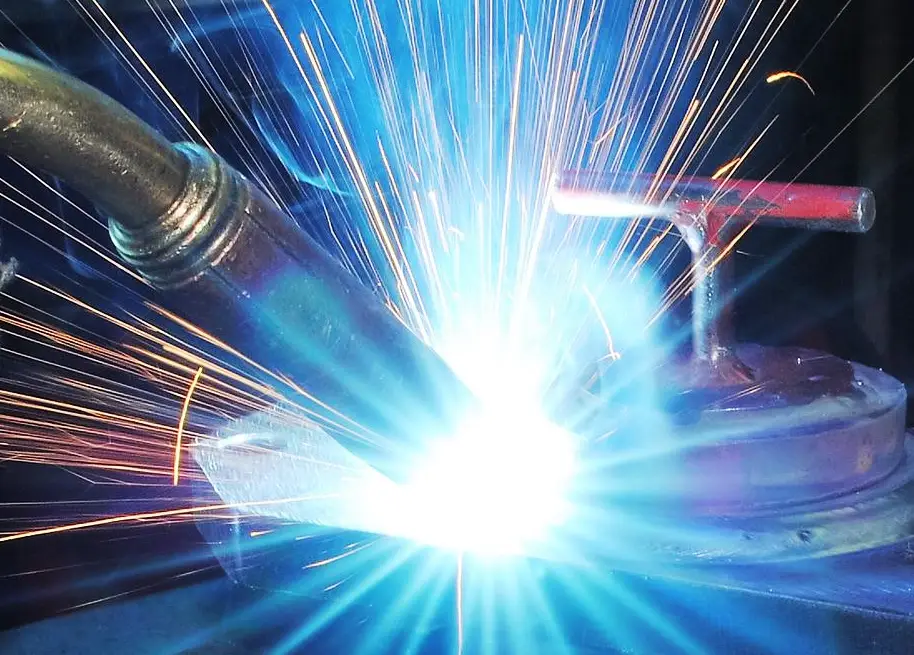

Welding cameras traditionally have been employed to aid automated or mechanized welding of inaccessible joints and ensure the integrity of critical welds.

Cameras are practical tools for many other welding applications, too, now that recent advances in electronics have enhanced the image quality and reduced the price of such equipment.

Welding cameras are particularly useful for improving working conditions, weld quality, set-up speed, positioning accuracy, and facilitating quality assurance.

Welding Cameras Use In Automated Welding Procedures

From job-shop manual welding to push-button automated welding, fabricators employ a wide range of automation techniques to improve productivity and weld quality, as well as to ensure a welder’s health and safety.

Relatively simple circumferential and linear joint-seams are often welded using positioners, rotators, column and booms, seamers, lathes, tractors, orbital welders, etc.

Such equipment may use sensors to automatically control the process (automated welding), or the operator may manually control the movement and/or torch (mechanized welding).

In either case, a clear view of the weld pool can significantly benefit the welding operation.

Applications and Benefits of Cameras in Automated Welding

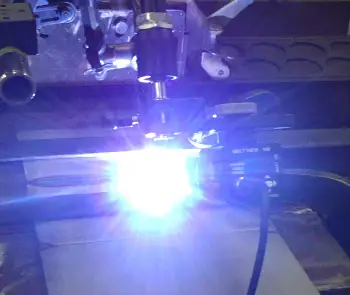

The use of camera systems in automated welding arose from necessity.

Welding in hazardous environments subject to nuclear radiation, vacuums, lasers, argon, or water entails the use of welding cameras to control the torch head remotely and wire feed positions as well as to monitor the welding process.

Welding cameras provide similar benefits in automated applications with restricted access (including bore cladding, orbital welding, and welding at height) or joints subject to preheating.

Weld Quality Inspection In Real Time

In addition to positioning the torch before and during welding, cameras may be used as a real-time post-weld inspection tool by positioning the camera for views of the solidifying weld pool.

In many cases, welding cameras are applied to monitor the welding of critical joints or expensive materials. For these applications, the cost of failure is significant, and the ability to take pre-emptive action is essential.

Improving Welding Speed And Accuracy

However, welding cameras are no longer restricted to the most sensitive and expensive welding operations. Advances in camera electronics have improved image quality and reduced purchase costs, such that welding cameras now prove beneficial to many more automated welding applications.

For example, a magnified view of the electrode and torch helps improve the set-up speed and accuracy of automated micro TIG and PAW, dabber TIG, and tube mill applications.

The performance of mechanical joint tracking systems is enhanced by camera supervision. Cameras applied to carriages facilitate welding upside down, at height, inside confined spaces, and around circumferential joints.

Automated systems with multiple weld-torches, like those used to manufacture turbine shafts, welded I-beams, spiral tubes, and tanks, may be effectively monitored and controlled from a single console.

Improving Work Conditions and Welders’ Safety

In addition, we live in an age where welding is increasingly seen as an undesirable vocation. Improving the welder’s working conditions is an effective practice for staff retention.

Semi-automatic welding with camera systems enables the welder to relocate away from the bright, hot, and smoky welding arc, and the often-cramped conditions. As a result, welding cameras are an effective method for reducing the incidence of accidents and operator fatigue by reducing metal shop hazards.

Cameras can also be used to improve the welder’s vision, particularly as eyesight wanes with age, and are especially important for welding applications that require the operator to concentrate on the weld-pool over long periods.

How Welding Cameras Visualize the Weld-Pool

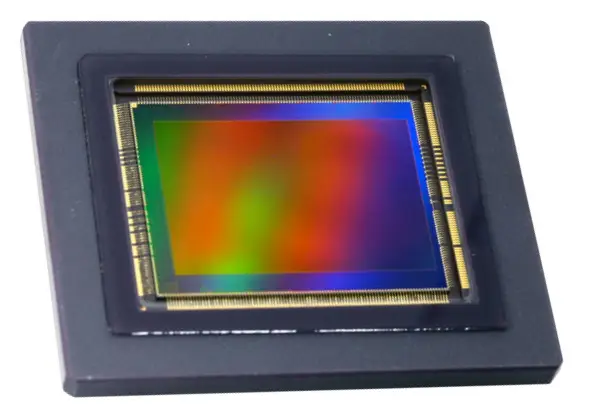

Most video cameras cannot provide a meaningful image of both the melt-zone and the joint or solidified weld during welding because of the incredible brightness of the arc and, to a lesser extent, radiation emitted from the molten weld pool.

When a scene is too bright for the pixels on the camera’s sensor, the pixels become saturated (i.e., the sensor suffers from blooming), and the image may exhibit smear as the pixel’s information is recorded.

Cameras with high dynamic range sensors and fast shutter speeds can provide a meaningful image of the bright arc, melt pool, and dark background. For welding, the sensor should have a dynamic range of 120 dB or higher. This dynamic range may be achieved using CMOS or CCD sensors.

In the video, as in photography, reducing the lens aperture and increasing the shutter speed may improve over-exposed scenes. When a scene is still too bright after modifying these parameters, a neutral density (ND) filter positioned in the optical path may be used to evenly reduce the amount of light reaching the sensor.

Employing a filter is not unfamiliar to those involved in welding, as the standard green filters found in welding helmets provide a similar reduction in light transmission.

Optical Filters For Visualizing the Weld Pool

Several other optical filters can be used to improve the visibility of certain features of the weld pool.

For example, a narrow band filter, which only allows light over a small spectrum to pass, can improve the visibility of the weld pool, and polarizing filters can reduce reflections on the surface of the rear weld pool.

Spot or graduated (apodizing) ND filters feature an area of high optical density. The high optical density area is positioned over the bright light and relatively weak optical density everywhere else.

As such, the variation in light is appropriately attenuated, and the picture of the weld pool and background improved.

Camera systems employing CMOS sensors may utilize a comparable method whereby different shutter speeds are assigned to pixel regions. The image quality may be further improved by digital processing of the camera output.

Using these techniques, it is not possible to completely visualize the weld pool and background at the same time. More advanced solutions combine synchronized, high-intensity pulsed laser or xenon strobe illumination and narrowband optical filters.

With such systems, significantly more light from the illumination source than light from the weld-pool or arc reaches the sensor. Light from the process is eliminated, while the process details may be seen with great clarity. These systems are employed in the research and development of various welding processes, as well as advanced weld-pool control systems and process defect detection.

Functional Considerations For Welding Cameras

Several practical issues are important to consider when investing in welding cameras. Many of these system features are determined by the application.

Imaging mechanism

For applications in which the camera is employed for remote monitoring and control, the operator needs to position the heat source or wire before, during, and after welding.

As such, the camera must be able to provide a meaningful image during both intense and low light conditions. Different methods are employed to achieve this functionality, including filter changes, high-speed shutters, and motorized irises.

Lenses

Motorized lenses are sometimes sensible for remote welding applications as they improve camera setup by simplifying focus adjustment. However, motorized lenses generally add cost, weight, and size to the system.

Fixed focal length lenses are smaller and cheaper, and often these are the most suitable choice as the camera is generally mounted in a fixed position.

Frame-rate

Welding cameras for monitoring commonly have a resolution and frame rate similar to PAL/NTSC standards. Recording the camera output at this rate provides an effective tool for root-cause analysis, operator training, and also quality assurance.

At faster frame rates and higher resolutions, the image of the weld seam or melt-pool may be used for feedback control, and the recorded images are very effective for process research and development (e.g., to visualize droplet transfer or melt-pool dimensions).

Lighting

When the camera is used to help install the process, the system may benefit from applying a halogen or LED light source to reduce the influence of varying lighting conditions.

The light source is commonly positioned next to the camera. Pulsed laser or xenon strobe illumination may be employed to improve the image quality significantly.

However, such equipment increases system cost and also may require the application of appropriate health and safety preventative measures.

Cable Length

There are five common signal outputs from a camera: analog, GigE, CameraLink, Firewire, and USB. The latter three methods have limited cable lengths and are therefore less appropriate for remote camera systems.

Display, Record, and/or Control

Analog systems may be interfaced with computers using a frame-grabber, or the video image may be displayed directly on low-cost LCD monitors.

The analog camera outputs for multi-camera systems (as used to monitor multiple welding torches or for monitoring both the seam and the solidifying melt-pool of the single torch) are easily displayed on a single monitor by way of a suitable transformer.

When an analog camera is used for quality assurance or troubleshooting, the image also may be recorded using a standalone digital video recorder (DVR).

GigE, CameraLink, Firewire, and USB-based systems require computer interfaces. Computer-based systems offer significantly increased functionality as the image may be used for process control and to facilitate quality assurance and trouble-shooting purposes.

However, the overall system cost is significantly greater due to the additional computer hardware and software.

Camera Position, Size, And Protection

The camera size can be a limiting factor for many applications in which access is an issue, like welding in small pipes.

The camera may be positioned to track the seam or monitor the rear of the weld pool.

Like the axis of a cold-wire feed system with gas tungsten arc welding, the imaging axis may be closer to either the base-metal or torch as dictated by considerations such as joint access, wire-feed location, camera access requirements, lens parameters, and camera mounting system.

Some systems employ a periscope mirror such that the camera may be mounted closer to the torch than otherwise possible.

Welding cameras may be subject to hot environments due to high ambient temperatures or preheating. Such equipment will require water or air cooling. In general, the camera will need to be protected against dust, spatter, and electromagnetic interference common to industrial environments.

The Future of Welding Camera Technology

We live in an era of rapid improvements in the cost and performance of electronic components and can expect high dynamic range (HDR) imaging to improve, become cheaper, and to be applied to more welding applications in the coming years.

For example, the performance of HDR camera systems may improve to such a degree that the arc may be totally eliminated with simple LEDs rather than lasers, or HDR cameras may become commonplace in welder’s helmets.

The latter configuration has been the subject of research at the Institute of Automation (IAT) in Bremen, Germany, since early in the new millennium.

In the different configurations that have been proposed, one or more cameras are mounted on the welding helmet. The vision system can be used to provide process data feedback (including torch angles and traverse speed), improve the view of the welding process (via clearer and magnified views that may be adjusted to the individual’s preference), and record the welding operation, and enhance welding training.

As with auto-darkening helmets, it may take years for such technology to catch on, but factors like increased productivity, safety, and worker comfort will drive demand for these systems.