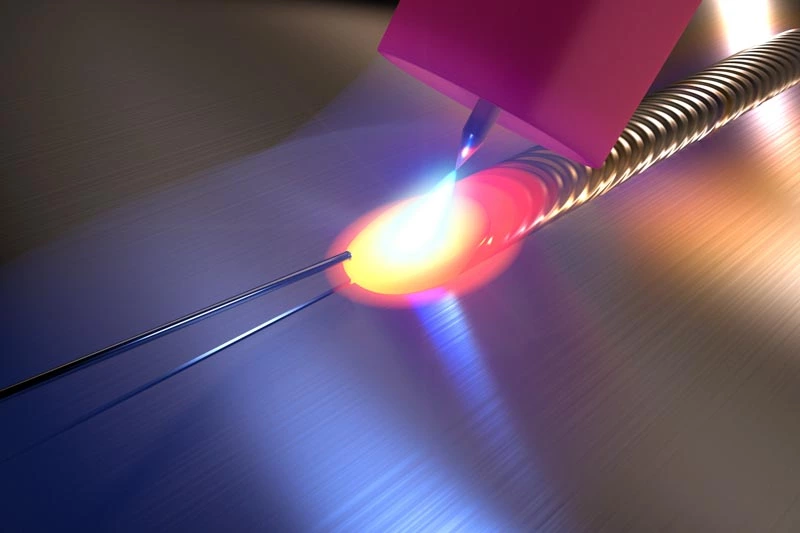

This new TIG welding process centers on altering the surface tension of the puddle in the weld by varying the chemistry of the metal directly at the weld. Historically a TIG welder uses a single shielding gas surrounding the electrode.

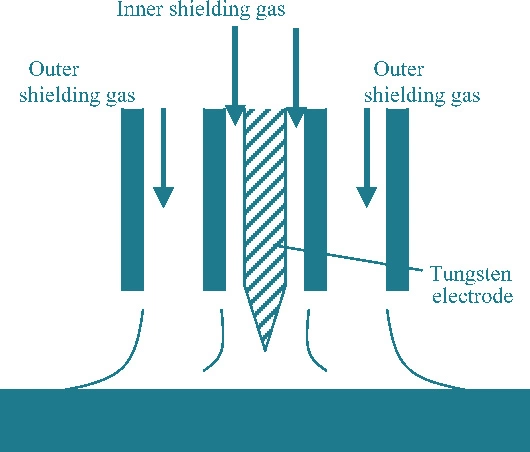

However, the advanced Japanese TIG welding technology utilizes two concentric streams of shielding gas. The inner layer of shielding gas is the regular inert gas used to protect the weld and the electrode. Around this gas, a stream is an added layer of an oxidative gas that reacts with the molten puddle. According to the patent, this outer layer of an oxidative gas can be either pure oxygen or carbon dioxide.

The choice of gas will obviously affect the reaction’s manner, but to the welder, the difference will remain largely unnoticeable.

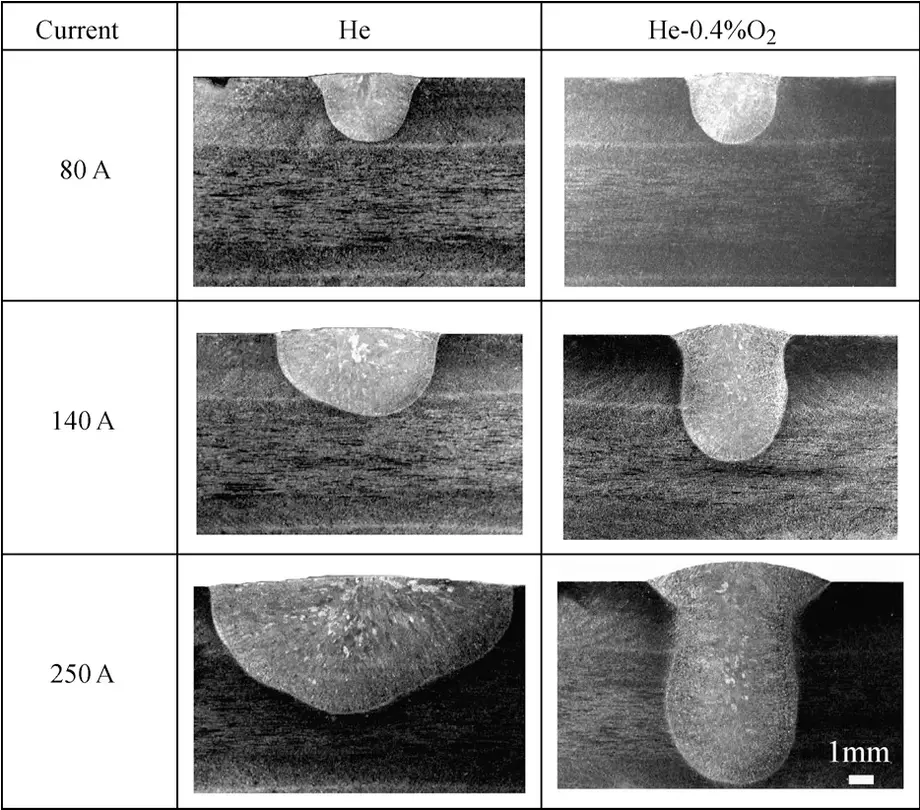

The addition of oxygen to the weld puddle reduces the surface tension at the periphery of the weld puddle, allowing the metal to flow back toward the center. The result of more liquid metal flowing back to the center of the puddle is inward and downward heat convection in the molten pool creating a deeply welded metal portion in the base material. (For those who absolutely must know, this is technically called Bénard-Marangoni convection.) Properly applied, the weld is left with an oxide coating of approximately 20μ (microns).

Advanced A-TIG Welding Patent

Like nearly every patent, aside from being bombastically cryptic, this TIG welding technology patent lists several alternative designs intended to cover the inventors on most other possible ways of performing the operation.

In this case, the subsequent designs detail two or more separate gas jets arranged around the periphery of the inner shielding gas stream in lieu of a single concentric oxidative gas stream.

According to the tests, the inventors run, these arrangements of the outer gas stream will have varying effects on the weld and the manner of welding. Still, the net effect of a deeper high-quality weld remains essentially the same. In other words, while the subtleties of arranging the outer gas flow make for fascinating consideration to the engineer, chemist, or physicist, the effect on the welder and the work they are producing is mainly invisible.

There is one notable exception perhaps to this, and that is the reduced degradation or consumption of the tungsten electrode. In side-by-side tests run by the inventors in the process of the development of this welder, the electrode in the twin shielding gas process showed essentially no degradation in the welding electrode. This will make the process more efficient from an operator’s point of view since electrode change out will be far less often.

Advanced A-TIG Welders

This newly patented TIG welding technology has been assigned to Taiyo Nippon Sanso Corp., one of Japan’s largest producers of industrial gasses. This sort of arrangement makes a certain amount of sense.

Companies that supply consumable materials, such as gasses in this case, tend to like to be able to offer technologies and equipment that will require the consumption of the products they produce. However, whether Taiyo Nippon Sanso will attempt to produce welders of this new technology, or license the production to a company already set up for machinery manufacturing, remains to be seen.

Sources:

- https://www.tandfonline.com/doi/abs/10.1080/10426914.2019.1666990?journalCode=lmmp20

- https://www.sciencedirect.com/science/article/pii/S2214785320383358

- https://www.twi-global.com/technical-knowledge/published-papers/investigation-of-the-a-tig-mechanism-and-the-productivity-benefits-in-tig-welding-may-2009

- https://www.sciencedirect.com/science/article/abs/pii/S0921509308001603

- http://www.jwri.osaka-u.ac.jp/~dpt9/MSE(2008)HeAA-TIG.pdf