Choosing the proper gas welding regulator is not only important for maintaining the proper flow of gases while you weld. It also improves safety and ensures the best welding results. You wouldn’t want a faulty regulator especially if you are dealing with combustible gases.

But which regulator is the best?

Although there are a few of them and each manufacturer ensures that theirs is the best, there are a few that are more reliable than others. Check out our picks that we have singled out after a detailed analysis of each and every one of them.

Welding Gas Regulators Comparison Table

| Regulator Image | Name | Specials | Type | Pressure | Material | Check Price |

|---|---|---|---|---|---|---|

| YesWelder Flow Meter Gas Regulator For Argon/CO2 Welding | Get 10% Off With Coupon: "-10 WELDPROS" | Argon/ CO2 regulator | In: 0-4000 PSI, Out: 0-60 CFH | Copper | Check Current Price |

| VICTOR Heavy Duty Oxygen Regulator | Heavy Dty | Oxygen/ Acetylene regulator | In: Oxygen: 0-3000 PSI, Acetylene 0-350 PSI. Out: Oxygen 5-125 PSI, Acetylene 2-15 PSI | Brass | Check Current Price |

| BETOOLL HW9003 Argon/CO2 Mig Tig Flow | MIG/TIG Regulator | Argon/ CO2 regulator | In: 0-4000 PSI Out: 10-60 CFH | Copper | Check Current Price |

| Uniweld RHP400 Nitrogen Regulator | Brass Piston Diaphragm | Nitrogen regulator | In: 0-4000 PSI Out: 10-400 PSI | Brass | Check Current Price |

| SÜA Oxygen and Acetylene V350 | Two regulators | Oxygen/ Acetylene regulator | In: Oxygen 0-3000 PSI, Acetylene 0-300 PSI, Out: Oxygen 0-200 PSI, Acetylene 0-15 PSI | Brass and plastic | Check Current Price |

| SPARC Dual Output Argon Welding | Dual Output Regulator | Argon/ CO2 regulator | In: 0-4000 PSI Out: 0-60 CFH | Brass | Check Current Price |

Best Gas Welding Regulators

The primary usage of a gas welding regulator is to ensure the proper flow of the gas consumed by the welding machine. Their job is to mix the combination of gasses properly so each one is emitted in the correct proportion. The idea is keeping the inlet pressure and the outlet pressure as constant as possible.

Gar regulators come in different sizes, shapes, and forms. They differ in terms of performance, maximum inlet pressure, size constraints, purity requirements, types of gas being used, and sometimes personal preferences. So whether you are doing MIG welding or TIG welding, you will need to make certain adjustments.

Let’s see which are the best types of gas regulators that you can find today.

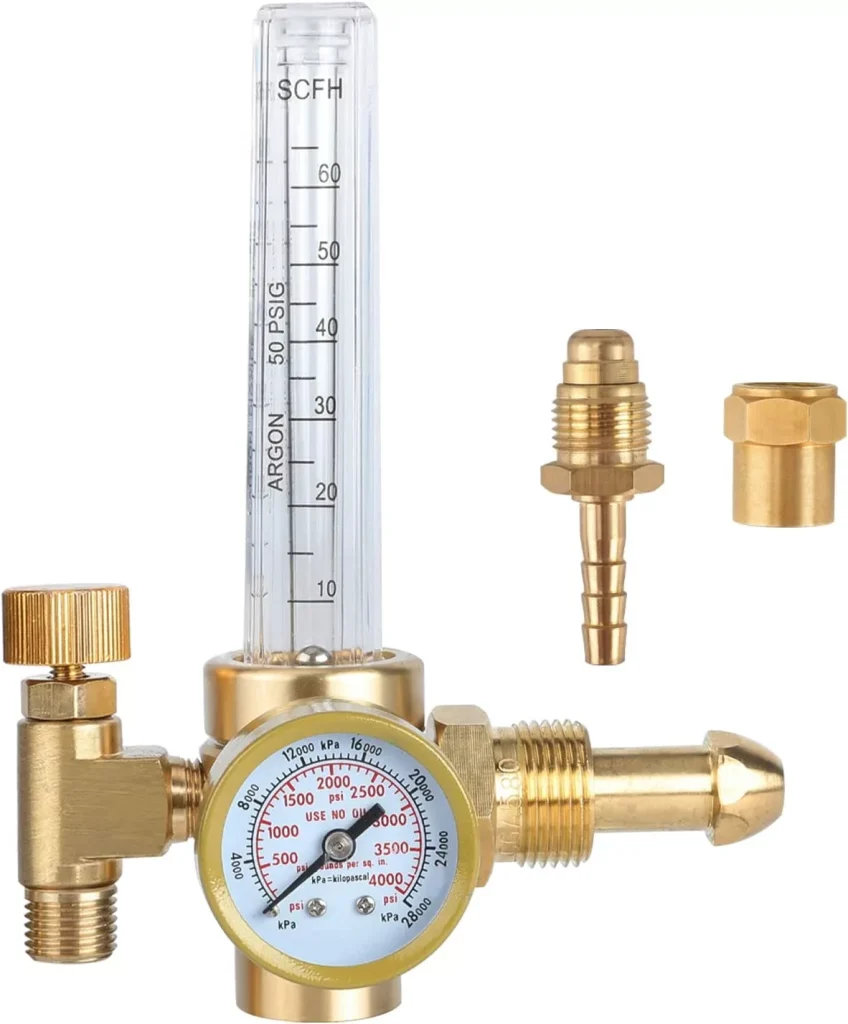

1. YesWelder Flow Meter Gas Regulator for Argon/CO2 Welding

The YesWelder Flow Meter gar regulator includes a high-density molecular brass filter set at the pressure reducer interface.

It helps to prevent impurities get into the gas cylinder. This actually greatly improves the normal flow of the meter and extends its life.

This regulator is made out of copper and comes with a flow gauge and a precision regulator. A very accurate 1 1/2″ diameter pressure gauge is fitted (reading from 0 – 4000 PSI) and is more than easy to read.

It actually has a very wide application as it comes with a CGA – 580 Tank that can fit 00% Argon, 75% Argon / 25%CO2, 80% Argon / 20%CO2 making it ideal both for MIG and TIG applications. The design is actually a combination of a flow meter and a regulator created as a single unit.

Pros & Cons Summarized

Pros

- Accurate and easy to read.

- Durable and sturdy.

- Great value for the money spent.

- Fits standard Argon, Argon/CO2 tanks.

- Combines both regulation and flow reading in one unit.

Cons

- Flow tube can not be rotated.

Specifications

- Inlet pressure: 0-4000 PSI

- Outlet pressure: 0-60 CFH

- Type: Argon/CO2 Flow Meter Regulator.

- Manufacturer: YESWELDER.

- Inlet Connection: CGA – 580 standard Argon, Argon/CO2T Tank fitting.

- Outlet Connection: Will fit both the female 9/16″ x 18 nut or the male 5/8″ x 18 fitting.

- Material: Copper.

- Package Dimensions:6.8 x 5 x 4.9 inches.

- Weight: 1.5 lbs.

2. BETOOLL HW9003 Argon/CO2 Mig Tig Flow Meter Gas Regulator

This is an Argon / CO2 regulator and flow meter coming from BETOOLL. It has a pressure meter measuring from 0 to 4000 psi.

This one is actually more reliable and accurate as it does not have a standard flow-gauge-style regulator, instead, it uses a diaphragm.

The output flow can be adjusted from 10 to 60 cubic feet per hour. It comes with a CGA-580 fitting, meaning that it can be used with argon, nitrogen, and argon/CO2 mixed gas tanks.

However, it does not fit CO2 gas cylinders. Also, a very nice thing about it is its female 9/16″ x 18 nut or the male 5/8″ x 18 fittings. This allows you to fit any Hobart, Lincoln, or Miller welding machines as long as they use a 5/8″ x 18 male nut.

Pros & Cons Summarized

Pros

- Flow meter is more accurate than flow gauge regulator.

- The output flow is adjustable from 10 to 60 cfh (cubic feet per hour).

- Can handle MIG and TIG welding both steel and Aluminium.

- Great unit for the value.

Cons

- Can be a little hard to read.

Specifications

- Inlet pressure: 0-4000 PSI

- Outlet pressure: 10-60 CFH

- Type: Argon/CO2 Flow Meter Regulator.

- Manufacturer: Szbrt.

- Inlet Connection: CGA – 580 standard Argon, Argon/CO2T Tank fitting.

- Outlet Connection:Will fit both the female 9/16″ x 18 nut or the male 5/8″ x 18 fitting.

- Material: Copper.

- Product Dimensions:6.9 x 5.1 x 5.1 inches.

- Weight: 1.63 lbs.

3. Uniweld RHP400 Nitrogen Regulator

This product is a brass piston diaphragm Nitrogen Regulator with a delivery pressure of 0-400 PSI. It comes with a CGA580 inlet connection and a 1/4 inch male flare outlet connection.

There is also a very easy to read contents gauge 0-4000 PSI and a delivery gauge 0-600 PSI protected by rubber gauge boots.

The Uniweld gas regulator can be used with CO2 gas cylinders with an F36 adaptor to a nitrogen regulator. In order to ensure smooth and accurate delivery and pressure adjustment, a large brass tee handle is set made out of stainless steel materials and regulator bushing that help to reduce galling.

Pros & Cons Summarized

Pros

- Easy to Read 2 inch gauges with protective rubber.

- Large brass Tee Handle with stainless steel pressure adjusting screw.

- Can also be used with CO2 regulation with a separate adaptor.

- Great unit for the value.

Cons

- Going around or over the maximum of 400 PSI can damage the regulator.

Specifications

- Inlet pressure: 0-4000 PSI.

- Outlet pressure: 0-400 PSI.

- Type: Nitrogen flow meter regulator.

- Manufacturer: Uniweld.

- Inlet Connection: CGA 580 inlet connection.

- Outlet Connection: 1/4″ Male flare outlet.

- Material: Brass.

- Product dimensions: 5.5 x 4 x 5.25 inches.

- Weight: 2.65 pounds.

4. Taprite T742HP Primary Double Gauge CO2 Regulator, Brass

The Taprite T742HP can be used with any CO2 tank with a CGA-320 valve.

The regulator comes with dual gauges, one to measure the PSI and the other to determine the CO2 left in the gas cylinder. You can use the knob on the front and adjust the output pressure.

On the other hand, the high-pressure ports have female threads in order to prevent them from being used as low-pressure outlets. An internal relief valve is built-in so it opens whenever the pressure exceeds 15 PSI.

A permanent Quad-Ring Seal is also added to prevent leaks from happening and there is also a NADS 1600C shutoff for safety as well. Horse barbs use a 5/16 inch I.D. pressure tubing and all regulators are pressure tested with impeccable flow rates.

The low-pressure gauge (the top one) is supposed to indicate output pressure to the keg and allows for pressure adjustment of 1 to 50psi. The high-pressure gauge (the one on the side) shows how much CO2 pressure is left in the tank.

Pros & Cons Summarized

Pros

- Dual gauges measure PSI as well as the volume of CO2 in the cylinder.

- Regulators are pressure tested to assure in-field reliability.

- Can be used to carbonate your own water.

- Great unit for the value.

Cons

- Does not have a pressure release valve.

Specifications

- Outlet pressure: 1-50 PSI.

- Type: CO2 flow meter regulator.

- Manufacturer: Taprite.

- Inlet Connection: Can be used on any CO2 tank with a CGA-320 valve.

- Material: Brass.

- Product dimensions: 6 x 6 x 6 inches.

- Weight: 2.55 lbs.

5. MANATEE Argon Regulator TIG Welder MIG Welding CO2

The Argon regulator TIG welder MIG welding C02 pressure regulator comes from the manufacturer MANATEE. Good for both seasoned welders and absolute beginners.

Besides argon, it supports CO2 mixtures and is suitable for MIG/TIG welding.

It has a high-pressure weld gauge so you can see how much gas you have left in the tank or use the ergonomic flow that is meant for different uses.

It includes a CGA – 580 Tank fitting sot it can easily be screwed onto Argon, Argon/CO2 mixtures, and Helium Tanks. The Square flow tube goes from 0 to 60 CFH and a 1 1/2″ diameter pressure gauge reading 0 – 4000 PSI. It delivers more than accurate gas meter readings.

Pros & Cons Summarized

Pros

- Compatible with wide range of gases.

- Adjustable flow 10-60 CFH (cubic feet per hour).

- Can be used in both MIG and TIG welding.

- Precise and easy flow adjusting knob.

Cons

- The dial is a little too small.

Specifications

- Inlet pressure: 0-4000 PSI.

- Outlet pressure: 0-60 CFH.

- Type: CO2/Argon flow meter regulator.

- Manufacturer: MANATEE.

- Inlet Connection: Fits CGA 580 Tank Fitting which includes all argon, helium, nitrogen and argon/CO2 mixed tanks.

- Material: Brass.

- Product dimensions: 8.74 x 7.48 x 4.41 inches.

- Weight: 1.9 lbs.

6. ZISS CO2 Argon Regulator with Gas Hose For TIG Welder

The ZISS gas regulator is a perfect choice for professional usage for MIT/TIG applications. It comes with a flowmeter and a pressure gauge with an indicator ranging from 0 to 4000psi.

The CGA580 Inlet Connection allows for standard Argon /O2/N2 Tanks to be connected while the welding hose can be fitted via female 5/8UNF-18RH.

Its ideal usage is for welding and cutting in the chemical and electronics industry.

Pros & Cons Summarized

Pros

- Compatible with wide range of gases.

- Sturdy built and easy to read.

- Can be used in both MIG and TIG welding.

- Ziss 10Ft Hose included.

Cons

- Plastic gauge.

Specifications

- Inlet pressure: 0-4000 PSI.

- Outlet pressure: 10-60 CFH.

- Type: CO2/Argon flow meter regulator.

- Manufacturer: Ziss.

- Inlet Connection: Suitable for standard Argon /O2/N2 Tanks with CGA-580 Inlet Connection.

- Outlet Connection: female 5/8UNF-18RH fitting.

- Material: Copper.

- Product dimensions: 7.09 x 7.68 x 8.66 inches.

- Weight: 2.64 lbs.

7. SPARC Dual Output Argon Regulator Flowmeter MIG TIG

The SPARC dual output gas regulator has multiple usages. It has a CGA580 Bottle Inlet Connection meaning that is paired with all the standard argon, helium, nitrogen, and argon/CO2 mixture gas bottles. It has an adjustable output flow of 0 to 60 CFH, with a preset 50psi.

It can handle not only MIG and TIG welding but is also applicable to both steel and aluminum.

Outlet connection options include a female 9/16″ x 18 nut and a male 5/8″ x 18 . There is also the standard 1/4″ barbed fitting included.

The flowmeter does not have a diaphragm, so it is more reliable than the flow-gauge style regulators. The pressure gauge measures from 0 to 4000 psi. Fits with all standard HTP, MIller, Hobart, and Lincoln welding machines.

Pros & Cons Summarized

Pros

- Reliable flow meter.

- Adjustable output flow is from 0 to 60 cfh (cubic feet per hour).

- Great customer service.

- 2 year warranty against manufacturing defects.

- Dual output heavily and quality built.

Cons

- Adjustments for the gas flow meter valves can be very touchy and sensitive.

Specifications

- Inlet pressure: 0-4000 PSI.

- Outlet pressure: 0-60 CFH.

- Type: Main – Argon, Also supports CO2/Argon, helium, nitrogen flow meter regulation.

- Manufacturer: SPARC.

- Inlet Connection: CGA580 Bottle Connection for argon and argon blend bottles.

- Outlet Connection: Female 9/16″ x 18 nut or 5/”8 UNF-18RH – 1/4″ Hose Barb Adapters Included.

- Material: Brass.

- Product dimensions: 7.8 x 7.8 x 5.25 inches.

- Weight: 2.79 lbs.

8. VICTOR Heavy Duty Oxygen Regulator

The VICTOR Oxygen regulators are perfect for heavy-duty usage as they are intended for intensive workloads.

It is made out of thick heavy brass and there are no painted thin metal sheets as well as no plastic materials. The oxygen delivery pressure ranges from 5 to125 psi.

It comes with a CGA-540 oxygen tank connector suitable for all American oxygen gas cylinders.

It also comes with a CGA-510 Acetylene tank connector that can fit all Acetylene and Propane gas cylinders, except MC and B Acetylene cylinders.

The delivery pressure hose connectors are 9/16″ – 18 RH male and Propane/ Acetylene regulator : 9/16″ – 18 LH female.

Pros & Cons Summarized

Pros

- Easy to read gauges.

- Very durable and built to resist intensive workload.

- Easy to install and start your work right away.

- Great unit for the money spent

- Fast shipping.

Cons

- Does not fit size MC and B acetylene tanks.

Specifications

- Inlet pressure: 0-350 PSI.

- Outlet pressure: Oxygen 5-125 PSI, Acetylene 2-15 PSI.

- Type: Oxygen and Acetylene flow meter regulator.

- Manufacturer: ESAB.

- Inlet Connection: CGA-540 Fits all American Oxygen Cylinders, CGA-510 Fits all Acetylene and Propane Cylinders EXCEPT Sizes MC and B Acetylene Cylinders.

- Outlet Connection: Oxygen: 9/16″ – 18 (RH Male) and Acetylene/Propane: 9/16″ – 18 (LH Male).

- Material: Brass.

- Package dimensions: 7.4 x 6.85 x 6.3 inches.

- Weight: 3.85 lbs.

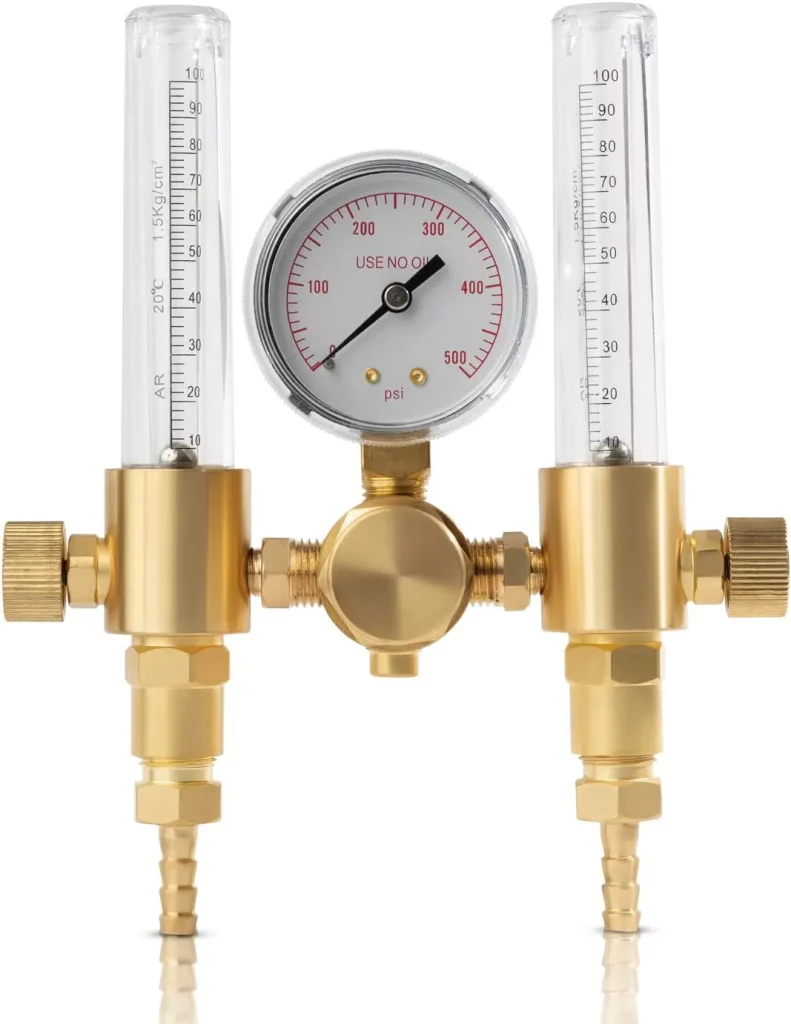

9. Argon CO2 Regulators Gauges Gas Welding Regulator

The Argon CO2 regulators provide accurate regulation of gas flow for MIG and TIG usage. It comes with dual gauges that enable easy reading going from 0 to 4500PSI.

Besides being accurate it is also safe as it includes an internal safety pressure relief design. The material used is brass and has CGA580 fitting for 5/8″ female and 9/16″ male outlets.

The knobs are made out of plastic material and enable easy flow settings. It is best used for commercial, industrial, and laboratory usage.

Pros & Cons Summarized

Pros

- Clear, large and accurate gauges.

- Great value unit.

- Easy to install and easy to set up.

- Internal safety pressure relief design.

- Fast shipping.

Cons

- Plastic adjustment knob.

Specifications

- Inlet pressure: 0-4500 PSI.

- Outlet pressure: 0-50 CFH.

- Type: Argon/CO2 flow meter regulator.

- Manufacturer: HandLtoolsmart.

- Inlet Connection: Standard CGA580 Bottle Connection for argon and argon/CO2.

- Outlet Connection: female 5/8″ and male 9/16″ Outlet.

- Material: Copper.

- Package dimensions: 6.22 x 5.39 x 4.76 inches.

- Weight: 1.79 lbs.

10. Oxygen Regulator Large Tank Gauge Cutting Torch Regulator

This oxygen regulator for large tank gauge cutting torches is more than a reliable piece of equipment. It is made out of sturdy and durable copper material making it more than reliable.

It offers an outlet pressure of 0-200 PSI and an inlet pressure of 0-4000 PSI.

The outlet thread is 9/16. 2-5/8” diameter gauges, while the inlet thread is CGA 540 female, and can be fitted to a standard gas cylinder.

This oxygen regulator includes 2-5/8 in. diameter gauges and a valve that displays the gas pressure more than accurately, allowing for precise usage. With the help of the built-in flow meter, you can easily adjust the gas flow making this gas regulator more than easy to use.

Pros & Cons Summarized

Pros

- Large and easy to read gauges.

- Easy to install and easy to set up.

- Decent low budget regulator set.

Cons

- Looks a bit cheap out of box.

Specifications

- Inlet pressure: 0-4000 PSI.

- Outlet pressure: 0-200 PSI.

- Type: Oxygen flow meter regulator.

- Manufacturer: Yaemart corporation.

- Inlet Connection: Standard CGA 540 Oxygen cylinder.

- Material: Metal, plastic.

- Package dimensions: 7.9 x 6.7 x 4.7 inches.

- Weight: 2.59 lbs.

11. Industrial Argon Regulator/Flowmeter Gauges for MIG and TIG Welders

On the other hand, there are three outlet connection options which include 5/8″ Female, 9/16″ Male, and Hose Barb. the inlet gauge goes from 0-400 psi but has a dual scale outlet gauge for Argon (0-30 CFH) and CO2 (0-20 CFH).

It even comes with a 5-feet long hose with 5/8″-18 male fittings at both ends. The flowmeter is also able to be fitted to all major brands.

Pros & Cons Summarized

Pros

- Good solid brass construction.

- Tree way adapter to suit different hose connections included.

- Good quallity hose included.

- Fit and easy to use.

Cons

- Gauges can be shaky and vibrate.

Specifications

- Inlet pressure: 0-400 PSI.

- Outlet pressure: Argon 0-30 CFH and CO2 0-20 CFH.

- Type: Argon, Argon/CO2 Mixtures flow meter regulator.

- Manufacturer: SÜA.

- Inlet Connection: Standard CGA-580 Argon, Argon/CO2 cylinders.

- Outlet Connection: 9/16″ Male, 5/8″ Female and Hose Barb.

- Material: Brass.

- Package dimensions: 10.6 x 5.5 x 5.4 inches.

- Weight: 3 lbs.

12. SÜA – Oxygen and Acetylene Regulators Welding Gas Gauges

The outlet hose fittings are 9/16″ – 18 RH & LH and the Oxygen delivery gauge measure from 0 to 100 PSI, while the Acetylene delivery gauge goes from 0 to 30 PSI.

Pros & Cons Summarized

Pros

- Good solid brass regulator for home use.

- Easy to read and reliable gauges.

- Heavy duty flow adjustment knob.

- Easy to install and use regulator.

Cons

- Even if heavy duty and resistant, knob can sometimes be hard to turn.

Specifications

- Inlet pressure: Oxygen 0-3000 PSI, Acetylene 0-300 PSI.

- Outlet pressure: Oxygen 0-200 PSI, Acetylene 0-15 PSI.

- Type: Oxygen and Acetylene flow meter regulator.

- Manufacturer: SÜA.

- Inlet Connection: Standard USA Oxygen CGA-540 / Acetylene CGA-510 cylinders.

- Outlet Connection: 9/16″ – 18 R&L Type B-B.

- Material: Brass and plastic.

- Package dimensions: 14.3 x 8.4 x 6.7 inches.

- Weight: 6.59 lbs.

Buying Guide of the Best Gas Welding Regulator

The best pieces of advice when determining which gas regulator to get is to find one that will regulate the gas pressure for the gas intended for your welding machine. But there are a whole lot of things that you have to take into account. So let’s consider them together.

What Gas is the Regulator Designed for?

Probably one of the most important things to consider is using gas regulators made out of correct materials. Using the one that is compatible with the gas you are intending to use or the one you are using the most is important here.

Using the wrong one may have hazardous effects on the entire process.

So fir instance, if you use an acetylene regulator to regulate propane gas, the propane itself will damage the inside of the regulator or cause it to disintegrate.

It will lead to leakage and also result in a very dangerous situation.(1)

Bar Outlet on CO2/Argon regulator

A bar outlet is also very important. it is best that you get gas regulators with a low bar input as it allows you to make far easier adjustments that way.

Most gas regulators have a 0 to 10 bar outlet. But if you have to set it to 0.2 it makes things far more difficult.

Thus 0-4 welding gas regulators are a far better option in this case as it is far easier to adjust the level of delivery pressure needed.(2)

Gauges On A Gas Flow Regulator (CFH/PSI)

Being able to clearly read the measures on the gauges is something that people disregard, but is very important to have.

Being able to tell the exact readings of the gas you are using is going to help in finishing the job properly.

You also have to know the difference in gauges with different gases, as Argon uses CFH (cubic feet per hour) while oxygen is measure din PSI (pounds per square inch)

Male and Female Connectors

There are two types of connectors, male and female ones, and gas regulators usually have everything labeled for users to known which one to use.

This is necessary as you do need to properly connect the gas bottle when working in order to have favorable flow rates.

But if you don’t have the required connectors you can still use an adapter for the bottle connection.

Frequently Asked Questions [F.A.Q]

Are argon and CO2 regulators the same?

The majority of CO2 regulators are the same as Argon ones. But the main difference is the cylinder fitting. CO2 welding gas regulators have a female fitting while all the other ones have a male one. CO2 regulators have a male thread which means that the regulators then have to be female.

How long do gas regulators last?

Welding gas regulators should be replaced every 10 years. The best type of indicator is visual signs of deterioration. However, each regulator has an expiration date stamped on it which you should follow.

What is SCFH in welding?

The abbreviation SCFH stands for standard cubic feet per hour. This is a type of measurement needed to understand how much shielding gas you are applying.

Conclusion

Although it is often disregarded, gas regulators are an important part of your welding machine setup. Beginner welders may not know this when they start but more experienced ones will tell them that this is a very important part of the entire process. In order to be able to weld properly, the gas service needs to be properly adjusted based on the various parts that we talked about above. Always consider carefully your regulators and follow the instructions so you can attain quality work.