At the start, I just got to say, If you have a cheap helmet and if you are working for a company that supplies you with all the welding equipment, just don’t bother cleaning and restoring lenses. Replacing them is the best option in this case. So throw away those dirty shielding lenses and replace them with new ones.

On the other hand, if you are a proud owner of a 300+ USD Optrel or Esab welding helmet with those expensive clear welding lenses, you should read this article.

Those lenses are too expensive for a, let’s face it a short-lived piece of plastic (especially if you are a type of welder that sticks his head when welding with MIG or flux core). So you should clean them and restore them as much as you can, and these are a few of the best ways to do it.

What Causes the Lens to Get Dirty?

- Dust, Dirt, and Grime – If you are a TIG Welder welding some stainless steel in a shop, kitchen, or some power plant, then this is not your concern. For the rest of us, grime and dusty workplace is our natural habitat. Dust will quickly accumulate on the welding helmet lens, especially if you periodically use a grinder in between welding beets. You will need to wipe it off many times during your work hours.

- Welding smoke – most of the electrodes for MIG and Stick produce weld smoke, and it will pile up on your welding helmet especially fast if you stick your head inside the welding fumes.

- Weld splatter – This one is the most damaging to your welding helmet’s lens. Sometimes, when you are in tight spaces or weld something dirty, you can’t prevent it by simply moving away. hot metal splatter will stick to the helmet, permanently damaging it (Tho in some cases, the lens can be brushed and restored)

- Scratches – Placing the helmet face down, welders do this all the time, especially if the helmet is not their own, and scratching its lens in the process. The moment you put down your welding helmet on its lens you can believe there will be a scratch there when you lift it up. Surface scratches you won’t see when you weld as long as there aren’t a lot of them, and they can be buffered and brushed in some cases. But the deeper scratches are something you will have to live with probably until you change the welding helmet lance.

Steps to Clean Your Welding Helmet Lens

Even so, it’s the first thing that comes to mind you should not clean a welding helmet’s dirty lenses with wet tissue or cloth, soft cloth, or any other. Why? Well, there is probably hot metal splatter stuck on it or a residue from a grinding wheel.

Second, when you swipe the cover lens with the soft cloth or any other, you will pull those metal particles and scratch the welding lens doing bigger damage.

1. Use water to clean welding helmet lens?

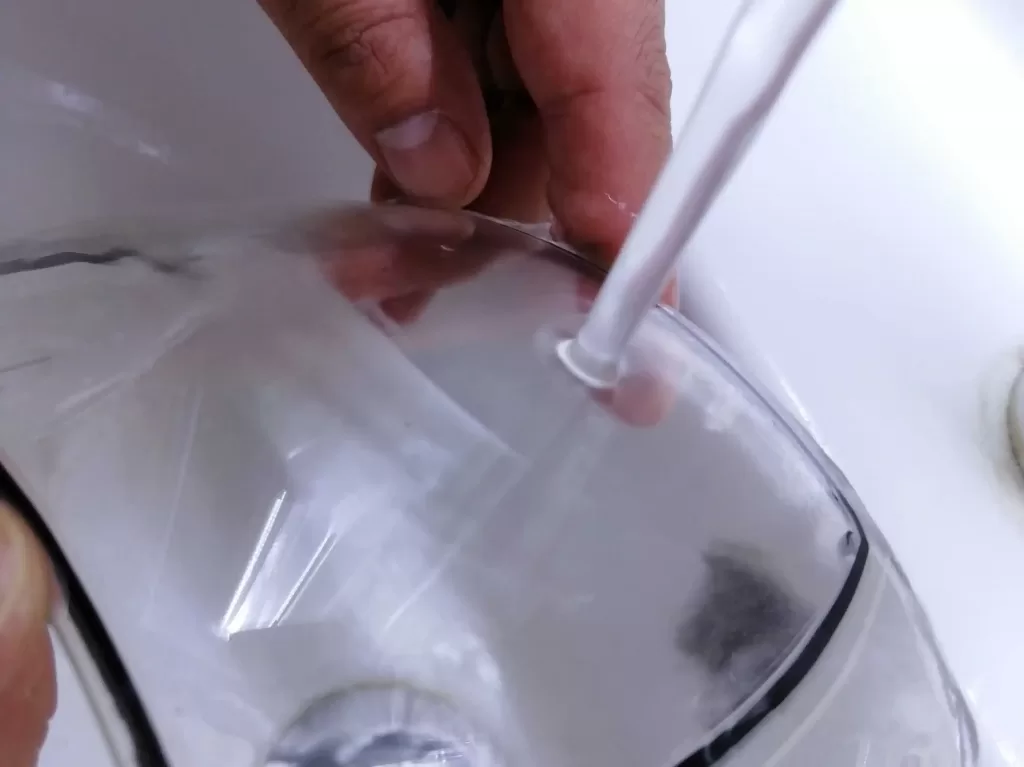

Most welders don’t do this because of the lack of time or laziness, but the smartest thing to do is to remove the cover lens and place it under the stream of water. Cold, hot, or plain room temperature water does not matter.

The water will remove potential dust and splatter particles. Then you can apply some careful cleaning process with a microfiber cloth or any other soft cloth that will remove the water and the rest of the dirt from the cover lens.

This won’t remove the fine scratches from the protective lens, but that’s not the point. The point is to clean the dirt and the dust from the welding fumes.

2. Final cleaning with furniture polish or a quality car wax

It’s also a good practice if you have time to do the final cleaning with a polish compound. These cans are dirt cheap and leave a wax coating on the welding hood that creates a kind of multi-layered lens protection.

This coating will make it harder for a hot metal splatter to stick and the fingers would leave less of a mark on a lens due to making your clear lens more slippery. It will take some time of your work but it’s the best way to get a clean welding helmet.

If the cover lens is extremely dirty, there is a special lens solution that will improve this process, but I would stick to just water and wax, or in the most extreme cases, I would just use dish detergent.

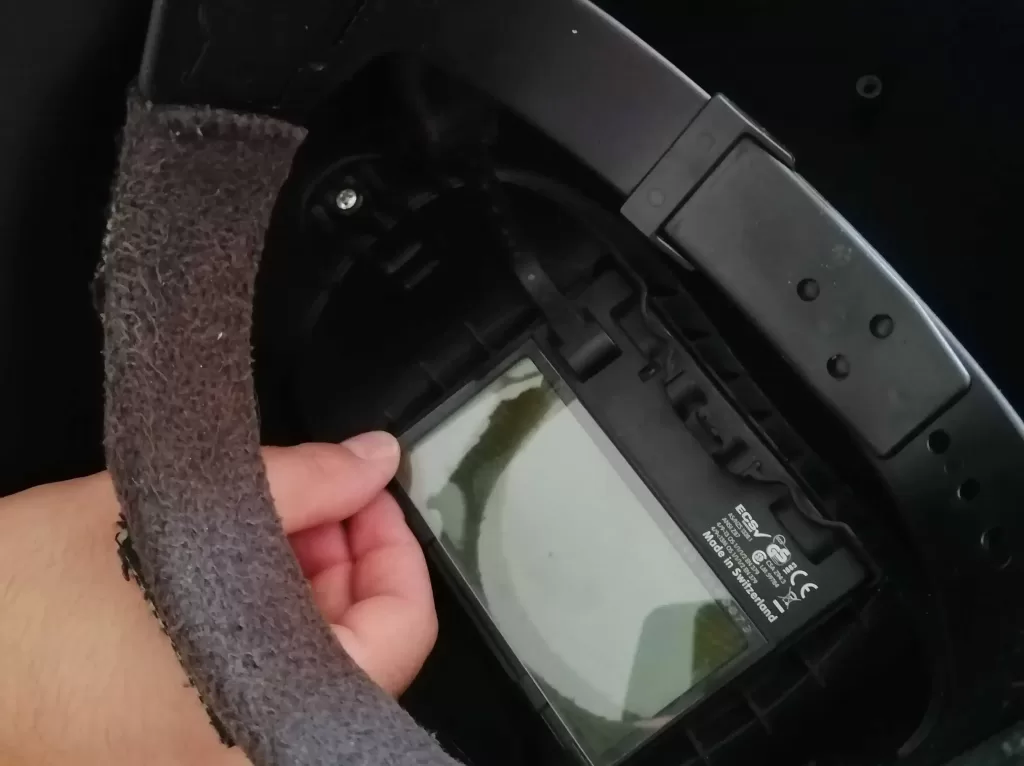

3. Cleaning the auto-darkening filters

For cleaning the auto-darkening filters themselves, well, I do not recommend doing it. It’s good practice to just keep your fingers out of the surfaces of the welding helmet’s auto-darkening filters, especially if you have dirty welding gloves on. But suppose ADF filters did somehow get dirty.

In that case, there are no specialized cleaning procedures, just read the helmet’s user manual and act accordingly. Still, as I say in most cases, you should just use a microfiber towel or soft-bristled brush to gently clean the sensitive surface layer of the ADF.

It’s of course, essential that you not use water for this part and do not rinse the front of the ADF filter or use anything that would scratch or damage the surface on the lenses.

4. Cleaning the insides of a welding hood

As you know, it gets pretty hot and sweaty during the welding process. The headgear and headband is dripping with sweat and should be regularly cleaned or it will become a breeding ground for germs. This can be mediated by wearing a welders hat, but you should at least wash the front headband every day after work.

Also, this is the number one reason why you don’t use other people’s welding helmets. Also, cleaning the helmet from the inside is a good practice because it’s literary what you have on your face for multiple hours every day.

Finally, be careful with battery-powered welding helmets around the battery area. You can easily damage circuits and sockets that house the battery or any hidden parts and it’s best to remove them all together during the cleaning process.

One more note for the inside cleaning – the protective lens that’s on the insides of the welding helmet is much more fragile than the one on the outsides. If you are playing on cleaning it be sure to only use water and no scraping of any kind, even the softest cloth will live a mark on it.

How to restore Welding helmet lens?

1. Use a polishing belt and soft buffing wheel.

Now what to do when cleaning does not help and your expensive welding helmet’s clear lenses are full of scratches and metal splatter marks on them?

Don’t throw it away! Especially if you have a buffing machine.

All you will need is a polishing belt and soft buffing wheel for your grinding stand or a light buffing compound addon for your angle grinder that will also do wonders.

Press the dirty lens against the buffing wheel and apply light pressure by moving it up and down. This way of cleaning your welding will remove scratched marks, dirt, and other foreign particles then do the same on the polishing belt and woala – you have a clean welding helmet and you saved up to 10 USD on the new replaceable clear lense.

2. Rubbing compound for polycarbonate safes (your lens is made of it)

If you don’t have a grinder or a shop, this one can also restore your front cover. Finally, there is this rubbing compound that car dealers and car shops use for final polish on your car after wet sanding it. It will work well for welding helmet lenses as much as for car headlights.

The downside is that this rubbing compound is expensive but if you are in the welding trade for the long run and you have an expensive welding helmet, it will pay off, considering you are using a few drops per cleaning.

Just place few drops on your welding helmet lenses and rub with a microfiber cloth till you remove all the soft scratch marks and other dirt. Do this multiple times if needed until you get the best result and save some money on replacement lenses.

Tips to Keep Your Lens Cleaner

- Keep your head away from the welding fumes as much as possible. Use magnifying lens if needed.

Besides the general health hazards that the welding fumes pose and a need to keep your respiratory system safe, the welding helmet will quickly be filled up with fumes residue and dust.

- Regularly clean your lens, use a cheap polish compound for finish cleaning. It’s effective at prolonging the lens use somewhat and will save you money and help with productivity.

- Never leave your helmet face down, especially in the workplace. The front shield lens will get damaged and scratched, and the exposed insides will fill up with dust. Properly store your helmet in a bag for this purpose.

- Remove batteries from the welding helmet when you don’t use it for more than a week to prolong their life. If the welding helmet has solar cells, live the helmet in a dark place after work to prolong their life. The hood should be stored in a bag or a welding helmet backpack.

- Wash and disinfect the front and back swat band every day after work. If you don’t, it will fill up with germs, sweat, and filth, and the pimples on your forehead will be the last of your worries.

Cleaning Passive welding helmet vs. auto-darkening hood.

The prime reason why most field welders are using those simple pancake passive hoods is cleaning. In the mud, sand, and generally on the outside weather conditions, modern helmets are a ballast on you.

It’s hard to keep the ADF filters lenses and the rest of the fine tech clean in these conditions and the helmet lifespan is greatly shortened from the constant wear and tear that for example, pipe welding requires. However, these simple helmets can be taken care of with just a clean rug and the front lens is cheap and replaceable so there is no need to take the time of your work to clean it.

So if you are going to do some fieldwork in bad conditions, don’t bother with cleaning and maintaining ADF hoods just buy a cheap passive helmet and use it. It will offer the same protection with little less clarity.