There is no easy way of going around this, but welding is dangerous. The process of welding might be one of the most important ones for our society as it helps us create so many things that we use every day.

However, to actually do it requires utilizing various safety protocols.

One of its most dangerous aspects is welding fume exposure. It might not be the first concern or the most threatening aspect of welding, as opposed to skin burns and eye injuries, or electric shock but keep in mind that this silent killer is as or more dangerous than all of the above.

Keep reading for more details about welding fume symptoms and safety.

This is an informative, well-researched article, a blog! Which cannot replace licensed medical examination. If you experience any of the listed welding fumes symptoms, please contact your primary care doctor for proper medical treatment!

What are Welding Fumes?

Welders are subjected to a variety of dangers while working.

These vary depending on the type of project they are working on, but the most obvious types of injuries include burns from spatter, welding blindness due to flashes, and back injuries because of the way they position their bodies.

Something that a lot of people tend to overlook is the welding fumes that could pose both short term and long term side effects.

Welding fumes are a mixture of metallic oxides, silicates, and fluorides. Fumes are created during the welding process in the form of fine particles after the metal you are working on gets heated above its boiling point and starts to release vapors. The welding smoke created may also contain electrode particles with the addition of the particles from the material that you are working on.

The severity of the released particles will depend on the welding process and the metal being welded. The substances released can be divided into three categories:

- Substances that affect your lungs and respiratory tract.

- Highly hazardous and poisonous substances.

- Carcinogen substances.

Source: https://www.osha.gov/welding-cutting-brazing/hazards-solutions

Fume Exposure And Its Effects

Welding fume exposure can be detrimental to a welder’s health and can cause some acute or chronic health effects on a person.

Short-Term Effects

Short-term effects do not cause so severe health problems but should not be taken lightly. One of the most common short-term effects is metal fume fever. Symptoms of metal fume fever can appear as long as 12 hours after exposure and will often come with chills, muscle ache, fever, thirst, coughing, wheezing, nausea, chest soreness, fatigue, and a metallic taste in your mouth.

Additionally, welding smoke can irritate your eyes, chest, the entire respiratory tract, nose, and throat. It can lead to coughing, shortness of breath, pulmonary edema, bronchitis, and pneumonia. It can also cause some gastrointestinal effects like nausea, vomiting, cramps, appetite loss, and slow digestion.

Although short-term exposure is usually treatable and does not cause so much damage, certain types of welding fumes can actually be fatal. For instance, cadmium is fatal while large doses of ozone and nitrogen oxides can lead to serious lung disease.

Source: https://www.hse.gov.uk/welding/health-risks-welding.htm

Long-Term Effects

Studies have shown that long term welding fume exposure could have serious health effects. People who do welding, soldering, or brazing are more prone to lung cancer, but also larynx and urinary tract cancer.

These long term effects happen due to the toxic substances found in welding smoke which may include cadmium, hexavalent chromium, nickel, arsenic, and beryllium.

Being exposed to these substances can eventually cause heart disease problems, hearing loss, various skin diseases, stomach disorders like gastroduodenitis, chronic gastritis, small intestine ulcers, and even affect the central nervous system.

Additionally, there is also the possibility of reproductive problems as studies have shown that people who work with stainless steel have a lower sperm count. Furthermore, those who cut asbestos covered surfaces could suffer from asbestosis, mesothelioma, or lung cancer.

Source: https://www.hse.gov.uk/welding/health-risks-welding.htm

Fume Exposure Factors

In order to improve your health and safety standards, you have to understand where the danger comes from. There are several fume exposure factors to take note of when trying to protect yourself.

- Types of welding processes.

- The combination of filler metals and base metals used.

- Welding rod composition.

- The type of coating on the electrode.

- The ventilation system used (mechanical or local).

- Location, working inside or outside. (stay upwind when working outdoors).

- Adopting certain work practices (remove coating surfaces before welding)

Source: https://www.osha.gov/Publications/OSHA_FS-3647_Welding.pdf

Welding Fume Testing and Sampling

Monitoring welders for welding fume exposure is relatively easy and should be considered favorable practice. It can be done with the help of a small battery sampler attached to the worker’s belt. Industrial hygienists take the gathered samples and compare them to the safety data sheets so as to identify the components released.

How to Control Welding Fumes?

Probably the best way of controlling welding fumes is utilizing some sort of exhaust ventilation systems. Actually, the most effective form of ventilation are local exhaust ventilation systems. There are alternatives that come in the form of respiratory protection, but these are seen as the least effective means of protection.

Local Exhaust Ventilation

Local exhaust ventilation systems are highly effective in removing fumes and gases from the welder’s working zone. Good practice in improving air quality standards would be to keep the fume hoods, vacuum nozzles, and fume extractor guns closed in order to remove the maximum amount of fumes and gases. Also, portable exhaust systems should be positioned to draw fumes and gases away from the welder.

The ventilation system should be maintained and cleaned regularly. If you are using gas shielded arc welding processes, exhaust can be provided with an extracting gun which will reduce exposure by 70%.

General Ventilation

General ventilation includes roof vents, opening a window or a door while working, and adding roof and floor fans. Unfortunately, these methods are not so effective. Even though they somewhat improve the health and safety measures, they can actually spread some dangerous chemicals around the workplace.

However, general ventilation works best when combined with the local exhaust ventilation to supplement it and improve working conditions.

Respiratory Protection

Respiratory protection is viewed as another highly efficient way of controlling fumes exposure. A powered air-purifying respirator welding helmet or (PAPR) is a good piece of protective equipment to have as it helps to protect the welder even when using a variety of welding processes.

This is a type of welding helmet that comes with a high-efficiency particulate filter and a gas filter. It increases the level of protection as the worker carries a tank on their back while working.

However, the downside is that a worker may still be exposed to fumes as the atmosphere around them may still be hazardous. Therefore, it is always good practice to keep a window or a door open when you are working inside to increase protection.

Also, it is good to use supplied air when working in restricted spaces.

However, be advised that powered air and supplied-air respirators should not be used immediately in atmospheres as they could be dangerous.

Source: https://www.awsi.com.au/blog/best-welding-respiratory-protection-to-use-when-welding-aluminium

Ventilation in Confined Spaces

According to OSHA, workers cannot enter a working area until air ventilation has eliminated all hazardous atmosphere. If a gas detector indicates that any atmospheric hazard is present, employers should ban entrance to the area until forced air ventilation is implemented to clean out the breathing zone.

Metal Fume Fever

Fumes may produce metal fume fever. Metal fume fever is the most common condition caused by exposure to welding fumes and gases. It primarily involves exposure to such chemicals as aluminum oxide, zinc oxide, or magnesium oxide. The most common source of these elements comes during various welding operations that cause both the metal and the welding wire to heat and create these welding emissions.

Signs and Symptoms of Welding Fume Fever Resemble:

- Respiratory disturbances

- Infection – influenza

- Fever – Acute Bronchitis

- Pneumonia – Chills, Shivering, Trembling, Nausea, and Vomiting may also occur

Symptoms

Generally speaking, early symptoms resemble the common flu. People usually experience fever, chills, fatigue, headache, and nausea. Throat irritation and a metallic taste in your mouth are also common. More serious symptoms include a burning sensation in the body, no urine output, shock, and collapse.

Cause

Work exposure to toxic fumes usually occurs when both the base metal and the filler metal are heated to such an extent that vapor is emitted containing the hazardous particles. A welder can inhale these particles in the form of fine dust or fumes.

Diagnosis

Due to metal fume fever resembling the flu, diagnosing it is usually anecdotal. It is mostly determined based on the patient’s occupational history. Depending on the level of exposure, physical symptoms may vary. Chest X-rays may sometimes prove to be helpful in diagnosing the condition.

Due to repeated metal oxide fumes, exposure rapid adaptation to metal fume fever can also develop.

Treatment

Treatment is commonly handled with bed rest and keeping the patient hydrated as well as including symptomatic therapy (aspiring for instance). Consuming cow’s milk before and after exposure is a traditional method of prevention, but not a scientifically confirmed one. Full recovery often requires one to two weeks.

Prevention

In order to prevent metal fume fever from happening workers should avoid direct contact with potentially toxic fumes. Personal protective equipment and exhaust ventilation systems should be utilized. Working in confined spaces should be avoided as best as possible.

Types of Metal and its Welding Hazards, Potential Dangers, and Symptoms

Exposure to fumes may depend on the type of welding a worker is using. Besides this, other factors like the type of metals and coating used and the welding work practices involved may determine the potential risks.

1. Aluminum

While working on aluminum metals a layer of aluminum oxide will form from the filler metal. This will result in aluminum oxygen compounds forming and being released through the fumes. Worker exposure and breathing in these particles can cause bronchitis due to particles getting lodged in the respiratory tract. These dust deposits can lead to an irreversible condition called aluminum lung.

Source: https://www.nj.gov/health/eoh/rtkweb/documents/fs/0054.pdf

2. Beryllium

Beryllium is known for being one of the main causes of metal fume fever. It is actually an alloying element that contains copper. Beryllium is dangerous as it contains carcinogen substances. Long-term exposure could lead to the creation of malignant tumors. These substances also have a toxic effect and can lead to metal poisoning.

Source: https://www.osha.gov/beryllium

3. Cadmium

Cadmium is very dangerous as overexposure to it could be fatal. It is used as a rust prevention coating and is an alloying element as well. Short term exposure can lead to severe lung irritation, pulmonary edema, and even death. Long term exposure can cause emphysema and kidney damage, chronic obstructive pulmonary disease, and can have irreversible effects on the lungs.

Source: https://www.osha.gov/cadmium

4. Carbon Monoxide

The processes of welding and cutting can create large amounts of carbon monoxide. Additionally, when using carbon dioxide as an inert gas shield hazardous concentrations of carbon monoxide can build up if adequate ventilation is not established. This usually happens due to the breakdown of the shielding gas.

Overexposure to carbon monoxide may lead to heart-pounding, flashes before the eyes, headaches, ear ringing, and nausea.

Source: https://www.osha.gov/OshDoc/data_General_Facts/carbonmonoxide-factsheet.pdf

5. Chlorinated Hydrocarbon Solvents

Chlorinated hydrocarbon solvents are usually used as a degreasing solvent during clearing. Some people don’t realize that when welding or cutting the heat or ultraviolet radiation generated from those processes could decompose the vapors and lead to the creation of highly toxic and irritating phosgene gas.

6. Cobalt

Cobalt oxide is a very dangerous carcinogenic substance that is found in welding gases. Being exposed to it too much may result in respiratory organ damage.

Source: https://www.cdc.gov/niosh/topics/cobalt/default.html

7. Copper

Copper welding fumes are usually found in Monel, brass, and bronze alloys, but also in certain welding rods. The risk of exposer includes effects like nose, eyes, and throat irritation. Extreme cases lead to nausea and metal fume fever.

Source: https://nj.gov/health/eoh/rtkweb/documents/fs/0528.pdf

8. Fluorides

You may find fluorides in ceratin coatings of some fluxes that are used for welding. Repeated exposure to fluoride concentrations in the air may lead to pulmonary edema (fluid in the lungs). It can also lead to skin irritation and rashes, but more importantly, it also has the ability to cause bone damage.

9. Iron Oxide

Iron oxide welding fumes are usually released during arc welding when materials that contain iron are heated. During this process, iron oxide fumes will end up in the air from both the base metal and the electrode.

Acute effects will surely lead to metal fume fever. But in chronic cases, it could lead to discoloring of the eyes, pneumoconiosis, and shortness of breath. Ceratin changes can be detected on X-rays.

Source: https://nj.gov/health/eoh/rtkweb/documents/fs/1036.pdf

10. Lead

Lead fumes may be released in the air when working with lead alloys or materials that have been painted with led paints. Lead poisoning occurs when a person is exposed to high levels of lead in a short period of time.

Symptoms of lead poisoning include abdominal pain, headaches, tiredness, loss of appetite, memory loss, pain or a tingling feeling in hands and feet, and weakness. Unfortunately, these symptoms don’t appear always at the same time and could gradually build up. So overlooking this condition does tend to happen.

Exposures to high levels of lead can lead to weakness, anemia, brain damage, and problems with kidneys.

11. Mercury

Mercury is used for coating metals in order to prevent corrosion and inhibit foliage growth. Mercury fumes are usually produced due to the intense temperatures created by a plasma arc or gas flame.

Inhaling mercury fumes can lead to health effects on the nervous system, digestive system, immune system, lungs and kidneys. Extreme exposure may even lead to death. Some of the most usual symptoms are tremors, memory loss, insomnia, neuromuscular effects, headaches, impaired cognitive and motor skills.

Source: https://www.who.int/news-room/fact-sheets/detail/mercury-and-health

12. Manganese

Manganese is important for steel and iron production and is a key component of aluminum alloys. It can be very reactive while welding so fumes are released easily.

Small manganese exposure could lead to nose and throat irritation as well as metal fume fever.

Extreme exposure to manganese affects fertility and an increased risk of brain damage. The most common symptoms are weakness, sleepiness, and loss of appetite. Prolonged exposer may lead to lung cancer, liver illnesses, and anemia.

Source: https://nj.gov/health/eoh/rtkweb/documents/fs/1155.pdf

13. Magnesium

Exposure to magnesium can lead to such health effects as metal fume fever and comes with symptoms that include chills, muscle aches, and fever. According to OSHA, the legal exposure limit is 15 mg/m3 of particles over 8 hours of work.

Source: https://nj.gov/health/eoh/rtkweb/documents/fs/1136.pdf

14. Nickel

Nickel fume exposure is known to cause ingestion damage, problems with inhalation, and issues with skin and eye contact routes. Certain symptoms that may appear are sensitization dermatitis, pneumonitis, and allergic asthma.

15. Phosgene

Phosgene is created when chlorinated hydrocarbon solvents are decomposed by ultraviolet radiation. This can create moisture in the lungs which creates hydrogen chloride that can decompose lung tissue. Some signs of phosgene exposure syndrome include coughing, watery eyes, blurred vision, a burning sensation in the throat and eyes, difficulty breathing, and shortness of breath.

Most people make a full recovery however some end up with bronchitis and emphysema as a permanent consequence of the exposure.

Source: https://www.cdc.gov/niosh/topics/phosgene/default.html

16. Ozone (O3)

Ozone is created in a combination of aluminum materials being welded using MIG or WIG welding methods. It occurs due to ultraviolet radiation from the oxygen in the air.

Patients exposed to ozone suffer from headaches, dry throat, coughing, a heavy feeling in one’s chest, shortness of breath, and fluid in their lungs.

More severe symptoms come with expanded exposure while chronic exposure leads to asthma.

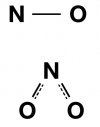

17. Nitrogen Oxides

The ultraviolet light given off from the arc can produce nitrogen oxides from the nitrogen and oxygen found in the air. low concentrations of nitrogen oxides can irritate the upper respiratory tract and lungs. High concentrations can lead to nitrogen oxide toxicity.

18. Vanadium

You can find vanadium in certain iron, stainless steel, steel alloys, nickel, and nickel alloys. Heating vanadium will cause it to be released in the air in the form of fumes that welders can inhale. Breathing it in can irritate the nose and throat, cause coughing and wheezing, and shortness of breath.

High exposure comes with nausea, abdominal pain, vomiting, and greenish discoloration of the tongue. Additional symptoms include headaches, dizziness, and tremors. Repeated exposure comes with anemia and kidney damage.

Source: https://nj.gov/health/eoh/rtkweb/documents/fs/3762.pdf

19. Zinc

Zinc is used when manufacturing galvanized metals, brass, and many other alloys. Of course, zinc exhaust can be accidentally inhaled when working on zinc-coated metals.

Zinc oxide fumes cause mild irritation of the eyes, nose, and throat. Acute overexpose could lead to metal fume fever. Long-term exposer could lead to dermatitis with skin cracks and redness.

Source: https://nj.gov/health/eoh/rtkweb/documents/fs/2021.pdf

All Sources:

- About welding, cutting and brazing hazards, by OSHA https://www.osha.gov/welding-cutting-brazing/hazards-solutions

- Controlling fumes and hazards during welding by OSHA https://www.osha.gov/Publications/OSHA_FS-3647_Welding.pdf

- Health effects of welding by National Library of Medicine https://pubmed.ncbi.nlm.nih.gov/12585507/

- Aluminum hazards by New Jersey Department of Health https://www.nj.gov/health/eoh/rtkweb/documents/fs/0054.pdf

- Beryllium hazards by OSHA https://www.osha.gov/beryllium

- Cadmium hazards by OSHA https://www.osha.gov/cadmium

- Carbon Monoxide hazards by OSHA https://www.osha.gov/OshDoc/data_General_Facts/carbonmonoxide-factsheet.pdf

- Potential health effects of chlorinated solvents by National Library of Medicine https://pubmed.ncbi.nlm.nih.gov/17119204/

- Cobalt hazards by NIOSH https://www.cdc.gov/niosh/topics/cobalt/default.html

- Copper hazards by New Jersey Department of Health https://nj.gov/health/eoh/rtkweb/documents/fs/0528.pdf

- Fluorides hazards by ATSDR https://www.atsdr.cdc.gov/phs/phs.asp?id=210&tid=38

- Iron Oxide hazards by New Jersey Department of Health https://nj.gov/health/eoh/rtkweb/documents/fs/1036.pdf

- Lead hazards by NIOSH https://www.cdc.gov/niosh/topics/lead/health.html

- Mercury hazards by WHO https://www.who.int/news-room/fact-sheets/detail/mercury-and-health

- Manganese hazards by New Jersey Department of Health https://nj.gov/health/eoh/rtkweb/documents/fs/1155.pdf

- Magnesium hazards by New Jersey Department of Health https://nj.gov/health/eoh/rtkweb/documents/fs/1136.pdf

- Nickel hazards by NIOSH https://www.cdc.gov/niosh/npg/npgd0445.html

- Phosgene hazards by NIOSH https://www.cdc.gov/niosh/topics/phosgene/default.html

- Ozone hazards by NIOSH https://www.cdc.gov/niosh/topics/ozone/default.html

- Nitrogen oxide hazards by ATSDR https://www.atsdr.cdc.gov/mmg/mmg.asp?id=394&tid=69

- Vanadium hazards by NJ Department of Health https://nj.gov/health/eoh/rtkweb/documents/fs/3762.pdf

- Zinc hazards by NJ Department of Health https://nj.gov/health/eoh/rtkweb/documents/fs/2021.pdf

Government Agencies That Control Hazardous Substances and Provide Worker Safety

- Center for Disease Control and Prevention (CDC) https://www.cdc.gov/

- Agency for Toxic Substances and Disease Registry (ATSDR) https://www.atsdr.cdc.gov/

- The National Institute for Occupational Safety and Health (NIOSH) https://www.cdc.gov/niosh/index.htm

- Occupational Safety and Health Administration (OSHA) https://www.osha.gov/

- The American Conference of Governmental Industrial Hygienists (ACGIH) https://www.acgih.org/