Meticulous welders know to stay out of drafts because windy conditions can make shielding gas drift, leading to porosity and metallurgically poor weld quality.

You will have to select TIG torch tips, tarps, and duck tape to minimize the impact of wind in the weld area. As an example, we present our recent job repairing a power boat’s stainless steel railings.

That’s why this article will discuss TIG welding outdoors, how and when can you do it, and whether you can do it safely.

Repairing Steel Railings Using TIG welding

The 34-ft craft, built-in 1985, had broken welds where the rail stanchions had been fusion-welded to a base plate bolted to the deck.

Most broken welds were on the left (port) side of the boat, where passengers boarded and exited via the gangplank. As people crossed, they put pressure on the railing, and, eventually, some welds cracked.

The bolts holding the plates were fastened with nuts on the underside of the deck.

But, access to the nuts required removing cabinets and paneling, an expensive solution that could potentially damage woodwork. The preferred approach is to lift the rail and make the repair weld from the bottom of the plate for a safer repair job and a more eye-appealing finish.

Because this usually isn’t possible, you can choose the gas tungsten arc welding (TIG welding) process because it gives the accuracy and delicate touch needed to deal with the poor fit-up caused by welding in place and using a thin material. Also, with GTAW, compared to MIG welding or gas welding, you can make cosmetically pleasing TIG welds without sparks that might burn the deck or start a fire.

Unlike weld processes using self-shielding weld metal or flux (Stick weld), many other GTAW applications such as track-side repairs for motorsports or offshore power boats require protection from the wind.

Beware Of Oxidation

The TIG welding process produces an electric arc as current passes through a conductive, ionized shielding gas feeding through the torch. The arc, which travels between the tip of the electrode and the work, generates heat to melt the base metal. Once you establish the weld pool, move the torch along the joint as the arc progressively melts the faying surfaces. If you need filler metal, usually add it to the leading edge of the weld pool to fill the joint.

Shielding gas (argon or helium or a mix of the two, and argon and hydrogen for 300 series stainless steel) is a protective gas that helps prevent or reduce atmospheric contamination of the molten weld metal. Some procedures call for backup purge gas to protect the underside of the weld and its adjacent base metal surfaces from oxidation during welding.

At the molten temperature, most metals exhibit a strong tendency to form oxides, and to a lesser extent, nitrides. Oxygen also reacts with carbon in molten steel to form carbon monoxide and carbon dioxide. These reactions may cause weld deficiencies, such as porosity and metallurgically poor weld quality.

In addition to this protection, shielding gas and flow rate also affect:

- Arc characteristics

- Penetration and weld bead profile

- Welding speed

- Undercutting tendency

- Weld-metal mechanical properties.

TIG Weld Preparation

For the repair project we mentioned, we matched a 316 stainless steel filler metal to repair the Type 316 stainless steel, thin-wall stanchion rails, with a TIG welder the power source set at 100 amp. However, most of the welds were well under that amperage.

The prep was minimal: no joint prep and the stainless steel was clean, except for wiping off sea-gull droppings.

We could only weld for short durations because the heat from the arc might damage the fiberglass deck and the rubber gasket under the plate. The gasket seals out water and reduces wear between the plate and the deck.

Still, the heat from the arc started the rubber on fire a few times. And the water had seeped in some of the weld cracks so he had to watch for hot water geysers.

TIG Welding Outdoors

Air-movement control is critical with TIG welding because the argon shielding gas is heavier than air so a slight breeze can quickly remove the gas from the arc. Even a shop’s slow-moving ceiling fan can disrupt the gas shielding.

When this happens, the welder sees a blue-gray discoloration and maybe a soot-like deposit near the TIG weld joint, and the arc is usually hard to start because the tungsten oxidizes.

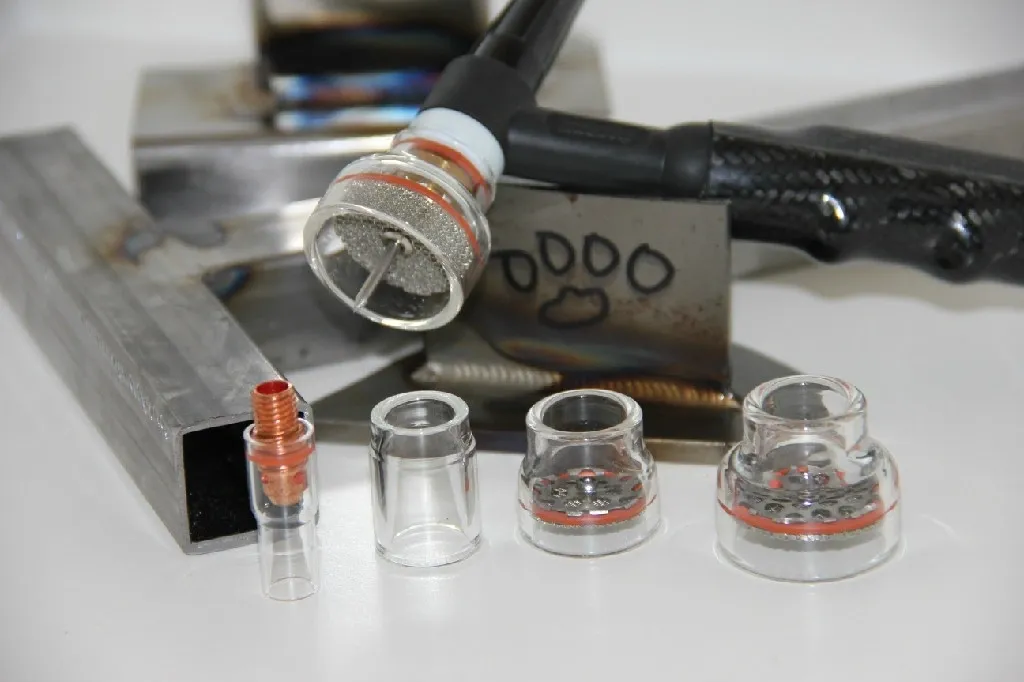

Your tool kit for TIG welding should include a number of cups, or nozzles, designed to direct the shielding gas for specific applications. Gas lens, nozzles, or cups, fit into the head of the TIG torch, directing the shielding gas to the weld zone. Within the torch body, diffusers feed the gas to the nozzle.

In this project, we needed to reach the back side, which had an acute angle, so we used a number four cup ( 1 /4 in. across the orifice face). It also worked for the other angles of the weld zones.

In case of strong wind weather conditions, we would have tried a flow straightener gas lens. It has a mesh screen that takes out the turbulence of the gas stream in the welding area. This turbulence can pick up the air, creating oxidation on the weld bead.

So pick the cup for the application — usually, the amount of space to work in — and the conditions — inside with no breeze or outside with some degree of wind.

This is critical when welding titanium, which is very reactive to oxygen in the arc. Here, welders typically use a cup that provides an elongated or trailing shielding to cover the hot work until it cools to 400°F to 500°F, minimizing contamination.

If there are highly unstable conditions, avoid welding to reduce risk of spending more argon, which can get into your lungs and cause fume fever.

Equipment for TIG welding in the Draft

A good addition to your toolbox can be CK Worldwide’s Gas Saver front-end kit. The kit saves up to 40% of shielding gas consumption while improving shielding-gas coverage in your TIG welding. With better coverage, welders can extend the tungsten up to 6 the diameter of the electrode beyond the edge of the gas cup. (This is achieved in draft-free areas using argon gas.)

Gas lenses ensure a laminar flow of shielding gas. (A laminar flow is a streamlined flow in a viscous fluid near solid boundaries.)

The lenses contain a porous barrier diffuser and fit inside the gas nozzle and around the electrode or collet. The lens lets operators weld with the nozzle one inch or more from the work, improving their view of the TIG weld pool and allowing them to reach places with limited access, such as inside corners.

CK offers Alumina or Pyrex glass cups to retrofit its CK 2 and 3 series torches or competitive brand equivalents. Alumina cups handle high-temperature welding applications. The glass cups aid visibility for inside corners, inside pipes, and around the tubing.

TIG Welding Repair Process

We plugged our portable TIG welder inverter power source, which runs in single-phase, into a 220-V line at the dock. The argon shielding gas flow was at 15 ft 3 /hr, which helps maintain an even shielding around the arc despite the slight breeze. Too much pressure can pull air into the arc, creating oxygen contamination.

CK rotary-amperage hand controller can help you vary the current, a real advantage for delicate welds. The controller can be used with either hand to weld when access is limited. This is a simple-to-use controller, helps you do a good job.

In addition, the unit’s remote amperage controls provide welding machine contactor on-off, activate gas and/or water solenoids, and handle current output control. The fingertip controls come in either rotary or linear-slide-potentiometer configurations.