The metal-cored wire is among the more versatile and flexible welding wires available for manufacturing today. Metal-cored wires cost roughly 33 percent more than solid wires, but it also carries the potential to increase travel speeds and deposition rates by 25 percent or more.

Given that labor comprises roughly 85 percent of a welding operation’s costs, the time savings can greatly outweigh the additional expenditures.

However, for a metal-cored wire to be worth the investment, you need to choose the proper wire and adjust your welding technique to achieve optimum performance. The goal of this article is to help you understand the cost savings and fundamentals of metal-cored wires.

About Metal Cored Wires

The metal-cored wires can be used to weld a wide variety of material thicknesses with equal success, and offer the opportunity to substantially increase deposition rates and travel speeds to produce highly aesthetic bead appearances.

Metal cored wire produces very little to no spatter compared with solid wire and flux-cored wires. Plus, a single wire size can be used on a wide range of material thicknesses simply by adjusting welding parameters, technique, and transfer process.

What To Consider When Choosing Metal-Cored Wire

The good news is that very rarely is metal-cored wire a bad choice for applications with material thicknesses ranging from 3/16 in. thru 4 in., being welded in the flat and horizontal positions.

If you are experiencing a problem with your metal-cored welding operation or it has not increased welding productivity compared to solid wire, it is almost certainly a result of using incorrect welding parameters, wire model, or technique.

For example, a ropy bead with poor penetration and a convex profile typically can be solved by adjusting wire feed speed, voltage, travel speed, and possibly even the gas mixture. Similarly, weld metal burn through or other problems caused by excessive heat and force also can be solved by adjusting the same variables.

Finding that metal-cored “sweet spot,” where the welds look and penetrate perfectly and the travel speeds are high, however, if you want to minimize weld defects it can be a bit tricky.

Yet, if there is a cardinal rule in optimizing the performance of metal-cored welding, it is experimentation. What works for one company or welder might not work for the next.

Getting the best results from your metal-cored composite wire requires fine-tuning a number of variables to achieve the ideal combination of travel speed, deposition, and weld quality. Your filler metal manufacturing representative or welding distributor can assist you with fine-tuning these variables.

Metal Core Wire Selection

One of the most critical factors in metal-cored welding is selecting the proper wire. Because there are many varieties of wire under the same AWS classification, each with very different characteristics, choosing the right one for your operation may require a little investigation.

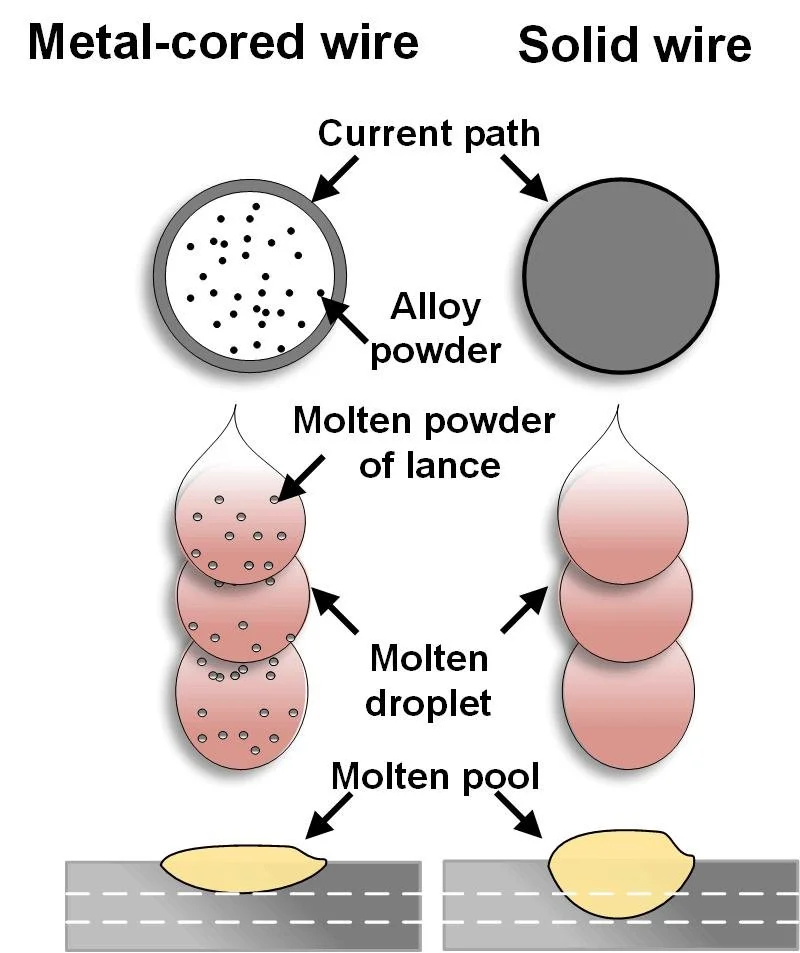

Wire diameter is ranging from .035-in. to larger wire diameter such as 3/32 in., and metal-cored wire is available for carbon steel, low alloy steel, and stainless steel applications. Compared to Solid MIG wire, metal-cored wire is a hollow tubular wire filled with a blend of metal, mineral, and chemical powders and arc stabilizers.

The majority of the core is iron, and additional elements are added to produce specific results based on the materials and applications for which the wires are designed.

Welding operations that manufacture painted equipment, such as bulldozers, cranes, forklifts, or tractors, for example, may want to select a metal-cored wire that produces very little spatter, that minimizes the formation of silicon islands or brings the islands to the center of the weld bead, where they are easily removed. This type of metal-cored wire can contribute significantly to a company’s bottom line by reducing the amount of time spent on post-weld cleaning weldments and other activities that do not contribute to throughput.

Likewise, operations that weld material with mill scale and other surface contaminants should look to a wire with sufficient deoxidizers, specifically manganese and silicon, to bring those contaminants to the surface of the weld so that they don’t remain trapped in the bead. Choosing a wire with a strong “driving” arc in the welding process also will provide better penetration through mill scale and other contaminants.

Shielding Gas Choice

External shielding gas plays a major role in the success of metal-cored welding. The wrong shielding gas mix can lead to insufficient penetration, burn through, excessive spatter and silicon deposits, or a number of other weld defects.

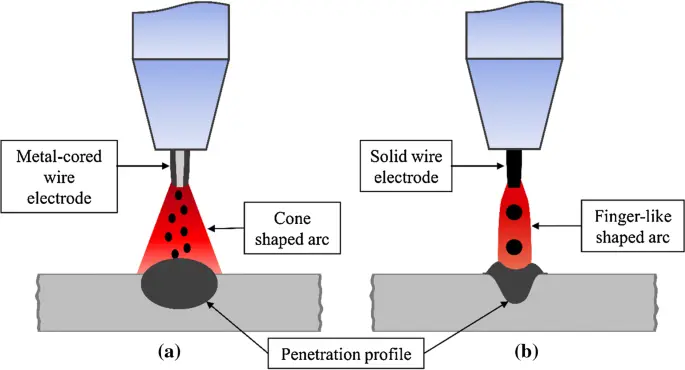

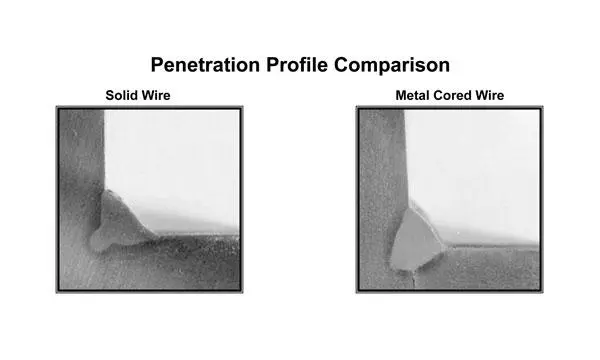

Thicker materials, which often contain mill scale, rust, and other surface contaminants, may require an arc with more force and drive to break through those contaminants.

In such cases, argon/ CO2 mixtures will provide a broader penetration profile and the arc drive necessary to weld thicker materials. Higher levels of CO2 will create more spatter, so it is generally recommended to use as low of a percentage of CO2 as necessary for the given application. (Note: The arc stabilizing and spatter reducing benefits of argon do not become significant until it is at least 75 percent of the overall gas mixture).

Like solid and gas-shielded flux-cored wire, a metal-cored wire can be used with either 100 percent CO2 or an argon/CO2 mixture with the richer argon mixtures being the most common. Metal-cored wire also can be used with a small amount of oxygen as part of an argon/oxygen mixture. The reactivity of the oxygen with the arc intensifies its heat and accelerates the spray transfer process without producing additional drive. The result is that an argon/oxygen mixture produces a softer arc with high deposition rates, which allows a metal-cored wire to weld very thin materials at high travel speeds and without burning through that might otherwise be caused by an Argon/CO2 mixture.

For mild steel applications, a 95 argon/5 oxygen mixture is commonly recommended. Stainless steel applications usually use less oxygen — a 98 argon/2 oxygen mixed gas often is used, like with solid wire.

Joint Configuration and Material Thickness

The joint configuration will dictate factors when using the metal-cored process, including wire selection, gas mixture, and welding parameters. Deep V-grooves, are often required for thick sections, for example, a hard-driving arc. Such an arc can be achieved through proper wire selection, 75/25 argon/ CO2 shielding gas, and proper voltage settings.

Maximizing your metal-cored welding wire performance also depends heavily on the application in which it is being used.

Although it often is prized for its ability to achieve high deposition rates and high travel speeds with a spray transfer process on thick material, the metal-cored wire also can perform very well on thin material.

When welding thin material, typically 11 gauge and thinner, a spray transfer mode may introduce too much heat and penetrate too deeply into the base material, causing burn through or warping. In these instances, a short circuit or globular transfer or pulse mode often provides successful results, but usually at the expense of travel speed.

Applications that require bridging gaps and welding in a vertical or overhead position can benefit from the lower heat input and calmer weld pool created by a pulse process or standard short circuit transfer with a metal-cored wire. Other variables, such as gas mixture can also be adjusted to achieve ideal results when metal-cored welding on thin material.

Tip Recess

Because of the heat it creates, metal-cored welding usually requires the contact tip to be recessed from 1/18 in. to 1/4 in. inside the nozzle of the welding gun, which is more than solid wire. That keeps the contact tip cooler and helps to increase consumable life while preventing the electrical conductivity from degrading.

A recessed tip also produces a longer wire stick out. That increases the voltage passing through the wire and facilitates the spray transfer mode.

In some instances, robotic welding applications or submerged arc welding will use an extended contact tip as a way of accessing confined joints.

Metal Cored Wire Feed Speed

Maintaining proper wire feed speeds, particularly in relation to travel speeds, is another important factor in optimizing metal-cored performance.

Proper feed speeds depend on the material type, its thickness, electrical parameters, and several other factors. Like solid and flux-cored wire, running a travel speed that is too fast for the feed speed can result in a ropy, convex bead with poor penetration and tie-in to the base material.

Conversely, running a wire-speed that is too fast can cause an unstable arc with excessive spatter and a turbulent weld pool.

A Final Thought

Of course, the metal-cored wire will not be the perfect wire for every application.

Welded to its full potential, however, metal-cored wire carries the potential to dramatically improve weld cycle times, bead appearance, and overall productivity in heavy equipment manufacturing, and to reduce a welding operation’s costs considerably.