Selecting the MIG gun that is the best match for your welding application, and maintaining it properly, is just as important to productivity as any other part of the welding operation.

Unfortunately, MIG guns very often are overlooked as part of the welding system.

In reality, however, as well as being responsible for delivering the current, wire, and shielding gas flow to the weld puddle, your MIG gun can have a significant impact on weld quality and bottom-line costs.

Therefore, we made this article about MIG gun maintenance, but we will also help you choose the MIG torch for selected welding process needs.

Choosing The Right MIG Gun

MIG Gun Rated Amperage

We’re all tempted by the “bigger is better” philosophy, and it is often overlooked when it comes to purchasing a MIG gun. But, thinking that way can make you spend more money than is necessary for this equipment, and it can also to costly downtime.

It is tempting to conclude that a welding procedure requiring 400 amps, for example, also requires a 400-amp MIG gun capable of operating at the duty cycle of 100%, meaning there is no downtime, or you don’t have to wait for a cooldown.

The reality is you will spend time moving parts, grinding, tacking, and completing other tasks. So as a result, you will not be welding nonstop, so the 100% duty cycle is not fully utilized.

Knowing this, you can very often purchase a smaller amperage MIG welding torch, so a 300-amp model would suffice for applications in which the MIG welder duty cycle is less than 100% (e.g., 60%) for less money, and still have it operate at the appropriate capacity.

A smaller, lower-amperage MIG gun also weighs less. That way, you can reduce wrist fatigue which could lead to downtime. Smaller torches are also easier to maneuver, which can help to improve weld quality and lessen rework.

Power Cable Length

When it’s possible, shorter power cables on a MIG gun can minimize costs and downtime, as well. As a rule of thumb, shorter cables are less expensive and, like a smaller MIG gun, offer better maneuverability. Shorter power cables also help to minimize wire-feeding problems that result from kinking and coiling. Therefore, you can spend more time welding and less time resolving these issues.

Here are other points to remember about choosing a MIG gun:

- Select MIG guns with rigid strain relief, which helps minimize kinking which can impact smooth wire feed, and cause an unstable arc, and poor weld quality.

- MIG guns are available with a variety of trigger options, such as standard, locking, dual schedule, etc. Choosing one might be a result of personal preferences.

- Look for sturdy triggers that will withstand work site abuse and that can be easily replaced. Doing so can minimize downtime for maintenance and repairs.

- Find the right neck for your application. Manufacturers offer fixed, rotating, and flexible necks of various lengths and angles. Therefore selecting the right one for your MIG welding application makes it easier to weld, and can help you get your repairs done more quickly and easily. Look for a neck with good protection that may cause electrical shorts or premature failure.

- Consider using the smallest handle that can meet the amperage needs of the selected welding projects. Smaller handles are easier to maneuver and can reduce hand fatigue. Some manufacturers also offer ventilated handles that help to reduce heat and make it more comfortable to use for longer periods of time.

MIG Gun Maintenance Tips

Inspecting your MIG gun regularly can significantly reduce costs and help you achieve good welding performance. Fortunately, preventive maintenance (PM) for a MIG gun often is not time-consuming or difficult. Here are some guidelines you can follow when inspecting your MIG torch.

Check The Feeding Wire Connection

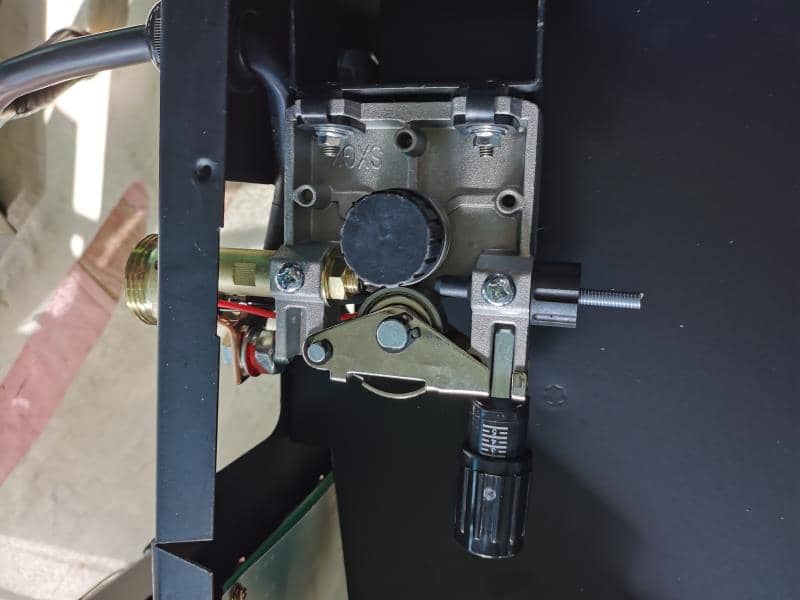

Regularly check the wire feeder connection or the place where the power pin plugs into the feeder. That way, you can be certain it is tightened properly and that there is no dirt or debris on it. Loose or dirty wire feeder connections can cause a heat build-up, leading to voltage drops that can affect the characteristics of the welding arc and may cause premature gun failure.

To obtain a secure fit, you should tighten the connection according to the manufacturer’s specifications. In addition, replace the direct plug if necessary.

Also, inspect the O-rings for cracks, as it might lead to gas leaks. Gas leaks often cause spatter and porosity, which increases downtime for cleanup and rework.

Properly Care For MIG Gun Liner

During the welding, it is not uncommon for the MIG gun liner to clog with debris, particularly from the MIG welding wire.

Over time, this accumulation can lead to poor wire feeding, bird nesting, and burn-backs regardless of the wire feed speed.

You can use compressed air to maintain and clear your liner from potential blockages when you change wires.

Also, track the time for your liner to wear can help you determent when to replace the next before problems develop. Always follow the manufacturer’s recommendation for trimming and installing the liner or any other welding equipment to prevent kinking and wire feeding problems.

Inspect The Torch Handle And Trigger Integrity

Typically, torch handle and trigger require little maintenance beyond visual inspection. That’s why you should regularly check for cracks on the handle or missing screws. Check that the MIG gun trigger is not sticking or otherwise malfunctioning. Replace these components of MIG torch or MIG welders as necessary.

Check The Neck Of The MIG Gun

Loose connections at end of the neck can cause electrical resistance that leads to poor weld quality and/or MIG wire consumable failures. That’s why you should always ensure tight neck connections.

Also, visually inspect the insulators on your MIG gun neck, and replace them if they show damage. These insulators prevent electrically live components from exposure, ensuring your safety and the longevity of your welding equipment and welding machine.

Inspect The Power Cable

Power supply cable maintenance is essential in eliminating unnecessary equipment welding costs. That’s why you should regularly inspect the welding cable for damage, including cuts or kinks, and replace it as necessary.

Remember that cuts in the cable can expose the copper wire, resulting in a potential shock hazard. Kinking of gas hose might obstruct gas flow and can cause wire feed issues. The latter can lead to weld defects and arc instability that require downtime to remedy.

Don’t Forget Welding Consumables

Frequently inspect your MIG gun nozzle and contact tip for signs of spatter buildup. Spatter can obstruct shielding gas flow and cause weld defects that will need to be reworked, therefore, more post-weld treatment. Spatter build-up can also wear consumables, causing them to fail prematurely and reduce contact tip life. If spatter build-up appears, replace consumables or clean them according to the manufacturer’s recommendation where a wire brush can help.

Also, be certain that the gas diffuser or gas nozzle is connected securely and choose the correct contact tip size. Loose connections can increase electrical resistance, which in turn leads to poor welding performance and can shorten the life of your consumables.

Final Thoughts

Just like the MIG welder settings and wire feeder, your MIG gun can impact your weld quality, productivity, and costs. Taking the time to select the proper MIG gun and contact tip, and maintain it regularly, can help this equipment last longer and ensure that you spend more time welding instead of resolving problems.

While robotic MIG guns look different, they have the same fundamentals. Therefore, maintenance includes inspecting contact tips, gas coverage, tip wear, tight connections, and many more.