The pulsed TIG welding is a feature available on high-end TIG welders. It’s meant to improve weld penetration while lowering the heat input.

But, there are many welding applications where pulse welding has an advantage. In this article, you’ll learn what pulse TIG welding is, how it works, how to set it up, which frequency to use and when.

What are Pulse TIG Welding and pulse frequency?

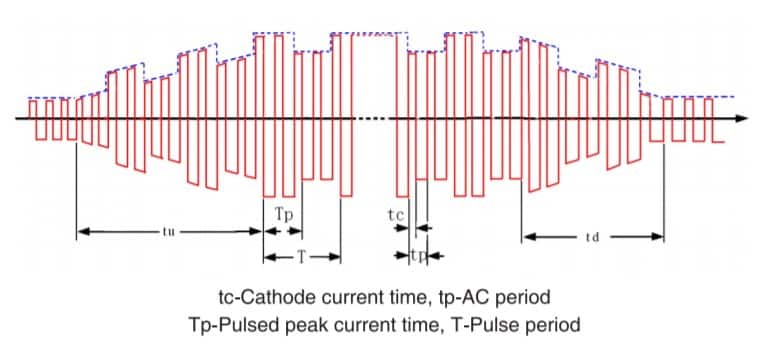

The pulse TIG welding process varies the amperage output while welding. The waveform is not straight but has higher and lower amperage values.

By setting the maximum amperage output and the low, background amperage, the TIG welder outputs an alternating current between the two at a set pulse frequency. As a result, you get numerous benefits and drastically improved productivity in some cases.

The pulse frequency determines how many pulses per second the welder outputs. Each pulse is a period of one maximum and minimum amperage output. So, 1Hz outputs one pulse per second (one high and one low amperage output), while 100Hz, for example, outputs 100 pulses per second.

Some TIG welders allow modifying the portion of low and high currents per pulse. For example, a single pulse can output maximum amperage of 25% of the duration of that pulse and minimum amperage for the remaining 75%.

So, if using 1Hz (one pulse per second), 0.25s would have maximum set amperage and 0.75s minimum.

Benefits of Pulse TIG Welding Process

It isn’t easy to name all pulsed waveform benefits without leaving any out. But let’s discuss some essential ways pulse TIG welding can improve your workflow.

Controlling the Heat Input And Welding On Thin Sheet Metals

Pulse TIG is the most efficient way of controlling the heat input and the heat-affected zone, especially for sensitive stainless steel or other thin sheet metal plates. By reducing the time of maximum amperage exposure, you’ll prevent warping, burn-through, discoloration, and impairing corrosion resistance properties of stainless steel.

Additionally, by optimizing the feeding of filler metal in rhythm with the pulse, you can reduce the volume of added metal. This prevents unnecessary filler metal buildup and heat input.

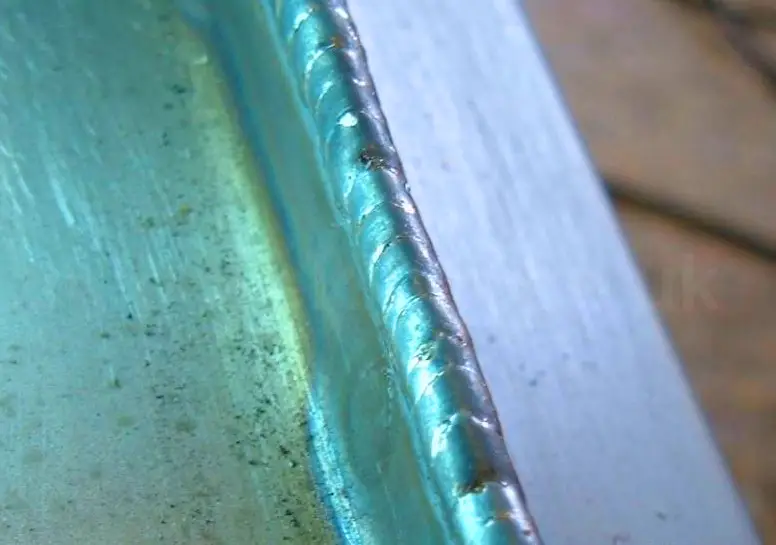

Smooth Welds And Smooth Bead Profile

TIG welding with pulse lets you moderate the amount of added filler metal and achieve smooth-looking TIG welds. Additionally, by varying the pulse frequency, you can increase or decrease the distance between the “dimes.”

Setting a pulse frequency high, like 500 pulses per second, results in extremely smooth welds that resemble a homogeneous mass. Of course, this does depend on how you dab the filler rod. But as a rule of thumb, the higher the frequency, the smoother the bead profile.

Another added benefit is that pulse welding helps you create a rhythm as you weld. This is especially helpful when walking the cup or performing long repetitive welds. You’ll synchronize better and achieve higher quality welds by following the pulse frequency with hand movements and filler rod addition.

Out Of Position Welding

Welding out of position often has gravity working against you.

So, to prevent the liquid puddle from falling down on you, you can use pulse welding to reduce the heat input and keep the puddle less liquid.

By managing your travel speed and tuning the right pulse frequency setting, you can significantly improve the overhead TIG welding experience.

Weld Agitation Improves Joint Quality

The pulse welding results in a small ripple effect, especially if you let it run a bit hotter. The more liquid the puddle, the better ripple effect the pulse welding provides. So, this is not the best for overhead welding, but in position, welds benefit greatly.

The weld agitation helps pull out contaminants in the weld and disrupt surface tension. Of course, pulse TIG welding doesn’t create weld agitation on a level like a TIP TIG process or similar advanced industrial processes. However, this little action is beneficial and helps achieve a perfect weld.

Edge Welds

Creating corner or edge welds is challenging, especially if joining thin sheet metal. As you start welding, the edge starts melting away, forcing you to maintain its shape with a filler metal.

However, using a pulse TIG lets you lower heat and create a smooth edge weld.

The higher the pulse TIG settings, the faster the welding speed and the smoother the joint surface.

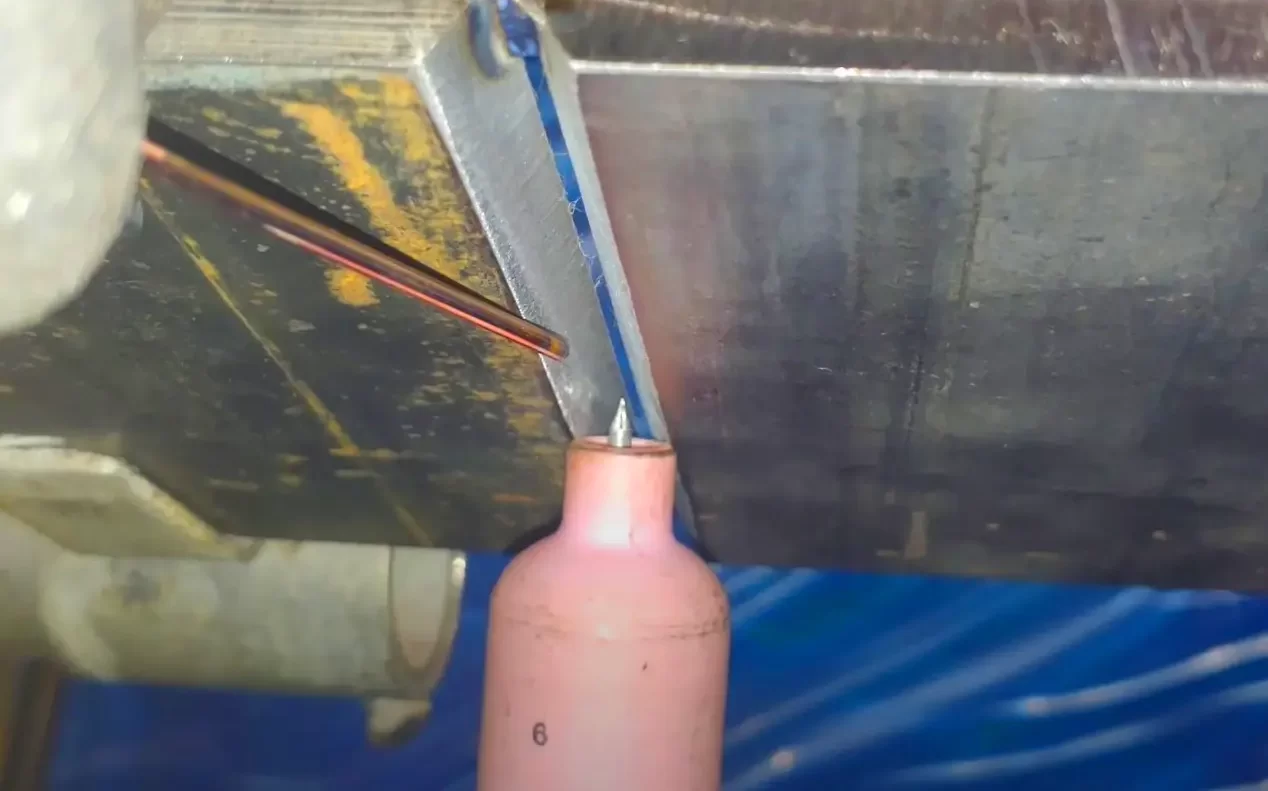

Welding In Tight Spots

If you are welding in a tight area where the TIG torch can barely glide along the weld and have minimal control over the rod, the pulse TIG can improve your chance of success.

With a steady hand on the welding torch and even placement of added metal, you can achieve a good TIG weld even in particularly tight spots. That’s why pulsing is so versatile. It provides a broader window before you burn through since it outputs less power and lets you weld at high speed if necessary.

The Challenge of Pulsed TIG Welding

Pulse TIG welding is notoriously difficult. It takes a skillful hand and an experienced welder to guide a pulsing torch along the joint, especially when adding a filler wire.

Pulse welding is not for beginners. You should first master the standard TIG welding process before attempting to pulse TIG weld. However, if you want to experience something similar to pulse welding, you can use your TIG foot pedal to “pulse” at a 1Hz frequency by pressing and releasing it at a rate of one cycle per second. That’s an excellent way to get started with pulse welding without getting a pulse-capable welder.

Don’t be discouraged if you attempt to use an actual pulse welding process and fail. Even professional TIG welders need some time to figure out how to apply pulsed arc properly.

Another challenge is tuning the pulsed settings and incorporating the arc in your welding techniques.

A high-speed pulse behaves very differently than a basic 1Hz pulse. So, to lay a nice stack of beads and increase productivity by pulsing arc, it takes tinkering with the machine and figuring out the correct settings.

What Pulse Settings To Use?

You can try our suggested pulse settings below if you need some guidance. However, keep in mind that these vary a lot by application! So, don’t try pulse welding on an important part that you cannot replace because you will make mistakes at first!

Pulse TIG Welding Mild Steel

Welding mild steel with a pulse is not recommended. It can lead to increased oxidation and brittle welds. As a result, the welds will have a higher chance of cracking and developing rust.

Still, if you really want to experiment, I suggest starting with a 1Hz frequency and less than 30% of heat difference between the upper and lower limit of power output. Please don’t pulse weld structural steel or anything that may jeopardize you or others unless you are a professional and the weld will undergo a strict inspection process.

Pulse TIG welding Stainless Steel

Welding stainless steel is a whole different story. The pulse welding process significantly improves welding efficiency and the production quality of stainless steel welds.

Stainless steel rapidly loses corrosion resistance as it gets overheated. Excess heat in the heat-affected zone concentrates carbon, which gets trapped as the metal cools down. This defeats the purpose because stainless steel is typically used in applications where corrosion resistance is central.

So, pulsed TIG welds are paramount to perfect stainless steel joints. The higher the frequency, the better the weld. The increased puddle agitation produces a better molecular grain structure and, consequently, a stronger weld.

But most importantly, a high-speed pulse constricts the arc and provides deeper penetration while narrowing the heat-affected zone. I suggest trying the frequencies in the range of 30 – 500 pulses per second. Depending on the thickness and the desired resulting bead appearance, you should find a sweet spot in between.

As for the difference between peak amperage and background current, I wouldn’t throttle the current below 50% of the peak current level.

Pulse Welding Aluminum

TIG pulsing aluminum is challenging. This metal requires high heat input because it dissipates heat quickly. So, lowering the heat input with background amperage is beneficial only when welding thin gauges. Otherwise, you may not achieve the necessary penetration.

Pulse welding is especially useful when welding corner joints on aluminum.

Plus, if you don’t use filler wire, the pulse setting of about 1.5-2Hz frequency can stack dimes nicely, and it doesn’t require any clean-up.

Higher pulses per the second number slow down your welding speed, which is a good thing for some applications. Welding aluminum requires a fast travel speed to prevent burn-through because the base metal underneath the oxide layer melts at a low temperature compared to the oxide.

Conclusion

Pulse TIG welding is beneficial in numerous situations, but it’s definitely not required to learn. Professionals benefit from pulse welding techniques if they want to push their welding quality to extremes. However, pulse welding will increase the productivity of the welding shop, especially when welding stainless steel.

Avoiding costly rework if the operator accidentally overheated the stainless steel part and impaired corrosion resistance saves resources. So, for professionals, pulse welding is often more about productivity than improved weld quality.

Sources:

- https://www.r-techwelding.co.uk/news/welding-talk-to-pulse-or-not-to-pulse-is-that-your-question/

- https://unimig.com.au/pulse-or-no-pulse-when-and-why-you-should-pulse-weld/

- https://www.millerwelds.com/resources/article-library/new-inverterbased-pulsed-mig-and-tig-welding-technology-reduces-sheet-metal-welding-costs-increases-productivity

- https://jattus.com/what-is-pulse-welding-and-what-do-you-use-it-for