MIG Welders are exposed to different hazardous elements every day. In addition, by working with electricity, they are at risk of electric shock, fires, and other potential illnesses.

These risks start as soon as you step foot in the workplace.

The best way to avoid the risk is to follow the MIG welding safety tips provided by welding safety organizations.

We made this article to point out the potential dangers, give you a tip on preventing them, or how to act if one happens. If you follow the given safety precautions, I’m sure you’ll stay healthy to enjoy your well-deserved retirement as a welder.

Basic safety measures and best practices either in the workplace or in your garage

You can never be too safe when it comes to welding. There are certain practices when MIG welding that nobody will tell you to do. Finding it out by yourself may also mean paying a heavy toll. But we are all friends here so here are some very useful safety tips that could keep you from harm.

Have a Soap Water Bottle Close to the Gas Regulator

It can be hard to notice a leaky gas regulator, especially while working in a noisy workshop or a construction site. So a water bottle with some soap comes in handy. If you can’t hear the leak but are still not sure if the regulator functions properly, just pour some soapy water on it. If you notice bubbles that’s a clear sign that a regulator is faulty and you have to tighten it or change it.

Keep the Power Cables and Gas Hose away from the Sparks

Organize your work area so both the power cables and gas hoses are not under the table nor stacked around it. Basically, keep it away from the sparks and spatter area.

They can damage the cables and the hose. The hose is particularly vulnerable as it can easily get ruptured by flying sparks.

It goes double if you are doing oxy-acetylene welding as the sparks could potentially ignite the gas.

Safe Distance For Gas Cylinder

Besides storing gas cylinders in an upright position, you also have to keep them away from the welding area.

You have to position them as far as possible from the working area so sparks, hot slag, or flame don’t reach them. If you can’t place them at a safe enough distance, a fire-resistant shield should be placed.

You also have to position them somewhere where they cannot be a part of an electrical circuit. Electrodes cannot be struck against a cylinder to avoid striking an arc.

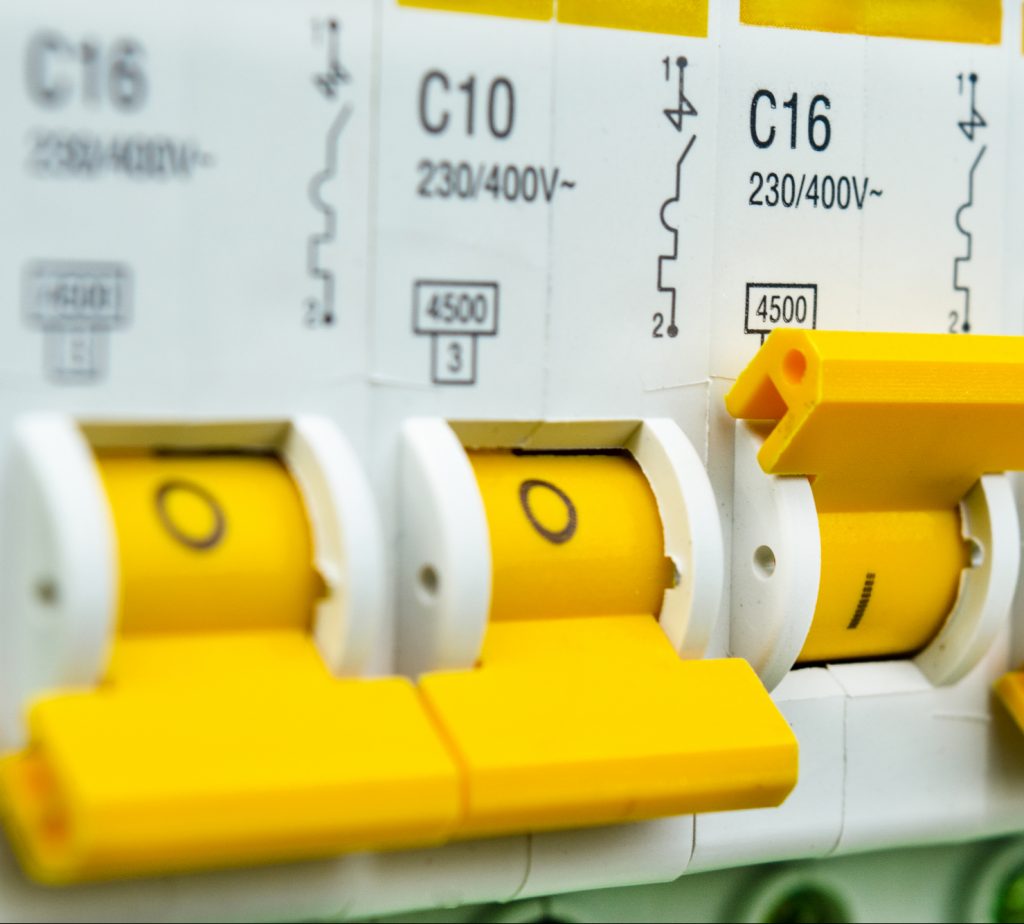

New Power Breakers

MIG welders draw a lot of power and thus need substantial wiring. You can’t be working with old or faulty breakers, you have to make sure that they are either new and working properly.

The size of the breaker depends on the amount of current a machine needs. So a welder that works at 27 amps needs 30 amps circuit breakers. The wire gauge also needs to be taken into account, so a circuit with a 20 amps circuit breaker will require a minimum 12-gauge wire.

To put it simply, a 220v welder requires a 30-40 circuit breaker while a 115v machine will need 20-30 circuit breakers at least.

MIG Welding Hazards and in-depth view on safety measures

Metal Inert Gas Welding (MIG) is one of the most common welding processes. It can weld a wide range of material types and is one of the most popular among hobbyists.

The MIG process produces different hazards. In many instances, besides the operator, everyone in the vicinity is at risk, including inspectors and other workers. Some hazards occur before, some during, and some even after the welding activity, so you must pay close attention.

All the MIG welding hazards are divided into three groups:

- Electric hazards and Magnetic Fields

- Compressed Gases, including inert gases

- Radiation

Pre-Operation Safety

As we said, some hazards occur before the MIG welding process. However, there are a couple of things you should do to prevent them.

The organization is critical, and all you need to do is follow welding safety practices and use the proper safety equipment to ensure a safe welding environment.

Provide Clean Workspace

A clean work area will significantly reduce the chances of accidents during arc welding, including MIG welding. It would be best if you got rid of any dirty plate that unknown substances may contaminate.

You should also remove all grease, paint, coating from your workpiece, and flammable items from your area before starting an arc. Doing that will reduce potential injuries, fire and create a protected area.

Remove Nearby Flammable Materials

Note that the MIG welding process includes hot work, sparks fly all around the workshop, and molten metal even several feet. By getting in touch with nearby flammable materials, they can cause fire hazards.

You can minimize the risk by removing any flammable liquid from the workspace. The best way to do it is by:

- Check the flame retardant qualities of the walls.

- Make sure you use the concrete floor in your workshop.

- Inspect the room and make sure there are no flammable materials 35 feet away from the welded materials

- Keep degreasing the nearby products.

Check the Ventilation

Toxic fumes are an inevitable part of welding, but you can keep them out of your breathing area. However, keep in mind that vapors can cause severe damage to your respiratory system.

To prevent the hazard, it is essential that you:

- Make sure the workplace has proper ventilation,

- You should use respiratory protective equipment if needed,

- When recommended, use the local exhaust ventilation,

- Be careful when working with carbon dioxide.

- Use a higher percentage during pulse-spray transfer or argon to reduce the risk of gas-related hazards.

Remove Jewelry

One of the first things you learn when starting a welding protection course is to remove all jewelry and loose items before welding. Also, loose clothing and long hair can be dangerous.

The main risk with loose clothes, welding equipment, and long hair is that grinder can get a hold of them if you are not very cautious. That can lead to severe damage.

In addition, weld spatter can destroy your precious jewelry and burn you in the process. The best way to avoid these injuries is to tie your hair and remove loose items and jewelry, but a clean nozzle reduces spatter.

Inspect Connections and Gas Lines

MIG welding uses a high-pressure shielding gas, which comes out of the bottles or cylinders. Before starting to weld, you should inspect all the lines and connections.

When dealing with cylinders, there is a couple of things you should pay attention to:

- Bottles must be chained all the time,

- Bottles shouldn’t be capped,

- Make sure your cylinder is tested and within OSHA standards,

- Position Cylinders far from potential hazards,

- When using a high-pressure bottle, make certain valves are either ON or OFF

- Make sure there are no gas leaks

MIG Welding Equipment

MIG equipment is not so different from other protective clothing. Here is a quick list of welding safety equipment you need to provide before actually welding:

- Welding Helmet: Welding helmets provide eye protection and keep you safe from UV light. Shade 10 or 11 lens auto-darkening helmet will ensure proper eye protection from the UV rays,

- Welding mask: will protect your bare skin from ultraviolet lightning and arc flash (really painful condition) and can be worn between your head and a welding helmet

- Safety glasses: Safety Glasses protect your eyes from sparks and flying spatter when grinding and cleaning the weld,

- Welding gloves: Leather gloves with insulation can protect you from electrical shock and burns caused by heat, spark, or molten metal. Some welding glove even has a reflective coating to deal with heavy plate welding heat.

- Long pants: Should be made of cotton leather or fire retardant material. Denim pants also protect your body from arc radiation.

- Leather boots: Protect your feet from sparks and falling objects,

- Welding jacket: Wear a proper leather jacket that will protect your body from sparks, spatter and weld arc radiation.

| Bad Practice | Hazards |

| No face protection | Arc eye, burn |

| No arm protection | Burn |

| Exposed cloth | Fire |

| Exposed solvent | Fire, Explosion, Toxic Vapor |

| Bystander exposed to Arc | Arc eye |

| Fire exit obstructed | Fire, burns |

| Fire bucket unsuitable for an electrical fire | Electric shock |

| Fume extraction is not effective | Inhalation of harmful welding fumes and gases |

| No work earth | Shock |

| Cable damaged | Stray arc, burns, electric shock |

Specific MIG Welding Concerns

When it comes to MIG welding safety, you need to be aware of very particular issues. Some specific concerns will affect your health slightly, but the high amounts can even cause death without any notice.

MIG welders should pay close attention to:

- Wire feeder

- Shielding Gases

- Welding Fumes

- Alloys in Auxiliary Materials

Wire Feeder Safety Issues

As much as practical, wire feeder have some specific issues.

Once you stop welding, the electrode stick-out leaves a hot, molten metal droplet that can easily penetrate your welding gloves and burn your hands.

In addition, once you change your MIG welding gun tips or wire, if you accidentally press the trigger, you can suffer a slight electric shock.

Finally, you can press the trigger by mistake or have an auto-feed feature enabled. Gun will continue to feed the wire and shielding gas, which will, in most cases, result in a hot wire bird nest. Pay close attention as auto-feed can set things on fire if it reaches flammable liquids or combustible materials, short circuit, or shock you.

If a fire occurs, make sure you have a proper fire extinguisher, sandbox, and other fire safety equipment.

Shielding Gas Safety Issues

MIG welding uses inert, non-active gases, primarily argon, to keep the welds clean. In some situations, helium can assist in protecting the weld against oxidation due to external oxygen influence.

Most shielding gases will fill your welding area like water from the bottom up. Once levels reach your breathing zone, you can suffocate without knowing. Welders usually start to feel tired.

After that, they pass out without any notice.

MIG Welding Fumes

MIG welding produces relatively low quantities of fumes compared to Stick welding and TIG welding. However, risks can be found when looking at details.

Welding aluminum release fumes which contain aluminium oxide. This oxide is a hazardous substance, which can cause dust deposits in the respiratory tract and lungs.

In addition, exposure can result in metal poisoning, known as welding shivers – flu-like symptoms that last few days.

In addition, when welding aluminum alloys, ozone can be created. A combination of the welding arc and a low quantity of fumes make it. MIG welding application creates ten times more ozone than any other process.

Inhaling ozone can cause acute irritant gas poisoning, mucous membrane irritations, and pulmonary edema.

Nickel Alloys as Auxiliary Metals

The highest risk in auxiliary materials causes nickel and nickel-based alloys. When MIG welding them, fumes can contain nearly 87% of nickel oxide, classed as carcinogenic.

If copper is present in nickel-based alloys, larger quantities of vapors are created than alloys with chrome or cobalt. As a result, copper oxide becomes the main component, which is highly toxic and can cause metal fever and burning sensation.

More on nickel welding here

Post-Operation Safety

Once you have completed your welding safely, you should take care of the post-operation measures. There are a couple of things you should do:

- Make sure you turn off your machine entirely,

- Close your has cylinders,

- Store your welding gun properly.

As you noted, you should be careful since you step into the workshop until you finish your welding. You should pay attention to visible light (ultraviolet light), infrared rays, toxic vapors, trip hazards, arc eye, and make sure not to catch sparks in your weld area.

Common MIG Welding Arc Hazards, and How To Prevent Them

Here are some tips brought to you by experienced welders to help you prevent common MIG welding hazards.

Electric shock:

MIG welding power source and related pieces of equipment require electricity to operate. Since electric hazards can cause severe damage, here are a couple of things you can do to increase safety:

- Make sure only qualified personnel should install MIG equipment and machines

- Before using the equipment, you should make sure it is working properly

- Make sure electrode holder cables and working tools are well insulated and don’t wear wet clothing

- Once it stops working, welders shouldn’t do any repair work or touch the lead with power still on,

- Welders shouldn’t ignore a blown fuse; it is a warning something is wrong,

Compressed Gasses:

Inert shielding gases aren’t toxic, but they can cause severe damage and are classified as health hazards. Here are a couple of things you can do to increase your safety:

- Always use the proper regulator that fits the pressure of your cylinder

- Never modify a regulator; they are built for specific cylinders

- Make sure you have a breathable air supply in your weld zone

- Work in a well-ventilated area, or provide an exhaust hood when working in a confined space

Radiation:

MIG welding produces radiation over a wide range of wavelengths which can be a severe health hazard. Bright light reflects from stainless steel and other blank surfaces, and it can cause permanent damage to your eyes, while high temperatures can cause severe burns. Here are a couple of things to keep in mind:

- Radiation is generated at the same time as the arc is generated; a higher current only increases it

- Burns can be avoided by wearing proper protective clothing. Short-sleeved shirts will leave your skin exposed, and pant cuffs can collect sparks

- Protect your eyes from sudden flashes by wearing auto-darkening helmets with side shields and filter lens

Conclusion

We can all agree welding is a dangerous occupation. MIG welders are at everyday risk of fires, toxic fumes, electrical shocks, and injuries from the second they step into the workshop until the end of their shift.

To prevent the possible hazards, first, you should be aware of them. Knowing where the danger comes from is crucial. By protecting yourself, you protect all the employees around you.

MIG welding can be a safe occupation once you follow all the safety guidelines, precautions, and common sense. Thoughtful manufacturers and companies will always provide adequate training for their workers. If you want to read more about MIG welding in specific you can check this article that goes into detail

Resources:

- 12 Tips to Increase Your Welding Safety, by Miller

- More information on MIG Welding Safety

- MIG Welder Safety by GoWelding Organization

- MIG welding: highly hazardous despite lower quantities of welding fumes, by SafeWelding

- Welding Occupational Safety and Health Standards, by OSHA

- Welding Safety, by Lincoln Electric