As a welder, you are most likely to weld steel most of the time. However, you might encounter non-ferrous metals every once in a while, which might be challenging to weld.

Non-ferrous metals, as their name states, don’t contain any iron, which carries unique characteristics and properties. Therefore, you will need to take a different approach.

To help you learn how welding non-ferrous metals works, you will first need to understand the properties. This article will cover the essential characteristics and how they affect weldability.

Fundamentals of Non-ferrous metals

Non-ferrous metals are non-iron-based metals such as aluminum and aluminum alloys, copper and copper alloys, and nickel and nickel alloys. Even though they are widely used in many industries today, they present different metallurgical characteristics and mechanical properties.

Some of the most used non-ferrous metals include copper, lead, zinc, titanium, nickel, and aluminum. Rare and precious metals such as mercury, platinum, tungsten, gold, and silver are non-ferrous metals, too.

Before actually digging into welding processes, you will need to understand the characteristics of the particular non-ferrous metal.

Properties That Affect Welding Non-Ferrous Metals

Even though each metal shows different properties, non-ferrous metals have common characteristics such as high malleability, high conductivity, non-magnetism, low weight, high resistance to corrosion, no oxidation, and low tensile and compressive strength.

Since these metals contain low to no iron, they are relatively more resistant to corrosion than ferrous metals.

With positive characteristics, the real-world applications of non-ferrous metals provide technological advantages and cost indispensable savings. Therefore you find aluminum in aircraft frames, magnesium in transmissions, titanium in golf clubs, zinc in electrical hardware, and bronze castings.

Aluminum properties and weldability

Aluminum is beside steel, one of the most weldable materials. Even though steel is more commonly welded, aluminum alloys are taking over several industries due to their beneficial properties.

Remember that aluminum is nearly three times lighter than steel, yet it shows similar strength when alloyed.

One of the crucial properties of aluminum and aluminum alloys is high thermal conductivity.

High thermal conductivity means aluminum conducts heat much faster and better than steel. In addition, aluminum and aluminum alloys have a low melting point.

Nonetheless, due to high thermal conductivity, aluminum requires higher welding heat, regardless of nearly half the melting temperature of steel. However, high heat input can cause burn trough, and sheet aluminum can wrap quickly. All the specific properties mean you will have to be extra careful when welding aluminum.

Aluminum alloys

Like other elements and metals such as iron, pure aluminum can be alloyed. Alloying elements such as copper, silicon, manganese, and zinc can provide high corrosion resistance, higher strength, and increased weldability.

All aluminum alloys can be classified into non-heat-treatable and heat-treatable aluminum alloys. Non-heat treatable alloys, as their name states, don’t rely on heat treatment. Instead, increasing the strengths and properties of these alloys is done in cold conditions.

Heat-treatable alloys can be heated after welding to regain the lost strength. Therefore, aluminum alloy is heated by the solution heat method. That way, heat treatment increases the alloying elements’ strength without cracking or defects.

With everything said, you understand aluminum and its alloys are used in applications that require a good strength-to-weight ratio. Nonetheless, they can be challenging to weld due to their physical properties, such as high thermal conductivity and electrical conductivity.

Welding Aluminum and aluminum alloy

Even though aluminum is one of the most weldable materials, aluminum welds can be tricky to master

Besides the characteristics we talked about, you should know that the surface contains aluminum oxides. These form once the oxygen meets the surface, and they increase corrosion resistance. However, if you don’t remove them prior to welding aluminium, you might deal with poor fusion since surface oxide can stay trapped inside the weld.

Remember that aluminum doesn’t change its color when heated due to thermal characteristics. Thus, you must get the perfect temperature to help filler metals melt, but without burning through or bending.

That’s why welding aluminum requires high voltage, amperage, and, thus, a high travel speed. If your arc is slow during high heat input, you are more likely to burn through the aluminum welds.

Even though the aluminum can be welded by several different methods, welders often choose MIG or TIG welding. GTAW welding is a go-to method when welding thin aluminium alloys, as it produces clean, aesthetic welds. However, many welders chose MIG welding due to the higher welding speed and fewer skill demands.

If you are looking for a detailed and extensive guide on aluminum welding, please check our comprehensive article.

Copper Properties and Weldability

Like aluminum, copper with various copper alloys is another common non-ferrous metal. However, its unique properties vary from steel, meaning the welding approach is slightly different.

Firstly, copper has the highest electrical conductivity of all commercial metals, and that’s why it is widely used for electrical conductors and wiring. In addition, besides electrical conductivity, copper alloys have high thermal conductivity and thermal expansion.

Therefore, you will find it really hard to melt copper to join it, even though the melting point is much lower compared to steel.

Welding Copper alloys

Before we start talking about welding copper, you should know there are hundreds of different copper alloys.

Each has its unique characteristics due to alloying elements, but aluminum bronzes, nickel, silicon, tin, and zinc are the most common.

Brass is a copper alloy that contains zinc as the primary alloy, and it is the most common alloy. However, bronze is one of the most weldable copper alloys.

Due to offsets in thermal conductivity, welding copper alloys require a preheating treatment. Preheating the copper lowers the required welding heat input and softens the heat-affected zone. Remember that copper thermal expansion can be 50% compared to carbon steel, leading to distortions. In addition, once the metals cool down, there is a risk of cracking. Thus, preheating and tack welding copper alloys are always recommended.

You can opt for either Gas Welding (oxy-fuel) or Arc Welding processes such as GMAW, GTAW, or Plasma arc welding to weld metal such as copper. Whenever possible, use the flat position for arc welding copper. GTAW and SMAW can be used for welding in other positions. Remember that copper-tin alloys, or bronzes, are the most weldable. This is because tin increases strength and hardness, and it doesn’t emit fumes like copper-zinc alloys.

Copper-lead alloys can be challenging to weld, as the lead oxidizes faster, resulting in contamination and porous welds. Due to toxic elements in copper, you should always weld in ventilated conditions and protect yourself from fumes.

Magnesium Properties and Weldability

Magnesium is a silvery-white metal that is characterized by excellent ductility and low weight. Keep in mind that magnesium is even lighter than aluminum.

However, pure magnesium isn’t as hard as aluminum, so it can be hard to weld.

That’s why most welding is done on magnesium alloys.

Magnesium is hardened by precipitation hardening, and aluminum, manganese, and zinc are mostly used as alloying elements. Like aluminium alloys, magnesium alloys have a low melting point and high thermal expansion.

Welding magnesium alloys

Adding aluminum to magnesium alloys increases the overall strength and hardness of the metal alloy, increasing the weldability. However, a low melting point and high thermal expansion mean you must be careful with the heat. Thus, high heat can result in distortion and eventually cracking. The key to successfully welding magnesium alloys is selecting filler metals. Since the magnesium can be brittle, the weld will fail if you try to join dissimilar metals.

In addition, dissimilar materials can crack due to lower corrosion resistance. Magnesium alloys are usually welded using the GTAW method. Arc stability is essential, as the arc should melt the metal before penetrating too deep. That way, you reduce the stress during the cooling of the molten metal responsible for cracking.

Nickel Properties and Weldability

Nickel is a silvery, tough metal that is characterized by excellent corrosion resistance. Due to its positive characteristics, you might have noticed nickel is part of many different alloys. In addition, nickel can be used as a coating.

Since nickel is rarely welded as a pure metal, we will mostly discuss welding nickel alloys. Nickel and nickel alloys are also widely used as filler metals for joining dissimilar materials and cast iron.

Welding nickel alloys

Most welding processes can easily join Nickel alloys since it shows similar characteristics as steel.

Wrought nickel alloys are most similar to austenitic stainless steel, but cast nickel alloys contain silicon which might cause cracking.

Mechanical properties of nickel alloys vary on the cold work in the base metal or the hardness of the remaining metal. Annealing can be done if the base metal is too hard.

Keep in mind that excess heat can affect the corrosion resistance in the HAZ. Therefore, some alloys are solution heat treated to restore resistance. The common issue with nickel welding procedures is the lack of flow. Since the metal spreads hard, you will have to weave the electrode.

Zinc alloys

Zinc is one of the most common protective coatings of steel since it offers good corrosion resistance. Coating steel with zinc to increase the oxidation resistance is also known as galvanizing.

However, since the zinc has a lower boiling point compared to the melting temperature of the steel, excessive fuming can occur. Therefore, when considering welding zinc alloys, make sure you do it in a well-ventilated area.

Welding Zinc alloys

Zinc can be alloyed with aluminum, copper, or lead to add certain properties to the base metal. Copper zinc alloys we mentioned are the most used, as they make brass. However, only low zinc brasses can be welded due to the toxic fumes they produce.

While welding zinc alloys can be easily done by GMAW and FCAW, most zinc alloys require joining processes other than welding. Prior to welding, you could remove the zinc coating by grinding the weld zones.

Removing the zinc thin layer is not mandatory, but you will have to increase heat to burn it away from the weld zone. In addition, you can burn it off by reducing the travel speed.

Titanium Properties

Titanium is a silver-gray metal that is stronger than steel yet as light weight as aluminum. Even though titanium alloys can be welded just like stainless steel and aluminum, titanium is a highly reactive metal. Therefore, special precautions and welding parameters are required during joining.

Welding Titanium alloys

Adequate shielding is crucial for welding titanium alloys, as they get extremely reactive when heated above 1000 F. Reaction with oxygen and nitrogen in the air lead to surface contamination.

Therefore, you must protect weld metal puddle by providing pure inert gas such as argon.

Like, aluminum, the surface must be cleaned since any dirt, rust, or contaminants can affect the weld. For cleaning, you can use a stainless steel wire brush.

Like aluminum, you can use GTAW when welding with thin titanium alloys or GMAW for thicker sections and higher productivity. Electron Beam Welding can be used to join titanium and dissimilar metals.

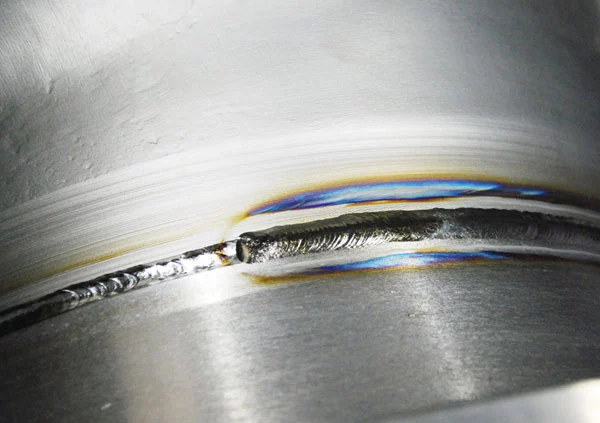

Keep in mind that the weld quality can be judged by its color. Good titanium weld has a silver or bright appearance. Yellowish to bluish colors indicate hardening, while dark colors result from an oxide layer.

Resources:

- https://www.kobelco.co.jp/english/welding/events/files/2015_KOBELCO_Nonferrous.pdf

- https://www.esabna.com/euweb/oxy_handbook/589oxy17_1.htm

- https://www.tws.edu/blog/welding/introduction-to-ferrous-and-non-ferrous-metals-learn-the-differences/

- https://www.twi-global.com/technical-knowledge/faqs/faq-i-have-to-weld-a-non-ferrous-metal-what-does-non-ferrous-mean-and-what-things-do-i-need-to-be-careful-about

- https://www.twi-global.com/technical-knowledge/job-knowledge/weldability-of-materials-nickel-and-nickel-alloys-022

- https://www.researchgate.net/publication/296951731_Material_joining_process_of_Non-Ferrous_metals

- https://www.forsteramerica.com/tips-welding-copper/