Proponents of laser-beam welding (LBW) and electron-beam welding (EBW) each pronounce the singular praises of their favored technology.

Still, it’s often true that a fabricator’s or manufacturer’s best solution involves both laser beam welding and electron beam welding technologies.

This is because both processes are well suited to joining components with complex geometries, and both can meet the most stringent industry demands for metallurgical characteristics of the final assembly.

Combining Laser Beam Welding and Electron Beam Welding

Having both laser beam and electron beam technologies in a single operation can streamline the manufacturing process when a component’s design incorporates multiple weld joints tailored separately for one approach.

Examples include sensors, medical devices, and products that require an inert gas or vacuum to be sealed within the finished part.

Laser welding is required either when the final assembly size is too large for an Electron Beam welding chamber, some component in an assembly is incompatible with vacuum processing (such as a liquid or gas), or when the weld is inaccessible to an electron beam source.

Electron-beam welding will be the primary choice when the completed assembly must be sealed with internal components under vacuum, when weld penetrations exceed 0.5 in., when the material is challenging to initiate laser coupling, or when the weld must not be exposed to atmospheric conditions until it has cooled to an acceptable temperature. Examples are aerospace welding of titanium and its alloys and many refractory metals, such as tungsten, niobium, rhenium, and tantalum.

Advantages of Laser Beam Welding and Electron Beam Welding Combined

More Straightforward Tooling And Shorter Cycle Times

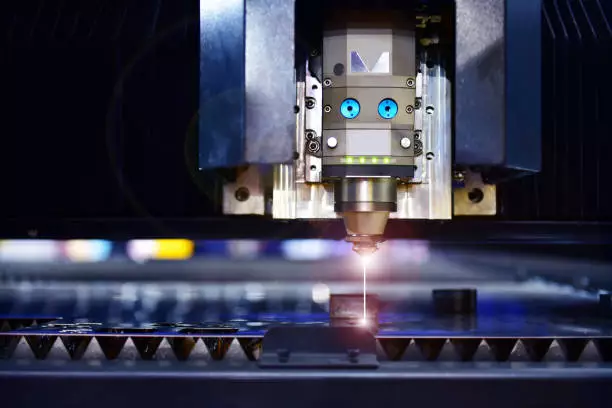

Laser welding energy sources use either a continuous wave (CW) or pulsed output of photons. The laser beam is always on with CW systems during the welding process. Pulsed systems are modulated to output a series of pulses with an off-time between those pulses.

The laser beam is optically focused on the workpiece surface to be welded with both methods. These laser beams may be delivered directly to the part via classical hard-optics or through a highly flexible fiber optic cable capable of delivering the laser energy to distant workstations.

Energy Output And Heat Source

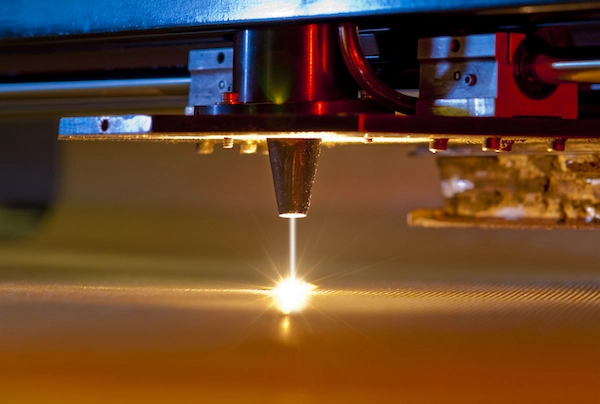

The laser’s high energy density allows the surface of the material to be brought to its liquidus temperature rapidly, allowing for a short beam interaction time compared to traditional welding methods such as GTAW (TIG welding) and similar processes.

Energy is thus given less time to dissipate into the interior of the workpiece. This results in a narrow heat-affected zone and less fatigue debit to the component.

Beam energy output can be highly controlled and modulated to produce arbitrary pulse profiles. Weld seams may be produced by overlapping individual pulses, which reduces heat input by introducing a brief cooling cycle between pulses, an advantage for producing welds in heat-sensitive materials.

A developer of laser cladding, electron-beam, and laser-welding applications noted that CW lasers could achieve penetrations up to and exceeding 0.5 inches, while pulsed lasers typically achieve only 0.030-0.045 inches. These results may vary between laser systems and largely depend on processing parameter choice and joint design.

Since the heat source in this type of welding process is the energy of light, the weld material’s reflectivity should be considered. For example, gold, silver, copper, and aluminum require more intense energy input. Once melted, the reflectivity is reduced, and the thermal conductance of the process progresses to achieve penetration.

Heat Affected Zone

As noted, the laser’s high power density results in small heat-affected zones and ensures that critical components are undamaged.

This is advantageous for surgical instruments, electronic components, sensor assemblies, and other precision devices.

Unlike EBW, LBW does not generate any x-rays and is easy to manipulate with automation and robotics.

Generally, LBW has more straightforward tooling requirements too, and there are no physical constraints because of working with a vacuum chamber. Shorter cycle times translate to cost advantages without sacrificing quality.

Higher Purity, Deeper Weld Penetration

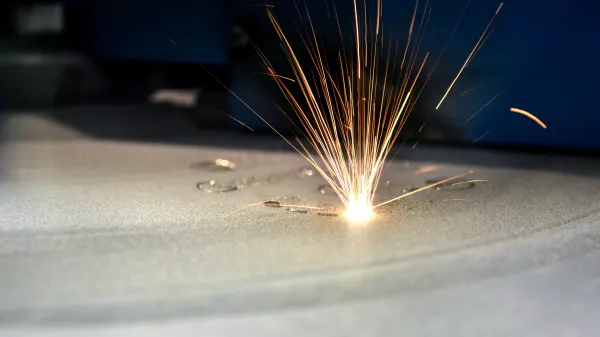

Widely accepted across many industries, EBW makes it possible to weld refractory and dissimilar metals that typically are not suited for other welding methods. The workpiece is bombarded with a focused stream of electrons traveling at extremely high speed. The kinetic energy of the electrons is converted to heat energy, which is the driving force for fusion. Usually, no added filler material is required or used, and post-weld distortion is minimal. In addition, ultra-high energy density enables deep penetration and high aspect ratios. At the same time, a vacuum environment ensures an atmospheric gas contamination-free weld that is critical for metals such as titanium, niobium, refractory metals, and nickel-based super-alloys.

Welding in Vacuum Environment

However, the primary necessity for operating under a vacuum is precisely controlling the electron beam. Scattering occurs when electrons interact with air molecules; lowering the ambient pressure allows electrons to be more tightly controlled.

Modern vacuum chambers are equipped with state-of-the-art seals, vacuum sensors, and high-performance pumping systems capable of rapid evacuation.

These features make it possible to focus the electron beam to diameters of 0.3 to 0.8 mm.

Combining With CNC Systems

By incorporating the latest microprocessor computer numeric control (CNC) and systems monitoring for superior part manipulation, parts of various sizes and mass can be joined without the excessive melting of smaller components. In addition, the precise control of both the diameter of the electron beam and the travel speed makes it possible to fuse materials from 0.001 in. to several inches thick. These characteristics make EBW an extremely valuable technology.

The process puts minimal heat into the workpiece, which produces the smallest possible amount of distortion and allows finish machined components to be joined together without additional processing

Typical Applications and Advantages of Electron Beam Welding

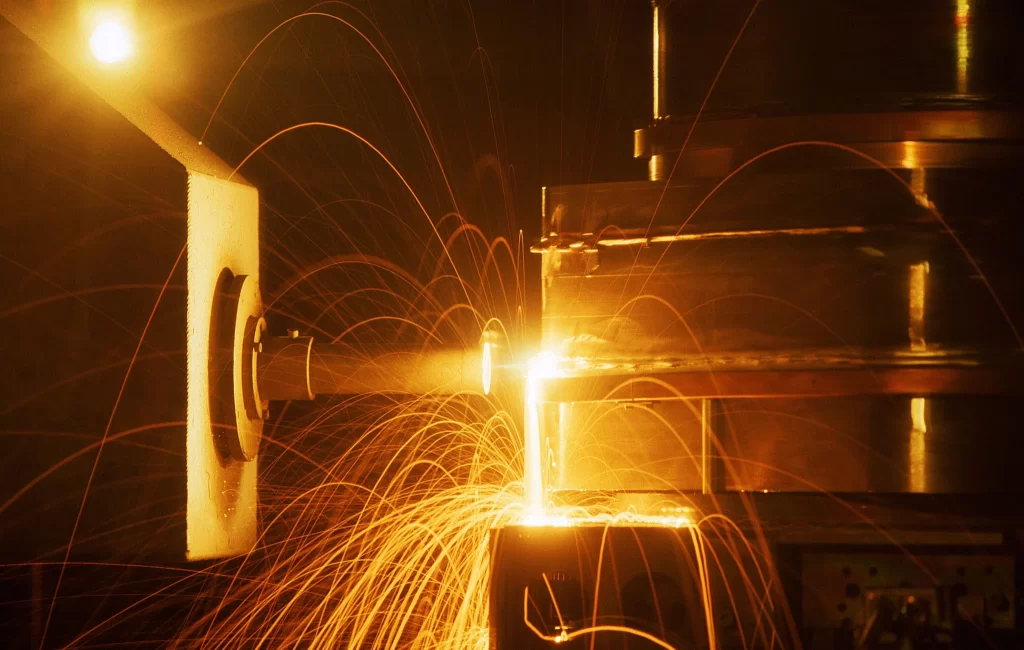

EBW is a process that will be in use for a long time. Since most EB welding is performed inside a vacuum chamber, it is an excellent fit for joining advanced materials used in such industries as aerospace, power generation, medical, and nuclear, which need to be produced in a vacuum environment to protect them from oxygen and nitrogen found in an open-air environment.

The welding environment’s cleanliness is one variable you don’t have to worry about.

In addition to providing the ideal welding environment, new EB welding controls allow for fast electromagnetic deflection of the beam, which allows the heat input of the weld and surrounding area to be customized for optimum material properties.

For example, this rapid deflection allows preheating, welding, and post-heating simultaneously by the rapid movement of the beam location, focus, and power levels. In addition, this provides the ability to weld difficult or “impossible to weld” alloys.

An area where EBW is finding increasing application in is the manufacturing of turbochargers for diesel engines, which are gaining popularity due to their great potential for improving engine efficiency. Turbochargers are used to pre-pressurize air going into the diesel engine to higher-than-atmospheric levels, thus providing more oxygen for the combustion process.

Many modern passenger cars and commercial vehicle engines are equipped with turbochargers. Manufacturers of these units had conventionally used inertia friction welding techniques to join the investment cast, Inconel wheel to the carbon steel shaft. Although this joining method produced a joint of adequate strength, the post-weld machining, grinding, and heat-treatment operations were expensive and time-consuming. As a result, several leading turbocharger manufacturers have adopted an alternative welding process using EBW.

EBW parts require a minimum of post-weld machining and heat treatment and, unlike other fusion welding processes. EBW requires no shielding gases, and the weld quality is exceptional. The welding process is exceptionally efficient (typically 95%), all the parameters are carefully controlled, and the process fully automated.

Using Electron Beam Welding With Laser Welding

LBW is commonly used for welding steel sheet metal components and machined components under 0.33 to 0.50 inches thick. Laser welding is also helpful for joining parts unsuitable for processing inside a vacuum chamber.

Some parts and associated welding fixtures may be too large to fit into the available Electron beam welding chambers. Aside from size, if the components being welded contain liquids that would interfere with vacuum pumping, laser welding would be a good choice.

It takes minutes to evacuate an EB welding chamber, and that time may not be worth it for a less sensitive weld.

Suppose components are highly valued and made of a material that would benefit from the vacuum environment, such as titanium and nickel alloys. In that case, the welds are more profound than 0.33 to 0.50 in., or if the laser beam has difficulty coupling with the material being welded, such as aluminum alloys, EB welding is often the process of choice over laser welding.

The example of gas turbine components is where EB welds are used for the deeper welds and welds requiring minimal distortion. The same assembly also had laser welds called out for sheet metal cover details.

While each technology has its benefits, in practical terms, many component designs incorporate both EB and laser welds. In these cases, performing both types of welding at the same facility streamlines the manufacturing process.