When appropriately used, oxy-fuel welding and cutting equipment is safe, and you don’t need extra protection. Of course, there is no substitute for training and diligence among welders that utilize oxy-fuel equipment, but the use of flashback arrestors provides an additional safety net.

Welding safety equipment and awareness have flourished for the last several years as manufacturers increased efforts to promote safety and educate workers.

This article will discuss oxyfuel welding safety, covering the common issues with flashbacks and backfire and the ways to prevent them.

Importance of Oxyfuel Welding Safety

The manufacturers of oxy-fuel welding, cutting, and heating systems have also raised awareness of safety issues related to their equipment. This positive trend continues even today. However, even a piece of adequate safety equipment, if misused, can create hazardous conditions, which increase the risk of accidents and/or injury.

Years of field experience have shown that, when appropriately used, oxy-fuel torches are safe and reliable without accessory safety devices such as check valves and flash arrestors. That said, we must emphasize that it takes the user’s training and diligence to operate oxy-fuel welding equipment safely.

In today’s fast-paced workplace, it is easy to skip certain safety practices, such as purging hose lines or ensuring that all gas passages are clear and free of dirt, oil, and debris.

Realizing this, most manufacturers will, at a minimum, install check valves on torches, and some are making check valves and flash arrestors integral to the torch. While this practice is good, manufacturers’ efforts to promote equipment safety can never replace the user’s responsibility to employ safe operating techniques.

Suppose a user neglects or ignores the manufacturer’s noted or published safety and maintenance suggestions. In that case, that person is an accident that might happen, and no accessory safety device will prevent all possible accidents. Most experts can unequivocally say that a huge number of oxy-fuel accidents are not caused by equipment malfunction but by user neglect, impatience, or lack of experience in the safe use of equipment.

Common Oxyfuel Welding Issues: Backfires, Sustained Backfires, and Flashbacks

Oxy-fuel welding, cutting, and heating torches are subject to three issues: backfires, sustained backfires, and flashbacks. Therefore, it is important to understand these terms and to be able to identify these reactions if they occur.

Unfortunately, manufacturers and distributors of oxy-fuel torches have not thoroughly explained to their customers exactly what these terms mean. The result is a general misunderstanding among end-users.

What Is A Backfire?

A backfire is the momentary retrogression of the flame into the torch tip. As a result, the user hears a “pop,” and the flame is extinguished. However, the flame may be reignited if an adjacent ignition source is present or if using a manual igniter is necessary.

Backfire is usually not a safety concern, and, in fact, many manufacturers induce backfires during design and production tests to ensure the flame integrity of torches and tips.

How Does Sustained Backfire Occur?

Sustained backfire occurs as the sustained burning of the flame back inside the torch, usually at the mixer, but could also happen further upstream under certain conditions. Sustained backfires often accompany a hissing or squealing sound and/or a smoky, sharp-pointed flame.

You should immediately close all torch valves to avoid damage or injury.

If a sustained backfire continues to burn without closing torch valves, severe damage to the torch can occur, and there is always an increased risk of fire.

Most sustained backfires can be contained inside the torch until the user can shut off the gas flow. There are, however, some torch designs with thin construction walls, where the flame can breach the wall and spew fire and molten metal in a short time.

Issues With a Flashback

A flashback is a momentary or sustained retrogression of the flame upstream of the mixer, usually in the torch or hoses. Flashback is a potentially dangerous situation, particularly if the flame reaches the hoses, where an explosion might occur, causing a rupture or separation of the hose. A flashback is caused by the reverse flow of gases upstream into the hoses or other equipment.

This reverse flow is usually the result of:

- improper shutdown and/or startup procedures;

- allowing cylinder pressures to become too low; or

- a check valve that is not working properly.

Flashback arrestors usually are adequate in preventing reverse flow flashbacks. However, they would not prevent a sustained backfire, nor were they intended to function that way.

What Are Flashback Arrestors?

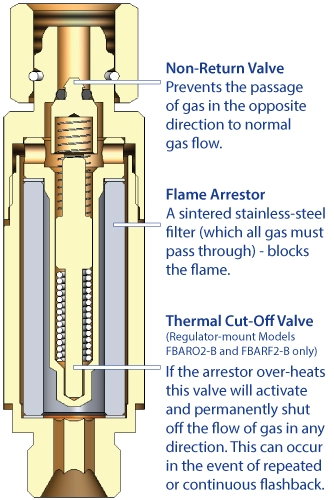

Flashback arrestors (FBAs) are standard safety devices that stop or restrain the progress of a flame front upstream of the insertion point. Probably 90 percent of all FBAs used on oxy-fuel welding, cutting, and heating torches are designs that have sintered stainless steel elements.

The remainder uses designs of coiled tubing to quench the heat associated with a flashback flame. These elements quench the flame front as it propagates back upstream toward the torch and/or regulator. However, remember that flashback arrestors are reliable if the device is used according to the manufacturer’s instructions.

There are two types of sintered element arrestors. One is mounted onto the outlet of gas flow regulators, and the other is mounted onto the inlet of torches. Regulator arrestors are typically larger and have a higher flow capacity than torch models because the sintered element has more surface area, allowing for more flow.

The sizes of torch mount arrestors are limited, so it doesn’t make the torch too unmanageable to handle. Torch arrestors are preferred because their location is ideal for preventing reverse flow flashbacks into the hoses.

Remember that if regulator mount arrestors are used, flashbacks can still occur in the hoses, with a high potential for injury. However, regulator mount arrestors are used when more increased gas flow is needed, and these will protect regulators and cylinders from the effects of flashback.

Issues With FBAs

Flashback arrestors can actually contribute to the likelihood of sustained backfires. Here’s how. Oxy-fuel gas mixers are designed to distribute appropriate oxygen and fuel gas volumes into a mixing passage or tip. In addition, a properly designed mixer will ensure adequate exit velocities of the mixed gas at the tip to prevent a sustained backfire.

This happens without incident when normal safety precautions are taken, and the pressures are set as the manufacturer recommends.

FBAs incorporating sintered elements create dramatic pressure drops across the sintered part and into the torch. This means pressures at the mixer are lower also. Unfortunately, lower pressures at the mixer mean lower exit velocities of the gas mixture at the tip or nozzle.

As a result, this could cause sustained backfire if the torch gets too close to the workpiece. Heavy heating applications are especially vulnerable to this event since heating tips use large volumes of gas and are highly susceptible to backfires, which could become sustained if mixer pressures are too low.

How To Avoid Sustained Backfires In Oxyfuel Welding And Cutting

One way to avoid the hazards associated with sustained backfires is to compensate for the pressure drop using flashback arrestors. Most arrestor manufacturers supply pressure drop charts. These charts should be closely followed when setting pressures in systems using flashback arrestors.

The charts are read as follows:

- Determine the flow rate and the recommended pressure based on the tip or nozzle used (this can be obtained by contacting the manufacturer or through the manufacturer’s literature).

- Since most charts use air or nitrogen as a test gas, correct the flow rates for the density of the actual gas used (i.e., oxygen and acetylene, propane, natural gas, etc.).

- Find the expected pressure drop on the chart at a given flow rate and pressure.

If these pressure drop charts are adhered to by end-users, this will ensure that adequate pressures are maintained at the tip and decrease the likelihood of sustained backfires. There are, however, some heavy heating applications where the flows are so high that it would be impractical to use torch mount flashback arrestors.

For example, some heavy heating tips require up to 1600 SCFH oxygen and 400 scfh propane. The pressure drops would be so dramatic on these tips that torch-mounted arrestors should not be used. Instead, high flow regulator and mount arrestors should be used, ensuring that the appropriate pressures are compensated for delivering adequate flows to the tip.

Final Thoughts on Oxyfuel Welding and Cutting Safety

In summary, you should always follow the manufacturer’s recommended safety and maintenance procedures. No one knows more about operating and maintaining the equipment than the manufacturer. Also, do not think that an accessory safety device makes the equipment immune from accidents—a false sense of security and lead to carelessness.

Finally, be extremely careful with flashback arrestors in heavy heating applications. If used, it is essential that the arrestor be a high flow model, probably a regulator mount, and that the appropriate pressure compensation charts are followed. This should result in safe and accident-free use of your oxy-fuel equipment.