Grinding is a finishing operation, that gives the required accuracy and precision by removing the extra material. You can grind the edges prior to welding to ensure a good fit-up of the pieces or grind the excess weld material to achieve the desired appearance.

However, to start grinding, you will need to understand what type of grinders you actually need.

With the huge market of types of grinding tools and grinders, making the right choice can be hard. That’s why we’ll cover everything you need to know about grinders, their classifications, and types, to help you make the right choice for your next welding project or job.

What Are Grinding Machines And How Do They Work?

A grinding machine, or grinder, is a tool widely used in small and large industries to grind any workpiece. This tool uses a grinding wheel or abrasive wheel the remove small pieces of metal’s surface, or even cut through metal.

Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformation. Today, technology advanced, so we are seeing even higher use of CNC grinding machines that allow the finest adjustments and grinding operations.

Precision grinding processes can achieve a 6 Ra surface finish, hold a size tolerance of fewer than 0.0002 inches, and grind parts to within 30 millionths roundness. In weld preparation or finishing, you probably won’t need that amount of precision, but it is worth knowing what grinders can actually do.

Types Of Grinding Tools Based on Uses

Based on use, all grinding machines can be classified into two classes:

- Non-precision grinding machines

- Precision grinding machines

This classification is primarily made depending on the precision of the finishing operation. As you can assume from the name, a non-precision grinder is likely to deal better with rougher and tougher surfaces, just like the ones you get after finishing your weld. Meanwhile, a precision grinder is capable of achieving highly precise results by achieving very close tolerances and removing even the finest amounts of metal.

Non-Precision Grinding Machine ( for Rough Grinding Applications)

As noted, non-precision grinding machine are usually used in rough grinding applications, and the most common types of grinding machines for rough applications are:

- Bench Grinder

- Pedestal Grinder

- Portable Grinder

- Flexible Shaft Grinder

- Swing Frame Grinder

Bench Grinding Machine

A bench grinder is a rather simple type of machine that is attached to a bench and can be raised to the appropriate working height.

Generally, this is a fixed, shop tool, but there are some designed for home use. These can be used to sharpen non-workshop items such as scissors, garden shears, and lawnmower blades.

These grinders usually have two grinding wheels and tend to have different grain sizes so that a variety of jobs. Some bench grinders, for example, are sold with a 36-grit wheel and a 60-grit wheel. The 36-grit wheel is course and usually used for stock removal, while the 60-grit wheel, is good for touching up tools, although it is not good for honing them.

Pedestal Grinder

A pedestal grinder is a larger version of a bench grinder that is mounted on a pedestal, which is bolted to the floor. These types of grinders are commonly used to hand grind cutting tools and perform other rough grinding.

Depending on the grade of the grinding wheel, it may be used for sharpening cutting tools such as lathe tools or drill bits. Alternatively, it may be used to roughly shape metal prior to welding or fitting. This grinder is belt-driven.

Portable Grinder

Portable grinders are handheld power tools that are used for grinding, cutting, or polishing. These versatile tools can be used for a variety of tasks when used with the proper grinder wheels according to the manufacturer’s recommendations.

You can use them for removing paint or rust prior to welding, cutting metal, stone or ceramics, post-weld polishing, and more.

This tool uses a small air compression system or electric motor employed to drive a gear head, along with a spindle. Several angle grinder discs can be fastened and attached to the spindle by tightening the screw. When the power is turned on, the attached disc with the gear head rotates rapidly and is then applied to the material for polishing, grinding, or abrasive cutting.

Flexible Shaft Grinder

Flexible shaft grinding machines are widely used in fabrication workshops, foundries, and heavy industries. Its unique design is very suitable for heavy and or lengthy jobs where it is not possible to lift the job or get the same close to the grinding machine.

Each machine is supplied with a flexible shaft and grinding Wheel. The machine can also be used for buffing purpose by attaching a buffing attachment, which can be supplied as extra equipment. The machine is mounted on castor wheels and can be easily moved around close to the job.

Swing frame grinder

Swing-frame grinder can be simply explained as any power-driven rotatable grinding, polishing, or buffing wheel mounted in such a manner that the wheel with its supporting framework can be manipulated over stationary objects. They are designed to work under severe-duty environments and are usually used in heavy-duty grinding process.

Precision Grinding Machine

Precision grinding is a precision manufacturing process widely used in various fields. Precision grinding provides an effective method to complete the manufacturing and finishing of metal parts with very tight and tight tolerances. It is typically used as the one of final machining processes on a part.

These are usually divided in several main groups of:

- Surface grinder

- Cylindrical grinder

- Tool and cutter grinder

- Special-purpose grinding machines

- Other grinding machines

Surface Grinding Machines

Surface grinding is the most common of the grinding operations. It is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look by removing the oxide layer and impurities on workpiece surfaces. This will also attain the desired surface for a functional purpose.

A surface grinding machine is a tool used to provide precision ground surfaces, either to a critical size or for the surface finish. The typical precision of a surface grinder depends on the type and usage however ±0.0001 in should be achievable on most surface grinders.

Further, surface grinders can be divided into several types of grinding machines, such as:

- Horizontal-spindle surface grinders: A grinding spindle with an axis that is oriented parallel to the table. The periphery (flat edge) of the wheel is in contact with the workpiece, producing the flat surfaces.

- Vertical-spindle grinders, or wheel-face grinders, are typically used for fast material removal. The face of the grinding wheel is lowered onto the workpiece below it. Vertical-spindle grinders work best for stators, wafers, rotors, gears, inner rings and inner plates, and stops and spacers.

- Vertical spindle surface grinder with rotary table: uses a cup, cylinder, or segmental wheels, and tools are widely used for high production applications; for finishing applications, the wheel axis is kept exactly perpendicular to the surface to be ground, and for roughing purposes, the axis is kept slightly tilted.

- Disc grinders and double-disc grinders: disc grinding is similar to surface grinding but with a larger contact area between the disc and workpiece. Double disc grinder removes material from both sides of the part simultaneously, providing surfaces that are flat and parallel in just one operation

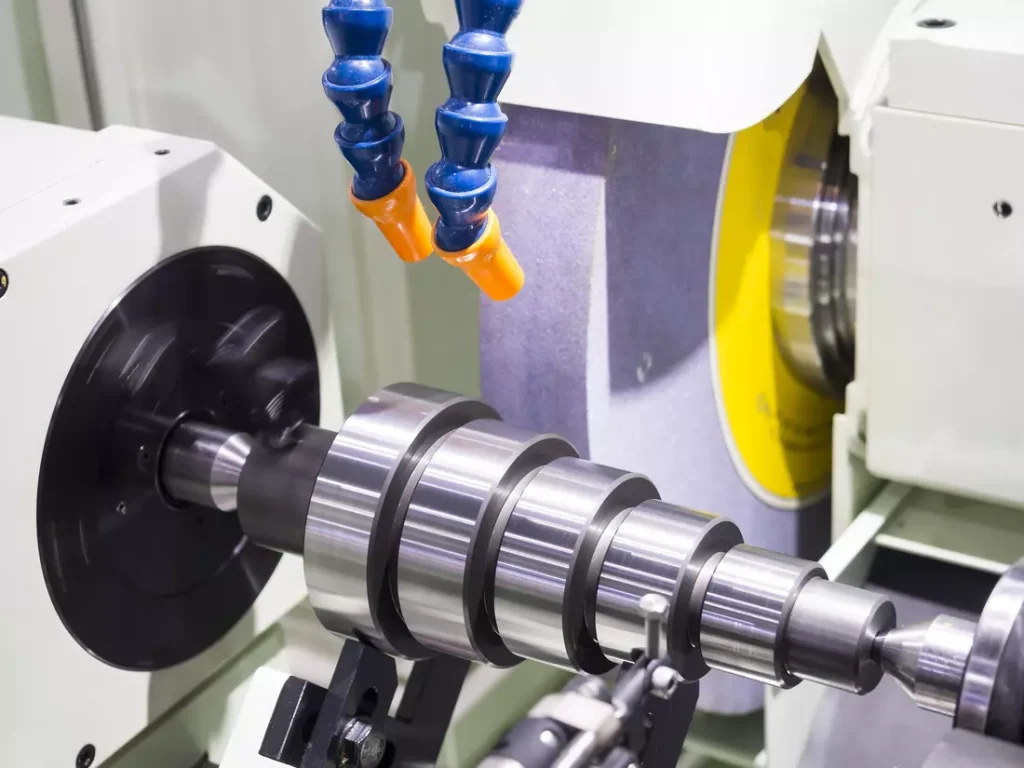

Cylindrical Grinding Machine

Most commonly, cylindrical grinding is used for grinding pieces with a central axis of rotation, like rods and cylinders. This process involves using a cylindrical grinder, which is a type of machinery categorized by rotation style and wheel device.

The working of a cylinder grinder is very similar to a lathe. The only difference is that the lathe uses stationary cutting equipment, whereas the grinder uses a grinding wheel. The cylinder grinders grind the materials having a central axis of rotation, for example, crankshafts.

Cylindrical grinder can be further divided into several groups such as:

- Inside-Diameter Grinding Machine: The inside-diameter machine uses a collet for grinding the interior of the workpiece. This cylindrical grinding machine applies a wheel that is smaller than the width of the substance.

- Outside Diameter Grinding Machine: The outside diameter machine uses centers for grinding the external surface of the workpiece. The centers turn the object when the object progresses through the grinding wheel.

- Plunge Grinding Machine: The plunge grinding machine is a type of outside-diameter machine. However, the grinding wheel moves radially towards the substance.

- Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the base metal through the grinding wheel all at once. This machine greatly reduces manufacturing time.

- Centerless Grinder The centerless grinding machines do not use centers or a collet to grip an object. These machines employ a regulating wheel placed opposite to the grinding wheel.

Tools and Cutting Grinder

Tool and cutter grinders are used mainly to sharpen and recondition multipoint tools like drills, reamers, milling cutters, taps, hobs, broaches, etc, and for accurate grinding of angles of single-point tools.

With suitable attachment, these grinders can also be used for light cylindrical surfaces, internal grinding operation on items like jigs and fixtures, gauge elements, etc.

CNC machine tool

CNC grinding machines are machine tools that use a rotating grinding wheel to achieve material removal on a metallic workpiece by means of cutting. Grinding machines are mostly used for the hard-fine machining of workpieces (parts).

The surface quality that can be achieved is very high, and grinding machines thus almost always find application in modern industry as a finishing process. Furthermore, through the increased performance of the grinding tools, grinding machines can now be used to achieve high material removal rates

Universal grinder

A universal grinding machine is a versatile tool that is used for grinding different types of materials. It is a machine that can perform both cylindrical and non-cylindrical grinding operations, which means that it can grind both round and non-round shapes, like many ordinary grinding machines.

Special Purpose Grinding Machines

Unlike universal grinder, which uses abrasive wheels or grinding head to work with different types and shapes of metal and applications, special-purpose grinders are designed to work on specific projects and applications. Such machines can use one or multiple grinding wheels, and they are designed and programmed to complete specific tasks.

Conclusion

In welding, grinding machines are used in weld preparation to remove paint, dirt, or rust, or to bevel the pieces and prepare the edges prior to welding. Additionally, you use a grinder to remove excessive weld metal imperfections and achieve the desired weld results and appearance.

To do so, you can use various types of grinding machines, including non-precision grinding machines and precision grinding machines. A non-precision grinding machine, such as an angle grinder or portable grinder, is a universal, but necessary tool for any metal fabricator. But if you are doing some kind of precise work, you’ll need a precision grinding machine to achieve the best result with minimal tolerances.

Resources

- https://www.theengineerspost.com/types-of-grinding-machine/

- https://universalgrinding.com/4-types-of-grinding-machines/

- https://phillipscorp.com/india/what-is-a-grinding-machine-types-and-how-it-works

- https://learnmech.com/types-of-grinding-machines-learnmech/

- https://www.americanmachinist.com/cutting-tools/media-gallery/21135372/chapter-17-grinding-methods-and-machines-cutting-tool-applications

- https://learnmech.com/types-of-grinding-machines-learnmech/