TIG welding is a complex and often intimidating process, but it is crucial in specific applications with exotic and precious metals. By understanding the basics, anyone can learn how to TIG weld gold.

When attempting to weld gold, pay attention to temperature, the right tungsten, and the right gas. With the proper knowledge and practice, you can become a master welder of gold.

Whether you’re a beginner welder or a professional, this article will provide you with the necessary tips and techniques to successfully TIG weld gold.

Can You Weld Gold?

Yes, it is possible to weld gold with an arc welding process such as TIG welding. With the right preparation and procedure, gold welding yields strong and reliable joints that are suitable for many different applications.

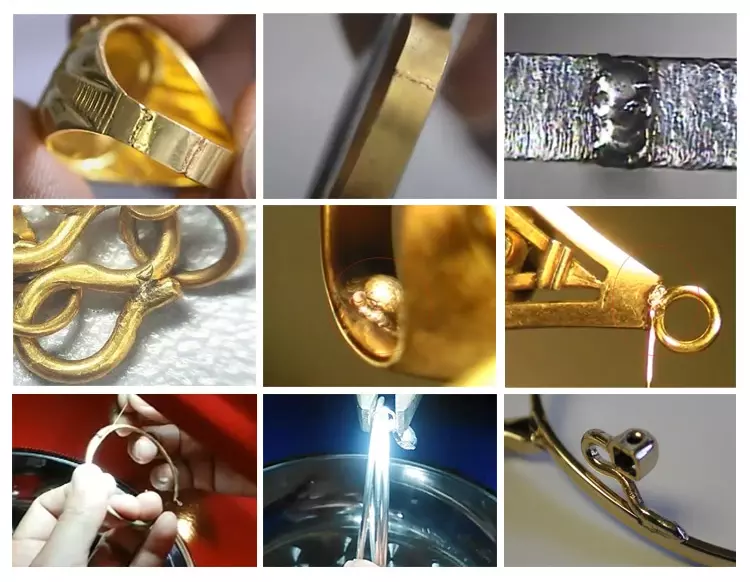

Therefore, gold welding is often used in applications where strength and durability are paramount, such as in jewelry making or medical devices and equipment manufacturing.

Gold is an excellent conductor of electricity and highly resistant to corrosion, making it an ideal material for various types of applications, but due to price, it is used in small bits. Gold alloys can also be welded with various metals, such as silver or copper. This type of welding creates strong and reliable joints that can withstand high temperatures and pressure without breaking apart.

What are the Potential Issues With Gold Welding?

One of the potential pitfalls of gold welding is the risk of overheating. When welding gold, it is important to ensure that the temperature does not exceed the melting point of the material (around 1,063°C). If overheated, the gold could melt and cause pooling, which can lead to defects in the weld. Additionally, high temperatures can also lead to annealing, which causes a decrease in the strength and ductility of the material.

Another potential issue is undercut. Undercuts occur when too much heat is applied and causes the metal to melt away from the surface, creating a concave effect. This defect can cause weaknesses in the weld and reduce its overall strength. To avoid this, it is important to use appropriate welding techniques such as adjusting the amperage and using shorter arc lengths.

Why Choose TIG Welding On Gold?

Gold is one of the precious metals that usually comes in small sizes and diameters, so most applications include micro-level resizing, re-tipping, repairing cracks, or casting defects. In these applications, micro TIG welders provide precision and the ability to produce high-quality welds.

Even though TIG welding requires a high level of skill and expertise, the end result is a clean, strong, and aesthetically pleasing weld. TIG welding is particularly suited for gold because it produces less heat than other welding processes, reducing the risk of warping, distortion, and discoloration. The alternatives are laser welding or pulse arc welding, but you are less likely to get your hands on these as an occasional welder.

How To TIG Weld Gold?

TIG welding gold is a delicate process and a craft that requires precision and expertise. The process of TIG welding gold involves using a Tungsten Inert Gas (TIG) welding machine to join two pieces of gold together.

The first step to TIG welding gold is prepping the metal. You will have to clean it with a lint-free cloth, and align and clamp pieces. This will help get the strongest results with proper fusion.

Next, you will have to set up the welding machine according to the type of gold being welded. For example, if welding 18-carat gold, use an AC current with a frequency of between 50 and 70 Hz, while 24-carat gold should be welded using a direct current with a frequency of 20 Hz or less. Setting the correct current and voltage settings are used in order to avoid overheating or underheating the metal, as this could lead to porosity in the weld joint or even cracking.

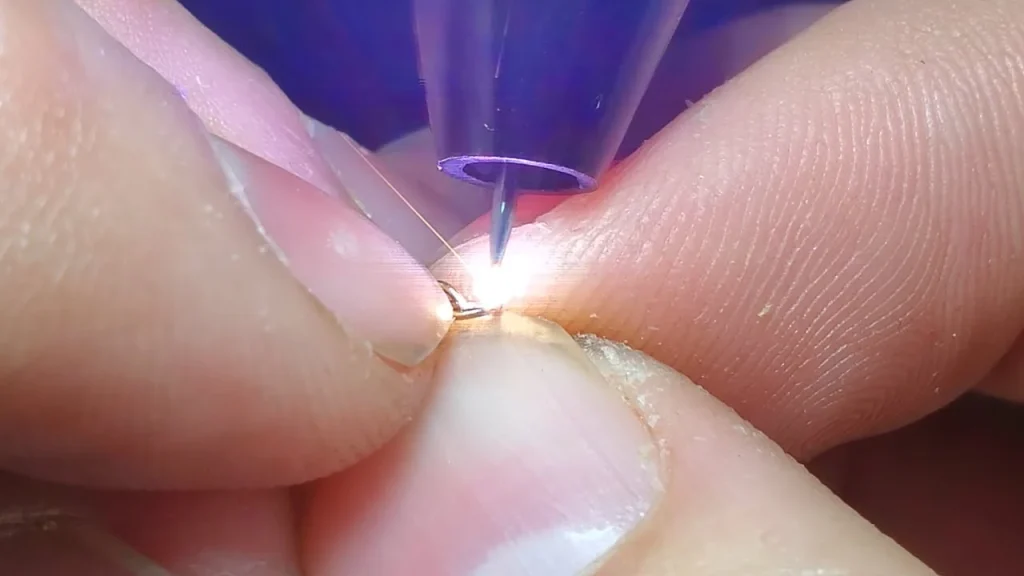

After setting up the machine, it’s time to start welding. When welding gold, use a .020” (0.5 mm) or .040” (1.0 mm) 2% lanthanated tungsten electrode that has been ground down so that its diameter matches that of the filler rod being used. Since you are working with smaller diameters, use a suitable micro-TIG torch rated at 50 amps.

Set up your torch at an angle of between 10 and 15 degrees and make sure you have good visibility of your work area. Once you have established an arc, move your tungsten electrode slowly along your weld joint whilst keeping a steady pace and making sure not to stay in one spot for too long.

As you move along, add more filler rod if necessary in order to build up your weld joint. Once you have finished welding, turn off your torch and allow your workpiece to cool down before removing any spatter or slag using a stainless steel wire brush or sandpaper.

What’s The Best TIG Welding Machine For Gold?

The most suitable TIG welder for gold is one that is capable of providing the necessary amperage and polarity for the job. Thin gold pieces might require micro welding with amperage down to 1 amp, and that’s where we usually talk about micro TIG welding. Meanwhile, thicker materials require higher amperages of around 25-30 amps.

The polarity should also be set according to the type of electrode being used; reverse polarity (DCEN) is generally used for tungsten electrodes, while the direct current (DCEP) is recommended when using a thoriated or lanthanated tungsten electrode.

When selecting a welder for TIG welding gold, it is important to consider certain features such as a high-frequency start, pulse, and post-flow control. A high-frequency start makes sure you don’t contaminate the pieces and tungsten, but the pulse arc welder is more important when working on delicate pieces. By setting pulses per second, peak, and background amperage, you can control the heat perfectly, so you can be sure you won’t burn through or damage your precious gold pieces.

TIG Torch And Consumables

The right TIG torch and TIG consumables required to TIG weld gold depend on the type of gold being welded. However, common gold welding applications will require a micro-TIG torch rated at 50 amps, which is capable of fitting smaller-diameter .020” (0.5 mm) or .040” (1.0 mm) 2% lanthanated tungsten. A small TIG torch will help you manipulate perfectly and get the desired precision.

With significantly smaller pieces, like jewelry, you won’t need a filler rod. Small gaps fill the fuse perfectly just by applying the heat of an arc. If the gap is bigger, you can use a gold-silver alloy or silver solder filler metal. This alloy is chosen because it has a similar melting point to the base metal and is therefore able to flow into crevices and form a strong joint.

Shielding The Gold Weld

The right shielding gas required to TIG weld gold is Argon. Pure argon is used as a shielding gas because it is an inert gas that can create an oxygen-free atmosphere to prevent oxidation of the gold during the welding process.

The use of an oxygen-free atmosphere is essential to prevent contamination and oxidation of the gold during the welding process, which can cause porosity, cracking, and other weld defects.

Argon also has a higher thermal conductivity than other shielding gases, resulting in faster welding speeds and improved weld quality.

Additionally, the thermal properties of gold during TIG welding are improved with the use of argon due to its low thermal diffusivity. This helps to keep distortion and warping of the material at a minimum. Gas flow of less than 5 cubic feet per hour will ensure that the gas shield is stable and does not impede or corrupt the TIG welds.

Protective Equipment And Safety Precautions

By wearing the appropriate safety gear when TIG welding gold, you can reduce the risk of serious injury or illness caused by sparks, intense light, heat, loud noise, and hazardous fumes. PPE gear includes a welding helmet with a face shield, heat-resistant gloves, and long-sleeved clothing made from natural fibers such as cotton or wool.

A welding helmet for TIG welding will protect the eyes and face from sparks and UV radiation emitted during the welding process. However, since you are dealing with small pieces, make sure the helmet is compatible with a magnifying lens. In addition, the auto-darkening function should support a low-amp start required for delicate pieces of gold.

Heat-resistant TIG gloves will protect the hands from contact with hot metal and spatter. Since the heat is not that high like with Stick or MIG, choose TIG gloves made of thin materials for increased dexterity. Additionally, it is important to wear appropriate footwear such as leather boots with rubber soles, to prevent electric shock.

Welding Technique

The proper technique required to TIG weld gold is to be cautious and use lower amperage than what is typically used when welding other metals. This is due to the fact that gold has a much higher melting temperature than other metals and requires more heat to be able to weld.

Preheating the gold helps it to reach its melting point more quickly, making it easier to weld, but it is usually done when soldering or brazing. Additionally, lower amperage is used because too high of amperage can cause the gold to become brittle and crack, resulting in a weak joint.

It is also important to use an inert gas like argon or helium when welding gold as these gases help protect the metal from oxidation. When welding gold or similar metal types, it is important to maintain a slow and steady speed for the best results.

Too fast of a speed can cause the weld area to become too hot and cause porosity in the joint. Additionally, using too much filler material can also lead to porosity in the joint as it will not flow correctly through the weld pool. Using a good quality tungsten along with good arc length control is also important as this will help ensure a clean and consistent weld.

Finally, it is important to keep in mind that when welding gold, there may be some warping or discoloration of the metal due to heat effects. It is therefore important to keep track of the temperature at which you are welding and adjust your settings accordingly. Additionally, it is important to ensure that you have adequate ventilation when welding with gold as the fumes released during welding can be hazardous if inhaled in large amounts.

Post-Weld Inspection And Cleaning

After TIG welding gold, it is important to inspect the weld for any defects, imperfections, or other irregularities that could compromise its strength and durability. In addition, it is also important to inspect the weld for its uniformity and depth. If there are any variations in depth or uniformity, the weld must be reworked or discarded.

Finally, it is important to perform post-weld cleaning to remove any contaminants or debris from the surface of the welded area. This helps to ensure that no contamination has entered into the welded area which can weaken or damage it over time.

Tips For Successful TIG Welding Gold

- Use a clean environment when TIG welding gold – make sure the area is free of dust, dirt, and other contaminants.

- Ensure that the gold alloy is properly fit and clamped – this will reduce the risk of cracking during the welding process.

- Use a lower amperage setting than usual when TIG welding gold – a range of 5-50 amps is ideal.

- Provide adequate gas coverage – typically argon is used when welding gold to ensure the weld puddle remains protected from oxidation.

- Use a smaller-diameter non-consumable tungsten electrode size than usual – a 2% thoriated or lanthanted tungsten should work great.

- Maintain a consistent arc length throughout the welding process – this will help ensure even heating and penetration of the gold alloy.

- Allow sufficient time for cooling after welding – this will help minimize thermal stress and prevent warping or cracking of the material.

Conclusion

TIG welding gold or reactive metals is a challenging task that requires specialized knowledge and skill. However, with the right preparation and practice, anyone can be a skilled welder that achieves great results. The process involves applying an electric current to the gold alloy, which creates heat and melts the material. The heat is then used to form a weld between two pieces of gold.

In order to ensure successful results when TIG welding gold or dissimilar metals, it is important to understand the electrochemical and metallurgical effects of the process, as well as the thermal properties that can affect the final product. Additionally, following safety protocols and utilizing proper tools are paramount for a successful welding experience. With these tips in mind, anyone can learn to TIG weld gold with satisfactory results, so happy welding.