Manual torch brazing is a common application performed both by individual welders and manufacturers to repair items such as cracked cast iron pumps or leaking air-conditioning assemblies.

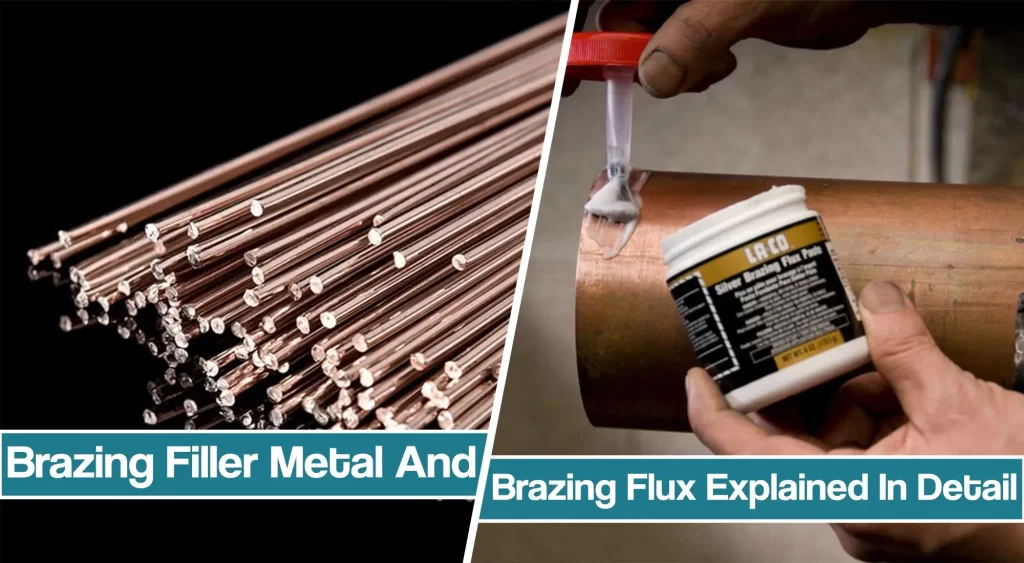

In this article, we will discuss common brazing filler metals and fluxes and their use.

For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The filler alloys come as bare metal, or flux-coated metal, in both rod and wire. Fluxes are either a white or black paste or white powder.

Fundamentals of Brazing

The brazing process is suited for joining thin sheets of metal to thick plate stock or metals of widely different melting temperatures.

In addition, it’s used in applications where joints are irregular, both for single-assembly and short-run production.

During the brazing process, molten filler metal cools and solidifies to create a metallurgical bond between workpiece materials. By definition, these fillers melt above 840 F°.

However, unlike welding, workpieces don’t have to melt for fusion to occur. Thus, the heating temperatures employed are below the melting point of the base metals.

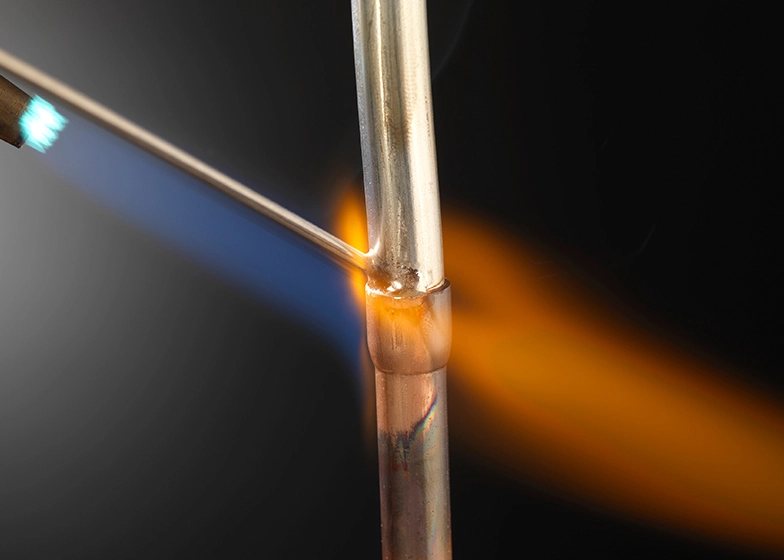

In manual torch brazing, operators keep a small gap between the metals to be joined, usually about 0.002 to 0.006. Often they do this with fixtures, such as clamps, typically judging gaps by eye. Sometimes this gap is predetermined, for example, when a component’s cracked pieces are placed next to each other in preparation for re-joining.

Operators then daub paste flux onto the joint area or dip the filler rod into powdered flux after briefly heating the rod. Next, they heat the joint area and touch it with the filler wire or rod, fed by hand. The filler metal quickly melts and capillary action draws the molten alloy through the closely fitting space. Once the filler cools, a strong joint is obtained.

If you wish to learn more about the brazing process, feel free to check out our detailed and comprehensive guide.

Brazing Filler Metals and Fluxes

About Brazing Filler Metals

Each filler metal has a melting range, some narrow and some wide.

The choice of filler metal depends on the application. For example, joining a thin-walled tube requires reduced heat, dictating filler that melts at a low temperature.

Other considerations include the base metal, service condition of the completed joint, and clearance between pieces.

For tight clearance, (0.002 –0.005 in.), a filler metal with a narrow melting range works well. Conversely, fillers with wide melting ranges work best for wide clearance (over 0.006 – 0.007 in.).

Filler Alloy Families

Only one filler alloy family is aimed at aluminum brazing, but many distributors don’t handle it because few facilities do torch brazing with aluminum.

On the other hand, most distributors provide the copper phosphorous and the copper phosphorous-silver combinations, falling under the AWS A 5.8 standard — the BCuP group of filler metals.

These and the high silver alloys, the BAg classifications, which also fall under the same standard, are used for most brazing applications.” (B stands for brazing, Cu is copper, P is phosphorous, and Ag is silver.)

BCuP alloys are primarily for brazing copper to themselves. One of the key features of brazing copper to copper is you don’t need an external chemical flux because the phosphorous in the alloy acts like a flux and deoxidizes the surface,” he says. Deoxidizing is necessary to get good wetting action critical to making strong joints. BCuPs can also be used with brass, but this requires the use of flux.

Distributors should not recommend BCuPs for steel brazing applications. This is because the phosphorous in the filler and the iron in the steel form a brittle iron phosphide at the interface, resulting in weak joints.

BAg alloys are primarily composed of copper, silver, and zinc. BAg-24, which contains 50% silver with 2% nickel, is frequently used for brazing carbides. In addition, individuals often braze carbide tool tips onto sawblades or tool shanks. For these applications, the nickel in the BAg alloy makes for strong joints, so tips are less likely to come off on impact.

In all, the silver alloy group is versatile. You can braze copper, brass, steel, bronze, nickel alloys, and stainless steel, either to themselves or each other.

Manufacturers quit making braze alloys containing cadmium in 1986 because the fumes from brazing with cadmium-based alloys are a toxic carcinogen. Some manufacturers believe you can use it if you protect the operators according to OSHA specifications for brazing with cadmium-based alloys. But, many consider it’s nothing but a hassle and a potential liability. Distributors should know plenty of cadmium-free alternatives that do just as good a job.

The fourth group of brazing alloy comprises bronze or brass brazing rods where the filler metals meet AWS specification RBCuZn (R stands for rod and Zn is zinc). RBCuZns are primarily for brazing steel and are helpful for wide clearances.

RBcuZn alloys are classified as braze welding rather than brazing. The alloys still flow by a capillary action, but not quite as easily as the others. Operators deposit the rod as they move along the joint, similar to welding, but again, the base metal isn’t melted. “Distributors typically sell a lot of RBCuZn alloy, usually as bare or flux-coated rod,” says Henson.

Brazing Fluxes

Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet AWS specification A5 31. The most common is class FB 3A, a white paste. White flux also comes as a powder.

Black paste, on the other hand, contains powdered boron.

The boron additive lets the flux stand up to applications with high temperatures and long heating cycles without breaking down.

Fluxes come in various sizes of cans or jars. In addition, some of the filler rod and wire is precoated with flux that has been color-coded for alloy identification.

The use of precoated rods often boils down to operator preference. For example, it may be more convenient to use in the field because operators don’t have to carry a separate flux container. Therefore, before you choose a suitable flux, you should set your goal straight.