Welcome to the hell that is aluminum welding. I am your captain and will be guiding you through this predicament. Who here has had difficulties with aluminum welding?

You don’t have to answer because I and everybody else already know what you are going to say.

The go-to welding methods are usually MIG and TIG welding. Both of them have a case when it comes to aluminum and welders can be in two minds about which one to choose. Today, I am going to particularly concentrate on the question about TIG welding aluminum. This method helps in going about some tricky welding variables like penetration, heat, aesthetics for which aluminum is known for being difficult to deal.

I have certainly welded my fair share of aluminum during my days and I have to admit I wasted a whole bunch of it as well. But once I got it right I kept doing it all the way. For that reason, I want to share with you my thoughts about proper aluminum TIG welding.

Basics and Challenges and How to TIG Weld Aluminum

TIG welding is usually not your typical process when it comes to mass production manufacturing, because it is slow.

However, this makes it perfect for welding aluminum due to its imperative on quality welds and appearance.

TIG welding aluminum allows you to control adding the filler metal, establishing the weld puddle, and ensuring proper penetration before adding the filler metal.

The tricky part when you TIG weld aluminum is applying proper heat input. Aluminum is very conductive and a lot of heat is required to establish the weld puddle. But it has to be controlled to avoid creating a runaway puddle and eventually burn through.

The equipment you use also plays a major role in your aluminum welding process. In our dedicated TIG welder review and buying guide we selected Everlast PT-250EX as the best TIG welder for aluminum. If you are on the fence about which TIG machine to get, please give it a read and see if it is something that works for you.

Polarity Settings – AC or DC Which One is Better?

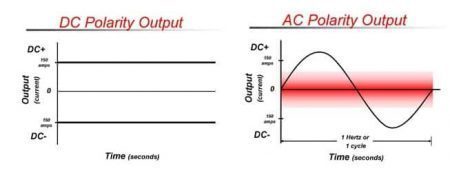

Polarity simply means the direction in which electricity flows. Direct current (DC) means that the electricity is flowing one way. Electrode negative further emphasizes that electricity flows from the welder, through the electrode, and all the way back to the welder.

When it comes to TIG welding, the direct current creates deeper penetration. Therefore, working on aluminum is probably the only time alternating current comes in handy.

Alternating current (AC) changes from standard and reverses in quick intervals, basically from 60 to 100, twenty times per second. An alternating current does not create deep penetration and is perfect for welding aluminum. More so, polarity flips create a sandblasting effect which helps in breaking the oxide layer and producing a clean weld.

But the biggest drawback of using alternating current on TIG welders is that due to it not being able to provide deep penetration you end up with a large bead on the surface.

AC TIG Aluminum Welding

The shape of the electrode tip for AC TIG welding is 1 to 1½ tungsten ball. Amperage control can be managed with the help of an AMPtrol on the torch, using a foot pedal, and by adapting the settings of the welding machine. Remote control is perfect as it allows the welder to start hot and then reduce the amperage while working.

The TIG torch is cooled down by an air-cooled unit so you have to be mindful about overheating the internal torch parts. There is a water-cooled unit as well and it functions similarly to a car radiator. Water-cooled units are good for longer use as they provide better cooling, but air-cooled units are smaller and way less expensive.

DC TIG Aluminum Welding

The biggest problem that comes with AC TIG welders is that they simply don’t have the required penetration and often result in shallow welds. It is basically unusable for working on aluminum pieces thicker than ¼ inches. Luckily, reverse polarity DC welds don’t come with such issues as you can create a proper, deep joint just in one pass. Besides getting a proper weld, you also save a lot of time while working.

Direct current is also very useful to fix deep pits and gouges in aluminum. One can fill a cavity and create a strong joint that holds in place very easily.

Weld Preparation and Adjustments

Preparation when welding aluminum, especially using the TIG welding process, takes a lot of time. You are going to get a great-looking weld for sure as quality and good appearance are almost guaranteed. However, efficiency, due to preparation, is not its strongest side.

Cleaning the Materials

Aluminum is unique in the sense that it generates an aluminum oxide layer with a higher melting point than the aluminum itself. If the oxide layer is not cleaned properly, it will make penetrating it quite harder and cause problems throughout the whole welding process.

To stop this from happening, the oxide layer has to be thoroughly removed. A dedicated stainless steel wire brush or a brass brush are your best options. You also have to think about contamination so it is advisable for you to use the same aluminum wire brush that you use for each project and use it to clean in one direction only.

| Removed Compounds | Way to Clean It |

| Oil, Grease, Moisture & Dust | Solvent or alkaline cleaning solution, Oxide removal spray (or vinegar), Microfiber rags, Hot water |

| Aluminum Oxides | Alkaline solution Proprietary deoxidizers Stainless steel wire brush Grind, fill Scrape all joints and surfaces before welding |

Adjusting the Balance Control

Setting up a proper balance control on your aluminum welder is crucial. Working in AC polarity means that the weld has an electrode negative cycle and an electrode positive part of the cycle. EN basically does the welding while EP is reserved for cleaning the oxide layer.

Older types of equipment usually had a completely balanced 50-50 ratio between EP and EN. Today, modern TIG welders possess a factory present balance of 75% EN and 25% EP.

It is best to turn down EN for materials that have a thicker oxide coating which can be hard to completely remove during preparation.

Adjusting the Output Frequency

An output frequency means the number of times per second the power source is able to switch polarity. Older TIG machines have a power source of 60 hertz, which can be determined based on its input power. However, modern TIG welders come with a factory preset power source of 120 hertz. Basically, the higher the AC output frequency is the more stable the arc.

You will get a wider arc cone if you turn down the AC output frequency to 80 or 90 hertz. This could prove to be helpful when working on outside corner joints. An output frequency of between 150 to 250 hertz is recommended for thinner materials as they require accurate weld placement to prevent heating up.

Welding thick aluminum pieces, of about 3/8in and thicker, requires a low AC frequency setting of 80 to 120 hertz and it helps to create a wider weld bead profile.

Amperage Rating

We basically use a rule of thumb when it comes to TIG welding aluminum which demands that 1 amp should be used for thousandth (0.001) of material thickness welded. Therefore, welding a base metal of 1/8 in. (0.125) requires about 125 amps.

If the base material is 1/4 inches thick, the rule deviates a bit so we don’t need that much amperage. So for instance, a base material aluminum piece of 3/8 inches can be welded with a 280 amp power source.

Electrode Choice

Gas tungsten arc welding aluminum requires the use of non-consumable tungsten rods and filler metal. Older transformer machines used to use pure tungsten, but nowadays with inverter welding machines 2% ceriated or 2% lanthanated electrodes are recommended.

Filler Rod

I recommend using the 4043 filler rod as it has the best all-around properties when it comes to availability, cost, and crack sensitivity. However, if you know the type of aluminum you are welding, a 4943 filler rod although new is a good choice and it even provides better flow and strength.

Recommended Filler Metals

| Base Metal to Base Metal | 1060, 1100, 3003, Alclad 3003 | 2219, A201.0 | 3004, Alclad 3004 | 5005, 5050 | 5052, 56552 | 5083, 5456 | 5086, 514.0, 535.0 | 5154, 5254 | 5454 | 6005, 60061, Alclad 6061, 6063, 6351 | 7005 | 354.0, C355.0 | 356.0, A356.0, 357.0, A357.0, 359.0 443.0, A444.0 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 356.0, A356.0, 357.0, A357.0, 359.0 443.0, A444.0 | 4043 | 4145 | 4043 | 4043 | 4043 | 5356 | 5356 | 4043 | 4043 | 4043 | 4043 | 4145 | 4043 |

| 7005 | 5356 | 4145 | 5356 | 5356 | 5356 | 5356 | 5356 | 5356 | 5356 | 5356 | 5356 | ||

| 6005, 60061, Alclad 6061, 6063, 6351 | 4043 | 4145 | 5356 | 4043, 5356 | 4043, 5356 | 5356 | 5356 | 5356 | 5356 | 4043, 5356 | |||

| 5454 | 4043 | 4043 | 5356 | 5356 | 5356 | 5356 | 5356 | 5356 | 5554 | ||||

| 5154, 5254 | 4043 | NR | 5356 | 5356 | 5356 | 5356 | 5356 | 5356 | |||||

| 5086, 514.0, 535.0 | 5356 | NR | 5356 | 5356 | 5356 | 5356 | 5356 | ||||||

| 5083, 5456 | 5356 | NR | 5356 | 5356 | 5356 | 5556, 5183 | |||||||

| 5052, 5653 | 4043 | 4043 | 4043 | 4043, 5356 | 5356 | ||||||||

| 5005, 5050 | 4043 | 4145 | 4043 | 4043, 5356 | |||||||||

| 3004, Alclad 3004 | 4043 | 4145 | 4043 | ||||||||||

| 2219, A201.0 | 4145 | 2319 | |||||||||||

| 1060, 1100, 3003, Alclad 3003 | 1100 |

Nozzle Size and Gas Lens

The size of your nozzle can have a great impact on your weld. To prevent weld porosity, I recommend using either a gas lense or a larger cup. This will improve gas flow and greatly prevent contamination of the puddle. Adding better shielding gas coverage that comes with a gas lens also allows you to switch your settings more towards the negative side and that way get a tighter arc and weld puddle.

TIG Welding Aluminum Gas Selection

TIG welding aluminum will require the use of either a pure argon shielding gas or zirconiated tungsten shielding gas. But the best gas that can be used is ultra-pure helium. It creates a much hotter arc compared to helium-argon mixes or pure argon.

The heat coming from the arc, courtesy of the shielding gas, also helps to melt down the oxide coating found on the surface and resulting in a better weld.

TIG Welding Aluminum Beginner Tips

TIG welding aluminum might sound a bit intimidating to a beginner welder but is nothing to be scared of. Consider these tips and best practices and you will be fine.

- Be mindful of your hand and TIG torch placement: Beginner welders should practice basic hand placement and control to avoid producing a lot of scrap metal.

- Coordinate your movement and filler deposition: Working on the flow of your hand and torch movement should be done without striking an arc.

- Practice puddle control: Aluminum can get hot quickly which means that the puddle has to be monitored and controlled. If you notice the puddle getting too hot, you can tone it down with the foot pedal to maintain a consistent width of the puddle.

- Don’t weave: The weaving technique can be used for a certain type of base metal, but not for aluminum. A stringer bead is a better choice.

- Travel speed: Going too slow can cause burn through of your workpiece, especially if you are working on thinner metal.

Good and Bad Sides of TIG Welding Aluminum

As with every welding process, there are also both positive and negative sides to TIG welding aluminum.

Advantages

- A filler electrode is not always needed.

- Creates a high-quality weld.

- Allows all position welding.

- Perfect for working on very thin metal.

- No slag.

- No spatter.

- Can be used on a variety of metals.

Disadvantages

- Equipment lacks portability.

- Needs clean base material.

- Low deposition rate.

- Slow.

- High skill needed.

- Not good for outdoor welding.

Frequently Asked Questions

Can you weld aluminum with TIG welder?

Yes, you can. The practice on how to do it is explained in the article above.

Is TIG welding aluminum AC or DC?

Both AC and DC can be used for TIG welding aluminum. However, AC is much more preferable as it doesn’t have deep penetration and prevents creating burn-through on the surface of the welded material.

Is TIG better than MIG for welding aluminum?

Both TIG and MIG are used for welding aluminum. TIG is good when you are in need of quality and clean welds, but takes significantly less time to finish.

Conclusion

I have given you all that you need to know and it is your choice if you want to pick up your machine and start TIG welding some aluminum. I have placed ceratin emphasis on the heat, torch movement, the way the workpiece is handled, protecting the puddle, and many other factors. Sticking to those pieces of advice will ensure positive results. But be sure to gain experience and get a lot of practice as well.

- sciencedirect.com – Aluminum welding fume-induced pneumoconiosis

- sciencedirect.com – Closed-loop Control of Laser Power

- thefabricator.com – Aluminum TIG with DCEN

- thefabricator.com – How to TIG weld aluminum

- oeh.tandfonline.com