Spray welding refers to several welding processes in the form of thermal spray. These are coating processes in which melted (or heated) materials are sprayed onto a surface.

The most significant advantage of thermal spraying is providing thick coatings over a large area at a high deposition rate compared to other coating processes such as electroplating and physical and chemical vapor deposition.

Depending on the heat source, spray welding procedures can include industrial plasma, flame, detonation guns, arc spray, and high-velocity oxyfuel. In this article, we will discuss the fundamentals of spray welding, the advantages, and the drawbacks.

What Is Thermal Spray welding?

In simple terms, thermal spray welding can be defined as an industrial coating process consisting of a heat source and a coating material melted into droplets that are sprayed at a high velocity.

The coating material can be a rod, powder, or wire, which is melted by various energy sources.

Next, they are fed and heated to a molten or semi-molten state and accelerated towards substrates in the form of micrometer-size particles.

Generally, the coating quality increases with increasing particle velocities. For example, in flame spraying and wire arc spraying, which were developed in the 1920s, the particle velocities are generally low (< 150 m/s). However, these are still used in thermal spray coating techniques.

On the other hand, plasma spraying, developed in the 1970s, uses a high-temperature plasma jet generated by arc discharge with typical temperatures >15,000K. High temperatures make it possible to spray refractory materials such as oxides, molybdenum, etc.

Spray Welding Equipment

Even though there are different types of thermal spray coatings, heat sources, and methods, a spray welding system is usually composed of:

- Spray gun (spray torch) – spray torch is responsible for reaching the melting point of coating material, acceleration, and spraying process

- Coating feeder mechanism: as the name states, the feeder mechanism is responsible for feeding the powder, wire, or liquid to the torch through tubes

- Media supply: responsible for transferring gases, liquid, or plasma that generates a flame

- Power supply: varies in the different thermal spraying techniques

- Control console: helps you adjust and control spray welding procedures

Different Spray Welding Procedures

Now that you got familiar with the fundamentals of spray welding, we will discuss different spray welding procedures. Depending on the heat source, several variations of thermal spraying are distinguished: plasma spray, detonation spray, wire arc spray, flame spray, high-velocity oxy-fuel coating spray (HVOF), and high-velocity air fuel (HVAF), warm spray, cold spray, spray and Fuse.

In this section, we will go through the fundamental of standard variations and their pros and cons.

Spray Arc Welding

The Arc Spray process utilizes a DC power source at high amps (usually 650 amp) to energize negative and positive wires.

Tiny droplets of molten metal travel through the arc and onto the base metal or joint being worked.

As a result, the spray arc transfer method is ideal for thicker metals, butt, or fillet joints.

In addition, spray Arc Welding can achieve high metal deposition rates when followed by the perfect combination of shielding gas, metal, and wire gauge and contact-to-tip distance.

However, spray weld is not suitable for positioned welding work. In this situation, the flying metal droplets and gravity do not create an ideal situation for the welding work.

Remember that spray arc welding requires a high current to transfer molten metal into droplets. The wire will strike the parent material if the voltage is too low. By raising the voltage to the transition level, the arc length will be increased to the short circuit transition level.

Advantages – Spray Arc Welding

- High metal deposition rates

- Very efficient process

- Good metal fusion and penetration

- Excellent weld bead appearance

- Can utilize larger diameter electrode wires

- Produces spatter-free weld

Disadvantages of Spray Arc Welding

- Only suitable for thicker materials (approximately 1/8 in. (3 mm) and thicker)

- Limited to flat and horizontal fillet weld positions

- It does not offer open root capabilities

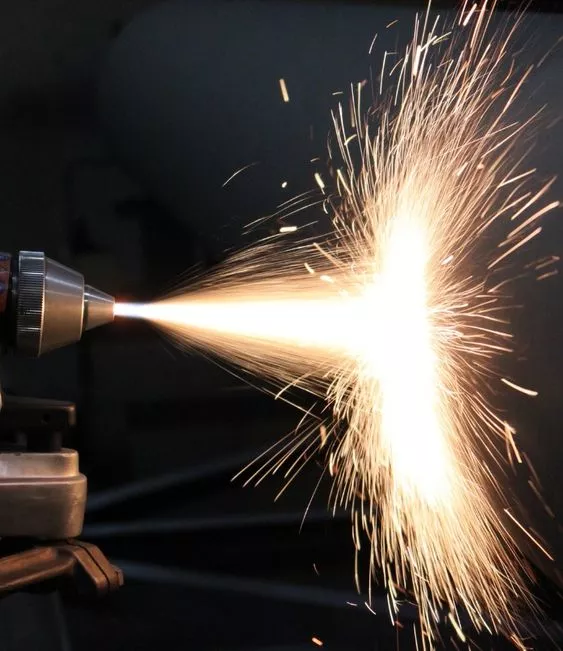

Flame Spraying Process

Flame spraying, also known as oxy/acetylene combustion spraying, is one of the first spray welding procedures developed in the 1920s. This technique utilizes a welding torch with the addition of a high-velocity airflow to propel molten particles onto the substrate.

The flame spraying process uses one of several welding gases for fuel, such as acetylene, propane, and propylene.

Wire or powder is injected into the flame, where it melts and is sprayed onto the work. Flame spray coatings are often melted after application to improve adhesion and coating density.

Advantages of Flame Spray Welding

- Relatively low surface heating (350 to 450C),

- High deposition rates (60-95%),

- Flexibility and versatility

- The simplicity of the process

Disadvantages of Flame Spray Welding

- Relatively low adhesion

- Possibility of high porosity,

- Low heating efficiency

- Not suitable for materials with a melting point over 2800C.

Plasma Spray Process

The plasma spraying process uses inert gases fed past an electrode inducing the “plasma” state of the gases. The plasma spray was developed to coat ceramics, although plastics and metals can be treated.

The process operates at a significantly high temperature, over 10,000C, higher than the metal surface of many materials. Then, the powder is injected into the flame, melted, and transferred to the sprayed material.

Advantages of Plasma Spraying

- Easy to use and apply.

- The bigger size of cermet particles.

- High wear resistance, low or no porosity, thick coatings

- Low heating of the substrate

Disadvantages of Plasma Spraying

- High oxidation rates sight process poor resistance

- Usually results in coating layers thicker than 1mm

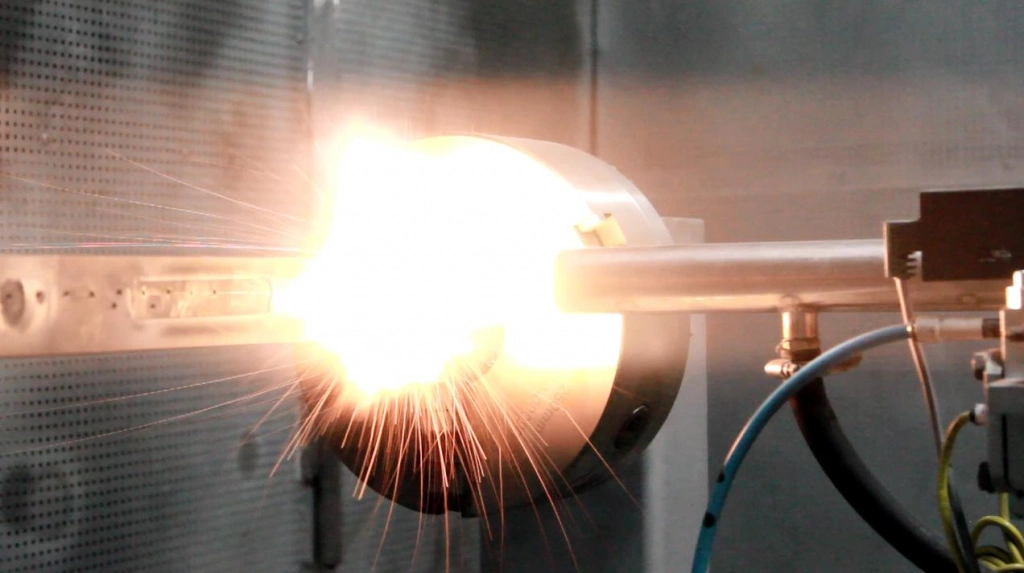

High-velocity Oxyfuel Spray Welding (HVOF)

Even though high-velocity oxyfuel spray is fundamentally the same as flame spray welding, there are specific differences.

This spray welding utilizes oxygen and a select group of flammable gases, including propane, propylene, or hydrogen, to cause combustion.

For example, the HVOF gun produces higher flame temperatures and sprays the particles significantly higher. This results in thoroughly melted materials and higher velocity; you get dense thermal spray coatings.

High bond strength and fine as-sprayed surface finishes with low oxide levels are some benefits of high-velocity oxyfuel spray.

Advantages of HVOF

- high levels of adhesion and low porosity (less than 1%)

- Thicker coatings

- Higher amount of retained carbides when compared to plasma or flame spraying

Disadvantages of HVOF

- Noise levels can surpas 130 dB

- Low deposition rates

- Slightly more expensive when compared to some methods

Cold Spraying Process

The cold spray process uses deformable particles introduced to a supersonic preheated gas stream. Solid powders are accelerated as the gas achieves supersonic speeds up to ca. 1200 m/s. As a result, metals, polymers, ceramics, composite materials, and nanocrystalline powders can be deposited as coating materials.

Since there is no heating of particles (the gas is heated to achieve a higher sonic flow speed), this process got its name cold spraying.

Detonation Spraying Method

Detonation spray welding was invented in 1955 by H.B. Sargent, R.M. Poorman, and H. Lamprey. The method is applied to a component using a specifically designed detonation gun.

This process involves the highest velocities (≈3500 m/s shockwaves) and temperatures (≈4000 °C) of coating materials compared to all other thermal spraying techniques.

These result in extremely low porosity (less than 1%) and low oxidation rates (0.1-0.5%).

Detonation spraying produces protective coatings that are reliable against corrosion, abrasion, and adhesion under low load. As a result, detonation spraying is commonly used for protective coatings in aircraft engines, plug and ring gauges, cutting edges (skiving knives), tubular drills, rotor and stator blades, and guide rails, or any other metallic material that is subject to high wear and tear.

Advantages of Detonation Spray Welding

- High adhesion and low porosity

- High feed rate (up to 12 kg/h).

- A higher amount of retained carbides when compared to plasma and flame spraying

Disadvantages of Detonation Spray Welding

- Hard to spray materials with a low density

- High noise (great than 140 dB)

- High price

Pros and Cons of Spray welding

Like any other welding procedure, spray welding has its ups and downs. Even though you could deduce some of the advantages and drawbacks from the text above, we will sum up the most significant pros and cons of spray welding procedures.

Pros

- Results in the smooth weld bead

- High penetration and suitable for metal thicker than 3/16

- High weld deposit rates increase productivity

- Minimal spatter

- Reduced cost: spray is used to strengthen a lower-cost material

- Versatile: Most metals, plastics, and ceramics can be sprayed

- Works within a broad thickness range

- Fast processing speed: spray goes on from 3 to 60 lb/hour (depends on the process being used)

Cons

- Requires specific welder training to perform spraying

- Gas costs are higher due to higher argon levels (> 85%)

- Recommended for a flat position and horizontal fillets only

- High heat can cause discomfort to welders

- Possibility of undercutting, especially on the top edge of welds

- Bonding of coating is mechanical, not metallurgical

- Line of sight process

- Poor resistance of coatings to pinpoint loading

Resources:

- https://www.engineeringchoice.com/spray-welding/

- https://republicdiesel.com/machine-shop-services/spray-welding/

- https://www.hengliamerica.com/product2/Spray-Welding-Technique/Spray-Welding-Technique

- https://en.m.wikipedia.org/wiki/Thermal_spraying

- https://www.corrosionpedia.com/definition/106/arc-wire-spraying