Welding light to medium metal can easily be done in a single-pass welding process, as it will give excellent results with a good tie-in. However, once your welding project includes significantly thicker metal, you will need a different approach.

Welding thick metal, commonly pipe welding, will require a multi-pass weld.

First and the most important is the root pass, which gives the base for all subsequent filler passes. Let’s explain the importance of root pass in welding and how to do it properly.

Key Takeaways

- What is root pass and hot pass in welding?

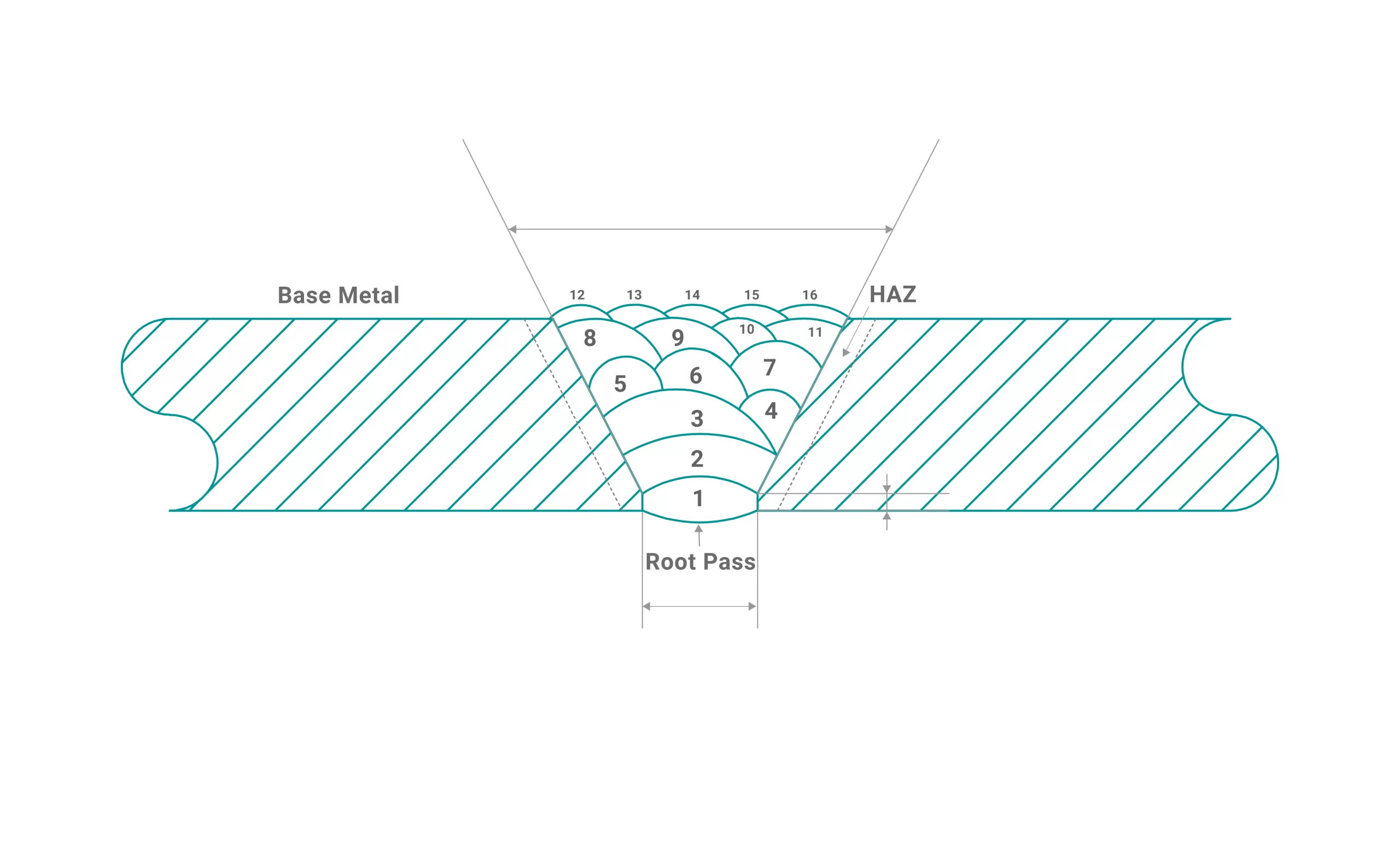

The root pass is the first layer in the multi-pass welding process that creates the base for the hot pass, fill pass, and capping.

- What electrode is used for root pass?

Most commonly, an all-position cellulose E-XX10 (E-6010) electrode is used for root pass.

- What is the other term for root pass?

Root pass is also called the first pass, starting pass, or initial pass.

- Why is root pass important?

The root pass should create a sound foundation for the following passes, ensuring good weld joint quality and strength.

What Is The Root Pass In Welding?

Root pass is a base or fundamental layer used in multi-pass welding to reach the desired thickness. The first weld bead creates a foundation for all subsequent passes, so it should be solid, durable, and strong.

The integrity of the entire multi-pass weld bead can depend on the welding parameters, skill, and technique of the welder.

Therefore, welders must be careful to get the best final weld bead. We can compare multi-pass welding to building a house. If your foundation is bad, the entire hose could collapse. It is the same with multi-pass weld. If your root pass has defects, the entire weld can collapse.

Due to high deposition rates and travel speed, root pass welding in the oil and gas industry and pipeline welding is usually done with Shielded Metal Arc Welding (SMAW). However, combination welding with TIG root pass, Stick hot pass, and cap pass can be employed in specific applications. Combo welders should be capable of successfully using different welding methods to achieve the best results.

Remember that the term can vary, so some welders refer to root pass as start pass or initial pass. However, these all denote the first pass, or the root pass in the weld joint.

Other Passes Used In Multi-pass Welding

If the root pass doesn’t go as planned, welders can use a hot pass. A hot pass is employed immediately after the root pass, always within five minutes, and it can help welders smooth or resurface the initial pass. As a result, you will spend less time grinding or brushing the starting pass.

To correct the issues with the root bead, you should use slightly more power. A few more amps with your welding machine will penetrate the surface of the weld root, solving the issues with incomplete fusion or turning convex into a concave weld bead.

After building the foundation of your weld bead, you will have to fill the beveled joint. To reach the desired weld depth, a fill pass is employed.

As the bevel thickness in the base metal rises, the number of subsequent passes increase. Therefore, multiple weld beads are used to deposit just the right amount of filler metal.

Once you have deposited enough filler metal, you should employ a cap pass. Capping is done with a stringer bead or weaving motion, and if you spend some time welding, you can even get some great-looking weld beads. As a result, your cap is like a cherry on top of the well-welded pipe cake.

When the weld bead is subjected to high stress, you can use multiple cap passes on the weld metal to reinforce it. While root pass is usually done with E-XX10s, filling and capping use 7018 electrodes.

Root Pass Technique In Pipeline Welding With SMAW

Since root passes are commonly used in pipe welding, we will give you some advice on the welding technique. Commonly, a 5/32 size all-position cellulose E-XX10 welding electrode is used (6010, 7010, 8010). The common travel speed is 12 inches per minute, and the pipe is welded with reverse (DC+) polarity.

The root pass with these electrodes and others that are primary cellulose coating is done using the drag (pull) technique, as the electrode touches both parts of the pipe, creating a weld pool.

You should drag the electrode in the vertical downward progression while it is positioned perpendicular to the pipe. If you’ve done everything right and used the proper technique, a small keyhole appears. For root pass, the current should be set as high as necessary, while the open circuit voltage (OCV) is set as low as possible. However, you should be able to strike an arc without sticking and get the right size keyhole.

In my experience, beginners can have issues maintaining a stable arc and good penetration.

Therefore, if the keyhole is getting too big and out of control, you should:

- Reduce the heat

- Increase the travel speed

- Increase the drag angle along with the travel speed

- Lower down the pressure, reducing the weld penetration and keyhole size

If the keyhole doesn’t appear, you are doing something wrong. So to solve it, you should:

- Maintain short arc length with good penetration

- Tune up the heat

- Reduce the travel speed

- Apply more pressure to get better arc results.

Of course, these are just general recommendations and basic guidelines, and the given welding parameters will depend on conditions and configuration. Nonetheless, they can help you get the best results.

Root Pass With TIG Welding

Certain pipe welding applications such as welding stainless steel or aluminum pipes in buildings, heating, and power plant pipes will require a TIG welding root pass. GTAW is used due to outstanding weld quality, cleanliness, and aesthetics.

Welding a root pas with GTAW is significantly more complicated, as you will need detailed weld preparation and high skill to perform it. Firstly, you will need to bevel the pipes, clean the joints and grind approximately one inch on the inside and outside to remove the mill scale.

Depending on the filler metal size, the root opening should be 1/16″ to 1/8 of an inch. You are ready to do weld once you align and tack the pipes to get an even gap.

In the US, there are two common techniques for TIG welding root pass. In northern states, the welders lay the filler metal along the root opening and then walk the cup around it. Meanwhile, welders in the southern states use smaller diameter filler, which is fed through the root and from the inside of the pipe.

Regardless of the technique, the shielding gas, commonly argon, plays a crucial role in ensuring the best results. Welders must ensure wind or draft doesn’t blow away the shielding from the weld pool. But compared to other processes, TIG welding root pass will also require back purging, as both the outer and inner parts of the root must be crucially clean.

So while TIG welding root pass is significantly harder than shielded metal arc welding, pipe welders that are familiar with the technique won’t have any issues finding a job.

Common Root Pass Issues

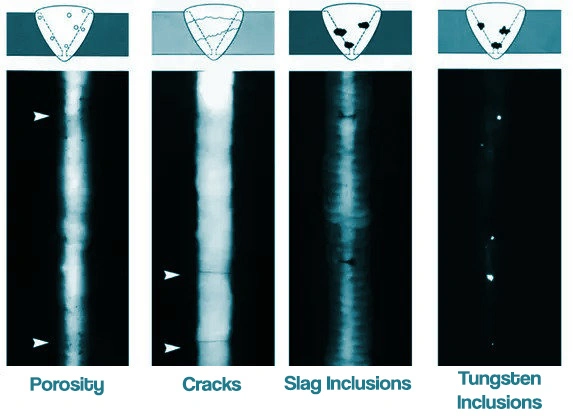

Starting and getting a keyhole in the root pass process is just one of the starting issues, but there is more. If you don’t use the proper technique, cleaning or welding settings in the fillet welds can cause slag inclusions, lack of fusion, incomplete penetration, or porosity.

- Slag inclusions are nonmetallic particles trapped in the weld metal, interfering with the properties and integrity of the weld bead. The best part about Stick electrodes is the flux that shields the weld area from defects, but the formed slag can represent an issue on its own. If you don’t clean the slag after the root pass and before applying hot or fill pass, inclusions can appear.

- Incomplete penetration occurs due to the low heat of the power source and fast traveling. As a result, the welding arc doesn’t extend and fill the entire welding joint, so the strength and structure of the weld is defective.

- Lack of fusion results from incorrect parameters, dirty base metal, or improper welding technique. As a result, the deposited metal doesn’t adhere to the base metal, causing a weak weld bead.

- Porosity shows as tiny holes in the welding bead, and it is commonly a result of improper shielding or contaminants. Shielding gas can get trapped in the weld pool, and contaminants such as paint, rust, or oil can interfere with the welding process.

X-Ray Testing Root Pass

At this point, you realized why rot pass is so important. Since there are a lot of issues that can occur in the first pass, weld testing is employed.

Industrial radiographic testing is the best method to check the integrity of the root pass since the rays penetrate the cap and the fill. A radiographic image shows any cracks, holes, or inclusions (either slag or tungsten), of course, if they are present. A good initial pass is bright, and there are no discontinuities.

The weld test procedure calls for x-ray testing once the pipe weld is completed. However, in my experience, you should always visually check the root pass after completion. Sometimes, poor penetration or porosity can be seen right after cleaning the slag.

In certain applications, weld inspectors can ask for radiographic testing right after the root pass. This practice can be expensive in welding thin pipes, and it is not stated by the inspection code. However, it might be required when dealing with extremely thick pipes when removing large amounts, and redepositing the fill could be more expensive than performing x-ray testing twice.

Final Thoughts

A root or starting pass is an essential part and sound foundation once the welding project requires welding thick metal using a multi-pass approach. A good initial pass will create a base for the following hot pass, fill pass, and capping and give the necessary strength for the best results.

However, the quality of the final weld bead can be affected by welding parameters, welding conditions, and joint configuration, but the operator’s skills and technique will also matter. Therefore, you will need practice to make things right, and root passes are a good starting point.

Resources:

- https://weldingtech.net/root-pass/

- https://www.lincolnelectric.com/assets/global/Products/Consumable_PipelinerConsumables-Pipeliner-PipelinerLH-D90/c2420.pdf

- https://blog.edgevarsity.com/index.php/2021/08/11/all-about-welding-passes/

- https://gowelding.org/welding/tig-gtaw/pipe-walk-cup/

- https://www.hobartbrothers.com/2012/08/smaw-the-low-down-on-the-lingo/