Hot wire TIG welding is not new, but it never got widespread adoption. However, as a welding process that has been around since the 1960s, it experienced substantial development and application in industrial applications.

People who see the hot-wire TIG welding for the first time are always quite flabbergasted because they believe that it’s unique and challenging to apply.

But, that’s not the truth. This welding process can be used almost everywhere in automated and manual welding.

This article will discuss the hot wire TIG welding process, how it works, its main benefits, and a few drawbacks. So, let’s get started!

What is Hot Wire TIG Welding

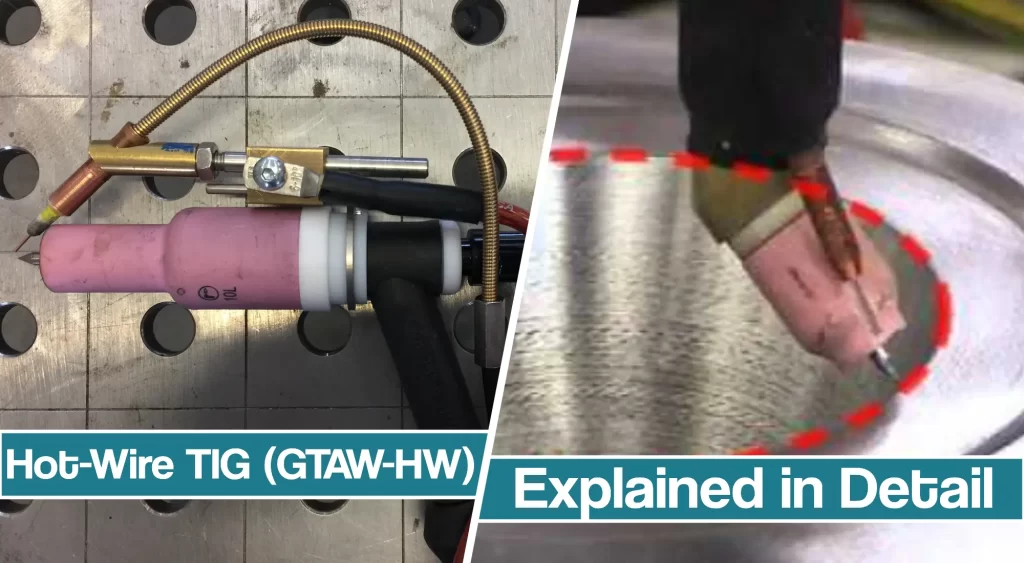

Hot wire TIG welding (GTAW-HW) is a welding process with a superior weld quality, travel speed, deposition rate, and cost-effectiveness than the traditional TIG welding process.

There are a few variations to how the GTAW-HW is applied. It can be done manually too, and our favorite example is the TIP TIG welding process.

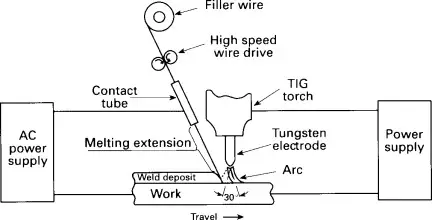

The main difference between GTAW-HW and the traditional TIG process is that the filler wire is electrically “hot.” The wire is energized by a separate energy source and fed via a wire feeding system similar to what is used by MIG welding machines.

When we refer to the GTAW-HW, we mainly talk about the automated hot wire TIG welding in industrial applications, but the same principle is used with the most efficient manual hot wire TIG method called TIP TIG.

This manual process also has one unique aspect the standard GTAW-HW does not, but we will cover this later in the article. For now, let’s stick with traditional GTAW-HW in automated applications.

How Hot Wire TIG Welding Process Works

The GTAW-HW requires a wire feeding system, a standard TIG torch, shielding gas, and a precision robot with a guidance system.

The torch tip is comprised of the TIG torch with an additional wire torch angled at a wire feeding angle for the desired application. These tips are very close to one another, but they never touch because the tungsten would get contaminated.

If the wire torch tip is covered by the TIG torch shielding cup, there is no need for additional shielding gas coverage. However, if the wire tip is not below the shield gas cup of the TIG torch, it is necessary to protect it from atmospheric contamination.

The wire is fed from a filler metal spool using a wire drive feeding system through a lead and into the wire torch tip. This wire is energized using a separate system because its voltage and amperage must be lower than the tungsten electrode. Otherwise, the wire would have a high enough open-circuit voltage (OCV) to arc with the welded part. This would cause tungsten contamination and undesirable arc.

The wire is energized because this makes it hot due to electrical resistance in the wire. So, unlike cold wire TIG welding, this pre-heated wire melts quickly in the weld pool and doesn’t chill it. As a result, we get a very fluid weld pool, an excellent filler metal deposition rate, and much higher welding speeds.

Hot Wire TIG vs Standard TIG

Considering that GTAW-HW competes with sub-arc welding and can deposit as much or more material as the MIG welding process, the hot wire GTAW is a hidden secret of the industry.

Standard cold wire TIG is no match at all. The hot wire GTAW can sometimes quadruple the filler metal deposition rate, achieving a better weld overall.

The hot wire GTAW can weld in a couple of passes what would take ten or more passes with cold TIG. But it’s not just about the deposition rate.

The preheated filler wire requires less energy to melt as it enters the weld pool, allowing you to use less amperage and prevent distortion when working with thin metal.

Additionally, the heated wire loses any surface moisture, diminishing the chances of any porosity. The weld appearance is superior to almost every welding process and certainly from arc welding processes like GMAW, GTAW cold wire, SMAW, and FCAW.

If you wish to learn more about the regular TIG welding process, you can read our full guide on how to TIG weld and how TIG welding works.

Electromagnetic Field and Hot Wire TIG

We talked about how GTAW-HW produces better welds but let’s explain one of the reasons why.

Since the hot wire current produces an electromagnetic field, it interacts with the tungsten electrode arc even if the wire doesn’t produce the arc itself.

So, to use this to advantage, many hot wire TIG systems use an AC power source for the wire and AC/DC for the tungsten electrode depending on the welded metal (ferrous/non-ferrous).

The alternating current energizes the wire, causing the electromagnetic field around the tungsten arc to deflect forward and backward in the welding pool. This causes the stirring effect, improving the edge wetting and breaking up of surface oxides of the weld pool. As a result, oxide inclusion is minimal, and we get the highest quality welds.

Additionally, this electromagnetic field forces the tungsten electrode arc to bend in the forward direction. This results in something called “electrode follow” and significantly improves the welding speed. The electrode-follow setting allows you to move the torch forward faster than the arc can lag behind, which happens in the traditional TIG if you try to weld more quickly.

Disadvantages of Hot Wire TIG

Apart from producing higher quality welds and improved deposition rate, this process also has some downsides.

Typically, this TIG welding method requires a higher upfront investment and more precision in controlling the process. GTAW-HW welding requires precise wire feeding speed and voltage control.

It is necessary to ramp up the wire feed speed and voltage of the wire simultaneously and precisely, requiring a more skillful operator.

Additionally, since this is a very precise automated process, it is used only where the automation can take place. However, as we will discuss soon, there is a manual hot wire process that can be applied for almost every task.

Example From Arc Specialties

Arc specialties is a Texas-based company that specializes in hot wire TIG arc automated bore welding machines. Their systems are used for cladding valves and fittings installed in high corrosion environments.

The ARC-05HG PLC GTAW horizontal bore cladder is a good example of a hot wire TIG welding machine. It’s an industrial unit with 450A of welding power for tungsten electrodes and a dedicated wire energizing system.

In the video below, you can see how the wire is added to the weld pool once its voltage is set on the touch screen control panel.

This system is used for cladding inner surfaces for corrosion or wear resistance and represents a good example of how hot wire TIG equipment lays consistent welds in an industrial setting.

TIP TIG – The Manual Hot Wire TIG Welding Process

The GTAW-HW requires a wire feeding system, a standard TIG torch, shielding gas, and a precision robot with a guidance system.

The torch tip is comprised of the TIG torch with an additional wire torch angled at a wire feeding angle for the desired application. These tips are very close to one another, but they never touch because the tungsten would get contaminated.

While the TIP TIG welding process can be manual and automated, we will stick to manual for this overview. It relies on the same hot wire welding principles, but it introduces a few of its own.

Unlike the regular hot wire TIG welding process, the TIP TIG uses a patented wire feed technology that oscillates the wire feeding system back and forward, creating a vibratory effect on the wire and the weld puddle.

The vibration introduced to the puddle agitates it, disrupting the surface tension. This improves the weld fusion, releases the stresses from the weld, and resolves pore defects. Additionally, it prolongs the period of weld liquidity, allowing the operator to deposit more filler metal.

The TIP TIG’s unique approach to weld pool agitation provides the best reproducible welding results of all GTAW-HW processes. It has the highest deposition rates, supports almost all metal alloys, and removes most weld errors compared to other processes.

We wrote more details about the TIP TIG welding process in our other article. If you weld pipe in all positions, we recommend you check it out. But all kinds of welding benefits from TIP TIG.

Conclusion

The GTAW-HW allows its operators to make error-free welds and automate the process. By combining a separate energized wire feeding system with a TIG torch, the GTAW-HW significantly improved upon the standard TIG we all know well.