A total-cost-of-ownership approach lets distributors slash customer GMAW costs. Successful suppliers and distributors are always looking for strategies to help their customers cut costs at all levels of their business.

One strategy involves a total-cost-of-ownership approach that lets distributors analyze customer GMAW or MIG welding process variables, including deposition effectiveness, power consumption, gas piping system, and shielding gas costs.

In addition, distributors should analyze these variables for all modes of GMAW, such as short arc and spray arc metal transfer. That’s why we show the total cost of MIG welding in the article.

The Total Cost Of MIG Welding

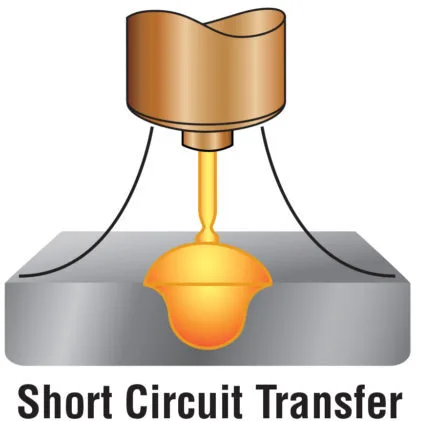

How Does Short-Arc Transfer Affect The Costs

Short arc transfer offers low thermal input to reduce part distortion and works in all positions. For example, using 0.045 in. diameter solid wire (E70S-3), a short arc occurs between 90-220 amp. A short-circuit is created when the tip of the wire touches the weld puddle. The welding machine output current then rises to a minimum of 370 amp to separate the wire from the weld puddle.

Today’s welding power supplies come with fixed voltage settings or dynamically variable slope controls that adjust the output voltage with increasing amperage. Both types control the energy available to separate the wire from the puddle.

This is critical because too much energy results in excessive spatter and lowers the deposition efficiency. On the other hand, too little energy leads to wire pile-up, resulting in incomplete fusion and poor weld quality.

MIG Welder Settings

Also, welding power supplies feature either fixed or variable inductance to control the rate of the current rise. As inductance is increased, arcing time also increases. This additional arc-on time produces a fluid weld puddle, yielding a flatter weld bead with good wetting at the edges.

The short circuit process occurs 50-230 times per second, depending on the application. Therefore, the power supply’s operating parameters and inductance impact weld bead convexity or concavity, which can affect the load-bearing capacity of the joint.

With correct parameters for the application, the spatter is a fine mist, and the welding sequence produces a “frying” sound.

Shielding Gas Effects

Cooling rates, metallographic structures, distortion, position, and shielding gas must all be factored into the weld procedure. For instance, shielding gas alters energy transfer and deposition efficiency. Carbon dioxide produces arc plasma having a narrow inner core with a low outer-envelope temperature due to the gas’s low thermal conductivity.

Using CO2 produces a narrow and deep penetration profile that might cause burn-through and part distortion on thin materials.

Also, the transfer from the wire tends to be violent, causing excessive spatter and yielding 85-93% deposition efficiencies. This is especially true when operators try to extract more from the process than is prudent.

In addition, due to the oxidizing nature of pure CO2, mechanical properties tend to weaken, requiring high-grade solid wires with additional manganese and silicon de-oxidizers.

Adding a gas mixture containing up to 80% argon and balanced carbon dioxide produces more minor crowning, better edge tie-in, and deposition efficiencies of 94 to 98%. That’s because argon’s low ionization potential achieves better arc ignition and stability. Argon also has a low thermal conductivity that yields a similar arc constriction but a shallower penetration profile than carbon dioxide. This enables higher deposition rates with minimal spatter on a broader range of materials. Argoncarbon dioxide mixtures yield high deposition and little spatter, ideal for all-position welding and thin material.

As additional current is applied, the end of the welding wire overheats and balls up 1.5 to 3 X the wire diameter. This creates a long arc length. Gravity then directs the metal transfer, producing instability and excessive spatter. Depending on the gas and process parameters, the deposition efficiency tends to fall between 80-90%. For this reason and welding position limitations, welders should stay outside the globular transition range of 200-220 amp when using 0.045-in. diameter solid wire.

Using the proper shielding gas lets short-arc welding be used on mild or stainless steel in marine, food, chemical, and low-temperature applications where it is essential to retain the base material’s mechanical properties.

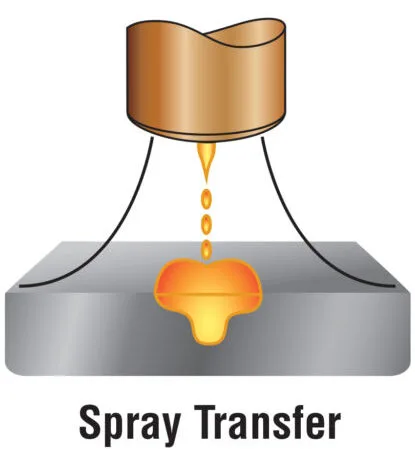

Spray Arc Transfer Costs and Result

Spray arc transfer is another GMAW mode. Depending on the gas, the minimum transition current for spray arc transfer occurs between 220-250 amp for the 0.045 in. diameter solid wire.

Above this range, the end of the wire electrode develops a taper that emits fine droplets of metal across the arc with virtually no spatter, yielding 97-99% deposition efficiencies.

The spray transfer mode yields high travel speeds and deposition rates because of good arc stability and high droplet rate.

However, the high heat input limits the weldment to the flat position. Therefore, the shielding gas and power supply are both critical elements in determining the spray transition range.

Power Supply Advances

Current inverter power supply technology operates at such high frequencies that it can lower the average energy input while maintaining the spray transfer mode. As a result, these new power supplies reduce heat distortion, lower fume emission, eliminate spatter, lower energy consumption, and provide all-position welding capabilities.

With this process, pure argon in the spray produces high arc voltage and long arcs, which create arc instability and excessive undercut at the edge of the welds.

Adding 5% to 20% carbon dioxide creates a mixture that stabilizes the spray transfer. The lower the amount of carbon dioxide, the lower the minimum spray transfer current and subsequent fume generation.

In fact, mixing 5% to 15% CO2 with argon creates a combination that can be used in both spray and short-circuit transfer modes. This is a fairly simple option that reduces cylinder inventory, facilitates onsite mixing, and lowers monthly rental charges and downtime during cylinder changeout.

In some cases, 1% to 5% oxygen may be added to argon to achieve superior arc stability and good tie-in (wetting) at the weld edge. Oxygen tends to provide a wider but shallower penetration profile as compared to carbon dioxide mixtures because of its lower ionization and higher thermal conductivity. Oxygen also tends to yield better toughness and strength because of the absence of carbon retention associated with carbon dioxide mixtures.

Gas manufacturers provide three-component gas blends offering the benefits of both carbon dioxide and oxygen to argon-based mild steel GMAW applications. Above-average quality and flexibility can be obtained with simple binary argon and CO2 gas blends. However, tri-mix blends offer incremental benefits, so they may not be justifiable in all cases.

The total cost of ownership in MIG welding

A comparison of the total cost of a 0.045-in. diameter solid wire using spray transfer with a 90% argon, 10% CO2 shielding gas; the short arc process using a 75% argon, 25% CO2 mix; and an all-position 0.045-in. E71T-1M flux-core wire using 90% argon and 10% CO2 reveals just how the cost per foot of weld varies with the process and gas supply.

For example, with a common fillet requiring 0.106 lb/ft. of filler material, an eight-hr workday, ten weld stations, and ten cylinders for backup, it can be seen how process and gas supply enhancements reduce the cost-per-foot of weld in spray arc up to 45.35% as compared to conventional short arc transfer. For example, using an all-position flux-core wire 71T-1M/T-9M with a CO2 or a 90% argon 10% CO2 shielding gas mix eliminates additional capital expenditures for positioning equipment.

System Variables

In all these processes, system variables such as raw materials, labor, and overhead weigh heavily into the customer’s total cost per foot of weld. The spray transfer mode increases productivity due to higher deposition rates and reduced spatter cleanup time. Employee downtime caused by cylinder handling is also trimmed.

Mixing the shielding gas onsite can yield a total savings of 53.76% compared to conventional short arc transfer.

However, using the 71T-1M wire and an onsite mixing system can provide a 42% savings while matching the all-position flexibility of the short arc process — with higher deposition rates.

The customer’s gas supply system is another critical element in achieving lower gas costs when using cryogenic liquids. Fully automated switchover systems like the IntelliSwitch let distributors use 230, 350, or 500-psi liquid or high-pressure cylinders as a supply source to the onsite gas mixer. This flexibility cuts customer costs for monthly cylinder rental by taking advantage of the best supply method for each gas.

A liquid argon primary cylinder with a liquid argon reserve provides the lowest cost with minimal residual or vent losses. Therefore, a liquid CO2 primary cylinder with four 50-lb high pressure-CO2 cylinders as a backup should be used.

The IntelliSwitch also features an economizer and low-loss technology that slash gas losses by 83%, lowering the cost per ft. of weld to less than half a cent.

In one application example, the blending and piping system cost was $11,700. Amortizing this over a five-year period shows the system adds just three cents cost per ft of the weld. The customer can own the equipment outright, or lease arrangements may be available. With leasing, the distributor charges the customer a facility fee. The customer benefits because the distributor is responsible for all maintenance and future system expansion. In addition, software packages with alarms and analyzers monitor and document system parameters for quality control and feedback.

Significant savings can be achieved by understanding the available processes and quality requirements, a tangible and powerful result of getting close to the customer.