Have you ever thought about plasma cutter flames and wondered just how much heat they put out? You’re not alone.

Plasma cutters produce an incredible amount of heat and they can be extremely daunting to work with for the first time.

The good news though is that you can learn to use plasma cutting safely and that once you do so, you can be able to cut through a material of almost any thickness for any reason that you need to.

Everyone is a little nervous when they first think about plasma cutting and rightly so but once you get the hang of it, it’s a very valuable skill to have.

So, we put together this simple guide to cutting machines so that you can get a full understanding of the hotness of plasma cutters and how to protect yourself so that you work safely with them in your work environment.

How Hot Is A Plasma Flame Cutter?

A plasma cutter is very hot, indeed. It’s possible to create a flame of up to 25,000 degrees Celsius or 45,000 degrees Fahrenheit! That makes it ideal for cutting through many different types of metal and materials.

However, it also means that the flame is so bright that you shouldn’t ever look directly at it – if you do, you’re going to give yourself permanent damage to your eyes and to your vision.

If you want to compare it to a standard oxyacetylene flame, then the oxyacetylene flame is about 9,000 degrees Fahrenheit – yes, it’s 5 times cooler than the plasma cutters output.

This also means that using plasma is a little more complicated. You can’t, for example, pop your plasma down on a work desk because the heat of plasma would cut straight through it.

Plasma needs to be suspended in a sort of floating box that prevents it from coming into contact with anything other than the material you want to cut with it.

All this heat comes at a price too, the electricity cost of running plasma cutters is immense and your electricity bill is likely to be sky high if you let it run any longer than you need to. You need to extinguish the plasma cutter flame as soon as you’ve finished cutting your workpiece.

Is A Plasma Cutter Hotter Than The Sun?

This depends, a lot, on where exactly you’re measuring the temperature of the sun from. What we can say is that a plasma cutter works with a flame that is about 4.5 times hotter than the surface temperature of the sun.

However, the temperature rises quite dramatically as you get further into the sun and by the time you reach the very center – it’s about 27,000,000 degrees which is incredibly hot, indeed.

No, your plasma cutter won’t get that hot, and, in fact, it can only really match the temperatures of the upper-inner layers before the sun becomes hotter than the plasma.

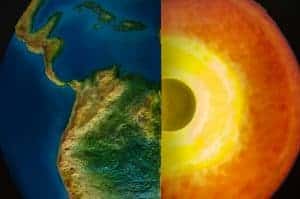

Is A Plasma Cutter Hotter Than The Earth’s Core?

So, now, let’s take a look a little bit nearer to us and the hottest thing we can think of in our present locality, the solar system, is the center of the earth.

It’s pretty hot down there at the earth’s core and you’ll find this is due to a large amount of iron being kept at very high pressure to create a high temperature.

How hot is the center of the earth? About 10,800 10,800 degrees Fahrenheit. That means that a plasma arc is going to achieve a flame that is more than 4 times hotter than the center of the earth is!

We hope that, by now, we’ve given you some reassurance that a plasma system produces an incredible amount of heat. We’d strongly suggest that you don’t put your finger in the flame to find out.

How Can You Modify The Heat Of The Plasma?

Plasma is the fourth state of matter.

That means that the individual molecules that compromise plasma have much more energy than they do in a gas (the third state of matter).

Within a plasma, you essentially have a thunderstorm acting itself out in miniature with the energetic properties of the individual molecules forcing electrons to bounce off the neutron core creating intense levels of power.

By now, you could be forgiven that thinking that plasma cutter machines must be too dangerous to use in your work area and that you’ll stick to other tools. Fortunately, it’s not too difficult to change the temperature to something a little less hot.

So far, we’ve been looking at the maximum temperature of the plasma jet but you’re not required to turn the power source up to full blast and turn the force of sun surfaces upon the metals you wish to cut.

Just adjust the controls on the outside of the plasma cutter to a more reasonable number and don’t forget that you can use other cutters on many materials – plasma cutters are best suited for specialist work where nothing else will do.

We’d also like to point out that if you feel that using plasma cutters simply too dangerous for you, don’t do it. Get help from a professional who can already plasma cut or alternatively, you can find another way to cut your material.

Plasma Cutter Safety Measures

If you want to stay safe while using a plasma cutter then it’s important to remember just how hazardous this can be without a safety plan. This is what you really need to know:

- There is a generation of heat and a spark to create the plasma arc and you need to ensure that this doesn’t interfere with anything around it.

- The plasma cutting arc when it pierces through metal will generate both sparks and potentially very hot metal surfaces.

- The workpiece, as well as the torch and nozzle, can get so hot that they can catch fire.

- You need to shield your eyes effectively from the bright plasma cutting flame and that means side shields on appropriately darkened safety glasses.

- You need flame-resistant clothing to ensure that you don’t catch fire when sparks start flying.

- Never operate a plasma cutter with matches or lighters in your pockets. They can get so hot they catch fire or explode.

- You must always be aware that the intense heat of the cutter can just easily burn through your gloves and skin as it can through what you are cutting.

Cooling A Plasma Torch

You will need to cool a plasma torch periodically to ensure that the nozzle and electrode don’t melt or catch fire. You need:

- A coolant designed to reduce the high temperatures that could damage the equipment

- It will then be released onto the back of the electrode via a slim opening and at high speed. This makes sure that the heat is quickly reduced and dispersed.

- Once the liquid has cooled the electrode, it is then used to cool the nozzle.

- The coolant swirls around the nozzle on the outer side to help preserve the nozzle’s lifespan.

- Once the coolant has passed through the nozzle it will pass out of the nozzle and back into the cooler for as long as the plasma cutting machine is switched on.

The Safety Gear That You Should Wear

You need to completely protect your body when plasma cutting. That means you want to wear protective eyeglasses, a fully heat-resistant bodysuit, a welding helmet, the appropriate shoes, and gloves. Using a plasma cutter is a dangerous job and you must take care of yourself while you do it using the right safety equipment.

Frequently Asked Questions [F.A.Q]

Can A Plasma Cutter Cut Rock?

Yes, but only if the rock conducts electricity. If not the plasma arc would die on contact with the rock and the rock would sit on the cutting table with barely a mark upon it. Most forms of rock don’t conduct electricity and would, reduce the circuit voltage to zero. This is not a problem, obviously, when cutting sheet metal because the metal is a conductor and plasma cuts conductive materials.

What Gas Do You Need For A Plasma Cutter?

A plasma cutter flame is generated by a pilot arc being pushed through a constricted opening that is filled with gas. This can be nearly any gas including shop air, oxygen, argon, and nitrogen. The plasma gas flow is automated by the plasma-cutting machine.

How Hot Does A Plasma Cutter Get?

The temperature of a plasma arc can reach up to 45,000 degrees. That’s Fahrenheit, not Centigrade. So, it’s important, if you want to avoid very high electricity bills to ensure that you keep the use of plasma cutters to a minimum while you work.

Is Lava A Plasma?

No. Lava is not plasma. While lava is very warm, indeed, it’s a form of molten rock ejected from a volcano and thus, it’s a liquid. Whereas a plasma is even hotter than the most energetic gas.

What Is Lightning Made Of Plasma?

The central column of lightning as it discharges can be a plasma gas state. The gas flow of electrons and positive ions creates a temporary plasma state and a very high voltage.

Conclusion

A plasma cutter can get to very high temperatures, indeed. It can rival the sun’s surface and be hotter than the earth’s core!

However, you can control the temperature of the flame when you spark the pilot arc and as long as you’re working with the right safety kit, you can cut through almost any material without too much challenge.

This makes working with plasma cutters an invaluable skill in many workshops. However, if you’re ever in any doubt about what to do or don’t feel safe, don’t do it – make sure to seek assistance and get somebody else to do metal cutting or to show you how to do it.

Resources:

- Plasma Arc Cutting – Process and Equipment Considerations at www.twi-global.com

- Heat Transfer in Plasma Arc Cutting by Valerian Nemchinsky at www.researchgate.net

- http://files.aws.org/wj/supplement/WJ_1975_03_s99.pdf

- Plasma Cutter Work Method Statement or Safe Work Procedure at www.web.archive.org, originally on www.safetyculture.com.au