Fabricators taking a hard look at the overall expense and process of their welding operation typically focus on the equipment cost and the labor associated with the welding process. The approach seems logical since welding equipment and consumables constitute an immediate up-front cost, and keeping parts moving through production represents the company’s livelihood.

However, labor constitutes over 80 percent of the total cost of a welding operation, making it worthwhile to think “outside the weld cell.” Therefore we will examine using metal cored wire to cut labor costs, as well as quality issues and overall throughput in pre-weld and post-weld activities.

Addressing problems

Many companies use Gas Metal Arc welding (GMAW) with solid wire for their welding processes. In addition, most shops have pre-and post-weld areas to ensure defective-free, visually appealing parts.

The main reason is that solid wire does not weld through mill scale or rust, making it necessary to perform pre-weld cleaning activities such as sandblasting. Also, because solid wire tends to generate spatter during welding, companies apply anti-spatter in the pre-weld area.

In addition, they maintain the post-weld area for grinding parts before a finishing application, such as powder coating or painting. The labor in both these areas essentially is non-value added because it does not create parts — it exists to compensate for the shortcomings of the solid wire welding process.

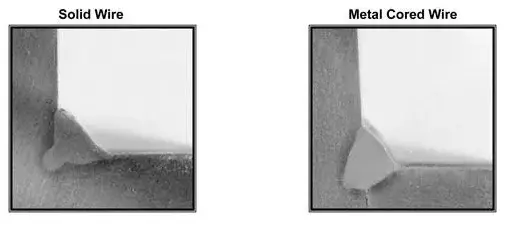

Shops that understand how solid and metal cored wires differ in performance can determine if switching a process will allow them to eliminate these non-value-added activities, reallocate labor, and improve throughput.

Advantages of Metal Cored Wire Over Solid Wire

A metal cored wire could offers many benefits and advantages over the solid wire in terms of reducing these pre-weld activities. First, a metal cored wire can weld through mill scale and rust and achieve a smooth weld bead. Second, it uses lower voltage settings and produces a more rounded penetration profile than solid wire giving welders more control.

Metal cored wire also produces a more stable arc that reduces, and sometimes eliminates, weld spatter. If a fabrication shop switches to the metal cored wire, the 14 minutes spent sandblasting and applying anti-spatter can be shifted to the welding cell, increasing throughput by 50 percent, saving time and eliminating the costs for purchasing antispatter or cleaning it off floors and machinery. In addition, eliminating grinding activities caused by spatter can reduce the risk of grinding injuries and related downtime and employee compensation costs.

Look Beyond The Weld Cell

The welding cell usually is the first place shop owners look when reviewing labor costs. Since metal cored wire costs about 50 percent more per unit than solid wire, evaluating throughput gains solely in the weld cell only shows a small gain. However, metal cored wire presents a more significant opportunity for cost savings and improved productivity in pre- and post-weld areas.

Using solid wire, a company could spend 40 minutes in the weld cell, producing a part requiring 20 minutes for welding and 20 minutes for non welding activities. Suppose the company switches to the metal cored wire. In that case, it could increase the deposition rate and travel speed by 20 percent, gaining four minutes of throughput and an overall productivity increase of 10 percent. If that gain seems small, remember metal cored wire also helps prevent rework and reduce the number of rejected parts caused by solid wire process deficiencies, particularly with thinner parts.

Compared to the metal cored wire, the solid wire tends to generate spatter if operators fail to maintain proper contact tip-to-work distance or gun angles. In addition, in robotic welding applications, the fingernail penetration profile of solid wire reduces the tolerance window with respect to the weld joint and could cause the robot to miss the weld joint more often and burn through parts, especially if the fit-up is not exact. Metal cored wire can help to minimize rework caused by such problems.

Pre-weld activities

For solid wire to burn through mill scale, welding operators typically increase the welding voltage causing the arc to lengthen, which makes it less stable. As a result, the heat-affected zone widens, undercut and burn-through problems increase, and weld quality declines. That is the reason that shops opt to grind and sandblast.

However, pre-weld activities subtract money and minutes from weld cell production.

In fact, every minute spent on parts in the pre-weld area means one less minute of welding and the potential for one less part being produced. The pre-weld area also can become a productivity bottleneck where operators wait for parts to be treated.

Consider a company that typically spends 30 minutes treating parts for welding preparation. That includes 10 minutes for sandblasting and four minutes to apply anti-spatter. Then, they spend the remaining 16 minutes fitting, tacking, lifting, and moving parts.

Post-weld Activities

Material and labor costs are attached to every part a company rejects or reworks. If a shop makes 100 parts per hour at a total cost of $1.00 per part and rejects 5 percent, it loses $5.00 per hour. If it operates seven days a week, 52 weeks a year, running three 8-hour shifts, it stands to lose $43,680 annually in material and labor. It also compounds the loss by not producing those 43,680 parts to sell.

By switching to the metal cored wire, a company could reasonably reduce its rejection costs to 1 percent or less. In this example, that would mean trimming its costs from $43,680 to $8,736 while increasing throughput by 34,944 parts a year. Another way to save on MIG wire is to buy electrode packages in bulk.

As with pre-weld activities, labor required for post-weld rework also is non-value added, compensating for process deficiencies rather than contributing to throughput. However, the metal cored wire can reduce rework and its associated labor costs by up to 80 percent. That means shops spending 30 minutes on post-weld activities would spend six, gaining 24 minutes of production time in the weld cell. Add this to pre-weld savings, and a firm gains a combined total of 42 minutes per part, making the company more productive and profitable.

Resources:

- How Metal-Cored Wires Reduce Hidden Welding Costs by www.welding.com.au

- How metal-cored wires reduce hidden welding costs by TheFabricator