One of the common reasons why a pipeline failure occurs is because of pipe corrosion due to crude oil.

An unorthodox welding process is a solution to this issue, thanks to its automated, innovative pipe cladding process. In this article, you’ll learn what oscillation welding is and how it works.

Why Oil Pipelines Corrode

With most of the world’s known, easily accessible oil reserves already tapped, the 21st Century has presented a technological shift in oil-field drilling.

Well producers are forced to go deeper to procure highly corrosive sour crude oil (H2S).

Sour crude oil is a sulfurous mixture that corrodes the iron in the carbon steel pipe that extracts it.

Due to that fact, the petroleum industry has been determined to develop drilling technology that can overcome these corrosive effects to produce oil.

Various forces contribute to the ongoing need to develop advanced technologies to battle sour crude petroleum pipeline corrosion, including: demand, environmental concerns, energy independence, and aging infrastructure.

For example, many of the sour-crude oil reserves in the Gulf of Mexico reside at very deep subsea locations that present volatile conditions, such as high pressures that increase the oil’s corrosivity (thus, making corrosion technology crucial to production.) Corrosion technology also provides safety and protection from environmental catastrophes resulting from corroded pipelines.

Oscillation Welding Using a Hot Wire GTAW Welding Process

In an effort to provide protection from pipeline failure and allow for oil production in new, deepwater sour oil fields, leading custom automated and robotic equipment manufacturer ARC Specialties Inc. has developed a new cladding technology that controls this corrosion to safely extract and process sour crude.

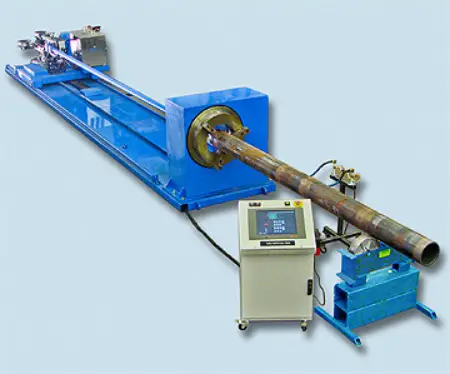

The KLADARC advanced TriPulse™ Hot Wire Gas Tungsten Arc Welding (GTWA) system leverages oscillation welding to deposit a metallurgically lined (or clad), two-layer corrosion-resistant alloy (CRA/Alloy 625) overlay (nominal thickness of 3.5 mm and guaranteeing the 3.0 mm minimum thickness) on clad pipe up to 20 feet long, with inside diameters up to 30 inches.

To learn more about how hot wire TIG welding works please refer to our separate article on the topic.

Ultimately, this patent technology reduces oxide inclusions and iron dilution in the cladding process – thus, mitigating the corrosive effects of H2S.

Weld Oscillation Process And Its Mechanics

Paramount to this 5-axis cladding machine’s advancement is the capability to oscillate the arc inside the pipe. This crucial element of oscillation in the process is driven by ball screws manufactured by Nook Industries Precision Screw Group as part of its Power-Trac line of precision ball screw assemblies.

This precision-rolled ball screw with a double bearing support provided a durable and efficient way to convert rotary motion to linear motion on the dual-torch oscillation axis (x and y) of the machine.

Ultimately, the dual-torch oscillation simultaneously overlays two layers of CRA onto the pipe’s inner surface and provides a molten “puddle” with longer residence time to bond and eliminate common problems of overlay welding — leaving holes that penetrate through the overlay layer and exposing the outer steel pipe to corrosive sour crude.

The dual-torch welding oscillation process involves feeding CRA wire into a 20-ft long torch that welds it circumferentially along the inner wall of the steel pipe.

The circumferential weld is created by Nook’s ball screws wiggling the torch into the pipe, back and forth, approximately 1 in./sec., while motorized pipe rollers steadily turn the pipe.

The first 20 feet of pipe is coated, then flipped 180°. Then, the torch returns to coat the other half of the pipes’ inside diameter.

Each oscillation places a heavy load on the ball screw, with the 20-ft torch decelerated, stopped, and reversed 120 times per minute, with loads running just under 1,000 lb. during acceleration.

The accelerate/decelerate rate is a rapid speed/load oscillation of 0.8 in. at around 1 Hz per second. The oscillation process also moves the weld puddle side-by-side, which generates approximately 2X the weld yield.

Additionally, this single-pass circumferential weld ensures that the CRA overlay is seamless and allows the pipe to undergo long-radius bending after the overlay process.

The oscillation process is a harsh application since it runs and repeats without stopping for hours at a time. Therefore, the reliability and performance of Nook’s ball screws is vital, and a fundamental basis for their patent oscillation welding process.

Conclusion

Oscillation welding really sets apart oscillation welding clad quality from the traditional methods of cladding and produces a long-life coating that prevents pipeline failure.

KLADARC’s cladding technology controls the H2S corrosion, and trust in Nook’s ball screws to coat the pipe is directly related to this crucial feature which allows oscillation welding to meet stringent quality assurance requirements for the petroleum industry.