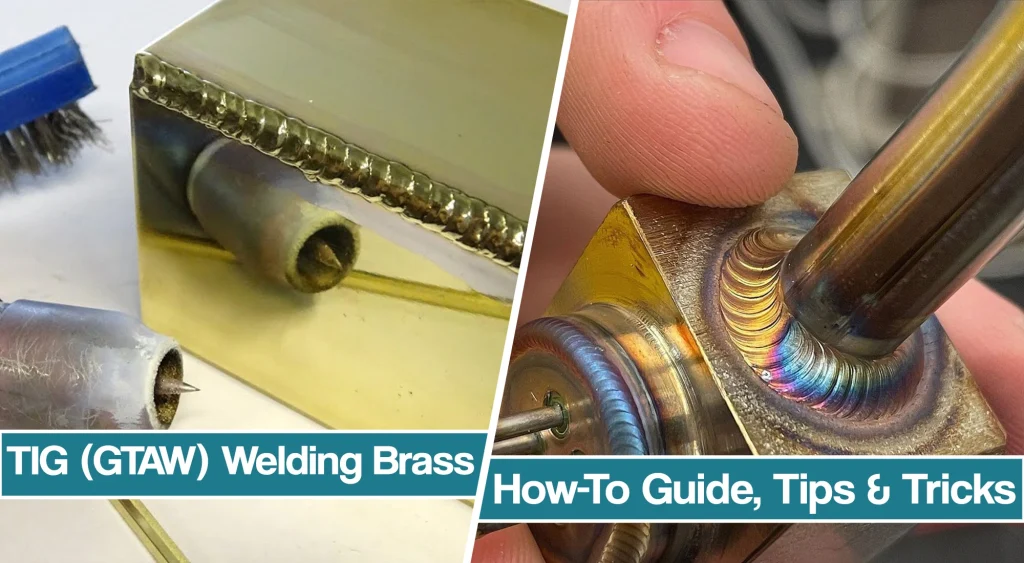

Welding brass is a common welding task in many applications, from creating ornate jewelry to building strong structural components. But what makes brass welding so challenging?

The combination of copper and zinc found in brass causes it to have a high thermal conductivity and low melting temperature.

Still, with the right preparation and techniques, TIG welding brass can be a safe and effective way to join two pieces of metal together.

This article will provide an overview of what makes brass welding challenging, explain why TIG welding is the best choice for brass, and provide step-by-step instructions on how to TIG weld brass. With the right knowledge and tools, you’ll be able to successfully complete any job involving welding brass.

How to TIG Weld Brass

TIG welding involves combining heat from an electric arc with a non-consumable tungsten electrode and a filler rod to create a strong weld joint. TIG welding is an excellent choice for working with brass as it offers a high degree of accuracy, precision, and control.

It’s important to keep in mind that brass weld metal has a low melting point and is prone to oxidation,

So it’s important to use the correct pre-heat treatment at 572-662°F and post-weld heating at 400-500°F for thin or approximately 1000 F for thicker pieces.

Additionally, using the right type of filler rod, such as copper-silicon alloys, silicon bronze, and aluminum bronze, can help reduce porosity and ensure a strong weld. 2% Thoriated tungsten will ensure stable arc and good overall results. Most brass welding applications will require a DCEN polarity, but you can also do it with AC current but with somewhat less pretty welds.

Correct amperage will depend on brass thickness, but as a rule of thumb, use between 70-100 amps for thinner brass and higher current settings (up to 250 amps) for thicker pieces. Features such as pulse can help get the best results. Argon is generally the preferred choice for most brass welding applications due to its excellent arc stability; however, argon-helium mixes can also be used for thicker brass alloys.

Maintaining an arc length of 1/4 – 3/8 inches and keeping the electrode pointed at an angle between 5 – 15 degrees from the workpiece will help you yield consistent results. By following these tips and techniques, you can successfully TIG weld brass with confidence. But we will talk about it in detail further in the text.

What Is Brass And Its Common Applications

Brass is an alloy of copper and zinc, and is one of the most common metals used worldwide. It is strong, ductile, malleable, and corrosion-resistant – qualities that make it ideal for a wide range of applications from engineering to manufacturing.

Low-zinc brasses have Zn content ranging between 5 and 20%, while high-zinc brasses have Zn content between 30% and 40%. The 60-40 brass is known as Muntz metal.

Commonly used brass items include fasteners, locks, door handles, plumbing fixtures, musical instruments, electrical components, and jewelry. In addition to these everyday uses, brass is often used in more specialized applications such as marine hardware and components for the oil industry due to its excellent resistance to corrosion from salt water. Brass is also often used for welding because it can be easily joined with other metals, including steel and aluminum.

What Makes Brass Welding Challenging?

Brass welding is a difficult process due to the nature of the material. The combination of copper and zinc found in brass results in high thermal conductivity and low melting temperature. The melting temperature of brass is around 900°C (1652°F). The thermal conductivity of brass varies depending on the alloy composition but generally ranges from approximately 50-78 W/mK.

The high thermal conductivity and low melting temperature of brass make it difficult to maintain an even heat input during welding. This can lead to inconsistent weld quality, warping, or cracking of the material. Additionally, brass is prone to oxidation which can cause porosity and other weld defects. The oxidation also results in a lower-strength weld which can reduce the structural integrity of the finished product.

Health Issues When Welding Brass

Another issue with brass welding is the producing zinc oxide, that when melted, can present health hazards. Molten zinc interacts aggressively with environmental contaminants and produces highly toxic fumes and spatters around the welded area. Toxic fumes and hot metal can cause severe damage, so pay extra attention.

Therefore, it is a good practice to wear protective gear, including TIG welding gloves, boots, or jacket. In addition, to deal with the toxic fumes, wear a proper fume extractor, employ local exhaust system or work in a well-ventilated area.

Why choose TIG welding Brass?

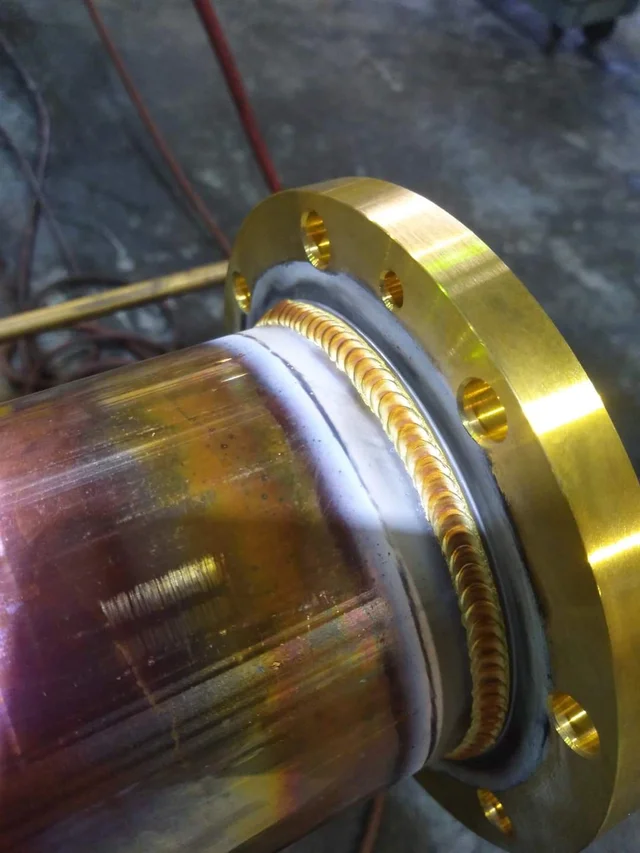

TIG welding is the preferred method for welding brass due to its many advantages. It produces strong, high-quality welds with minimal distortion and offers excellent control over the weld and filler metal. Its low heat input also reduces the risk of warping or cracking the workpiece.

Compared to other welding methods, such as MIG or Stick welding, TIG welding can produce cleaner welds with less spatter and a better finish, making it ideal for visually critical applications.

Additionally, TIG welding brass requires no additional flux or shielding gas, which makes it more economical and convenient than other methods.

You can also MIG weld brass or use acetylene gas, but TIG offers somewhat better heat control. Oxyacetylene welding is also a popular choice due to its lower price and skill requirements.

Weld Preparation And TIG Welding Brass

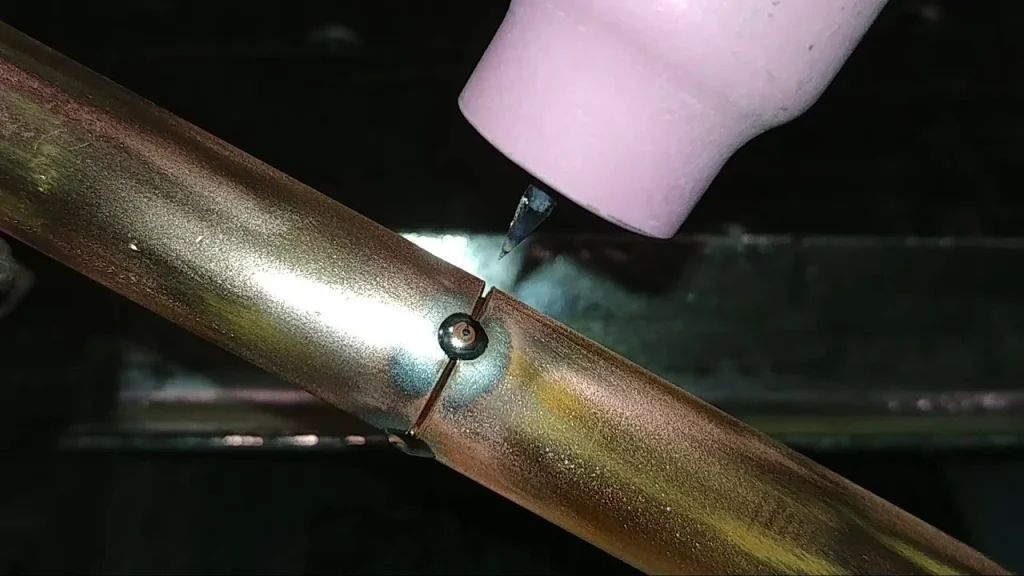

Prior to TIG welding brass, you must thoroughly clean the brass surfaces. Any contaminants such as oil, dirt, and grease can cause lack of fusion and porosity that even shielding gases cant deal with. It is also important to remove any oxide layer that may be present on the surface. You can clean the surface with a wire brush or a grinder.

Additionally, preheating the parts at approximately 100-350°C (572-662°F) helps to reduce stress during welding and also prevents cracking. It is important to ensure that the preheat temperature does not exceed 450°C (842°F) as high temperatures can lead to embrittlement of the material. Preheating also helps to reduce distortion and shrinkage during welding.

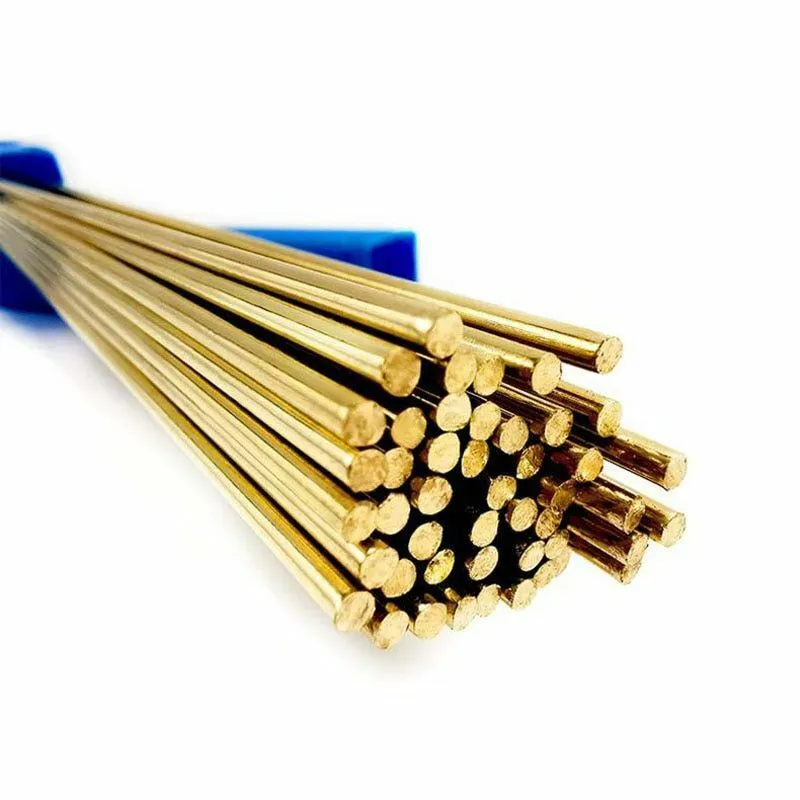

Filler Rod Selection

When TIG welding brass, selecting the right filler wire is essential. The most common types of TIG rods used for welding brass are copper-silicon alloys, silicon bronze, and aluminum bronze. Copper-silicon welding rod is a popular choice for welding brass because it offers good corrosion resistance and great weldability.

Silicon bronze welding rod has excellent corrosion resistance and is often used in applications that require high strength and ductility. Aluminum bronze is a strong alloy that is resistant to corrosion and erosion but can be difficult to weld due to its high melting temperature.

The type of tungsten used for welding brass will depend on the alloy being welded. Pure tungsten or an alloy such as thoriated tungsten should be used when welding copper base alloys such as brass. Thoriated tungsten offers better arc stability and less electrode erosion than pure tungsten, making it an ideal choice for welding brass.

It is important to remember that welding tip rod for TIG welding brass should be slightly larger than the thickness of the workpiece being welded. This will help ensure optimal penetration and prevent any potential porosity issues from occurring. Additionally, choosing a filler rod that contains deoxidizers can help reduce surface oxidation and prevent discoloration in the finished weld. Wrong filler metal can cause loss of properties or discolored weld on the brass surface.

Welding Parameters When TIG Welding Brass

When TIG welding brass, there are several precautions and techniques that must be taken in order to ensure a quality weld. Firstly, it is important to select the right shielding gas for the application. Pure argon is generally the preferred choice for most brass welding applications due to its excellent arc stability; however, argon-helium gas supply mixes can also be used for thicker brass alloys.

It is important to choose the proper amperage, current, voltage, heat input, travel speed, and arc length settings based on the thickness of the material being welded. Too low an amperage can lead to incomplete fusion or poor-quality welds, while too high an amperage can cause excessive heat input, which can lead to warping or cracking of the material. Senior welders recommend you regularly pulse your amperage during the TIG welding process. Pulsing at 30 pulses per second can yield excellent results.

Depending on the grade of the brass, you can use both AC or DCEN. Typically, DCEN is used for thicker pieces with silicon bronze filler. AC will get you a cleaner puddle with less outgassing, but it is reserved for thinner brass and yields less pretty welds that require machining at the end.

TIG Welding Brass Technique

Proper technique must be employed in order to ensure a quality weld. This includes maintaining a steady arc length and keeping filler rod additions small and frequent. Additionally, a slight weaving motion should be used when welding thin materials in order to prevent burning through the material.

When welding brass with a TIG torch, it is important to ensure that the tungsten electrode is properly sharpened and free of any contaminants.

A clean and sharp electrode will help to ensure that the arc remains stable and that the weld puddle forms correctly. It also helps to maintain good arc visibility during welding.

Additionally, you should maintain an arc length of 1/4 – 3/8 inches and keep the electrode pointed at an angle between 5 – 15 degrees from the workpiece. These techniques will help achieve strong, durable welds with excellent results.

Post-heat Treatment

The post-heat treatment is used to reduce welding stresses, improve the mechanical properties of the welded joint, and ensure a strong, durable weld. For thin sheet metal, temperatures between 400-500°F (204-260°C) are recommended. Meanwhile, thicker pieces or brass alloys with lower melting points will require temperatures between 1000-1200°F.

The temperature and duration of post-heat treatment depend on the type of brass being welded and the thickness of the material but it can reduce the risk of cracking or warping due to uneven cooling after welding.

Quick Tips For Successful TIG Welding Brass

- Use a filler rod with a similar composition to the base metal for best results.

- Use a low current setting (between 70-100 amps) for thinner brass and higher current settings (up to 250 amps) for thicker pieces.

- Consider preheating the piece prior to welding and post-heating afterward to reduce the risk of cracking.

- Use an Argon/Helium mix as your shielding gas for most applications, as it produces stronger welds and avoids porous welds.

- When welding thicker pieces, use a pulsed TIG technique to ensure good penetration and reduce the risk of warping or distortion. Use the stitch welding technique on sheet metal work to avoid defects.

- To prevent porosity, keep the tungsten close to the workpiece and move it slowly at a consistent speed.

- Make sure to clean the brass surfaces of all oils, dirt or debris before welding.

- Wear protective gear, including gloves, respirator, face shield, and flame retardant clothing since zinc content can present many health issues.

- Use flame welding methods, including oxyacetylene gas, if you cannot get the best result with other welding processes.

Alternatives to TIG Welding Brass

TIG welding is not the only method of joining copper and copper alloys such as brass. There are alternatives such as MIG welding, soldering, brazing, and mechanical joining. MIG welding is a good choice for thick sections of brass and bronze, as it results in strong welds with good penetration.

Soldering is a great low-temperature choice for thin sections where the base metal does not need to be melted like with welding. Brazing is also an option for large joints, where high-temperature filler metals and braze welding flux are used to join two pieces of brass base metal.

Welding Brass To Other Metals

Welding brass to steel is possible, but many seasoned welders don’t recommend it. The popular methods for brass-to-steel joining are blazing and soldering. When joining brass components to ferrous metals such as steel or stainless steel, it is important to use a filler rod that has a higher melting point than the base metal.

Brass material typically has a lower melting point than steel or stainless steel, so you need to be cautious. That’s why a suitable filler material for this application is an alloy of copper and nickel, such as nickel-copper (NiCu) or copper-nickel-silicon (CNSi).

TIG can be used when joining brass to aluminum, but it will require a special aluminum alloy filler rod with a similar composition to the base metal. It is also important to adjust the welding parameters accordingly when joining aluminum alloys. However, due to the nature of base metal, welders use other methods such as brazing, soldering, or epoxies more successfully.

Conclusion

Although there are alternatives to TIG welding brass such as MIG welding or brazing, TIG welding offers the highest quality welds that are created with precise control over heat input and weld puddles. It requires a great deal of skill and knowledge to get the best results. You can find more no TIG welding technique and how to TIG weld

By understanding the properties of brass and its unique challenges, using the right filler rod and welding parameters, practicing proper technique, and following up with post-heat treatment, TIG welding brass is an achievable task.

Resources:

- https://www.weldingtipsandtricks.com/tig-weld-brass.html

- https://www.millerwelds.com/resources/article-library/tig-brazing-with-silicon-bronze

- https://app.aws.org/forum/topic_show.pl?tid=12524

- https://bakersgas.com/blogs/weld-my-world/welding-repairs-tig-welding-brass

- https://www.polytechforum.com/welding/tig-welding-brass-35096-.htm

- https://www.twi-global.com/technical-knowledge/faqs/faq-how-can-i-weld-naval-brass