Nickel is a versatile metal that is known for its strength, corrosion resistance, and ability to withstand high temperatures.

The TIG weld process is one of the best methods for welding nickel, as it allows for precise control and minimal heat input. But, welding nickel can be challenging due to the metal’s tendency to crack and warp under heat.

In this article, we will take you through the process of TIG welding nickel, including tips and tricks for achieving a strong, clean weld every time. From selecting the right filler metal to controlling your heat input, this guide will give you the knowledge you need to tackle nickel welding with confidence.

Nickel Alloy Types And Applications

Nickel is a silvery-white metallic element used in alloys such as austenitic stainless steels and other corrosion-resistant alloys. Nickel is highly resistant to oxidation and corrosion, making it an ideal material for many industrial applications. This is also ductile and malleable metal, which allows it to be easily formed and machined into a variety of shapes.

There are several different types of nickel alloys, each with its own unique properties.

These include nickel-chromium alloys (NiCr), nickel-iron alloys (NiFe), nickel-molybdenum alloys (NiMo), nickel-copper alloys (NiCu), and nickel-titanium alloys (NiTi). Each of these alloys has different levels of corrosion resistance, strength, hardness, ductility, and other characteristics that make them ideal for specific applications.

Nickel alloys are used in a wide range of industries including aerospace, automotive, chemical processing, medical device manufacturing, oil and gas production, nuclear power, and more. In the aerospace industry, nickel-based superalloys are used to build engine components due to their high strength and temperature tolerance. In the automotive industry, nickel alloys are used in exhaust systems to reduce noise and increase efficiency.

Can Nickel be TIG Welded? – Weldability of Nickel and Nickel Alloys

The weldability of nickel and nickel alloys is determined by the specific properties of the alloy in question. Generally, nickel alloys are considered to be highly weldable with conventional welding processes, although some are more difficult than others. The source of difficulty often comes from their higher levels of hardness, strength, and corrosion resistance.

In terms of their weldability, these alloys can be classified according to the means by which the alloying elements develop the mechanical properties, namely solid solution alloys and precipitation-hardened alloys.

- Solid solution alloys are pure nickel, Ni-Cu alloys, and the simpler Fe-Ni-Cr alloys. These alloys are readily fusion welded, normally in the annealed condition. As the heat-affected zone (HAZ) does not harden, heat treatment is not usually required after welding.

- Precipitation hardenable alloys include Ni-Cu-Al-Ti, Ni-Cr-Al-Ti and Ni-Cr-Fe-Nb-Al-Ti. These alloys may be susceptible to post-weld heat treatment cracking.

How To TIG Weld Nickel & What’s The Best Way To Weld Nickel?

The first step in how to TIG weld nickel and nickel alloys is to prepare the workpiece by cleaning it thoroughly with a wire brush or grinder to remove any dirt or contaminants.

Then, the parts to be welded should be clamped firmly together in order to ensure proper alignment during welding.

The next step is to set up the welding machine with the correct parameters. The current, voltage, and amperage settings will depend on the thickness of the nickel alloy being welded, but the common applications won’t require more than 250 amps of power. To prevent overheating, it is important to adjust settings such as pulse, ramp-up and down amperage and use the foot pedal.

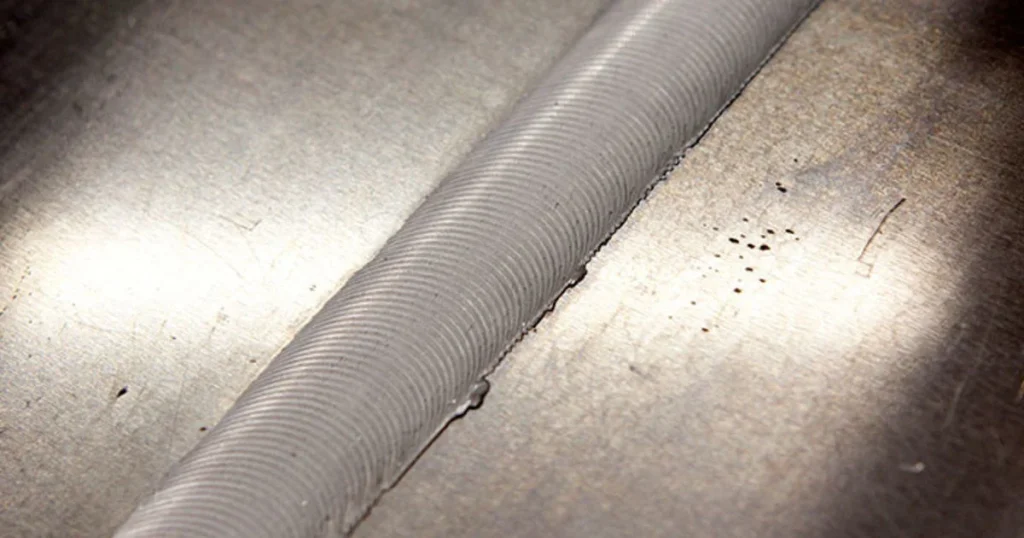

Use 2% thoriated tungsten electrode and argon as the shielding gas. Move slowly along the joint while maintaining a consistent distance between the electrode and workpiece, usually around 1/8 inch. As you progress along, gradually increase the amperage until both sides of the joint are melted together. Once this is done, quickly reduce the amperage and move away from the joint in order to avoid overheating.

It is important to keep in mind that welding nickel alloys can be difficult due to their high thermal conductivity and their tendency to harden when heated. This can cause cracking or other defects if not handled properly.

Weld Preparation And Cleaning For Nickle Welding

Before beginning TIG welding of nickel and nickel alloys, it is essential to clean the weld joint surface thoroughly. Weld cleaning helps to ensure that the quality of the weld is not compromised by contaminants and oxidation that may be present on the surface. Proper weld cleaning also helps to prevent porosity, spatter, and poor penetration in the weld.

Mechanical cleaning can also be used to clean nickel and nickel alloy welds prior to TIG welding. This method involves using abrasive materials such as stainless steel brushes and Scotch-Brite pads to remove any slag, rust, or other residues. The pickling solution dissolves oxides on the surface of the material, leaving a clean and bright surface suitable for welding.

Filler Material Used In Welding Of Nickel Alloys

The proper filler rod for TIG welding nickel and nickel alloys depends on the specific alloy being welded. Generally, the most common filler metals used are AWS ERNi-1, ERNi-2, and ERNiCu-7.

- AWS ERNi-1 is a high-purity nickel welding rod that is used for welding nickel alloys that have a low carbon content. It is also suitable for welding superalloys and can be used in applications that require a high level of corrosion resistance.

- AWS ERNi-2 nickel welding rods contain higher carbon steel content than ERNi-1, making it suitable for welding nickel alloys with higher carbon levels. It is also suitable for welding corrosion-resistant alloys such as Hastelloy and Inconel.

- AWS ERNiCu-7 is a copper-nickel alloy filler wire that is suitable for welding nickel alloys with high copper content, such as copper-nickel alloys, Monel, and Inconel 625. It has excellent corrosion resistance and is often used in seawater applications.

What Tungsten Electrode Is Used For Welding Nickel?

For TIG welding nickel and nickel alloys, alloyed thoriated tungsten is recommended. This type of tungsten contains a small amount of thorium oxide, which helps to increase electrical conductivity and arc stability when welding. The tungsten electrode is ground to a point with approximately angle 30 to 40 degree.

When selecting the right tungsten size for TIG welding nickel and nickel alloys, it is important to consider the amperage being used in the weld. Generally speaking, for welding at high amperage (above 150 amps), it is recommended to use larger diameter electrodes with a minimum of 1/16” diameter. For lower amperage (less than 150 amps), smaller diameter electrodes can be used such as 3/32” or 1/16” diameter electrodes.

Shielding Gas

The right shielding gas for TIG welding nickel and nickel alloys is typically a mixture of Argon, Helium, and Hydrogen. This mixture provides an inert atmosphere that shields the weld from contamination and oxidation, which can lead to cracking and other defects. Argon is the primary component in the shielding gas, with Helium and Hydrogen added in minor amounts to improve arc stability and reduce spatter. Depending on the alloy being welded, the exact percentages of each gas may vary; however, a typical mix for welding nickel alloys would be 75-90% Argon and 10-15% Helium, with a trace amount (1-2%) of Hydrogen.

Using this shielding gas mixture provides several benefits to the weld. Argon helps to maintain a stable arc and prevent contamination by oxygen or nitrogen in the atmosphere, while Helium can reduce weld spatter and increase arc stability. The addition of Hydrogen helps to reduce porosity in the weld, making it stronger and more ductile. Additionally, this combination of gases increases penetration into the base metals, making it easier to form a strong bond between them.

What’s the best Welding Technique for Nickle Welding?

The right technique for TIG welding nickel and nickel alloys is one that uses a clean, oxygen-free environment.

It is also important to properly adjust the current and voltage settings when welding with TIG as too high of a current can cause porosity in the welds while too low of a current can lead to incomplete fusion.

Furthermore, it is important to use the correct torch angle when welding as this can affect arc stability, as well as the shape of the weld bead. A torch angle of between 5°-15° should be used when TIG welding nickel and nickel alloys. It is also recommended that pulse welding be used in order to control heat input and reduce distortion.

Interpass temperature (measured 50mm (2”) from the joint should not be allowed to rise above 150°C (302°F) although some alloy suppliers recommend an interpass as low as 100°C (212°F) for certain alloys such as Alloy C276. Heat input should be limited to approx

Finally, it is important to use post-weld treatments such as stress relieving, solution annealing or aging in order to ensure maximum weld properties for certain alloys such as Inconel or Hastelloy. Proper post-weld treatments can help avoid cracking caused by thermal stress relief or metallurgical change, but it is only applied in specific cases and applications

What Are The Potential Issues When TIG Welding Nickel?

Nickel and its alloys are readily welded by Gas metal Arc Welding, Gas Tungsten Arc Welding, Shielded Metal Arc Welding, or Submerged Arc Welding processes. However, common issues during the TIG Nickel alloy welding process are:

- porosity

- oxide inclusions and lack of inter-run fusion

- weld metal solidification cracking

- microfissuring

Porosity occurs once oxygen and nitrogen from the air, surface oxide, or hydrogen enter the weld pool contamination. Careful cleaning of component surfaces and using a filler material containing deoxidants will reduce the risk. The oxide on the surface of nickel alloys has a much higher melting temperature than the base metal so that it may remain solid during welding.

Oxide trapped in the weld pool will form inclusions, that impact the overall strength and properties of the weld. Nickel alloys are susceptible to the formation of liquation cracks in reheated weld metal regions or parent metal HAZ. This type of cracking is controlled by factors outside the control of the welder such as grain size or impurity content.

Strain-age or re-heat cracking is likely to occur during post-weld aging of precipitation-hardening alloys but can be minimized by pre-weld heat treatment. Solution annealing is commonly used, but over-aging gives the most resistant condition

Welding does not normally make most nickel alloys susceptible to weld metal or HAZ corrosion. However, when Alloy 400 will be in contact with caustic soda, fluosilicates, or HF acid, stress corrosion cracking is possible.

Tips For Successful TIG Welding Nickel

- Set the amperage to the correct level for the nickel alloy being welded.

- Use 2% thoriated non-consumable tungsten electrode to minimize contamination.Use an argon-based shielding gas with a minimum of 98% purity.

- Use a clean and well-maintained TIG torch with a high-frequency start.

- Ensure all joints and weld surface is clean and free of rust, grease, and dirt.

- Use a foot pedal or other control to adjust amperage as needed throughout the welding process.

- Use a smaller, more focused arc to ensure better penetration, avoid stress corrosion cracking, and get better weld quality.

- Move the torch slowly and steadily to avoid creating gaps or holes.

- Use a filler rod that is compatible with the nickel alloy being welded.

- Allow the weld to cool slowly to prevent cracking or warping.

Final Thoughts

TIG welding nickel is a skill that any welder can learn with some practice. It is important to use the correct settings and technique when welding nickel and to make sure the weld area is clean before beginning. As with all welding, safety must always be a priority.

With the right tools and knowledge, TIG welding nickel can be a rewarding experience, allowing welders to create strong, reliable welds that will last for years.

Resources:

- https://www.twi-global.com/technical-knowledge/job-knowledge/welding-of-nickel-alloys-part-1-107

- https://www.weldingtipsandtricks.com/metals-and-how-to-weld-nickel.html

- https://www.corrotherm.co.uk/blog/weldability-of-nickel-alloys-a-guide

- https://teandersen.com/uploads/MNzKXPAN/technical_update_welding_of_nickel__nikel_alloys.pdf

- https://www.nickel-alloys.net/article/welding-of-nickel-alloys.html