When it comes to MIG (Metal Inert Gas) welding, the choice of shielding gas can significantly impact the welding process and the quality of the final welds. While commonly used gases like argon and carbon dioxide have their merits, helium has emerged as a game-changer in the welding industry.

Helium, with its unique properties, offers exceptional benefits when used as a shielding gas in MIG welding.

This article delves into the world of MIG welding with helium shielding gas, exploring its advantages, considerations, and techniques. Join us on this journey as we uncover the secrets to achieving impeccable welds by harnessing the power of helium shielding gas.

Inert Gases In MIG Welding

Inert gases play a crucial role in MIG (Metal Inert Gas, Gas Metal Arc) welding as they serve as shielding gases to protect the molten weld pool and the electrode from atmospheric contamination.

Argon and helium are common shielding gases that are chosen as shielding gases because they are chemically inert and do not readily react with the weld pool or the surrounding atmosphere. By surrounding the arc and the weld area, they create a protective atmosphere that displaces oxygen and other contaminants.

The choice of inert gas depends on various factors, including the welding process, the material being welded, and specific welding requirements. Argon is the most commonly used inert gas in MIG welding due to its affordability, effectiveness, and versatility. Helium is another popular option, particularly for applications that require higher heat input and greater penetration.

How Does Helium Affect MIG Welding Arc?

Helium, a noble gas renowned for its low density and high thermal conductivity, has found its application as a shielding gas in MIG (Metal Inert Gas) welding. Unlike traditional gases like argon and carbon dioxide, helium offers unique advantages that make it a desirable option in certain welding scenarios.

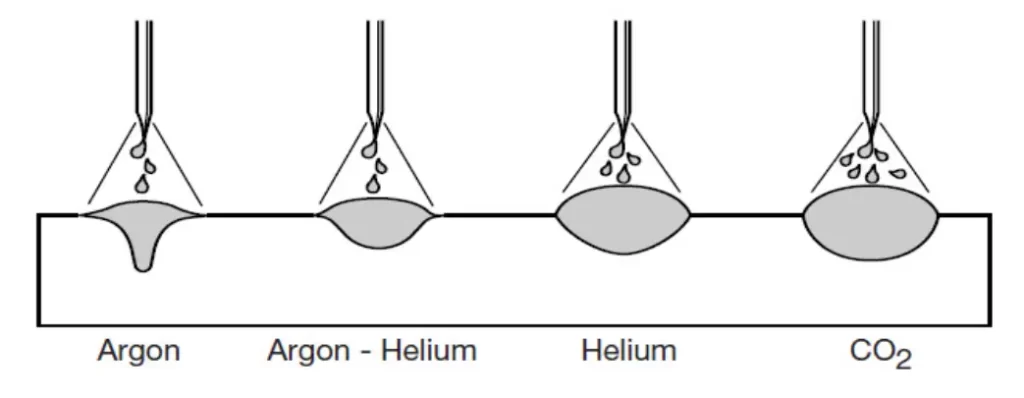

Firstly, helium’s low density allows for faster gas flow, resulting in better arc stability and penetration. This characteristic is especially beneficial when welding thicker materials or when a deep weld penetration is desired.

Secondly, helium’s high thermal conductivity aids in efficient heat dissipation, reducing the risk of overheating and distortion in the welded material. This property is particularly advantageous when welding heat-sensitive alloys or materials prone to warping.

Furthermore, helium’s ability to transfer heat quickly promotes faster welding speeds, increasing productivity and reducing overall project time.

Can You MIG Weld With Pure (100%) Helium?

Pure helium is not commonly used as a shielding gas in MIG (Metal Inert Gas) welding. While helium possesses unique properties that can benefit the welding process, it is typically used in combination with other gases rather than as a standalone gas.

There are a few reasons why pure helium is not commonly used. Firstly, pure helium tends to create an unstable and erratic arc, making it challenging to control during welding. This can result in an inconsistent weld bead and compromised weld quality.

Secondly, helium is a lighter gas compared to other shielding gases like argon and carbon dioxide. As a result, it tends to displace the surrounding air more easily, leading to increased gas flow rates and potential difficulties in containing the shielding gas within the welding area.

Lastly, pure helium is more expensive compared to other shielding gases. Its scarcity and high production costs contribute to its higher price point, making it less economically viable for most welding applications.

Why Is Industrial Grade Helium So Expensive?

Helium was first introduced as a shielding gas in the welding industry in the mid-20th century, particularly in the 1940s and 1950s. One of the primary reasons for helium’s high cost is its scarcity. Helium is an inert gas that is obtained from natural gas deposits through a process known as cryogenic gas separation.

However, the concentration of helium in natural gas sources is typically low, making its extraction and purification challenging and costly. Furthermore, helium is a non-renewable resource. Once released into the atmosphere, it tends to escape the Earth’s gravitational pull and dissipate into space. This limited supply and difficulty in replenishment contribute to its high price.

What Are The Alternatives To Pure Helium Welding?

While pure CO2 (carbon dioxide) is not a direct replacement for pure helium as a shielding gas in all welding applications, it can be a suitable alternative in certain scenarios. CO2 is generally more cost-effective compared to helium, making it an attractive option, especially for budget-conscious welders or projects with cost constraints.

Additionally, carbon dioxide provides good weld penetration due to its higher thermal conductivity compared to helium. It can deliver higher heat input, which is beneficial for welding thicker materials or achieving deeper penetration.

CO2 also allows for faster welding speeds due to its ability to transfer heat quickly, just like helium. This can be advantageous for improving productivity in certain applications.

However, while pure CO2 can provide adequate shielding for some welding applications, it may not offer the same level of protection against oxidation as helium. As a result, CO2 is commonly used for welding carbon steels and low-alloy steels. It may not be as suitable for welding non-ferrous metals or materials sensitive to oxidation, where helium or a helium-based mixture is often preferred.

Due to high costs and low availability on the market, many hobby and less demanding welders choose carbon dioxide as a replacement for helium in mixtures and pure shielding, but usually when welding steel.

Another alternative when MIG welding non-ferrous metals is mixing argon and helium, usually in a 75-25% ratio.

MIG Welding With Argon/Helium Mixture

The argon/helium mixture offers excellent arc stability, enhanced penetration, and improved heat transfer, making it suitable for a range of MIG welding applications. Its versatility makes it particularly advantageous for aluminum welding, stainless steels, non-ferrous metal welding, and welding thicker materials.

The combination of argon’s stability and helium’s heat conductivity helps maintain a steady and controlled arc throughout the welding process. Helium’s high thermal conductivity, when combined with argon, enhances heat transfer and increases the penetration capability of the welding process. The helium component accelerates heat transfer, enabling faster travel speeds while maintaining proper penetration and weld quality.

The increased heat input and penetration capability of the argon/helium mixture make it well-suited for welding thicker sections or heavy plates. The combination of gases ensures sufficient heat transfer and weld fusion in challenging applications involving thick materials. Additionally, it can be used when MIG welding stainless steel, aluminum or non-ferrous metals.

When it comes to MIG welding mild steel, welders will once again choose CO2 (carbon dioxide) instead of helium. The ratio of 75% Argon and 25% CO2 is known as one of the most popular mild steel mixtures – C25. The added carbon dioxide will increase weld penetration and arc stability on steel, which is also the role of helium. However, CO2 is significantly cheaper, and you can find it in local breweries, paintball, or aquarium tank stores.

In What Applications Is Pure Helium Suitable Option?

Pure helium can even be used when particularly high heat input is required, for example, when TIG welding (Gas Tungsten Arc Welding) thick copper material. Helium is also fine for thicker sections of stainless steel. Some TIG welders that specialize in SS use only Ultra High Purity Helium. As with aluminum it adds a lot more heat and requires a faster travel speed and higher flow rates.

However, keep in mind that when using pure helium, a powerful high-frequency spark, and adjustable ignition parameters are very beneficial. You might find it super hard to start an arc below the 150 amps, so make sure you have a powerful enough TIG welder to run pure helium properly.

Pros and Cons Of MIG Welding With Helium Shielding Gas

Pros of MIG Welding with Helium Shielding Gas:

- Improved penetration: Helium, with its high thermal conductivity, facilitates deeper weld penetration, making it suitable for welding thicker materials or achieving greater joint strength.

- Higher welding speeds: Helium’s ability to transfer heat quickly allows for faster welding speeds, leading to increased productivity and reduced project time.

- Enhanced arc stability: Helium can contribute to a more stable arc during welding, resulting in improved control, reduced spatter, and enhanced weld bead appearance.

- Heat dissipation: Helium’s high thermal conductivity aids in efficient heat dissipation, reducing the risk of overheating and distortion in the welded material.

- Suitable for non-ferrous metals: Helium is often preferred for welding non-ferrous metals like when you weld aluminum, copper, and titanium due to its ability to provide the necessary heat input and ensure proper fusion.

Cons of MIG Welding with Helium Shielding Gas:

- Erratic arc behavior: Helium, when used as a pure shielding gas, can create a more erratic and less controllable arc compared to other gases, demanding greater skill and technique from the welder.

- Higher cost: Helium is generally more expensive than other commonly used shielding gases like pure argon and CO2, which can impact the overall cost of the welding process.

- Increased gas flow rates: Helium’s low density can result in higher gas flow rates compared to denser gases, leading to increased consumption and potential difficulties in containing the shielding gas within the welding area.

- Limited material compatibility: While helium is beneficial for non-ferrous metals, it may not be as suitable for certain ferrous materials or applications where reduced heat input is required.

- Limited availability: Helium is a scarce resource, and its availability can vary regionally, potentially leading to supply constraints and affecting its cost and accessibility.

Conclusion

MIG welding with helium shielding gas offers both advantages and limitations. The high thermal conductivity and improved penetration of helium make it a valuable option for welding thick material and achieving deeper weld penetration.

Additionally, its ability to transfer heat quickly allows for higher welding speeds, enhancing productivity. Helium can contribute to a more stable arc, better control, and enhanced weld bead appearance. However, the erratic arc behavior and higher cost of helium compared to other shielding gases pose challenges. The increased gas flow rates and limited availability of helium should also be considered.

Resources

- https://www.thefabricator.com/thefabricator/article/consumables/whats-up-with-helium-for-welding-applicationsr

- https://www.alleima.com/en/technical-center/shielding-the-weld/

- https://www.pirate4x4.com/threads/mig-welding-with-helium.874058/

- https://weldingweb.com/vbb/threads/43682-Pure-helium-with-MIG

- https://www.millerwelds.com/resources/article-library/what-gas-should-you-use-for-mig-welding-in-diy-applications