Choosing a career in welding means that you are going to come across various types of materials. One such weld metal is definitely going to be a nickel.

Nickel is known for its corrosion-resistance properties and the ability to perform in different environments.

These two characteristics alone make it a very valuable material that can be used for various purposes. But how does nickel welding work? A welder should maintain the necessary properties across a weld metal or a weld pool for the product to perform as adequately as possible.

To say it bluntly, try not to mess things up too much so you don’t end up with a piece of scrap that you are going to regret. To help you not end up with a pile of scrap metal, our article details tips and good practices needed for nickel welding.

Nickel Alloys and Properties

Characteristics that make nickel so useful are that it is very versatile, possesses corrosion-resistance properties, and performing under high temperatures.

Thanks to these advantages it has become a popular choice for usage in extreme environments and is often seen used in steam turbines, aircraft turbines, nuclear power plants, petrochemical, and chemical industries.

However, in order for it to perform well in various extreme conditions, the weld zone and the weld pool have to possess consistent properties.

Failing to weld it properly will result in a product that is not going to withstand the extreme environment it is meant for. Welders need to make sure that the end product is of high quality and that there are virtually no flaws. A flawed product will not be able to perform in harsh environments and will eventually fail its purpose.

Nickel Alloys Properties

A welder has to have a thorough understating of the most important properties used to weld nickel.

- Low Conductivity – Alloys nickel is often combined with chromium to create heating elements. Low conductivity elements made from these materials can get red hot fast when applying an electric current.

- Corrosion Resistance – Nickel alloys are resistant to corrosion more than other materials and can withstand certain types of acids and alkaline solutions.

- Resistance to Oxidation and Scaling – You can heat it up all the way to red hot temperatures without fear of them scaling.

- Hardness and Strength – Adding aluminum and titanium can substantially strengthen up the heat-affected zone of some nickel alloys.

Welding Nickel

One of the best parts about welding nickel alloys is that it can be done with any type of welding process or method, except oxyacetylene and forge welding.

Conditions needed to weld are similar to those of working on austenitic stainless steels. However, cast nickel alloys, especially those that have a high silicon content, are going to present a problem.

The most widely used welding processes are gas-tungsten arc welding (TIG welding), shielded metal arc welding (MMA or Stick), and gas-metal arc welding (MIG). In order to perform successful nickel alloy welding you will need a quality TIG welder so don’t bother with any random cheap machine.

Weld Preparation for Nickel Welding

As every welder with any welding experience will tell you, preparation is the mother of success. This goes for all types of materials but is especially important for nickel alloys. The most important part of your preparation process is having sufficient access to the welding torch so full penetration can be achieved.

Contamination can also be detrimental, especially Sulfur, Lead, Phosphorus, Bismuth, and Boron which are found in machining or cutting fluids. Various greases and oils, marker pens, corrosion products, and thermal crayons can all cause solidification or hot cracking. So make sure to keep your workshop tidy and your welding area clean with some wire brushing before you start.

Design of the Weld Preparation

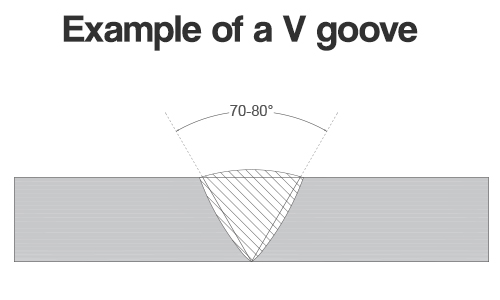

You are going to notice that nickel alloys are sluggish in nature. Because of that, the joint design of the weld preparation has to be done perfectly to achieve good access to manipulation. But it should not be done too wide as it might cause solidification cracking.

Usually, a V-preparation with an angle of 70 to 80 degrees works best.

However, changing to a double V or U preparation at an angle of 30 to 40 degrees when working 10 mm thick material can work.

The fluidity of the weld pool can be improved by adding 10% Hydrogen. Thinner root faces of 1.6mm are required due to the difficult nature of weld preparation.

Nickle-Bronze Welding Flux

Welding of these types of alloys does not require the use of flux. But, it is needed for Monel and Inconel. Fluxes are only used as a thin paste made by mixing dry flux and water for Monel. As for Inconel, a solution made of shellac and alcohol (1.0 lb (0.45 kg) of shellac and 1.0 gal (3.81) alcohol mix) can be used. Welding K Monel requires a solution made out of Inconel flux and lithium fluoride.

Shielding Gas

The best shielding gas is either argon or helium, or a mix of the two. Using shielding gases in addition to oxygen, nitrogen, and carbon dioxide should not be done as it may cause porosity or erosion of the electrode.

You can still use argon with around 5% of hydrogen as it may help avoid porosity in pure nickel. It can also prevent oxide formation.

Nickel-Plated Welding Rodes

Welding rods of the same composition as the alloy welded should be employed. This practice should ensure uniform resistance to corrosion without any galvanic effects. There are situations when a special silicon Monel rod can be used, though.

The most suitable welding rod that we found useful is the HTS-528 Brazing rod as it can be used for joining nickel together or with iron, carbon steel, copper, stainless steels, brass, or bronze.

Pre Heating

Preheating is usually not necessary, but if you notice some moisture on the workpiece you should remove it. An interpass temperature of about 250 ̊C is used for most but some like the C276 require going all the way to 100 ̊C.

Nickel Welding Tips

Our guide to nickel alloy welding also comes with some very useful welding tips.

- Be sure to limit heat input.

- Heat can build up quickly as these alloys are not very thermally conductive.

- Low amperage is required as opposed to welding stainless steel.

- Make sure that you let the weld cool down a bit between passes.

- When TIG welding nickel alloys, use oversize cups for better shielding.

- Always clean the surface while welding and between passes.

- It does not harden due to fast cooling.

- Nickel welding rods and filler metal can be used for cladding other less corrosive and heat resistant metals.

Common Nickel Welding Defects

Oxygen or Nitrogen from the air or from surface contamination can lead to the porosity of the weld. Porosity can be avoided by using consumables that contain Titanium, Niobium, and Aluminum, but cleaning everything thoroughly or purging it fast can also do the trick. Be sure that the gas hoses are in good condition as draughts can disturb the gas shield.

Post-weld Treatment

Post-weld treatment, neither thermal nor chemical, isn’t necessary. However, if you want to improve corrosion resistance, you can add a full solution anneal. But if you seek to relieve the stress of fabricated structures to avoid age hardening or stress corrosion cracking, heat treatment may be required.

Nickel Soldering

Soft soldering can be used for high nickel alloys or on sheet metal, but no more than 1/16 in. (1.6 mm) thick. It should only be used when the solder is not readily corroded.

These types of metals should be joined by solders of 50-50% and 60-40%. The surface must be cleaned of any dirt, surface oxide, or possible discoloration.

Conclusion

This would be all that you need to know about the welding of nickel alloys. It may sound simple enough but a small mistake can lead to ending up with a poor product. Be sure to keep your workshop and the base metal clean, avoid contamination, use the required filler metals, mind your heat input, and follow the best practices and you will be good to go.