Trying to find some flux core wire for your next welding project but finding the number of options out there confusing? Don’t worry – I can help narrow things down for you.

I’ve tested several wires and worked out their strengths and weaknesses for you and, at the same time, I’ve put together a guide on how to choose the right wire for the right welding job.

Choosing flux cored wire can be easy when you know how and whether you’re working with mild steel or stainless steel – I’ve got you covered.

Flux Core Wire Quick Comparison

| Image | Name | Specials | Thickness | Spool Weight | Check Price |

|---|---|---|---|---|---|

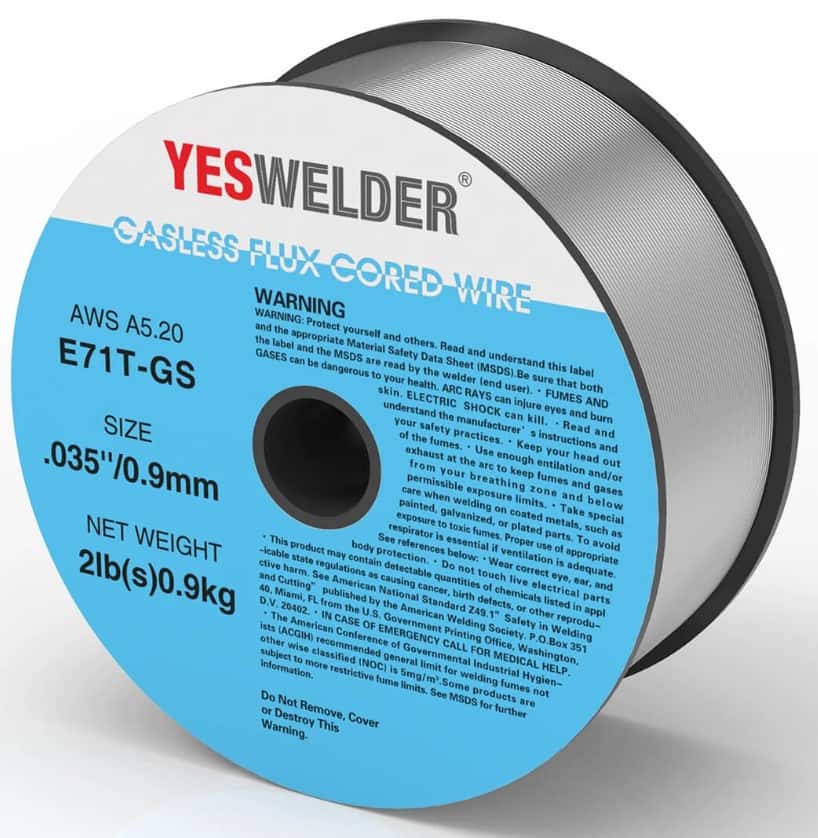

| YESWELDER Gasless Flux Core Welding Wire | Get 10% Off With Coupon: “-10% WELDPROS” Best For Money Wire | 0.035" | 2lb | Check Current Price YesWelder |

| LINCOLN ELECTRIC Innershield CO ED030584 .035"NR-211... | Best Wire Overall | 0.035" | 1lb | Check Current Price Amazon |

| Eastwood Flux Core Wire 0.030in – 2lb – 4 Inch Spool | Best For Hobbyists | 0.030" | 2lb | Check Current Price Eastwood |

| Forney 42300 Flux Core Mig Wire | Best Affordable Wire | 0.030" | 2lb | Check Current Price Amazon |

| INETUB BA71TGS .030-Inch on 10-Pound | Best Value Wire | 0.030" | 10lb | Check Current Price Amazon |

| Hobart H222106-R19 2-Pound E71T-11... | Affordable Brand-Name Wire | 0.030" | 2lb | Check Current Price Northern Tool |

Best Flux Core Wire Reviews

1. YESWELDER Gasless Flux Core Welding Wire .035-inch

YesWelder Gasless is a decently priced flux core wire that offers excellent performance for the money spent. It is an all-position, single-pass, flux core wire that is meant for welding carbon steel, and of course, It does not require any shielding gas.

This MIG welding wire produces very little to no spatter, and it provides a smooth and stable arc. However, compared to brand-name flux core wires, you should keep your tip clean and maybe use a dip to avoid spatter and clogs.

Nonetheless, the biggest advantage of YESWELDER Gasless Flux Core Welding Wire is that it creates a full slag coverage you can remove and chip off easily once the welding bead cools off. Typical applications include butt, lap, and fillet welds, this wire also works well on rusty, dirty, and painted material. It’s excellent for windy outdoor conditions, and that’s where flux core weld takes an edge over solid wires.

Note: YESWELDER recommends DCEN polarity when you are using their flux-cored welding wires. The package comes as a 2 lb or 10 lb spool sealed in a vacuum package that can be stored without the fear of corrosion.

Overall this is an excellent quality general purpose flux core welding wire that is decently priced, and I would recommend it. Keep in mind that flux-cored wire welding can produce dangerous fumes. Some welders complain about the amount of smoke released when working with YesWelder flux core welding wires.

Pros

- Very good bead appearance

- Excellent slag removal with a full slag coverage

- Can be used in all welding positions

- Works fantastic in outdoor conditions

- Can be used with MIG wire feed welders

- Good vacuum package

Cons

- You should keep the gun tip clean to avoid clogs

- May produce some smoke during welding

2. Lincoln Electric Innershield ED030584 NR-211-MP.035, 1 LB Spool

Lincoln Electric Innershield is a great flux core wire which excels in delivering a neat bead while working with it. In fact, I feel like it might be the best flux core wire on the market.

It is very easy to work with, and I liked the fact that it flows near perfectly in almost every situation. Ease of use means you’re going to achieve a great level of productivity. Lincoln Electric Innershield flux core wire provides superior welds when compared to aftermarket brands due to far less weld spatter and smoke when welding.

However, when buying brand-name fluxed core welding wire, you will have to be ready for a high price. I’d expect a 2lb spool from most manufacturers at the price of a 1lb spool of the Lincoln Electric Innershield ED030584 wire. Nonetheless, Lincoln perfected their fluxed core welding wires, so you really get what you pay for.

So, if you intend to do a lot of flux core welding 1lb spool may not be the most economic choice for your welding projects. However, if you are planning to tackle some thicker metals, you can always buy a 10 lbs spool of .045 flux core wire diameter for a reasonable, yet high price.

Overall, this flux-cored arc welding wire is as best as you get on the market. The fact that is built in the US may be the biggest advantage over cheap flux core wires. In addition, the manufacturer suggests Lincoln Electric machines for the best performance.

Pros

- Possibly the best bead appearance

- Good welds created in windy conditions (no tenting)

- Excellent slag removal and the freezing characteristics were speedy

- Great results in vertical or overhead welding or multiple passes

- Can be used to weld thinner metals or thick stock

Cons

- High price in self-shielded wire market

- Shows best results when working with Lincoln welders

3. Eastwood Flux Core Wire 0.030in – 2lb – 4 Inch Spool

The Eastwood Company is well known for its efforts in the hobbyist, DIY, and auto body shop market, and the results are more than satisfying. Their flux core wires are no exception, as you will get excellent value for the money spent.

Eastwood flux core welding wire provides consistent performance, with great feed ability, low spatter, full slag coverage, and easy slag removal. With standard 4″- 2lbs and 8″ – 10 lbs spools, this ER71T-11 wire is designed to fit all flux core welders capable of supporting them, including Eastwood machines.

One of the biggest advantages and the reason we put this fluxed core wire on our list is the price. Besides decent performance, you won’t have to break your bank when purchasing.

Overall Eastwood ER71T-11 flux core welding wire is decent and affordable. You get excellent value for the money spent, and you get a 1-year warranty if something goes wrong with a delivery.

Compared to the brand-name wires we mentioned in our reviews, it might take you some time to get used to the settings. Nonetheless, end results are more than satisfying.

Pros

- Affordable welding wire

- Decent results at various welding projects

- Tailored to fit any welder capable of flux core welding process

- High tensile strength

Cons

- Might take some time to get the settings right

4. Forney 42300 Flux Core Mig Wire, Mild Steel, E71TGS.030-Diameter, 2-Pound Spool

My choice of the best flux-cored wire for mild steel is the Forney 42300. I found that no matter what the condition of the material was that it produced excellent quality welds. My claims are supported by the extraordinary number of positive reviews on the internet.

The biggest limitation with this wire is that the manufacturer recommends single-pass welding only, while other flux core wire usually support multi-pass welding operations.

However, assuming that you can live with this, the price is very fair. The majority of users report nothing but satisfaction with this product.

Still, some seasoned welders found Forney 42300 performing worse than renowned flux core wires such as Lincoln Electric Innershield. Nonetheless, as a beginner, you will find it easy to use and satisfactory.

Overall, this might be one of the most popular flux core wires, and I get the feeling the reason is the excellent value for the money spent.

Keep in mind that some users have reported they received a broken plastic spool. That’s why I suggest buying from a trusted supplier that offers a money-back guarantee, such as the one we listed below.

Pros

- Has no issues at all with rusty, dirty, and painted materials

- Handles the windiest of outdoor conditions without any problems

- Very high travel speeds

Cons

- Recommended Single-pass applications only

- Moderate levels of spatter

- Some users report receiving damaged spools

5. INETUB BA71TGS .035-Inch on 2-Pound Spool Carbon, Steel Gasless Flux Cored Welding Wire

Another candidate for the best flux-cored wire for mild steel has to be the INETUB BA71TGS. This flux core welding wire is made in Italy, and the manufacturer claims to offer a much higher level of precision in manufacturing.

I found that this flux core wire works particularly forgiving and that the welds created were very strong and of the best quality. If you’re looking for a .035 stainless steel flux cored wire then you can do much worse than this.

However, some welders had problems getting the settings right. So it seems like it might take some time to get used to this welding wire. In addition, I get the feeling that the gasless version of INETUB is not as popular as the MIG welding wire counterpart.

I do need to point out that the 10 lb spool that it comes with may be too much wire for some flux core welding users.

Those who do a lot of mild steel welding are going to find that they get value for money, though, while as an occasional welder you might look for a smaller spool of cheaper wire, such as YesWelder or Forney products we mentioned above.

Overall, INETUB BA71TGS is more than a decent and renowned wire for outdoor welding you will love. You can use it in any welding position, or multi-pass method when welding thick metals.

Pros

- Really smooth arc action

- Great levels of feed-ability

- Very low spatter

- Nice bead appearance

Cons

- The price is a little higher than most

- It might take time till you get the settings right

6. Blue Demon E71TGS .035 X 2# Spool Gasless Flux Core Welding Wire

Blue Demon E71TGS might be the best flux core welding wire for home users and hobbyists. It’s very much aimed at this section of the market and runs well even with a 110V welding machine.

You won’t have issues welding galvanized steel with this wire as many welders report positive results. The price is very good and you don’t need large stocks unless you are going to use them immediately.

However, even though there are a lot of positive reviews, I get the feeling like this Blue Demon flux core welding wire is designed for hobbyists and affordable 110V welders.

When working with high-end machines, this wire tends to get too hot, causing burn through and lots of spatter.

On the other hand, some had problems where the wire felt too cold. So, it might take some time and patience to master the welding machine factors and settings to get the best results with this Blue Demon wire.

The great part about Blue Demon is that they offer smaller spools. So you don’t have to spend a fortune which is significantly important if you are a hobbyist, DIY lover, or occasional welder. In addition, you can use a small spool to try it, and if it fits your need, you can always opt for more.

Pros

- The best price wire – very good for hobbyists

- Works well with galvanized steel and zinc coated steel

- Comes in small spool sizes – ideal for testing before you commit to buying more

Cons

- Higher levels of spatter than most other gasless flux core wires

- Struggles in professional quality MIG welding machines

7. Hobart H222106-R19 2-Pound E71T-11 Carbon-Steel, Flux-Cored Welding Wire, 0.030-Inch

Hobart is a big name in the welding wire market and it should come as no surprise that they make one of the best flux core wire spools you can find. If you want good quality flux core welding wire for small project use – this one is ideal.

Many satisfied welders report the wire feeds well and the bead quality is good when working on single-pass applications. However, some users didn’t enjoy the spatter and smoke it produces. It seems like you shouldn’t expect those problems with brand-name, made in USA wire.

However, the 2lb spool availability means you can try this easily and see if it’s right for you without committing to a large order, too. In addition, there is a twin pack option, meaning you get great value for the money spent.

Overall Hobart wires perform well, and you will find it excellent if you are a beginner, hobbyist, or occasional welder. Once you get a hang of it, it is certain you will buy it again.

Pros

- Works in both single-pass and multiple pass welding

- Very good on galvanized steel

- Small spool size available

Cons

- Higher price than some other welding wire

- Medium level of spatter produced when welding

- Higher levels of smoke than you’d expect

8. ESAB Sureweld T-11 Flux-Cored Welding Wire

ESAB Sureweld is an excellent wire for use on single or multiple pass lap, fillet, and butt welds on mild steel in all welding positions. This self-shielded flux-cored welding wire meets all requirements for E71T-11 classification.

One thing you notice about high-end wires is that they produce smooth arc action, full slag coverage, easy slag removal, and low spatter. ESAB Sureweld is no exception, as the results are more than satisfying.

This wire is more than suitable for general-purpose mild steel fabrication and structural fabrications where no seismic requirements are present. In addition, the manufacturer states wire is great for automotive, civil construction, industrial, and general fabrication welds.

The great thing about this welding wire is versatility, as you can choose either .030 or .035 depending on a given project. In addition, you can either opt for a 2 lbs spool to give it a shot, or 10 lbs if you are planning any serious business.

However, since we are talking about high-quality welding wire, you will have to be ready to pay quite a few bucks. Nonetheless, you really get what you pay for, which many satisfied owners confirmed.

Pros

- High-quality brand-name wire

- Smooth arc action with low spatter

- Satisfying results

- Various spool and wire sizes

Cons

- Some find it expensive

Buying Guide For Flux Core Wire

Flux Core Wire vs Solid Wire

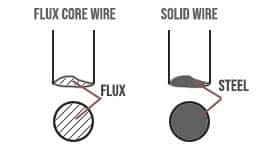

t’s important to draw a distinction between flux core wire and solid wire, which is the other type of wire using in welding.

Flux core wire has a “flux core” which means that as the wire melts, it creates a gas bubble over the welding pool and the slag created.

This eliminates the need for gas for shielding, which is mandatory when working with solid wire. However, it is still possible to work with shielding gases when using certain flux-cored wires to create even cleaner welds.

The Diameter And Spool Size

The size of the wire you use is always important. The flux core welding machine that you choose will tend to limit your choices of wires. You can, of course, adjust the feed wheels and nozzle tips to accommodate other sizes of wire but they tend not to be the limiting factor in your wire choice.

What does fix the flux core wire sizes I can use? The amperage the welding machine runs at and the plate type that you’re working with.

The rule is that the lower the amperage is set at, the thinner the flux core wire should be. The thinner the plate, the smaller the size of wire required too.

It’s important to check the specifications of both the wire and your welding machine when choosing wire size – this isn’t’ something which is standard between wires – not all wire types are the same.

As for the spool size? You can get a better price for your wire if you buy bigger spools but don’t buy more than you need for a reasonable period of time – waste is expensive.

The Application

You must buy the right type of flux core wire for the right type of materials that you intend to weld.

That means steel wire when you weld steel and stainless steel wire when you weld stainless steel.

If you get this wrong then you may find that your welding starts to rust once the project has been completed – nobody wants rust all over stainless steel, do they?

A Guide To The Specification Codes On Flux Core Wire For Mild Steel

There are specification codes for flux core wire that is used on mild steel and I’ve got a brief guide to help you work out what they mean:

- An “E” is a statement that the wire is to be used as an electrode. That is it’s continuously fed and will be used up in the weld pool. You feed this through the welder to the nozzle of the MIG welder

- A “7” is a statement of the tensile strength of the flux core wire and it will offer a strength of 70,000 lbs. per square inch.

- A “1” is a statement that the wire is fit for use in all positions when welding (including overhead, horizontal, flat and vertical)

- A “T” is a statement that the wire is flux-cored and can be used without a shielding gas

- An “11” is a reference to the usability characteristics e.g. it supports DC polarity, all positions, and multi-pass welding

- If you see “GS” this means that the welding wire is only to be used for single-pass welding

Tips For Using Flux Cored Wire

- If you are using a MIG welder then you can choose to swap between flux core wire and solid wire. When you are using flux wires, it’s important to use the right drive roll when welding. If you choose a knurled drive then it will grip the wire more effectively and, in turn, feed the wire to the MIG gun in a smooth fashion

- When changing a MIG welder between flux core wires and solid wires make sure to check and change the polarity of the machine when you change the drive

- If you are gasless MIG welding then you’re going to need to reduce the tension in the welder when working with flux core wires – this is because the softer center of the wire will distort when the tension is the same as with solid wire and this can make feeding difficult or reduce the quality of the weld

- Make certain that when changing between flux core wire types that you are feeding the right diameter of wire into the right diameter drive rolls. If you fail to feed say, 0.030 wire into the 0.030 side of the drive roll – you will have problems working with the wire

- If you want good flux core welds then you’re going to need to ensure the contact tip matches the diameter of the wire too

- You should make sure the wire diameter matches the gauge of mild steel as recommended by the manufacturer. So, for example, 0.030 mild steel flux wire can weld up to 18 gauge mild steel at up to 1/4″ (depending on the amperage your welder is producing)

- You need to choose the right size of spool for the welding machine. A 10 lb spool requires an 8-inch spool, for example. Don’t forget that a flux wire welder working with a 10 lb spool will save money on wire but might still be better off buying 2 lb spools if they cannot store the wire properly

- Make sure you remove the wire at the end of the job and store it properly. If you don’t you might need to carry out a huge cleanup project when you next use the welding machine.

- If you want to work with mild steel flux cored welding wire then you must have DCEN (direct current electrode negative) support. This, in turn, means you must connect the MIG gun to the negative terminal on your welding machine. If your welding machine is flux core only then you will find this is the default setting.

- Don’t forget that if you want to work with a shielding gas – you must change the polarity from DCEP to DCEN too.

What Is Flux Core Wire?

Flux core wire is a gasless welding wire which has a hollow center filled with flux that is surrounded by the welding material (usually mild steel).

Inside Flux Core Wire

So, what is flux? It is a collection of compounds that, when melted in a flux core welding machine, form a protective shield for the weld preventing it from being contaminated by particles in the air.

It will also contain compounds to assist in shaping the weld pool while increasing the deposit rate of the metal.

In addition, it may also use scavengers and/or deoxidizers which help to force impurities out of the weld and into the slag (which can then be chipped off after the welding job is finished).

There are two kinds of flux core wire: self-shielded and gas-shielded.

You tend to find gas-shielded wire being used in large commercial operations. Whereas gasless MIG wire tends to be used in home, DIY and small commercial environments (and that’s why it’s the focus of this article).

Frequently Asked Questions (FAQs)

What Is Flux Core Wire Used For?

Gasless flux core wire is used to generate its own shielding gas for a weld. This prevents impurities from contaminating the weld and because there’s no need for gas – it makes for a more portable welding solution than standard solid wire welding might.

This approach to welding is also valuable in windy, outdoor conditions where a shielding gas might be blown away from the weld.

Can I Use Flox Core Wire In A MIG Welder?

Yes, it’s fine to use flux core wire in a MIG welder and there’s no need to buy a separate flux core welder.

As I touched on previously, this can help make the welding machine more portable or tackle jobs in adverse climate conditions. You may also find that you get a greater degree of weld penetration when using flux core wire.

Is There Flux Cored Aluminum Wire?

No. Though you may find some chancers on the Internet selling “flux cored aluminum wire” when you read the small print – you’ll find that it says “we recommend using Argon shielding gas”.

In fact, this is not optional it’s essential. You cannot use flux core welders to weld aluminum and you must use a MIG welding machine that can provide a shielding gas to the nozzle. This is simply because aluminum is too reactive in the air for the flux core MIG wire to work without shielding gas.

Conclusion

The best wire in my tests was the Lincoln Electric ED030584 which I felt delivered the best value and feature combination.

However, I also felt that if you were mainly welding at home that you might want to consider the Blue Demon E71TGS which was great value for money for hobbyist applications.

The INETUB BA71TGS is also an excellent choice and the premium manufacturing is obvious. We also like the fact that it’s an ethical choice. However, you need to buy this in bulk, so make sure you need a lot of it as it won’t store forever.

The important thing is to remember that the best flux cored wires for your project will be those which suit the materials you are welding and the power of your welding machine. When you understand these two things, you can then select the right wires with confidence.