Copper is one of the longest-used metals, as it shows traces throughout history. However, due to its positive properties, it is still useful today.

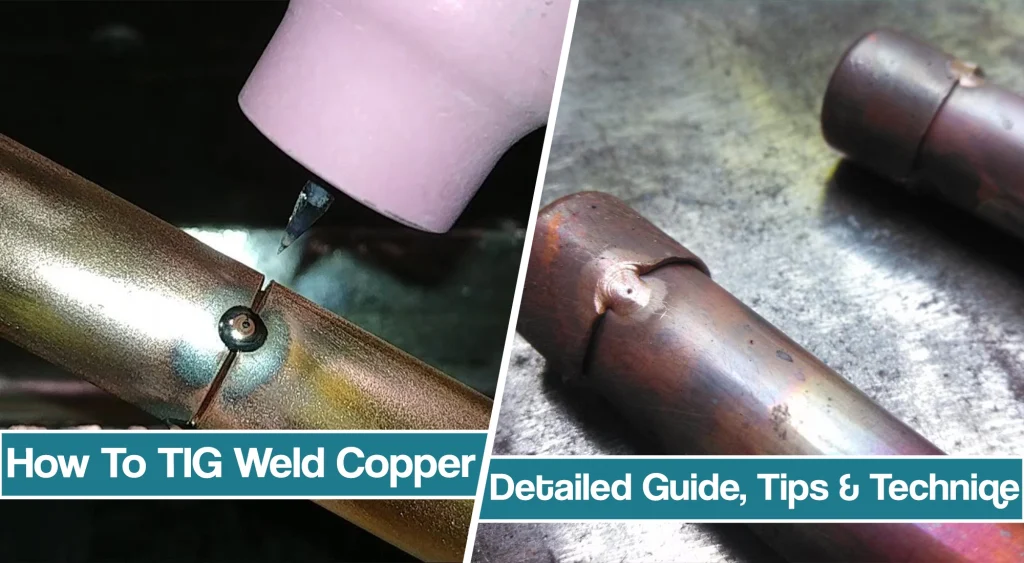

Every now and then, welders get a job that requires them to weld copper pipes or other components, and not many are familiar with the process.

Welding copper isn’t the easiest task due to its unique properties, which can lead to cracking, distortion, or wrapping. The TIG welding method can help a lot in controlling the heat, and today, we’ll give you an insight into how to TIG weld copper successfully.

Properties and importance of Copper

Copper is a soft, malleable metal that is a good conductor of electricity and heat. It is one of the most abundant elements on Earth, found in ores as well as in trace amounts in rocks and soil. Copper has been used for thousands of years in a variety of applications, including jewelry, coins, and architecture.

Copper is today used in a variety of applications, including electrical wiring and plumbing. It is also used to make coins and jewelry, as well as to construct buildings and monuments.

Copper is also used in the automotive industry for heat exchangers and radiators, as well as heat sinks for electronic components. In the medical industry, copper is used for medical implants, such as pacemakers, as well as for surgical tools. These include specific grades, but for common household welding and applications, you should buy oxygen free copper.

How To TIG Weld Copper: Why is Copper Hard To Weld?

Copper is a very challenging material to weld because it has several properties that can affect weldability. Pure copper is a ductile metal, which means that it is relatively malleable and can be easily deformed without breaking. This can lead to warping and distortion of the material during welding, making it more difficult to achieve a clean, consistent weld.

Another issue is that copper has a high thermal conductivity, which means that it transfers heat quickly and easily. This can cause the weld joint to cool faster than desired, leading to incomplete fusion and poor weld quality.

In addition, copper has a low melting point, which can cause it to become too hot and burn too quickly during welding. This can be especially problematic when attempting to weld thin or small pieces of copper, as the heat can be difficult to control.

Is TIG Welding Good Copper Welding Method?

The main advantage of TIG welding copper is its high-quality welds, which are achieved through precise control of the weld parameters. This includes the size and shape of the weld pool, the speed of the welding process, and the heat input. Additionally, TIG welding is very versatile, as it can be used on a variety of metals and alloys, including copper, copper pipes or copper fittings.

TIG welding can be used on thin materials, which makes it great for joining thin pieces of copper or repairing delicate items. However, TIG welding does have its drawbacks. It is a slower process than other welding methods, and it requires more skill and experience. Additionally, it does not produce a high weld deposition rate, so it may not be suitable for applications that require large-scale welding.

How To TIG Weld Copper – In Short

To TIG weld copper, you need a few key components. First, you need a suitable TIG welder for the job. The right TIG welding machine for copper should have a higher welding current than the one for steel due to the thermal properties of copper.

You will also need a tungsten electrode, usually made from either pure tungsten or thoriated tungsten. The size and type of tungsten electrode will depend on the thickness of the copper being welded and the amperage of the welding machine.

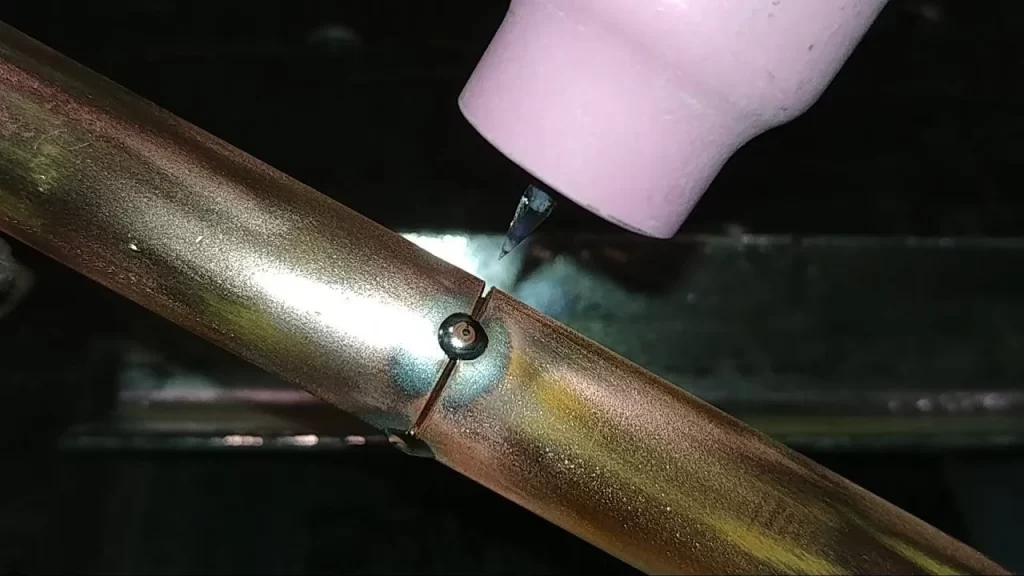

Additionally, for shielding gas, the go-to method is 100% Helium on straight polarity, but welders also go for Ar/He mixtures. It will help to protect the weld from contamination and reach the desired heat and penetration on copper tubing or copper pipe.

For the TIG welds technique, you should keep your filler rod inside the protective gas to prevent contamination. Once you establish the weld pool, you should go fast with the high amps (around 200A) and leave the weld as fast as you can to prevent the heat build up and meting through the metal.

Finally, you will need a filler material, which may be a clean copper alloy rod, depending on the application. Even though it might sound complicated, you can achieve it successfully by following our step-by-step guide.

TIG Welder For Copper

To TIG weld Copper, you will need a TIG welder with a Constant Current (CC) power source, as well as a foot pedal or fingertip control.

The amperage required to TIG weld copper will depend on the thickness of the material. Generally, TIG welders for hobbyists are rated from 25 to 250 amps. However, due to thermal properties, copper will require 30-50 amps more compared to the same thickness steel.

The polarity for TIG welding copper should be set to direct current electrode negative (DCEN). This means that the electrode (the tungsten) will be connected to the negative side of the power source, and the workpiece (the copper) will be connected to the positive side. That way, you get enough heat and penetration.

There are a few special features that can be beneficial. For instance, a pulse feature can be helpful for welding thin gauge materials, as it can help reduce heat input and improve the quality of the weld. Additionally, a post-flow feature can be useful for protecting the weld puddle from oxidation. Lastly, balance control can be beneficial when welding copper, as it allows the user to control the ratio of cleaning action to penetration.

How To TIG Weld Copper: Selecting the Tungsten For Copper Welding

The best tungsten electrodes for TIG welding copper are those made of thoriated tungsten. Thoriated tungsten is a type of tungsten that has been alloyed with a small amount of thorium oxide (ThO2). This addition to the tungsten helps to increase its electrical conductivity, which is important when welding copper.

Additionally, thoriated tungsten also has a higher melting point than pure tungsten, making it more resistant to wear during the welding process. This is important when welding copper, as copper has a relatively high melting point and can easily cause the tungsten electrode to degrade during welding. Thoriated tungsten electrodes also have a lower rate of contamination compared to other tungsten electrodes, making them an ideal choice for welding copper. Copper welds best with a pointed electrode (sharp point).

TIG Filler Rods For Copper

When TIG welding copper, the best filler rod type to use is silicon-bronze rods. Silicon-bronze alloys are known for their superior strength and good weldability. They also have a low melting point, which makes them ideal for welding copper. They provide excellent corrosion resistance and good electrical conductivity. Additionally, they are also relatively inexpensive, making them an economical choice for welding copper.

In comparison to other types of filler rods, such as aluminum-bronze or deoxidized-TIG rods, silicon-bronze alloys offer superior strength and weldability. They also have a lower melting point than other filler rods, allowing for quicker and easier welding.

In addition, they provide superior corrosion resistance, which is important when welding copper. Additionally, bare copper wire filler ERCu can be used when welded copper has a purity of over 98%. An alternative is solid copper electrical wire, which can yield suitable results in specific cases.

Shielding Gas Choice

The TIG welding process requires inert gases that don’t interact and contaminate tungsten or weld pool. Commonly used TIG gases are argon and helium. Pure argon is a go-to choice in any TIG welding for thickness under 1/8 inch. However, argon somewhat lacks heat which is crucial when battling the properties of copper.

TIG welding copper with 100% helium

All copper alloys absorb heat very well, 4 times more than mild steel does. Welding copper with 100% helium, you get that extra heat transfer which makes this a much faster welding technique with more penetration and on higher amps than usual.

With 100% helium, you get everything you need to weld thick copper successfully, but it is not without drawbacks.

Pure helium doesn’t offer the best arc stability, it is expensive, and it can cause spatter due to higher temperature. In addition, things tend to get too hot around it, so you should be extra careful.

TIG welding copper with He/Ar Mixture – 80% helium, 20% argon

Many consider 80% helium and 20% argon as the best shielding gas mixture for TIG welding copper, especially when weld metal goes over 1/8 of its thickness. Helium provides excellent heat and penetration, which works great with copper or other thick metals. Still, argon is cheaper, and it helps stabilize the arc, so welders usually use a helium/argon mixture when TIG welding copper.

Unlike 75/25 Ar/He for steel, various copper alloys still require a helium-rich mixture, which is costlier, but it provides excellent results. However, there are different opinions and personal preferences of welders, and some even prefer 100% argon on copper sheet thinner pieces.

Weld Preparation

The weld preparation for TIG welding copper is an important step that should not be overlooked. The surface of the copper should be cleaned before welding to remove any dirt, dust, and grease that may be present. This is done by using a wire brush or grinding wheel to remove any traces of foreign material.

It is important to prepare the area to be welded by properly dressing the edges. This is done by grinding the edges to ensure that they are flush and will not interfere with the welding process. This step also helps to ensure that the weld is as strong as possible and will not have any weak spots due to poor preparation.

Preheating The Copper

The correct preheat temperature for TIG welding copper depends on material thickness, but it is typically 50 to 750 °F. Preheating of the copper is done due to the high thermal conductivity of copper, but it should not exceed the maximum recommended temperature of 800 °F.

The segments of the pieces of metal to be joined must be preheated at first in a uniform manner. This helps to dissipate the heat gradually, and this, in turn, reduces the probability of cracking.

In addition, high temperatures will help you maintain a stable arc with proper penetration throughout the weld. If the pieces cool down, the copper will absorb the heat rather than reaching the melting temperature required for it to fuse with other piece and filler rod.

Welding Safety When Welding Copper

Due to the thermal properties of the copper, preheating the base metal and using 100% helium can cause huge heat build-up. In addition, copper is highly conductive, meaning that it can transfer electrical current quickly. As a result, contact with the arc or excessive heat can lead to serious burns or electric shock.

That’s why you should always wear proper personal protective equipment (PPE), such as safety glasses, gloves, and flame-resistant clothing. It is also important to ensure that the workspace is free from combustible materials, as sparks generated during welding could ignite these materials. The alloys in copper, such as zinc, can generate toxic copper fumes, so make sure you weld in a well-ventilated area or use a respirator if there is no local or general exhaust system.

Additionally, make sure you are using a proper power supply for the job at hand; if the power supply is not sufficient for the amount of amperage required for welding copper, then it could cause damage to both the power source and the operator.

Welding Technique For Copper

The key to the successful welding of any metal, including copper, is consistency. Keep the arc length moderate, and feed the rod at a steady rate. But keep in mind that copper cools down quickly. Therefore, you shouldn’t go too slow.

Moving too slowly will extinguish the arc, but you can overcome this by increasing the heat with your foot pedal or torch control. Of course, as long as you don’t burn holes through it.

When TIG welding sheet copper, make sure you don’t burn through it. Since copper requires high heat, you can easily burn through it, so be cautious. You can use the pulse feature to deal with thin metals, but the regular TIG welding is carried out at DCEN polarity, which provides better penetration and heat input.

Alternatives to TIG Copper Welding

Besides welding processes, you can join copper with other methods, including:

- Oxy-Acetylene Welding: Oxy-acetylene welding is a common alternative to TIG welding copper, as it produces a strong bond with minimal heat input. This type of welding utilizes oxygen and acetylene gases which are combined and ignited at the tip of a welding torch. This creates an extremely hot flame that will heat up the metal to the necessary melting point. Depending on the type of copper being welded, the temperature of this flame can range from 2,600 to 3,000 degrees Fahrenheit (1427-1649 Celsius). This welding method is less expensive than TIG welding and can be used for thin gauge metals or large cast components.

- Soldering: Soldering is another alternative to TIG welding copper, which involves the use of heat and filler metal to join two pieces of metal together. This type of welding does not require high temperatures like other types of welding, and it is typically used for thinner gauge materials. The most common solder used for copper is an alloy composed of tin and lead, though lead-free alloys are also available. The advantage of soldering over TIG welding is that it requires less time and energy as well as being more cost-effective.

- Brazing: Similar to soldering, brazing is another alternative to TIG welding copper that involves the use of heat and a brazing rod to join two pieces of metal together. This type of welding requires higher temperatures than soldering, typically ranging from 1,400 to 2,000 degrees Fahrenheit (760-1093 Celsius). While brazing may not be as strong as TIG welding copper, it can be used in situations where strength and aesthetics are not a major concern. Additionally, brazing is usually more cost-effective than other forms of welding due to its relatively low-cost equipment and supplies.

Final Thoughts

TIG welding copper can be hard, but the first step in getting a strong weld is understanding the issues and challenges. Once you get the hang of the welding settings, preparation, filler material, and tungsten selection, you are set for success.

Weld preparation for your copper project is crucial as the welding processes itself, so do not hesitate to spend more time considering all options. Finally, by following our detailed guide, investing practice, and patience, you shouldn’t have too many issues in TIG welding copper.

Resources:

- https://www.weldingtipsandtricks.com/tig-copper-welding.html

- https://workshopinsider.com/weld-copper/

- https://www.everlastgenerators.com/forums/showthread.php/4589-Can-you-weld-copper-with-your-TIG-welder

- https://www.metalworkmasters.com/welding/how-to-tig-weld-copper/

- https://blog.thepipingmart.com/metals/tig-welding-copper-nickel-pipes-an-overview/