The joint is 10 in. long. How long should the fillet weld be if it is expected to be the full length? The question is simple, but the answer is a bit more complicated.

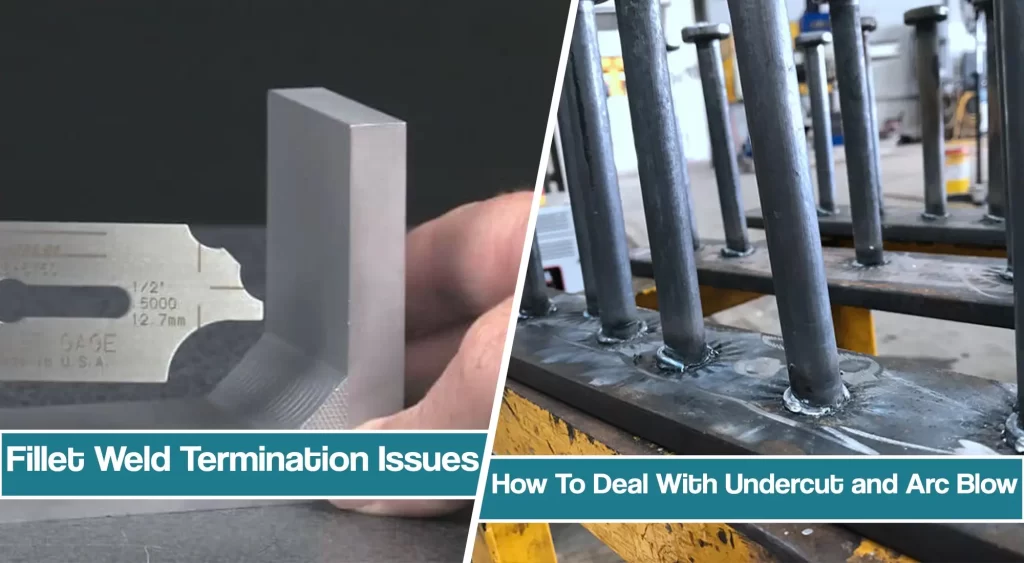

Anyone who has ever welded has likely experienced the difficulty associated with fillet weld termination at the very end of a joint — in a quality manner.

Beyond this workmanship concern, however, we must also consider some design-related issues.

Finishing The Weld – Workmanship-related Concerns

First, let’s tackle the more specific topic — the workmanship-related concerns. The welder, or the programmer of a robotic welder for that matter, must overcome two physical phenomena when terminating a weld at the end of a joint. One is the result of thermal conductivity, where the molten metal can flow out of the cavity, and the other is the result of magnetic properties where arc blow occurs.

Thermal Energy Issues

In the center of the length of a weld, the thermal energy associated with molten weld metal is conducted away from the joint in multiple directions. As the arc approaches the end of the joint, the ends of the joined material become hotter, as there is no place ahead of the weld into which thermal energy can be conducted.

As the ends of the material become hotter, the rate of thermal conductivity decreases, further restricting the transfer of heat.

Thus, the end of the joint rapidly increases in temperature, causing several weld termination issues.

Weld craters should be filled to the full weld size, which combined with thermal energy properties can cause issues. This requires the welder to dwell at the end of the joint, filling the cavity while adding more thermal energy to the material.

As a result, sometimes, an undercut occurs. In other cases, the molten weld metal flows out of the crater, off the end of the joint being welded, and ends up on the shop floor. Yes, you can realize these are not ideal things to deal with.

Fillet Weld Termination Arc Blow Issues

Simultaneously, the welder may face another problem: Arc blow. A magnetic field surrounds the electrode when we use direct current (DC) power. In the center of the joint, this magnetic field is conducted into the surrounding material in a generally uniform manner.

As the arc approaches the end of the joint, the magnetic field becomes constricted, preferring to remain in the metal being welded rather than be transferred into the surrounding air.

The concentrated magnetic field acts on the arc, attracting or repelling it. As a result, the arc is displaced or “blown” away from the weld crater — hence the term “arc blow.”

Starting a weld isn’t quite as tricky as terminating the weld, but the same arc blow conditions can exist at the start as well, due to the same issues of the magnetic field.

Addressing the Weld Termination Issues

To compensate for both the buildup of thermal energy and for arc blow, if given the option, most welders will opt to stop the weld short, terminating it perhaps one fillet weld size short of the end of the joint. Similarly, the weld may be started one weld size from the opposite end.

Thus, if we return to our original question and assume a ¼ in. fillet weld, then for a 10 in. joint, the total length of the fillet would be 9½ in.

In the past, some codes required that welds be initiated and terminated one weld size from the end.

That requirement, however, posed another problem: If the welder welded the entire length of the joint — even with good weld quality for the whole length — an inspector might require the ends of the welds to be ground off due to the regulations. The inspector could argue that the code says “fillet welds shall be initiated or terminated not less than one weld size from the end of the joint.”

And then, there is the situation where no weld length is shown on the welding drawing — just an arrow with a fillet weld symbol and an arrow pointing to the joint. The weld that terminated one weld size from the end of the joint may be required to “complete the weld,” which, for our example, means making a ¼ in. fillet weld on either end of the joint — and to make each segment ¼ in. long. In other words, puddle a bit of weld into either end of the joint.

This practice, of course, causes the welder, who is concerned with things like preheat, heat input, and cooling rates, to shudder.

We’ve discussed the option of stopping the weld short or carrying the weld to the end of the part. There is yet a third option — the weld can be wrapped around the end of the part. For example, when an angle is welded to a plate, this option may be called an end return.

The AWS D1.1 Structural Welding Code

Steel currently deals with the issue of weld termination in clause 2.8.3.1. as follows: General: Fillet weld termination may extend to the ends or sides of parts or may be stopped short, or may have end returns except as limited by the following cases:

What can we learn from D1.1 on this topic of weld termination? First, we see that any one of the three options — full length, stopping short, using end returns — is generally acceptable, although exceptions exist.

| Material Thickness (T) in. | Minimum Size Of Fillet Weld in. |

|---|---|

| T < 1/4 | 1/8 |

| 1/4 < T < 1/2 | 3/16 |

| 1/2 < T < 3/4 | 1/4 |

| 3/4 < T | 5/16 |

Usually, weld quality can be more consistently achieved by starting and stopping the weld approximately one weld size from the end of the joint. Accordingly, the designer should assume that a full-length weld will not actually be the full length of the joint and correctly determine the fillet weld size.

Conclusion

In general, the termination shouldn’t be a significant focus of the welding inspector so long as it meets the minimum length and decent weld quality.

However, there are certain exceptions that are listed in D1.1, and they state when welds should be stopped short, or the end returns limited. But, remember that there are unacceptable termination options, these need to be clearly communicated to everyone involved in the fabrication process: the engineer, the welder, and the inspector.