Auto-darkening welding helmets these days are a light years away from their humble beginnings.

New technologies that get incorporated in today’s auto-darkening welding helmet offer considerably better protection than what we have seen before, especially comparing to passive helmets.

Though Passive helmets still have their uses especially at pipelines, Automatic helmet versions of today’s offer improved productivity and much better protection from bright light, UV and Infrared radiation as well as from molten metal splatter that comes your way.

This is made possible with the combination of technologies such as auto-darkening filter lenses, multiple infrared or even x-ray sensors like on Miller’s hoods, a combination of replaceable batteries and solar cells, and many other components that we described as simple as possible in this article

Essential Components of an Auto-Darkening Welding Helmets

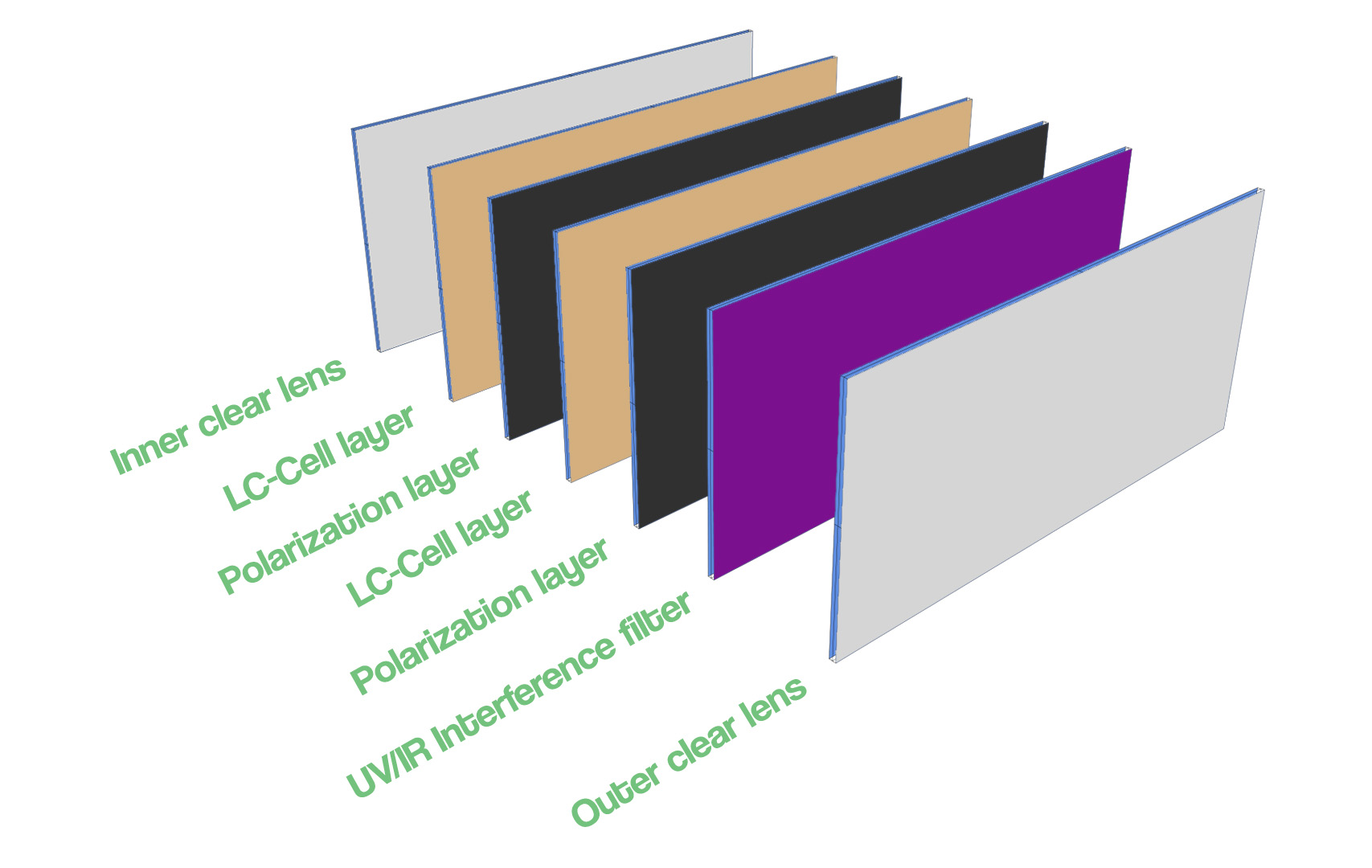

First, we’ll explain the different elements of an auto-darkening welding lens. Each component of the auto-darkening lens is necessary to provide complete protection during the welding process.

In the end, we’ll point out how they combine and work together to protect your eyes.

The UV/IR Filter

The UV/IR interference filter filters the high level of ultraviolet and infrared rays.

The filter is operational no matter if auto-darkening lenses are activated or not. This filter contains a thin glass substrate with several metallic layers.

Five layers of silver and six layers of aluminum oxide make the combination of metallic layers. Three metallic layers reflect and absorb 99.99% of the IR radiation and protect the liquid crystal panel from heat damage.

For UV protection, metallic layers work together with the other layers to stop ultra violet rays. In conjunction, they absorb and reflect 99.9997% of UV radiation (UVA, B, and C) within the range of the auto-darkening welding lenses shade.

It is worth pointing out that glass is a natural UVB filter, reducing the chances of getting sunburnt. It also absorbs light on the blue end of the spectrum.

Here is a good video by optrel that explains the damage the IR and UV radion can make. Apart from the silly voice, the video really explains everything well.

Polarization Filter

A polarization filter will darken the visible light. When looking at the picture, the first two polarizing filters are arranged at the same orientation. The other two polarization filters closest to a UV/IR filter are oriented at 90-degree angle compared to the other two polarizes. The movement of these filters changes how much light they dim.

When looking through two polarization filters, they are at their darkest when they are arranged at 90 degrees.

That’s how they provide the most protection. But, conversely, when looking through filters arranged in the same orientation, they will darken the light only slightly.

LC Cell (LCC)

Liquid crystal cells in LC cell layers can turn the lights. When they are lying flat, they twist the light by 90 degrees angle.

When the liquid crystals are stimulated by electricity, you can control how far they bend the light. At some point, they don’t refract the light at all.

Arc Sensors and Light Sensors

Light sensors and arc sensors on the front of the lens activate the front liquid crystal panels. Once they sense a higher amount of light, they will automatically darken the lens to the chosen shade level.

Sensors stop the light from passing by in the standard welding procedures. In addition, arc sensors deal with intense light produced by welding arcs.

How Do the Auto-Darkening Helmets Work?

All of the explained components work combined to provide an auto-darkening feature. The auto-darkening technology starts on once you strike your first arc.

Before starting, you should check if your welding helmet is secured and on.

Keep in mind that the LC cell layer requires the power to work, so make sure you carry a quality pair of spare batteries. When you strike an arc, photo sensors detect it and activate the front LC panel.

Cells turn against the light adjusting the pre-determent lens shade. Auto-darkening filter lenses will then darken, and you will notice an immediate change, adjusted by the light sensitivity.

When you stop welding, the same arc sensor notices the lack of light and changes orientation to lighten the lens.

Once you switch off your helmet, liquid crystals between polarized filters twist the light by 90 degrees. This orientation means ADL is off, but the lens will stay dark, approximately shade 5-6. This feature represents a safety measure that protects your eyes from severe damage if your helmet fails. You can also think of it as pair of high-quality sunglasses.

Lens Reaction Time

Auto-darkening welding helmets are as good as the speed they go dark. This feature is critical if you are working with low amp TIG welding, and they determine how fast the lens darkens.

Many auto-darkening helmets go dark within 1/25,000, while some cheaper helmets go 1/10,000 of a second. Even the slowest ones take less than a millisecond, which is about the time of a camera flash.

The switching speed, which is defined as the time for shades to change, also varies. However, keep in mind that change is fast enough even to notice it, as it is usually less than 200 microseconds.

How to Test Your Lens

If you can still see the bright light once you strike your welding arc, you can tell your auto-darkening helmet doesn’t work properly.

The safety feature that offers passive lens shade number 5-6 protection will keep your eyes safe, but welders need different shades when doing high amperage welding projects.

If you want to avoid eye damage, you can go outside and test your lens before you start to weld. Put your welding helmet on, and look directly at the sun. If an auto-darkening lens doesn’t switch on, you know you have an issue, and you shouldn’t continue welding.

Most modern helmets even have the test button inside, so you can press it and make sure everything is okay. We also have a separate article about how to test your auto darkening welding helmet where we wrote about different testing methods. Sometimes the sun is not bright enough so you should know a few backup methods.

Can Auto-Darkening Welding Helmet Go Bad?

The first thing you notice once you get your new auto-darkening welding helmet is that most manufacturers provide a recommended lifespan.

In addition, there is a life expectancy of a helmet’s electronic.

You can prevent potential eye damage by carrying a spare battery with you. Most of the modern helmets notify you when your battery is low.

If you pay attention and maintain your lenses properly, they will last for quite some time. Keep in mind that quality helmets usually last longer and provide better protection from welding burns and arc flash.

How Does X-Mode Deal With ADF Helmet Limitations

Even though auto-darkening helmets are pretty great, they have few limitations regarding the sensors. If you work in cramped positions, sensors can be blocked, which means the helmet loses the ability to go dark.

In addition, if your sensitivity is too high, once the helmet senses sunlight, it can darken, which can be harmful when working outside. In other words, the helmet won’t go dark during the welding process, or it will go dark when it isn’t necessary.

To deal with the sensitivity problem, Miller welding helmets introduced a unique feature called X-Mode. Once you turn it on, built-in antennae will sense electromagnetic field or magnetic frequency rather than arc light. That means a helmet with an X-Mode feature won’t darken unless a weld arc from your torch is present.

This advantage is significant in pipe welding, especially in smaller-gauge piping and in mirror welding. y. X-Mode’s improved functionality in out-of-position welding also prevents the welder from getting flashed.

Things to Consider When Buying an Auto-Darkening Helmet

There is a wide variety of auto-darkening welding helmets out there in the market. However, to get the best welding helmet that suits your needs, you should consider various things.

Everyone pays attention to the viewing area, lens sensitivity, controls, sensors, size, shade levels, cost, and weight when choosing a helmet.

To choose the best welding helmet, you should fit the equipment specifications to your needs. In the US, the industry standard for welding helmets is promulgated by the American National Standards Institute (ANSI) Z87.1

The Occupational Safety and Health Administration (OSHA) sets out requirements for welding helmets in the workplace.

Viewing Area

To maximize your efficiency on the job, you should buy a helmet with a larger viewing area. In addition, you should choose a helmet that offers enough coverage to be able to see your entire project without having to move your head.

In addition, some of the modern welding helmets offer side windows that will increase your awareness of what’s going around you and prevent the tunnel-vision. So even though it is not the most important factor, a more extensive view area helps.

Light Sensitivity

Light sensitivity settings are essential, and that’s why the helmet is made. If the sensors don’t help the helmet detect the arc, it is useless.

In addition, if your sensors are overly sensitive, you can have trouble working on the field since it will turn on the shade each time it notices the sunlight.

Functionality Controls

Fine controls help you increase your productivity, and they can either be set inside or outside your helmet.

They should be comfortable and large enough for you to use with gloves. The welder should quickly choose a shade level, delay, sensitivity and switch to a grind mode.

Internal functionality controls are protected from intense heat, but they can be hard to use since you have to take off your helmet to tune them.

Modern-day helmets even have a liquid crystal display that offers smooth shades change.

External controls improve productivity, as they are usually large enough to use with your gloves. The best example would be the grind mode on your welding helmet. It is best if it sits outside but this too comes with a few cons. The external grind button can break or jam if the hood is not made with high quality.

Sensitivity Control

The best part about an auto-darkening helmet is that it can automatically adjust the shade. However, eyes can react differently to light intensity.

Some eyes are not comfortable even with a small amount of exposure, while others can handle a pretty harsh lighting condition.

To get the most out of your helmet, you can fine-tune the sensitivity settings to match it to your eyes’ reaction.

Delay Control

To make sure the welder’s eyes adapt to the bright light after a darkening function, you can use a delay control. It determents how fast darker shades level turn into lighter shades.

Most of the delay controls offer settings from 0 to 2 seconds. For shorter processes, you can always set it up to 0,5 while after a long welding period, it is best if you set it to 2 seconds.

Number of Arc Sensors

Sensors are responsible for detecting the arc during the welding processes, and the number is significant if welding in cramped spaces.

If your welding helmet has only one sensor, it won’t make the lens darken once you block it. That’s why you should opt for a helmet with at least three sensors.

Lens Reaction Speed

For the new welders, lens reaction time is not so crucial since the human eye won’t even notice the rate of your helmet.

But, if you are a professional welder, that deals with arcs the whole day, having a slow auto-darkening welding helmet will increase eye fatigue.

Power Source and Lifespan

Various welding helmets use different power sources to control the auto-darkening feature. Most helmets use lithium, rechargeable, or changeable batteries, while some even use solar power.

Helmets with replaceable lithium batteries usually last longer, while solar power provides electricity by looking at arc or sun. Remember that sometimes, you’ll need to keep solar-powered helmets pointed at the sun before actually welding, as solar panel needs to collect as much power as possible.

Auto-darkening helmets with non-replaceable batteries tend to last 5-8 years.

Comfort and Weight

Many welders spend many hours wearing a helmet, and that’s why comfort and weight are paramount. Welding when your neck is hurting and your shoulder starts going numb is really bad for your health but also bad for your work.

You increase your productivity by wearing a lightweight helmet with a comfortable headband you can tighten easily around your head.

In addition, wearing a heavy helmet during long projects can cause neck pain and give you a headache.

Finally, welding requires attention to detail and high levels of concentration.

Therefore, choosing a helmet that provides enough comfort while protecting you from harmful light is essential.

Auto-darkening Helmets vs. Passive Welding Helmets

While passive helmets are more affordable and easy to repair, auto-darkening welding helmets increase productivity. Since passive helmets have fixed shade, you have to flip them all the time.

In addition, you can keep your auto-darkening welding helmet on all the time and finish your project faster. However, even though helmets have the same design, there are noticeable differences we’ve pointed out in our separate article that compares passive and auto darkening welding helmets.

How to Detect and Treat Arc Eye

If your auto-darkening helmet is working properly, you shouldn’t worry about an arc eye, also known as flash burn. However, even if you ensure maximum protection, accidents do happen, so you’ll need to know what you should do.

Condition acts as sunburn, and it occurs once the eyes are exposed to ultraviolet light. In most cases, the eyes will heal after a couple of days, but more prolonged exposure can cause severe damage.

Here is an excellent video from the ophthalmologist on welder’s arc eye injury and treatment.

Welder’s Eye Symptoms

Welder eye symptoms may vary, but the most common things you feel after an accident are:

- Pain in the eyes

- Light sensitivity

- Watery or bloodshot eyes

- Blurred vision

- Feeling something is stuck in your eyes

How to Treat Arc Eye

In most cases, the condition resolves within a day or a two, but if it doesn’t, there are a couple of treatment options:

- It would be best if you rest your eye or even wear an eye patch to relax the eye muscles so they can heal

- If the condition leads to infection, you should use antibiotics prescribed by your doctor to stop it

FAQ

Are auto-darkening helmets safe?

If used correctly, Yes! Welding helmets are an essential part of your protective equipment.

Do auto-darkening helmets go bad?

Most manufacturers will note the lifespan of the helmet in the instruction manual. Some can last quite a few years, while some go bad after a couple of years.

Are cheap auto-darkening helmets any good?

Cheap welding helmets will provide enough protection, but they lack some fine-tune options. In addition, they can flash you occasionally.

Summing Things Up

Auto-darkening welding helmets provide continuous protection to a welder. In addition, they reduce the need to flip your mask, increase your productivity and reduce the risk of injury.

Even if you are not currently welding, auto-darkening helmets protect you as you move through the workplace. They offer protection by other welders arcs and bright sun to each welder in the same area.

Before making a choice, you should understand how do auto-darkening welding helmets work. Once you get yourself familiar with a process, it is easy enough to choose the right helmet that will keep you and your skin safe from UVA radiation, IR rays, and high temperatures.

Resources:

- ANSI/ISEA Z87.1-2020 Standard at safetyequipment.org

- The functionality of the auto-darkening filter at Optrel.com

- All about welder’s flash or arc eye at www.ishn.com

- Welding – Radiation and the Effects On Eyes and Skin at Occupational health and safety