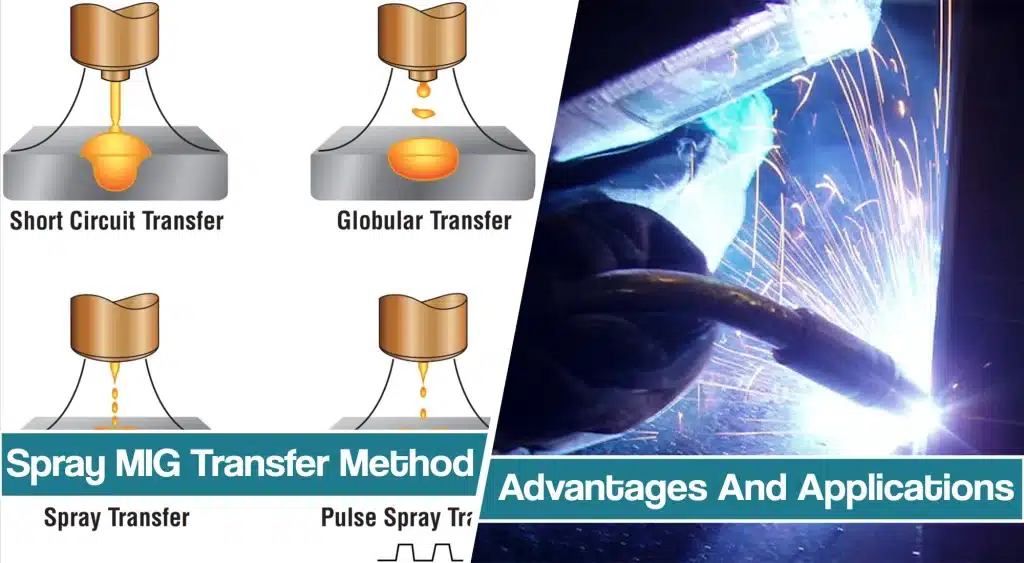

Spray transfer MIG welding is a highly efficient and versatile welding process that has revolutionized the metal fabrication industry.

Unlike other welding methods, spray transfer MIG welding utilizes a continuous stream of small molten droplets to join metal pieces together, resulting in stronger and cleaner welds.

In this article, we will delve into the intricacies of spray transfer MIG welding, exploring its principles, advantages, and applications. Whether you’re a seasoned welder or a curious beginner, this comprehensive guide will provide you with a clear understanding of this advanced welding technique, enabling you to tackle complex welding projects with confidence.

What is A Spray Transfer In MIG Welding?

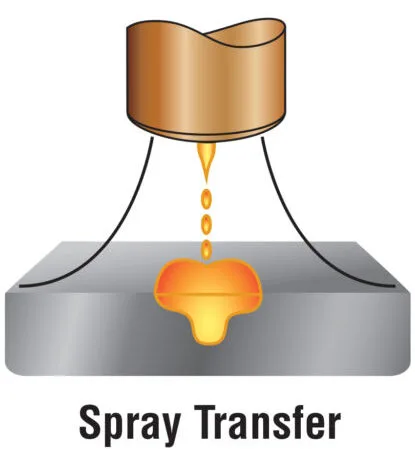

Spray transfer is one of the four main modes of metal transfer in MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW). It is a high-energy, controlled process that allows for efficient and precise fusion of metal components.

The spray transfer mode is characterized by the transfer of small molten droplets in a fine, controlled spray pattern.

These droplets are propelled across the arc, similar to a fine spray of water from a hose nozzle. The high velocity of the droplets allows them to bridge the gap between the electrode and the workpiece, resulting in a stable and continuous arc.

What Do You Need To Achieve Spray Arc Welding?

In spray transfer, the welding current is set relatively high, typically above 200 amperes. This high current causes the electrode to melt rapidly and results in the detachment of small molten droplets from the electrode tip. These droplets are propelled toward the weld pool at a high velocity due to the electromagnetic forces created by the welding current.

To achieve spray transfer, three key welding parameters must be present:

High Welding Current: Spray transfer requires a high current to ensure the continuous detachment of small droplets from the electrode tip. This high current generates sufficient heat to melt the electrode quickly and consistently.

High Wire Feed Speed: The wire feed speed must be set appropriately to ensure a consistent supply of welding wire. This helps in maintaining a stable arc and consistent droplet detachment.

Appropriate Shielding Gas: A shielding gas, such as argon or a shielding gas mixture of argon and carbon dioxide, is used to protect the molten metal from atmospheric contamination. The shielding gas flows through the welding gun and surrounds the arc and the weld pool, preventing oxidation and ensuring a clean weld. Additionally, proper shielding gas, such as CO2, can increase the welding pool fluidity, to get even higher speeds.

Advantages of Spray Transfer MIG

Spray weld transfer mode in MIG offers several advantages that make it a preferred choice for various applications. Here are some key advantages of spray transfer:

- High Deposition Rates: Spray transfer allows for high welding speeds and deposition rates. The continuous stream of small molten droplets ensures efficient material transfer, enabling welders to complete projects quickly and increase productivity.

- Superior Weld Quality: Spray transfer produces high-quality welds with excellent fusion and minimal defects. The controlled transfer of droplets results in a smooth and uniform weld bead, ensuring strong and durable joints.

- Deep Penetration: The high energy and heat input of spray transfer enable deep penetration into the base metal. This is particularly beneficial for thicker materials, allowing for robust welds and better joint integrity.

- Minimal Spatter: Compared to other metal transfer modes, spray transfer MIG welding generates minimal spatter. The small droplets are more easily controlled, reducing the amount of molten metal that splatters and adheres to surrounding surfaces, minimizing post-weld clean-up.

- Good Weld Pool Control: Spray transfer offers good control over the weld pool, allowing welders to manipulate the shape, size, and direction of the weld bead. This control is valuable for creating precise and aesthetically pleasing welds, as well as for welding in challenging positions or tight spaces.

- Versatility: Spray transfer can be used with a wide range of metals, including carbon steel, stainless steel, and aluminum. This versatility makes it suitable for diverse applications across industries such as automotive, construction, manufacturing, and aerospace.

- Reduced Heat Affected Zone (HAZ): The high welding speed and deep penetration of spray transfer result in a smaller heat-affected zone, minimizing distortion and preserving the mechanical properties of the base weld metal.

Applications Of Spray Transfer MIG

The applications of spray transfer MIG welding are extensive, including:

Structural Fabrication: Spray transfer is widely used in the fabrication of steel structures, such as bridges, buildings, and heavy machinery.

Its high deposition rates and strong welds make it efficient for large-scale projects.

Automotive Manufacturing: Spray transfer is commonly employed in automotive manufacturing for welding body panels, frames, exhaust systems, and other components. It provides high-quality welds with good strength and appearance.

Aerospace Industry: Spray transfer is utilized in the aerospace industry for welding critical components, such as aircraft frames, engine parts, and fuel tanks. Its ability to produce high-integrity welds is crucial for ensuring the safety and reliability of aircraft.

Pipe Welding: Spray transfer is often preferred for welding pipes due to its deep penetration and high-speed deposition. It is used in applications such as oil and gas pipelines, water distribution systems, and industrial piping.

Heavy Equipment Manufacturing: Spray transfer is suitable for welding heavy equipment, such as mining machinery, agricultural equipment, and construction machinery. It provides durable welds that can withstand the demanding conditions of these industries.

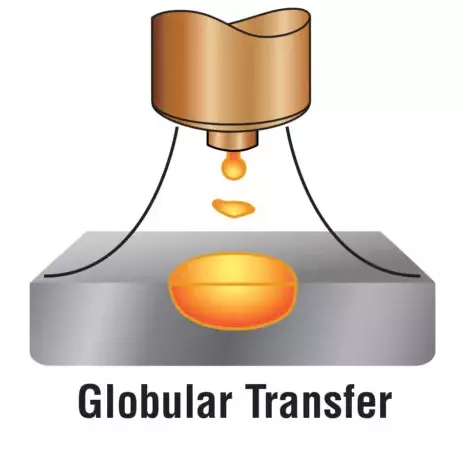

Spray Transfer VS Globular Transfer

Spray transfer involves the controlled transfer of small molten droplets from the electrode to the weld pool, while globular transfer involves larger droplets (larger than electrode wire diameter) that are transferred in a less controlled manner. Spray transfer is generally preferred over globular transfer in many applications due to its superior weld quality, higher productivity, and better control over the welding process.

While globular transfer can be useful for welding thick materials, it often produces more spatter and less control over the weld pool compared to spray transfer. Meanwhile, spray transfer offers advantages such as high deposition rates, excellent weld quality, deep penetration, minimal spatter, and higher versatility than just welding in flat and horizontal positions.

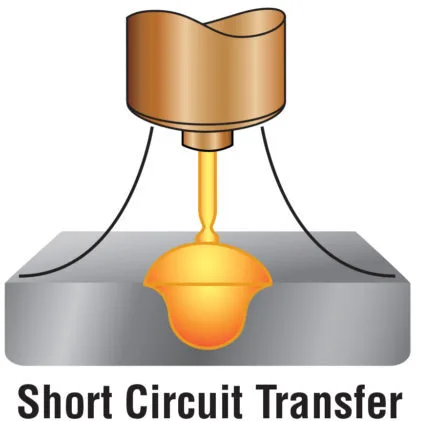

Spray Transfer Vs Short Circuit Transfer

Spray arc transfer involves the continuous transfer of small molten droplets, while short circuit transfer involves the periodic transfer of larger droplets.

While spray transfer offers higher productivity and better control, short-circuit transfer is preferred for thinner materials and situations where lower heat input and reduced distortion are desired.

A short-circuiting transfer is suitable for thin materials, provides better control over heat input, and generally produces less heat and distortion compared to spray transfer.

However, spray transfer is commonly employed in applications that require high-quality and high-strength welds.

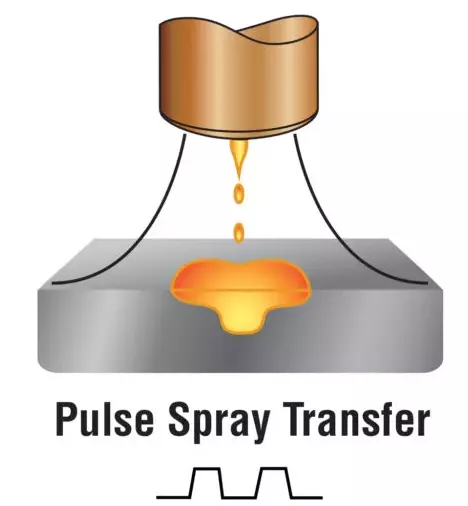

Spray Transfer Vs Pulsed Spray Transfer

The choice between spray transfer and pulsed spray welding transfer modes depends on factors such as material thickness, desired weld characteristics, required control over heat input, and specific project requirements.

Each mode has its strengths and considerations, and the welding process must be selected based on the specific needs of the application at hand.

While spray transfer is known for its high productivity and excellent weld quality, pulsed spray transfer offers advantages such as improved control over the heat-affected zone, reduced distortion, and enhanced weld bead appearance. It is often preferred for welding thinner materials, complex geometries, or when aesthetics are critical.

Pulsed spray transfer, on the other hand, involves the alternation between a higher current level (called the peak current) and a lower current level (known as the background current). This mode provides better control over heat input, reduces the risk of burn-through on thin materials, and allows for precise weld bead control.

Drawbacks of Spray Transfer MIG Weld

While spray transfer MIG welding offers several advantages, there are a few drawbacks associated with this welding process:

Higher Equipment Cost: Spray transfer MIG welding typically requires a higher-end power source capable of delivering the necessary high currents and pulse control. As a result, the initial equipment cost can be higher compared to other welding processes.

Limited Suitability for Thin Materials: Spray transfer is more suitable for thicker materials due to its high heat input and deep penetration. When working with thin materials, it can be challenging to control the heat and prevent burn-through or distortion.

Greater Sensitivity to Fit-Up: Spray transfer is more sensitive to joint fit-up and cleanliness compared to other welding modes. Imperfections in joint preparation or fit-up can result in porosity, lack of fusion, or other defects.

Increased Shielding Gas Consumption: The continuous spray of molten droplets requires a higher flow rate of shielding gas to protect the arc and molten weld pool adequately. This can lead to increased consumption of shielding gas compared to other transfer modes, adding to the operational costs.

Limited Welding Positions: Due to the higher heat input and molten droplet transfer, spray transfer MIG welding is more challenging to perform in certain welding positions, such as overhead or vertical-up. Special techniques or equipment may be required to achieve satisfactory results.

Conclusion

Spray transfer in MIG welding is a highly efficient and versatile process that offers numerous benefits in terms of productivity, weld quality, and control. The continuous spray of small molten droplets allows for high deposition rates, excellent fusion, and deep penetration, making it suitable for a wide range of applications across industries.

Although spray transfer MIG welding has some drawbacks, such as higher equipment costs and limited suitability for thin materials, these challenges can be mitigated with proper training, technique refinement, and careful parameter selection.

With its ability to produce strong, clean, and precise welds, spray transfer MIG welding has become a favored choice for demanding projects in structural fabrication, automotive manufacturing, aerospace, and more.

Resources

- https://www.hobartbrothers.com/resources/technical-articles/welding-transfer-modes-tips-for-achieving-the-best-results/

- https://gowelding.org/welding/mig-gmaw/transfer-types/

- https://www.basicwelding.co.uk/blogs/news/what-is-spray-arc-welding

- https://bakersgas.com/blogs/weld-my-world/mig-welding-tips-for-the-short-arc-and-spray-technique

- https://www.weldingtipsandtricks.com/how-to-mig.html