Many welders are realizing the benefits of gouging with plasma. It’s easy to understand why. Plasma gouging is faster, easier, safer, and quieter than other metal removal methods —benefits that save operations a considerable amount of money.

Plasma can cut through rusted and painted metal, and about 90% of our work is done outside in the elements.

Gouging is just an added benefit. But, depending on your gouging needs, plasma gouging can quickly become necessary.

Plasma is a lot faster than carbon-arc and grinding. The metal removal rate is faster. It takes less time, and the clean-up is easier because there is little to no mess.

The plasma is cleaner, faster, and not nearly as loud. Plasma gouging also uses fewer consumables too.

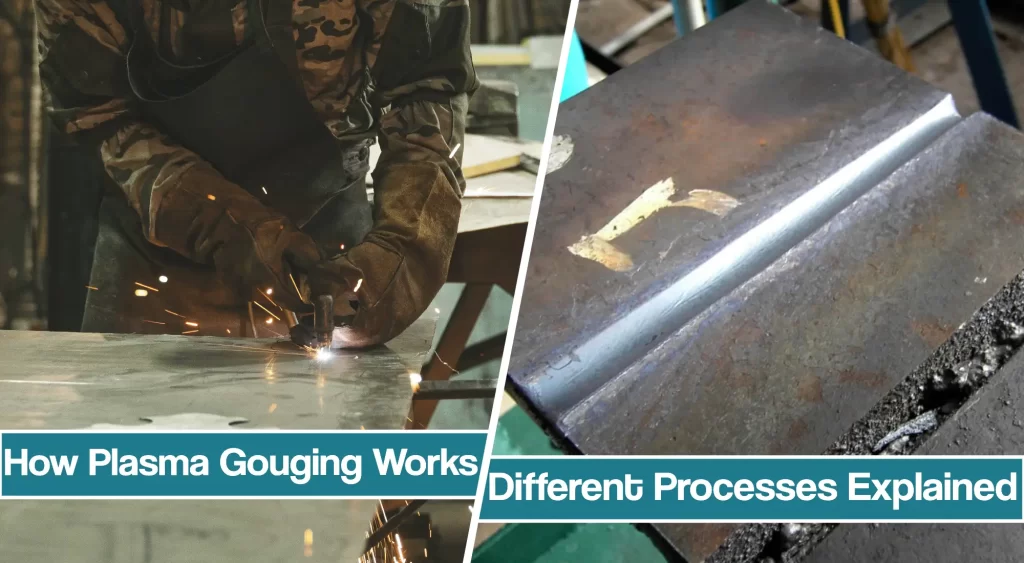

Different Gouging Processes

There are four different gouging methods in everyday use: mechanical, oxyfuel, carbon-arc, and plasma.

Mechanical Grinding

Mechanical grinding may involve hand-grinding, hand-milling, routing, or chipping. While mechanical grinding eventually gets the job done, the process is time-consuming, loud, and dangerous:

Pipeliners, construction workers, and fabrication operators have seen their share of injuries, especially eye injuries, a common occurrence in the metalworking industry, which reports several eye injuries per day.

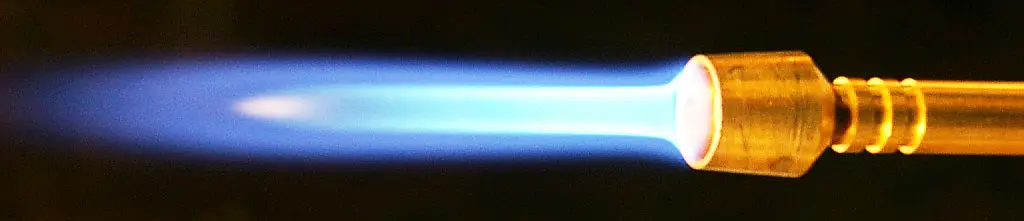

Oxy-Fuel Gouging

The following method, oxyfuel gouging, involves using fuel gas to heat steel to its ignition temperature. Once the metal is hot, it is rapidly combusted, then blown away by a jet of oxygen gas.

Oxyfuel is quieter and faster than mechanical gouging, but oxyfuel welding or cutting are hard to control, even if you have years of experience. Also, its use is limited to carbon steel.

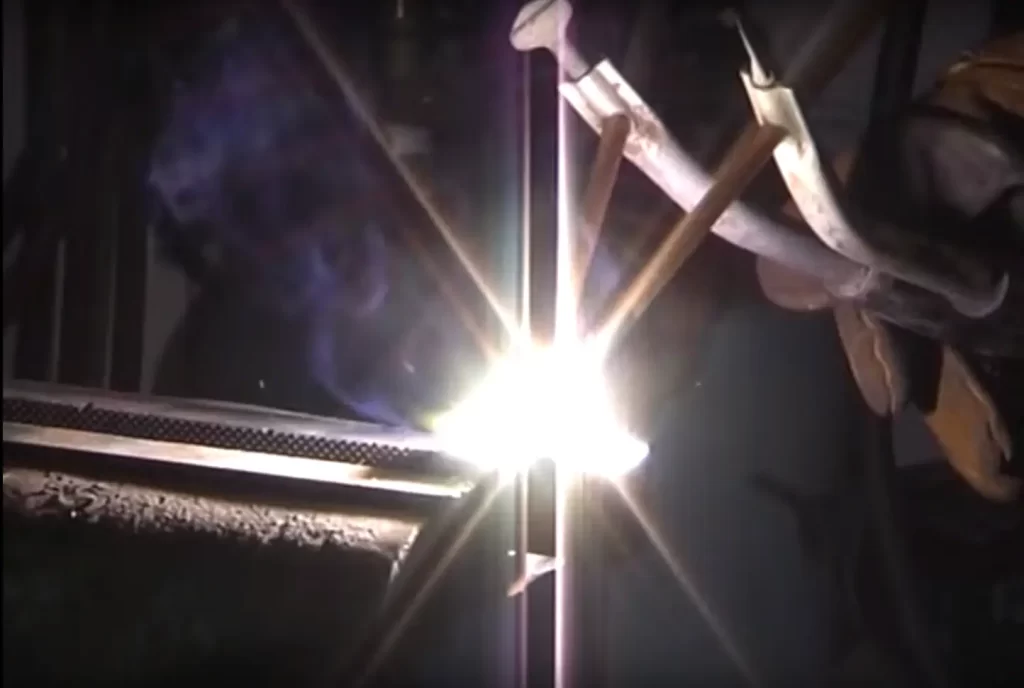

Carbon-Arc Gouging

In the carbon-arc process, an electric arc is generated between the tip of a carbon electrode and the metal workpiece.

Then, a jet of air is directed around the tip to remove molten metal from the area, forming a groove.

This process is more versatile than oxyfuel gouging as it works on several different metal types: mild steel, cast iron, nickel alloys, copper, and aluminum. It’s also easier to learn and overall does an excellent job of removing metal.

The problem with carbon-arc gouging is that, like mechanical gouging, it is loud. In addition, it creates a lot of smoke and fumes, and like oxyfuel gouging carbon-arc is hard to control.

It’s not uncommon to remove too much metal or to wind up with extra carbon deposits or inclusions on the base metal.

Another problem: carbon-arc gouging is tedious and time-consuming because the process requires operators to stop repeatedly to re-feed the rod. You have to keep adjusting your rod. The rods are only about 12-in. long, so you adjust them once or twice, and then it’s time to replace it.

Another benefit, as with plasma cutting, is that the process works on most any type of metal, including mild steel, stainless steel, aluminum, copper, and more.

How Plasma Gouging Works

Plasma gouging works in a way similar to plasma cutting. When cutting with plasma, a plasma arc is formed between a negatively charged electrode inside the torch and a positively charged workpiece.

The heat from the transferred arc melts the metal rapidly, and a high-velocity gas jet blows the molten material away.

The process is nearly identical to gouging, except that the operator doesn’t completely blow the molten material away. Instead, only some of it is blown away.

This is achieved by holding the torch at an angle and using special gouging consumables that produce a broader and softer arc. In addition, many plasma systems have a dedicated operation mode for gouging that enables the arc to stretch without going out.

Some manufacturers even include gouging consumables in the start-up kit that comes with new machines.

Plasma Gouging Equipment

The equipment needed for plasma gouging is nearly identical to what is needed for plasma cutting. For hand gouging, a plasma system consists of a power source, a gas supply (often just air), a torch, and lead.

If you are looking for a plasma cutter, please check out our in-depth buying guide with reviews.

Unique cut charts and instructions in the operator’s manual explain safety, parts, and operating parameters for gouging.

Many manufacturers supply accessories designed explicitly for gouging, such as metal heat shields to surround and protect the operator’s hands and leather lead protectors.

These generally do not come standard with a new system, but are worth the investment if you expect to do a lot of gouging.

Shielding Gas For Plasma Gouging

Many different plasma and shielding gases — including air, nitrogen, oxygen, an argon/hydrogen mix, and other combinations — can be used when gouging with plasma; however, it’s a good idea to check the operator manual first just to be sure the gas to be used is compatible with the particular plasma system.

Some general rules when deciding on which plasma shielding gas to use:

• Air plasma provides the lowest cost of operation and acceptable quality on mild steel, stainless, and aluminum.

• An argon/hydrogen mix can produce a clean, bright, smooth gouge on aluminum and stainless.

• Nitrogen gas is good if you want to extend the life of your consumables.

Modern air plasma torches provide good cooling, high cutting capacity, long consumables life, and consistent cut / gouge quality — all attributes that improve gouging performance and allow for a more controlled gouging process.

Plasma Torch Systems

Another feature of modern air plasma torches is their design. In the past, all hand plasma torches were designed with a 75° or 90° angle. Today though, it is possible to purchase a straight torch, something that’s especially useful for gouging.

There is a significant advantage to that torch. It blows sparks away so you can see where you are gouging. This is a plus because you don’t remove more metal than you need to. You can cut down to the vertical weld and see what you are doing, so you don’t take away too much material. The torch keeps the arc going constantly and doesn’t kick out.

The straight torch makes it easier to gouge in tight spaces or corners because the arc can hold a distance of up to two inches.

In addition to the straight torch, better plasma systems also come with a quick-disconnect feature that makes it easy to switch between torches.

For example, you can have two torches—a standard 75° to 90° torch with cutting consumables, and a straight torch, ready with gouging consumables—and then quickly and easily switch between the two, depending on the job at hand.

That feature is one many companies who gouge with plasma really appreciate. SIt takes about a matter of a minute to switch over. It’s very convenient.

Plasma Gouging Techniques

Operators use various techniques to achieve different gouge profiles and sizes, whether gouging by hand or using a mechanized method like a track cutter.

The most common way involves positioning the torch at a 40° to 60° angle to the work surface while the pilot arc is formed and transferred to the plate. Once contact is made, the operator simply aims or feeds the arc into the area to be gouged, while moving the torch forward.

Variations in the torch angle and speed, along with amperage levels, are used to control the depth of the gouge. A steeper angle and slower forward movement result in a deeper gouge, while a lower angle and faster forward movement result in a shallower gouge.

Plasma Gouging Applications

Today plasma arc gouging has wide industrial applications, from shipbuilding and maintenance, to heavy equipment manufacturing and repair, to the manufacturing of truck bodies, tanks, and steel structures.

Plasma gouging removes strong backs, lifting lugs, temporary brackets, tack welds, and rivets. It’s also suitable for demolition or salvage operations.

In foundries, it removes excess material from castings. And, it can help to prepare plate edges for welding by removing any extra metal that may be on the plate.

In foundries, it removes excess material from castings. It’s a good way to fix and maintain bridges, heavy equipment, pipelines, and more, and it’s useful at removing cracks and imperfections. And, it can help to prepare plate edges for welding by removing any extra metal that may be on the plate.

With plasma, you just drop your hood and go. If the quality of the steel is good, you can gouge all day on one electrode.