Automated welding systems add speed, accuracy, and repeatability to the welding operation. They can also help companies increase their productivity and reduce costs in a relatively short period of time. However, obtaining such benefits and realizing a quick return on investment (ROI) aren’t matters of chance. They’re the result of careful equipment selection, system integration, and training. Peripherals can also help.

Peripheral robotic welding equipment refers to the additional equipment integrated into the automated welding system to maximize its performance. When selected and appropriately implemented, peripherals can provide a more efficient throughput and minimize unnecessary downtime.

To help clarify the role of this equipment, as well as the benefits of using peripherals, the following are answers to several frequently asked questions.

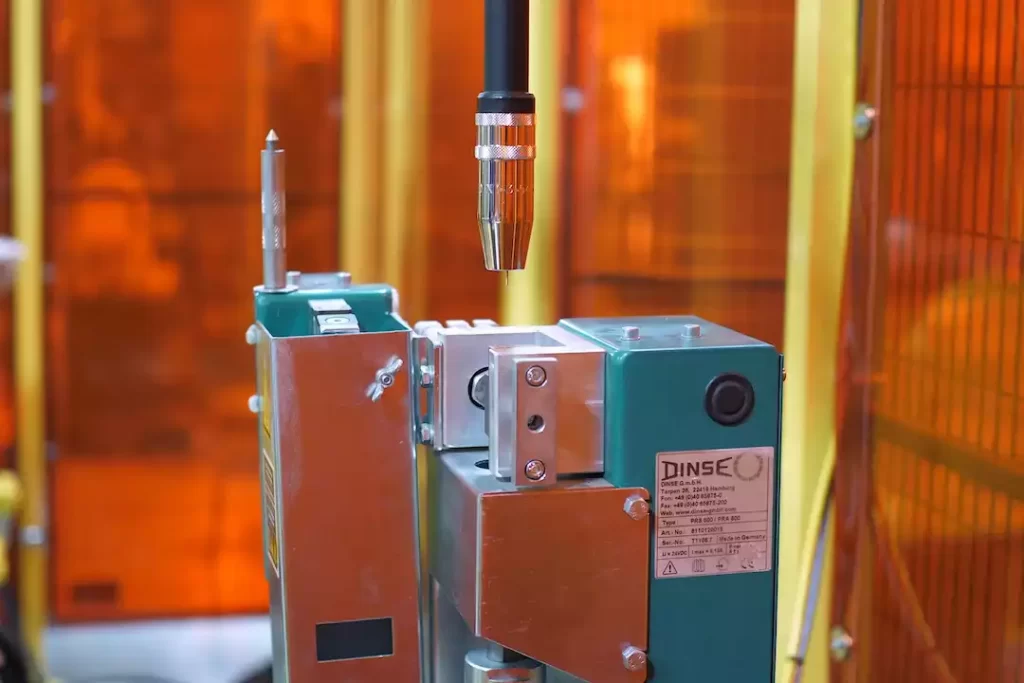

Why Is A Nozzle Cleaning Station Important?

A nozzle cleaning station (also called a reamer) cleans spatter inside of the welding consumables on the front end of the MIG welding gun, including nozzles, contact tips, and retaining heads. There are several benefits a nozzle cleaning station can offer.

First, by keeping the nozzle clean, this equipment helps reduce the risk of losing shielding gas coverage that could potentially lead to expensive rework.

Secondly, it helps lengthen the life of the consumables (nozzle, contact tip, and diffuser or retaining head) and the robotic MIG gun. Longer equipment life translates into less downtime and less equipment cost — both factors that contribute positively to a company’s ROI of its automated welding system.

What’s the benefit of adding an anti-spatter sprayer to a nozzle cleaning station?

An anti-spatter compound (typically in liquid form) can provide additional protection to consumables. A sprayer applies the anti-spatter blend to the front-end consumables after cleaning them. In many cases, the sprayer can be mounted on the nozzle cleaning station, integrating it into the overall process of nozzle cleaning.

Recall that the rule of “less is more” applies. Excessive anti-spatter usage can lead to unnecessary costs and the compound may build up on the nozzle, the welding robot and the parts being welded. In the long term, a high spray volume could cause additional problems that are just as harmful as spatter build-up itself.

The What-Where-Why of Wire Peripheral Robotic Welding Equipment

How Can A Wire Cutter Help The Operation?

Many robotic welding applications require consistent welding wire stick-out (also called electrode extension) when the arc initiates. A wire cutter can help maintain that consistency.

As its name implies, a wire cutter cuts the welding wire to a specified length, and it also removes any inconsistencies at the end of the wire, resulting in more reliable and smoother arc starts. For companies that program their robot to seam track (or find the joint) through touch sensing, the consistent wire stick-out allows for more reliable and repeatable welds by helping the robot more easily locate the correct spot to begin welding.

Most wire cutters are capable of cutting different types of welding wire, including stainless steel, flux-cored, and metal-cored, usually up to a 1/16-inch diameter. Companies may prefer to mount the wire cutter on a nozzle station or locate it remotely, according to their needs.

How Do Neck Inspection Fixtures Work?

This peripheral verifies that the robotic MIG gun’s neck is set to the intended tool center point (TCP), allowing it to be readjusted after a collision or if the neck becomes bent due to routine welding. Most inspection fixtures will accommodate standard necks for a particular brand of robotic gun.

After determining the tolerances for the program, a trained welding operator simply adjusts the neck to meet the correct specifications. This adjustment helps prevent costly rework due to missing weld joints and can help prevent the downtime to reprogram the robot to meet the welding specifications with the existing bent neck.

For companies that maintain a large number of robots, a neck inspection fixture can also help prevent confusion when exchanging necks from one robotic MIG gun to another. Welding operators simply remove a bent neck, exchange it with a spare that has already been inspected and adjusted, and put the robot back in service immediately. The damaged neck can then be set aside for inspection while the robot is still online.

Safeguarding Robotic Welders

Although robotic welders are one of the most expensive pieces of equipment on a plant floor, welder manufacturers may ignore the safeguarding needs. Safeguarding should compile with Occupational Safety & Health Administration (OSHA) regulations and American National Standards Institute (ANSI) standards. Usually, ignoring regulation represents a challenge and danger for any manufacturer deploying robotic welders.

Collision Protection For Robots

It can happen again and again that the welding robot collides somewhere while moving fast, and the torch neck is affected, meaning it can be deformed. If the front end of the welding torch is then, for example, 10 mm to the side, all welding seams are also offset by 10 mm if the damage is not noticed immediately.

Depending on the type of collision detection, the particular robot manufacturer can provide either a shock sensor or a safety clutch protection.

In addition, a solid mounting arm can be used in cases where collision detection is integral to the robot.

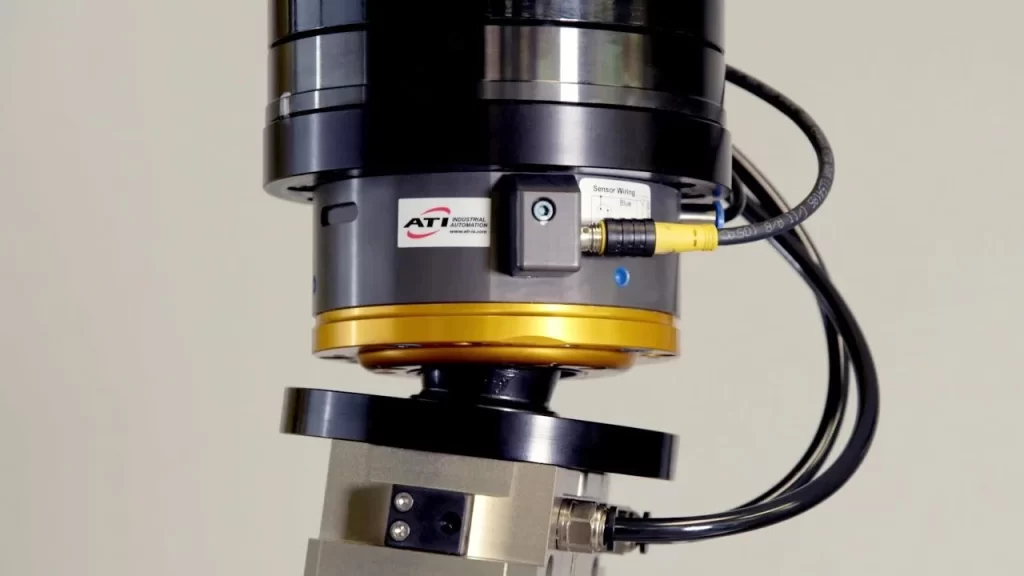

Use of Clutch in Collision Protection

The sensitivity of a clutch or shock sensor can be calibrated to accommodate the robotic welding gun’s mass and moment of inertia. The clutch has both mechanical and electrical functions. The clutch first recognizes the physical impact, which sends an electrical signal back to the robot controller, causing the system to stop. That way, the clutch prevents damage to the robot and the robotic gun and also alerts the welding operator overseeing the operation.

Collision Detection Software

Some robotic systems can monitor current rates and/or torque via robot collision detection software. As a result, the software stops the robot in the event of an impact. A solid arm mount would be used instead of a clutch in this situation. As its name implies, a solid arm mount is solid. However, it does not provide electrical feedback but relies on the software to stop the robot during an impact.

Mounting Arms

Both clutches and solid arm mounts require mounting arms that attach to the robotic MIG gun. A mounting component generally comprises a durable aluminum alloy that can resist breaking during an impact. Its purpose is to hold the mechanical MIG gun in a specified position (even after a welding operator replaces the torch), so the robot can repeat the same weld throughout the welding process.

Clutches and solid arm mounts are also quite robust and require little to no maintenance. However, if a company feels that maintenance or repairs are necessary for one of these peripherals, maintenance personnel should contact their welding distributor, integrator, or robotic equipment manufacturer for advice.