Unlike self shielded flux cored wires, metal core welding wires require a shielding gas.

But, metal-cored wire has unique characteristics that can minimize costs, improve weld metal quality and productivity of your shop.

In this article, you’ll learn about the metal cored wire welding, its advantages, and how these wires work. We will also discuss the difference between standard, self-shielded flux-cored wire and a metal-cored wire.

Sometimes, metal-cored wires may be exactly the right product to address your welding challenges.

Why Should You Consider Metal-Cored Wires

In the right applications, metal-cored wires can address many of your quality and productivity issues, and they can also lower their overall operating costs.

Metal-cored wires are certainly not new (they were developed in the mid-1970s), but they have definitely changed over the years. Today, these metal-cored wires provide significantly more reliable, higher-quality welds than earlier versions.

Metal-cored wire also provides better gap bridging capabilities and faster travel speeds, along with lower spatter levels and higher deposition rates compared to solid wire.

The wires achieve these results because of their chemical and mechanical structure.

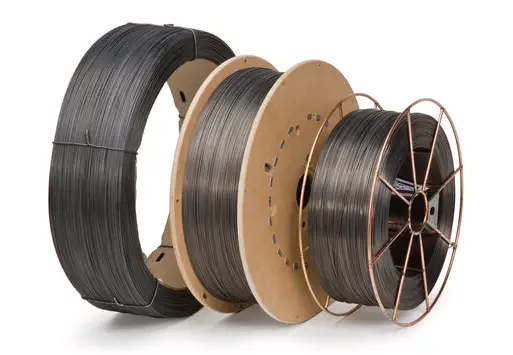

Metal-cored wires consist of a hollow metal sheath filled with metallic powders, alloys and arc stabilizers. These special chemical formulations provide distinct benefits, from increasing deoxidation to providing higher impact strengths and/or reducing silicon deposits in the final weldment. They also allow metal-cored wires to weld through mill scale and other contaminants while producing little to no spatter, resulting in reduced post-weld cleanup.

Metal-cored wire also produces a broad, cone-shaped arc and a wider penetration profile compared to solid wires, for example. This wider arc shape results from the current traveling through the outside of the metal-cored wire’s metal sheath during the welding process (generally, a spray transfer mode). The broader arc provides higher filler metal deposition rates, minimizes porosity, and reduces undercut in the final weld.

The benefit for your shop? With metal-core wire, you gain the potential for welding more efficiently using a MIG welding process by reducing quality issues and minimizing rework.

These benefits, however, do not come without a price. On average, metal-cored wire costs more per pound than other types of filler metals. Still, they can yield productivity increases that help you negate that upfront cost. And as a shop owner, metal-cored wires may also offer you the opportunity to improve your cost margins and revenue compared to many other types of filler metals.

Reducing the Non-Value Added Activities In Your Shop

One of the best ways to help you justify a process change to metal-cored wires is by assessing the non-valued added activities in your welding operation. Non-value added activities include grinding, sandblasting, applying anti-spatter, or any of those tasks that do not directly contribute to the company’s productivity.

These types of activities are very typical in many welding operations; however, they are often completed to compensate for deficiencies in the MIG welding process.

They can also hinder productivity by causing bottlenecks in the workflow.

Metal-cored wires are capable of welding through mill scale, dirt, oil, grease, and other debris while still producing quality welds, which eliminates the need to grind materials before sending them to the weld cell.

And, because the wires produce little to no spatter, they eliminate the need for pre-weld anti-spatter application or post-weld grinding, too. As mentioned previously, they also offer faster travel speeds than other wires and higher deposition rates.

The benefits of metal-cored wire features are threefold. One, you can gain greater productivity through faster welding. Two, you can add to that productivity by eliminating unnecessary steps in the pre-and post-weld areas. And, three, you can reallocate labor from those areas to other portions of the welding operation that contribute directly to the company’s throughput.

Quantify the potential improvements metal-cored wires can provide by monitoring their current welding process and assessing the time and cost of their non-value added activities.

First, you should quantify how much time you spend on grinding or other such pre-weld activities, along with the amount and cost of the labor necessary to complete them. Remember to factor in the cost and time for maintaining, repairing or replacing grinding or sandblasting equipment, too.

Likewise, if you use anti-spatter, calculate the cost for purchasing the solution, the labor necessary for applying it, and the time and labor needed to clean the area. In the post-weld area, quantify the labor and time that you need for grinding spatter and/or reworking rejected parts, along with the associated costs. Consider if and where you could reallocate labor from the pre and post-weld areas to other areas of production (upstream or downstream) if they reduced the volume of non-value added activities.

Lastly, consider the possible improvements that would occur in the welding cell by converting to metal-cored wire. Remember, metal-cored wire can increase welding time and overall productivity.

Applications For Metal-Cored Wires

You might have a variety of jobs that are good candidates for metal-cored wire. Typically, those operations that weld materials 3/16 inch thick and greater, or those who weld material with mill scale can achieve the greatest benefits from metal-cored wire.

This includes welders in the heavy equipment and agricultural equipment manufacturing markets, as well as those in heavy trailer manufacturing, railcar fabrication, and automotive, chassis and wheel manufacturing.

Metal-cored wire usually can be alloyed to meet most types of steel found in these industries, from mild and stainless to low alloy.

Welding jobs that require flat, horizontal and vertical down-welding positions are good candidates, too. Metal-cored wire can be used for overhead and vertical up-welding if your welder uses a pulsing power source and high-argon shielding gas mixtures (75 percent minimum). Doing so, however, is slower than in other weld positions. You need to determine whether the benefits of metal-cored wire can make up for that slowness, or if another product would be better suited for your overhead welding applications.

Applications using high-strength steels — 80 to 100 KSI — may also benefit from metal-cored wires. Again, these wires can be readily alloyed to meet the chemical and mechanical strength of those materials. Often, they are also less expensive for these applications. Even though lower-strength metal-cored wires (70 KSI) are more expensive than similar strength solid wires, higher-strength metal-cored wires tend to be less. These savings are particularly true for 90- and 100-KSI metal-cored wires.

Metal Cored Dual Shield Wire Vs. Self Shielded Flux-Cored Wire

Metal-cored wire and flux-cored wire are available in same diameters, and look pretty much the same. Right? Well, they actually have one major difference.

Self-shielded flux-cored wire don’t require a shielding gas while metal-cored wire does. But, the biggest weld improvement difference between the two is that metal-cored wire produces less spatter and requires less time cleaning welds. You can learn more about self-shielded wires and MIG wires in our article here.

Both flux core arc welding and metal cored wire welding produce high deposition weld metal, but flux core arc welding produces deeper penetration. Both of these wires contain alloy compositions in their cores so they can be used to weld special alloy steels.

Metal-cored wire offers lower pre and post weld cleanup so that’s the primary way the metal-cored wire impact can be felt in your shop. Plus, it will minimize weld defects related to arc instability and spatter.

Conclusion

Metal-cored wire is a tubular wire filled with alloying compositions and beneficial compounds like arc stabilizers. It’s slightly more efficient than flux-cored wire because metal-cored wire doesn’t contain any slag creating elements, which allows more weld metal to be deposited in the weld pool. MIG welding in flat or horizontal position has never been easier thank to less post weld cleaning.