Due to mechanical characteristics such as high tensile strength and low weight, aluminum is widely used in industry today. However, those characteristics make aluminum challenging to weld.

Aluminum pieces can successfully be joined using MIG welding or TIG welding, but soldering is more suitable in specific applications.

Like welding, aluminum soldering is more challenging than soldering iron, but you can achieve satisfactory solder aluminum results as long as you follow our detailed guide.

Overview Of Soldering Aluminum and Aluminum Alloys

Soldering is a metal joining technique where filler metals are heated until they reach melting point and start to flow into the joint by capillary attraction. Soldering is fundamentally the same as brazing, but the soldering filler metal has a melting point lower than 840ºF, while the brazing alloy melts above this temperature.

Even though this is a pretty straightforward metal joining process, soldering aluminum and aluminum alloys can be pretty hard due to the aluminum oxide layer.

Aluminum oxide cannot be soldered, so you must scrap it off. Removing aluminum oxide can yield satisfactory soldering results, but before oxide reforms, you must do it quickly.

To protect your soldered joints from defects, you will also have to use specialized welding equipment, including flux. Aluminum soldering flux will protect the joints and improve wetting, resulting in solid joints.

Another issue you might have to deal with when you solder aluminum is the heat characteristics. Aluminum has a relatively low melting point of 1220ºF (660ºC), but it acts as an excellent heat sink.

Therefore, you must use low-temperature solder and make sure you heat it properly. So, while heating aluminum, make sure you observe the temperature of the base metal, not the heat source.

Identify Aluminum Alloys Before You Solder Aluminum

Aluminum alloys are classified into series based on alloy composition and additives. Even though pure aluminum can be soldered, it is significantly more challenging due to its mechanical properties.

Alloying elements improve aluminum properties, making it easier to solder. However, not all alloys are readily weldable. For example, the 1000 and 3000 series (1XXX & 3XXX) are more accessible to solder than the 6000-series. On the other hand, the 5000-series aluminum is hit or miss.

That’s why it is crucial to identify the aluminum alloys prior to soldering. If your aluminum soldering project includes unlabeled aluminum alloys, you might need an expert opinion or identification methods.

Joining two aluminum pieces can be challenging, but joining aluminum to copper is extremely easy. However, joining aluminum and steel might require specialized welding methods.

Aluminum And Aluminum Alloy Surface Preparation

Before any metal joining process, including soldering, you must first prepare the surface. Surface preparation includes removing grease, dirt, and other surface debris. In addition, you will need to remove any aluminum oxide formed.

As a result, the surface must be clean before soldering. You can use a stainless steel brush or steel wool to do so.

In most cases, you can decrease the surface using solvents, but a wire brush or chemical cleaning will do the job if the surface is heavily oxidized.

To achieve capillary attraction, you must ensure proper joint clearance.

Clearance varies with the specific soldering method, base alloy composition, solder composition, joint design, and flux composite, ranging from 0.005 to 0.020 in. (0.13 to 0.51 mm) when chemical fluxes are used. Meanwhile, when using reaction-type flux, you should provide 0.002 to 0.010 in. (0.05 to 0.25 mm) spacing.

Aluminum Soldering Flux

To successfully solder aluminum, you will need an aluminum soldering flux. However, just because flux is strong enough to solder an alloy like stainless steel doesn’t mean it’ll work on aluminum.

Aluminum soldering fluxes are available in gel, paste, liquid, and solder paste forms. Organic liquid flux works best at 350-600F, while paste flux is activated at 530F and can withstand up to 780F.

Depending on the form that flux comes in, you will need to apply it differently. If soldering wires are laid, you can dip them into liquid flux.

Aluminum Soldering Filler

After identifying the aluminum alloy grade, you will need to choose a brazing alloy intended for the aluminum soldering project. A proper match will make your soldering aluminum easier.

Low-temperature solders melt between 300 and 500ºF (149 and 260ºC). Solders in this group contain tin, lead, zinc, and/or cadmium and produce joints with the least corrosion resistance.

Intermediate temperature solders melt between 500 and 700 ºF (260 and 371ºC). Solders in this group contain tin or cadmium in various combinations with zinc, plus small amounts of aluminum, copper, nickel or silver, and lead.

High-temperature solders melt between 700 and 800ºF (371 and 427ºC) and contain 3 to 10 percent aluminum and small amounts of other metals such as copper, silver, nickel, and iron to modify their melting and wetting characteristics.

Soldering Heat Source

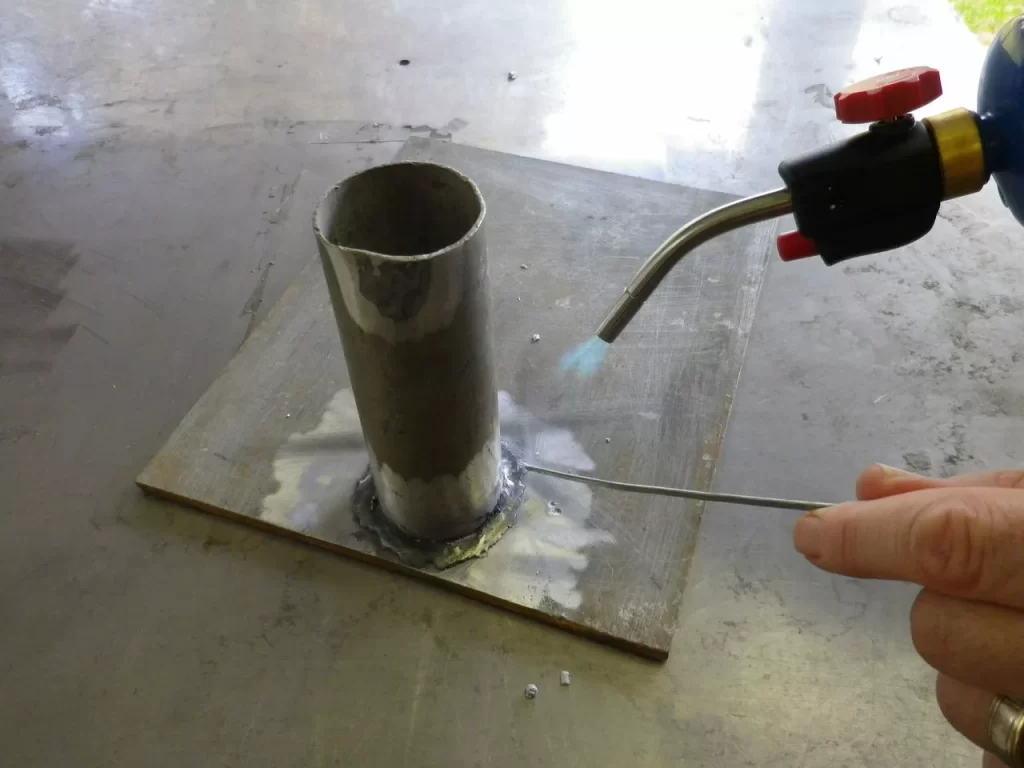

Aluminum needs heat to accept solder. You can use a soldering iron for joining aluminum wire, but other jobs will require the use of a torch. Typically, a low-temperature torch is used, with a flame tip that reaches 600 to 800ºF. You want to be measuring the temperature of the aluminum, not your heat source, especially when you join thin aluminum sheets.

Soldering aluminum is not like soldering copper; it’s not enough to just heat up and melt the solder. Even with the suitable flux and solder combination, you won’t achieve soldering if the aluminum isn’t hot enough to accept the solder alloy.

For example, soldering iron melts at a lower temperature so that you won’t need too much heat. In addition to this, it has to reach this temperature within a specific period (usually under 8 minutes) or else the flux will be spent, all without having done its job. Fortunately, there are many heating methods, such as ovens, induction, soldering iron, torch, hot plates, etc.

Post Soldering Cleaning

Once your solder is dry, you’ll want to remove any excess flux. However, since solder cools extremely quickly, you won’t need to wait too much. If you use water-based flux, you can rinse your piece in water, but you will need acetone if it’s the resin-based flux.

To remove post-soldering oxides, you might need a pickling solution. Aluminum oxide in the softer metal can quickly form on the aluminum surface when affected by heat, and that’s one of the challenges of aluminum soldering.

Tips For Successful Soldering Aluminum

To successfully solder aluminum, you will need to follow several steps. Here are some tips on how to do it:

- Identify the aluminum and aluminum alloy you are about to solder

- Clean the aluminum surface thoroughly and make sure you remove aluminum oxide

- Choose specialized solder flux, filler metal, and a heat source such as soldering irons

- Provide tight fit and joint design that would encourage capillary attraction

- Make sure parts are clamped, as any movement during soldering can affect the results

- Apply flux to clean the joint, protect the solder and prevent more aluminum oxide from forming

- Use your torch or soldering iron to heat the metal object adjacent, and follow the manufacturer’s instructions to make sure you don’t overheat the aluminum

- After the soldered joint cools off, remove flux residue and post solder aluminum oxide

Strength Of The Soldered Joints

Since copper is one of the most accessible metals to solder, aluminum-copper joining is easy and results in relatively strong joints. However, the soldered joint is somewhat weaker when compared to a copper-copper joint. The results of the tensile tests show cracks in base aluminum, while the solders remain unaffected.

On the other hand, aluminum to aluminum is more challenging and results in the weakest bonds. For example, joining 3003 aluminum to copper forms a significantly stronger bond compared to 3003 to 3003 aluminum solder.