Silver is a relatively soft, shiny metal. It tarnishes slowly in the air as sulfur compounds react with the surface forming black silver sulfide. Sterling silver contains 92.5% silver, while the rest is copper or other metal. It is used for jewelry and silver tableware, where appearance is essential.

However, silver is most commonly joined by silver brazing due to mechanical properties. In this article, we will discuss the essentials of the silver brazing process, brazing methods, silver brazing alloys, and potential difficulties.

About Silver Brazing

Silver brazing is a joining process where a non-ferrous filler metal, also referred to as the alloy, is heated to melting temperature (above 800°F). Molten filler metals start to flow between two or more close-fitting parts by capillary attraction.

As a rule of thumb, the higher the silver content is, the higher the melting point and vice versa. So, for example, a silver braze alloy with 50% silver would melt at over 1200 F, but a solder with a 5% silver content might melt at around 500 F less.

Once filler reaches melting temperature, the molten filler metal interacts with a thin layer of the base metal. As a result, silver brazing produces strong, sealed joints due to grain structure interaction. Additionally, silver brazing produces joints that meet mechanical performance specifications, electrical conductivity, pressure tightness, corrosion resistance, and service temperature.

Silver Brazing Vs Silver Soldering

The terms silver brazing and silver soldering are often used interchangeably. Knowing the fundamentals of both metal joining operations, they seem pretty much the same.

Silver solder is commonly used in jewelry, copper, and brass, but it is weaker compared to silver braze due to the lower melting temperatures of soldering alloys. Meanwhile, while brazing is the same as soldering, the silver brazed joint is usually stronger due to the higher melting temperature of the alloy.

Fundamentally, the point of both welding techniques is to reach the temperature to make filler metals flow but not to interfere with the mechanical properties of the base metals.

Please check out our comprehensive article if you want to know the general differences between brazing, soldering, and welding.

Safety Precautions and Potential Hazards

Remember that cadmium oxide fumes formed by heating and melting silver brazing alloys are highly toxic. To prevent injury and exposure, you should always wear personal protective equipment. In addition, you should always braze silver in the well-ventilated area.

Additionally, extreme care must be used to grind all cadmium surfaces. Surfaces other than cadmium plating can be easily cleaned mechanically, but otherwise, chemical solutions are a better choice.

Silver Brazing Techique and Tips

To successfully employ a silver brazing operation, you should follow a couple of tips and steps. Just like welding, brazing requires joint preparation and cleaning, selecting filler metal, applying flux, and eventually welding.

In specific situations, flux residues need to be cleaned after the brazing, but generally, there is little to no need for post-braze cleaning.

Surface preparation

To ensure the capillary attraction once filler metal flows, you will need to clean the joints and provide joint clearance.

Firstly, you will need to clean oils, paints, surface oxides, or castings from the parts you are about to join. You can clean the surface using an emery cloth, wire brush, or sandpaper, followed by an acetone wipe.

Next, you will need to ensure clearance and fitment. Even though different brazing alloys will require additional clearance, it ranges from 0.002 to 0.005 in. (0.051 to 0.127 mm) for the best filler metal distribution.

Soldering silver is commonly used on the edge & lap joint, while brazing is suitable for the butt, corner & tee joint.

Silver Brazing Rods

While there are many brazing rods on the market, the most common choice is a multi-purpose, silicon bronze brazing rod. This is a general-purpose brazing rod suitable for metals such as steel, copper, cast iron, and dissimilar metal combinations.

In addition, most silver alloys can be categorized by their silver content. As we mentioned initially, the silver content determines the fluidity and melting points ranging from 1145 to 1650ºF.

Most common silver rods contain 33% silver, 40% Silver, and 55% Silver, copper, and zinc are the rest of the composition.

Silver brazing rods often come in several different forms:

- Bare brazing filler: with this wire, you will have to use flux separately to ensure braze joint protection. You can coat bare wire by gently warming the end of the wire in your flame, then dipping it in the powder.

- Flux-coated: these rods are pre-coated, so you don’t need to do it yourself. However, these wires are usually more expensive, and the coating tends to fall off once you bend it.

- Flux-impregnated: in this case, the flux is in little nicks on the wire. This works very well, and the rods can be bent without the fear of defects. However, the flux impregnated wires are the most expensive of these three types.

Flux Choice

Flux chemically cleans the metal and keeps it clean during the Brazing process. Remember that the melting point of the flux must be lower than the melting point of the silver brazing alloys.

The base metal should be heated until the flux starts to melt along the joint line. However, you should apply more heat to parts with high heat conductivity. That way, it is much easier to clean areas protected by flux.

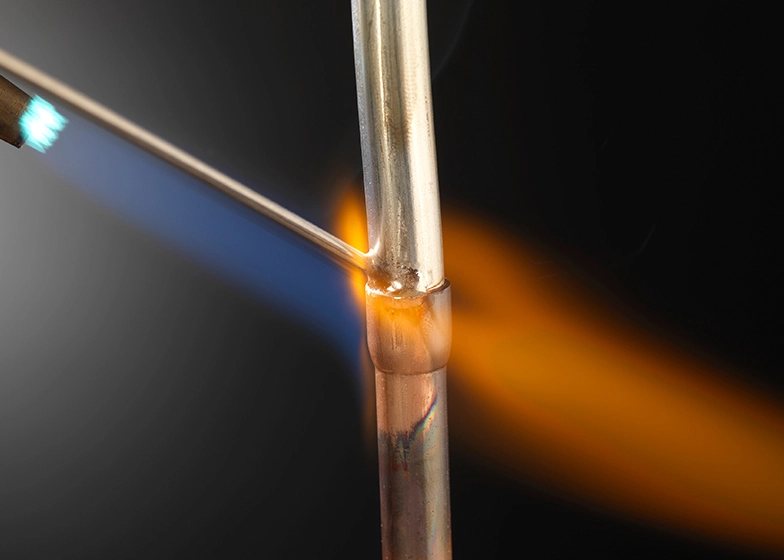

Silver Brazing Process

Once you have managed to clean and adequately fit up the parts, you are about to join and select filler metals and flux; it is time for the metal joining process.

You should use a slightly reducing/carburizing flame and keep the torch moving to avoid hot spots. Hot spots may cause the base metal to melt, which you are trying to avoid.

Try to heat an area opposite to where you add filler metal. This way, you will ensure the filler metal flows through the joint.

Silver Brazing Applications

Soldering and other brazing methods are a very versatile processes that most welders should master. The most significant advantage is that you can use it to join several different dissimilar metal combinations such as stainless to copper, bronze, brass, carbon steel, etc.

Silver brazing is often used to join carbide tooling inserts for machining operations.

The main reason is the fact low-temperature brazing process doesn’t affect the mechanical properties of ferrous metals or dissimilar metals. Additionally, you can use silver brazing to make a brass belt buckle with stainless steel hardware on the back size.

Remember that silver brazing is a cost-efficient metal joining method, so many smaller applications are suitable and preferred.