Until recently, tight tolerances and thermal distortions have made laser microprocessing of metals difficult at best.

However, improvements in pulsed-Nd:YAG lasers are letting manufacturers tackle micro-welding, micro-drilling, and micro-cutting jobs with higher efficiency than previously possible.

Both Nd:YAG lasers (neodymium: yttrium aluminum garnet) and CO2 lasers can thermally affect processed materials. Side effects and efficiency of pulsed laser welding include heat-affected zones (HAZ) where material structure and metallurgical properties are modified, leading to corrosion risk, change in hardness, and heat-related deformation. Others are recast (slag, dross) on the processed surfaces and heat diffusion to sensitive adjacent components.

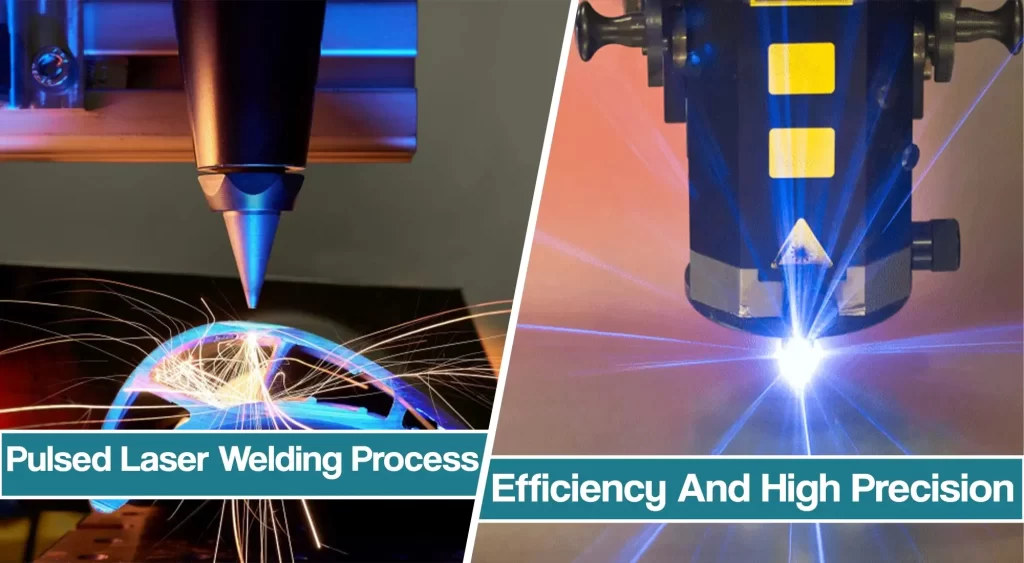

High Precision And Efficiency Of Pulsed Laser Welding

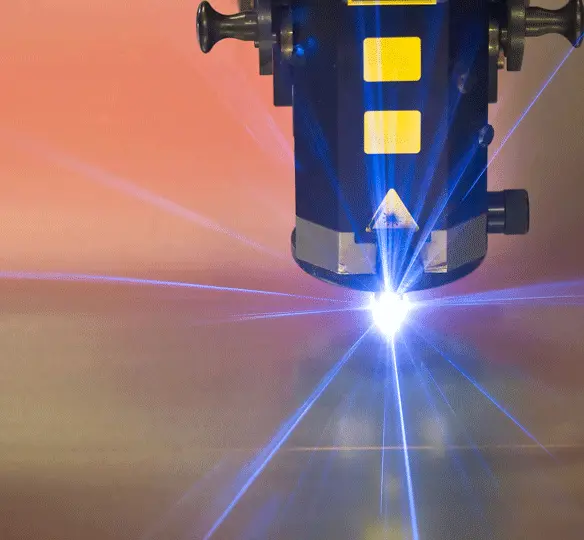

Unlike CO2 or continuous-wave (CW) Nd:YAG lasers, pulsed-Nd:YAG systems minimize these thermal effects by adapting pulse length and form to closely match specific process qualities.

Pulsed laser welding peak power can reach far above 20 kW to provide large aspect ratios (the ratio of depth to width of holes, cuts, or welds) at low average power, typically below 1 kW.

Also, compared to CO2 lasers, which work at about 10 m in the mid-infrared range, pulsed Nd:YAGs operate at near-infrared wavelengths of 1.06 m. These shorter wavelengths let the laser beam focus more precisely than CO2 lasers.

In addition, Nd:YAG beams transmit almost loss-free through standard glass or quartz optical components. Therefore, Nd:YAGs can employ lenses and mirrors frequently, costing less than the CO2 laser’s typical zinc-selenide components. In addition, these lasers can use an optical cable to increase beam-delivery options compared to conventional beam-bending mirrors.

Even for laser macro processing of metals, pulsed Nd:YAG provide an alternative to the more-expensive high-power CO2 lasers, especially where minimal heat-affected zones and high aspect ratios are desired. And its fiberoptic technology offers cost-effective and straightforward beam delivery with robots and time-sharing energy strategies.

The Use Of Pulsed Lasers in Welding

Thanks to current-controlled real-time-power-supply technology, pulsed Nd:YAGs have expanded into the electronics and medical device industries. With this power source, temporal properties of laser pulses can be adapted and meticulously controlled to match metallurgical conditions within the weld pool, letting companies make efficient micro spot welds with direct (conventional) or fiber-beam delivery. Beams can be focused on small spots (> approximately 0.0008 in.) for applications such as welding and bonding thin wires.

For seam welds, fiberoptic cables guide the laser beam to a processing head integrated into a CNC or robot. Smooth laser welds are achieved by using special pulses.

Joining Highly Reflective Metals

Comprehensive studies show that pulsed-Nd:YAG lasers join even highly reflective metals — previously impossible with other laser types — and dissimilar metals, such as copper and steel or steel and aluminum.

Lasag AG, Thun, Switzerland, developed a technique in cooperation with the Fraunhofer Laser Institute, Aachen, Germany. It involves a single laser pulse, guided by high-speed galvos, that creates a ring or linear seam weld within 20-50 msec.

Lasag’s research indicates that this stepless high-speed accurate, and discrete one-pulse welding (SHADOW) method minimizes thermal side effects while showing superior strength versus standard spot or seam welds.

The watch industry already uses SHADOW for welding delicate brass or bronze components.

The Use of Pulsed Lasers in Drilling

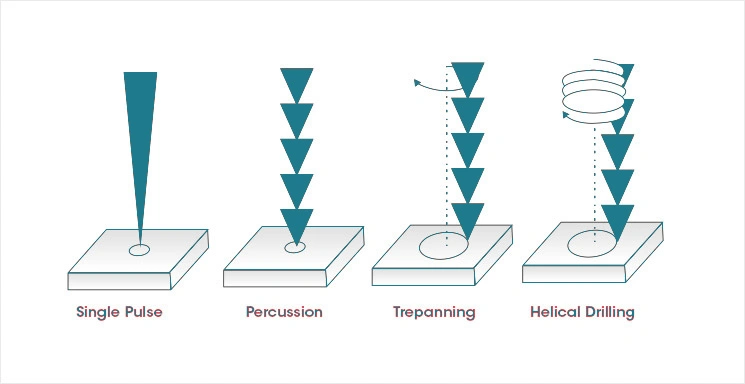

Drilling with pulsed-Nd:YAG lasers is a well-established process in industrial production. Companies use methods such as single-pulse, percussion, or trepanned drilling depending on the required geometrical tolerances, productivity, and acceptable side effects. Trepanning is less interesting here as productivity with it is low compared to the other methods.

Single Pulse Drilling

Single-pulse (shot) drilling tackles high-speed production of blind or through holes and delivers aspect ratios typically below 15:1.

High-production throughput, however, is a trade-off with tolerances generally above 10% compared to trepanning with motion systems. For many applications, this is acceptable where cycle time is more important than quality.

An example of single-pulse drilling is found in the automotive industry, where it creates a scribed guideline for breaking off (cracking) a connecting rod for diesel engines—scribing, in effect, drills blind holes close enough to make a notch. Depending on the holes overlap, this might be an array of holes or a continuous scribe. In this application, a pulsed-Nd:YAG laser scribes an approximately 0.012-in. to 0.040-in. deep notch on both interior sides of the rod bore, typically taking 2-3 sec per notch.

A narrow notch is preferred because the cracking force needed to separate the connecting rod’s upper and lower parts depends on the depth of the notch and its radius at the bottom. In addition, a narrow notch shows few side effects such as HAZ and contamination from removed material. It also requires less pulse energy.

To ensure no connector-rod bore deformation after cracking, companies should use proper laser parameters and materials harder than Brinell 230. Suggestions are cast steel (C70), 33MnVS4, or sintered metals.

Improving Accuracy and Quality

Today, various connector rods are successfully notched with previously unachievable accuracy and quality. In addition, Lasag has designed a dual-processing head for high productivity from a single laser source, which has extended the separating technology based on laser-scribed notching into other powertrain components such as bearings and crankshafts.

Another single-pulse drilling application in the automotive industry is manufacturing filters. One steel fuel filter, for example, has tube walls approximately 0.020-in. thick drilled with approximately 0.002-in. diameter holes.

The manufacturer produces more than 500 filter holes/sec at tolerances of about ±10%. The process may also be well-suited to producing noncircular holes as well.

Percussion Laser Drilling

Percussion drilling delivers successive laser pulses to the same spot and is the best trade-off between throughput and hole quality. The process has become standard for creating cooling holes in turbine-airfoil blades made from Hastelloy (or similar nickel alloys) and lubrication holes in power-train components.

This drilling technology routinely makes holes with diameters between approximately 0.012 in. and 0.060 in. and aspect ratios up to 40:1 in a matter of seconds. Higher aspect ratios are possible, but the processing time is dramatically increased.

End users can minimize side effects such as recast in holes, microcracks in walls, or burrs at hole exits by optimizing the pulse structure and auxiliary parameters (such as part support via tooling/fixturing, nozzle height, and assist-gas control).

Pulsed-Nd:YAGs also can shape the entrances of such holes, often required for the cooling efficiency of finished products.

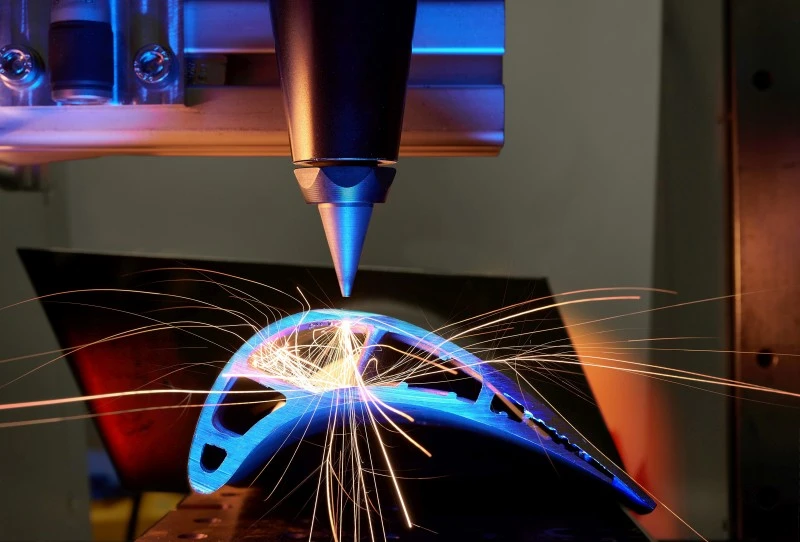

Pulsed Lasers In Cutting Applications

Pulsed-Nd:YAG lasers are also used in cutting applications requiring speed, minimal kerf width, and high tolerances. A good example is the manufacturing of stents as medical implants. In this process, the laser cuts complex structures into the walls of small biocompatible steel or nitinol tube. Kerf widths more minor than 0.0008 in. are achieved for tubes with a wall thickness below approximately 0.012 in. However, HAZ must be kept below 0.0004 in. to minimize expensive and time-consuming postprocessing.

Pulsed Nd:YAG lasers cut difficult-to-machine materials such as hard metals and polycrystalline diamond, as well as fragile materials like cubic boron nitride used in the tool industry.

To date, the best compromise between kerf quality and productivity is the solid-state slab laser. Kerf-edge thermal damage can be kept below about 0.001 in., slashing costs for finishing tools. In fact, finishing can be done with short-pulse QS-Nd:YAG.