First, let me give it to you straight.

You don’t want an oversized welding gas cylinder or something too small that requires refills every other day.

How long your welding gas cylinders will last depends on the gas flow rate.

A cylinder with a capacity of 80cf will last about 4h if the flow rate is set at 20cfh. In comparison, a 125cf cylinder will last 12.5h if you use a flow rate of only 10cfh. Estimating how much gas you have left depends on the gas type but it’s fairly easy to do.

You can experience many problems if you select the wrong cylinder. Thankfully none of them are permanent and are fairly easy to solve. You should also consider a few other things other than the size. You will learn all of this in much more detail in the article below. Plus at the end, I will give you some buying tips so that you don’t get yourself in a situation that you can’t refill your cylinder or worse.

Now let’s start with the burning question for most beginners.

What size welding gas cylinder do you need

Well, it depends.

However, generally speaking, you will want a 40, 60, 80 or 125 cubic feet tank. These are the sizes that a hobby welder or a small welding shop would generally use. There are bigger shielding gas cylinders on the market, like 200cf or even 300cf but they are used mostly for industrial manufacturing.

Keep in mind that we are talking TIG argon gas and MIG blends here. Pure CO2 will be discussed later in the article. You can learn more about welding gasses in general in our dedicated article for it.

Do you have a local gas supplier nearby? Do you not mind taking more frequent refilling trips?

If that’s the case then you could get yourself a smaller tank like 40 or 60cf.

But if you do more work and you don’t like going for a refill often then it is a good idea to go with 80 or 125cf. So I would just recommend going with 125cf of the bat if you are welding often. However, bigger thanks mean bigger problems. They are more difficult to move around and there is a higher hazard of being tipped over. On the other hand, refills are cheaper because a big price of refill is fixed.

Thankfully, if you do make a mistake and get a too big or a too small gas cylinder, you can correct this at your next refill. Trading in cylinders is a common practice but there will be a fee associated with it. So if you got a small tank, you could get a larger tank on your trade in. However, make sure you check this with your local gas supplier in advance.

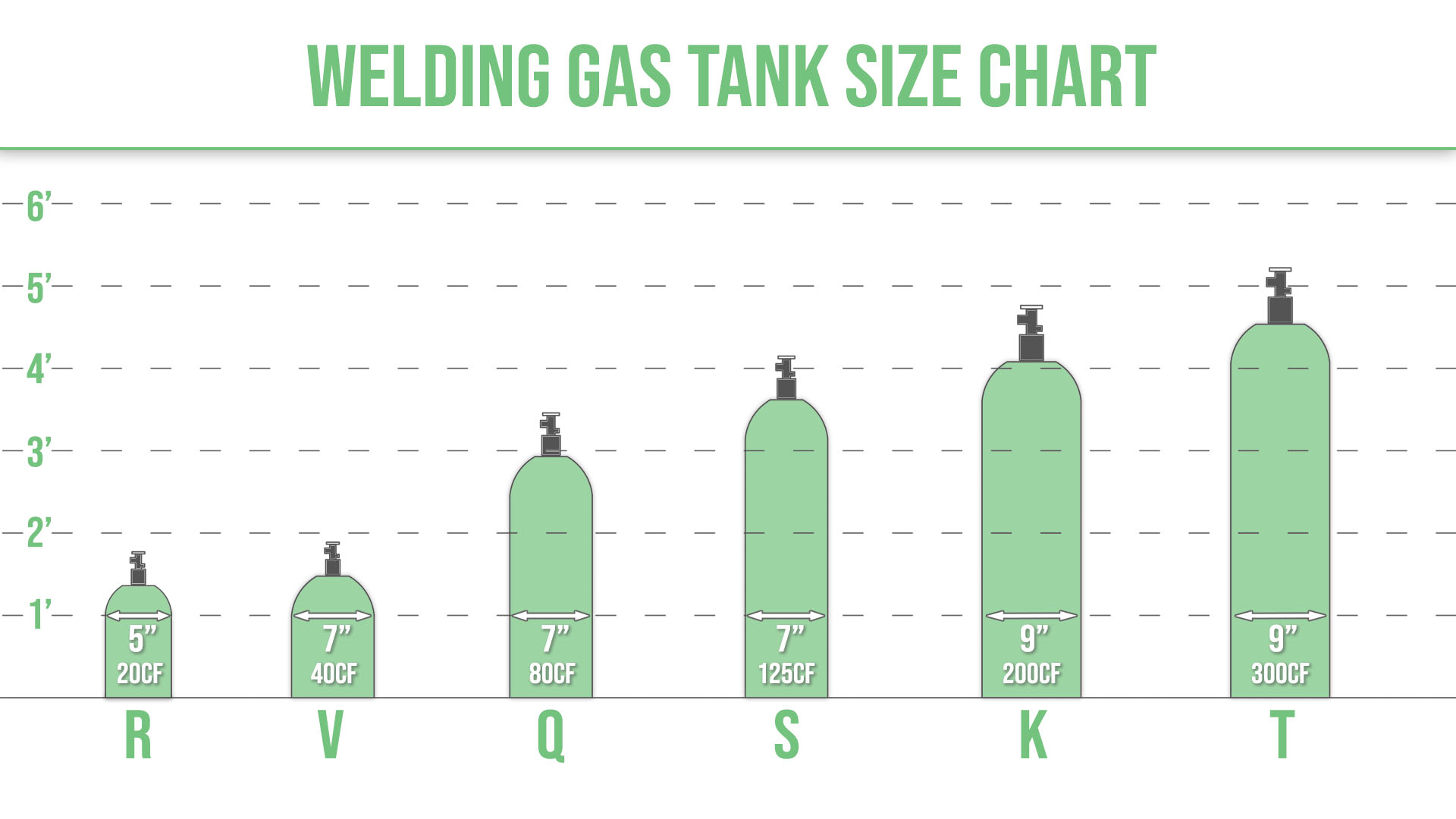

Popular MIG/TIG Welding Gas Tank Sizes Chart

Here is a handy welding tank size chart showing their volume in cubic feet (“cf”) compared to their height and diameter. This should help you figure out if you have enough space to store the gas cylinder you have in mind.

The 125cf gas cylinder is one of the most common choices with welding shops and hobbyist welders because it represents a perfect compromise in volume and size. While it is quite large and heavy, it is not as big as industrial-scale enormous tanks and its refills give you twice the gas for just a little bit more money than some of the smaller tanks.

MIG/TIG Welding Gas Tank Specifications – Argon and MIG blends

The table below shows specifications for TIG welding and MIG welding gas blends. It will help you get an even better understanding of the gas tank size you need. The size of the cylinder is also indicated by a lettering system that is often used to mark the cylinders.

| Size | 40 cf (#2/V) | 80 cf (#3/Q) | 125 cf (#4/D) |

|---|---|---|---|

| Height | 22 in. | 35 in. | 45 in. |

| Diameter | 6½ – 7¼ in. | 6½ – 7¼ in. | 6½ – 7¼ in. |

| Empty Weight | 24 lbs | 47 lbs | 58 lbs |

| Full Weight | 28 lbs | 56 lbs | 71 lbs |

| Full Pressure | 2015 PSI | 2015 PSI | 2265 PSI |

If you are unsure if the gas cylinder size you are interested in can fit safely in the storage area, double-check everything. Your welding cart also needs to support the cylinder sizes you want to get. So don’t overload the cart. If the cylinders can’t fit then get a bigger cart.

A handy tip is to call the gas supplier company in your area and see what size they recommend. They have a lot of experience with the gas supply mechanisms, your area’s climate, storage regulations and other important pieces of information. This can help you in deciding your gas tank size.

Using 100% CO2 Gas Cylinders for MIG

Some welders use 100% CO2 as a shielding gas for MIG welding. This is not perfect but it has its pros like lower operating costs and deeper penetration.

On the other hand, MIG welding with this shielding gas will make the arc less stable.

There will be more sparks and drops flying away from the weld pool and the deeper penetration can also be a problem when welding thin metal.

We have a dedicated article about using a 100% CO2 shielding gas for MIG welding so if that’s something you are considering make sure you give it a read. There is a difference in these gas cylinders when compared with TIG/MIG blends from above.

- The carbon dioxide welding gas tanks are not rated by cylinder volume but by their weight. The whole industry rates them like that so this is something to expect.

- You need a different gas tank regulator than with the TIG/MIG gas blends described above. This is because the threads on carbon dioxide cylinders are different and the regulator that is used with pure argon gas cylinders or MIG weld argon/co2 mix cylinders will not fit on the CO2 gas bottles.

CO2 Tank Specifications And Use Time Estimation Table

The table below showcases the common carbon dioxide gas bottle sizes and how much welding time you can get out of them.

| Size (weight in lbs) | H x W (in.) | Cubic Feet Volume | Usable Time |

|---|---|---|---|

| 1 ¼ | 10.5 x 3 | 11 | 1/2 h |

| 5 | 18.25 x 5.5 | 44 | 2 and 1/4 h |

| 10 | 20.5 x 7 | 87 | 4 and 1/2h |

| 20 | 27.5 x 8 | 175 | 8 and 3/4 h |

| 50 | 47 x 8 | 440 | 22 h |

How Long Will Your MIG/TIG Welding Gas Last

This depends on two things.

Your welding gas tank volume (“cf”) and the gas flow rate or cubic feet per hour (“chf”). You set the flow rate on the gas tank regulator when you are doing any MIG or TIG welding process.

The flow rate depends on the work you are doing and the environmental conditions. If you are working outside and it’s windy for example then you will need to crank it up and increase the gas flow.

Other factors that can increase the need for the shielding gas use are the position you are in like overhead welding, the need to use a purging gas, long pre flow and post flow times, increased airflow in your work area and etc.

How to calculate welding time for your gas tank and a flow rate

A simple formula is needed to figure out how long the welding tanks will last with MIG/TIG arc welding processes:

Gas welding time (in hours) = cylinder volume (cf) / flor rate (cfh).

So for example let’s say you have an 80cf argon tank and you are doing some tungsten inert gas work and your flow rate is about 20 cubic feet per hour. You can expect somewhere around 4h of welding time. It’s not 100% precise math, but the error margin is low, making this formula an excellent rule of thumb that pretty much every welder uses.

The table below will give you precalculated expected welding time in accordance with the gas bottles volume and different flow rates.

| Tank Volume / Size | 10 cfh | 15 cfh | 20 cfh | 25 cfh | 30 cfh | 35 cfh | 40 cfh |

|---|---|---|---|---|---|---|---|

| 40 cf | 4 h | 2.6 h | 2 h | 1.6 h | 1.3 h | 1.15 h | 1 h |

| 60 cf | 6 h | 4 h | 3 h | 2.4 h | 2 h | 1.7 h | 1.5 h |

| 80 cf | 8 h | 5.3 h | 4 h | 3.2 h | 2.6 h | 2.3 h | 2 h |

| 125 cf | 12.5 h | 8.3 h | 6.2 h | 5 h | 4.2 h | 3.6 h | 3.1 h |

How Much Gas is Left in the Tank?

You don’t want to get an unpleasant surprise and find out that you are running out of gas when you have a deadline to finish a project. This is especially true with welding shops.

Experienced welders usually have spare welding gasses tanks in a shop but not everyone likes to stock up.

That’s why you should occasionally check how much welding gas you have left.

Thankfully this is a straightforward thing to do.

The TIG welding gasses like argon tanks and MIG bland mixes show their remaining inner pressure on the regulator. So all you have to do is check the pressure gauge.

When argon cylinder/MIG bland of argon/CO2 are full the pressure gauge will show the maximum value of about 2015psi. That’s the inner pressure of the gas tank. So when you are MIG or TIG welding and the gas is being spent, the pressure will drop as the tank gets more empty.

The pressure shown on the gauge will tell you exactly how much gas is in it. 1000psi means that there is about half of the gas bottle capacity left. So if the bottle is 60cf and the gauge reading says 1000psi then that means that there are 30 cu ft of gas left.

However, you can’t do the same with the 100% Co2 MIG welding shielding gas cylinders. That’s because they experience a sharp drop in pressure at the end of their capacity. The only way to reliably know how much gas is left in a CO2 gas cylinder is to observe their weight.

Additional tips when getting a cylinder

Now let me help you avoid some common mistakes when getting a gas bottle. Whether its an argon tank or something else there are some universal tips to keep in mind and afterward we will take a look at the basic gas cylinder safety you should know.

- The “neck” area of the cylinder just underneath the cylinder valve can have a leasing company brand name etched on it. If you are buying a used cylinder and it is marked in this way, make sure that your local gas supplier will actually do exchanges or refills on a branded tank. This is something that can make your purchase obsolete if you are unable to refill the tank.

- If you are MIG welding aluminum the appropriate gas to get is 100% argon because aluminum welding demands more purity in shielding gas and stability. If you are MIG welding stainless steel it’s a good idea to use tri-mix of argon, co2 and helium. With TIG its best to use a pure argon gas cylinder for everything but sometimes a mix of helium and argon is a good idea because helium helps with penetration and heat.

- You can get cylinders made from steel or aluminum cylinders. Aluminum cylinders have the advantage that they are lighter and their paint is much more aesthetically pleasing. They are also more resistant to corrosion but also more expensive.

- I recommend using a quality regulator. Don’t save upon it. Don’t get the unnecessarily expensive stuff either but the quality of reporting the regulator does is important. If the regulator is constantly being stuck and its needle doesn’t move, it will make it difficult for you to estimate how much of the gas is left.

- The ambient temperature can influence the pressure of the gas tank. If the gas tank gets hot, its pressure will increase, while the pressure will decrease if it gets cold. The gas expands with heat and contracts when cooled down.

Now let’s take a look at some safety tips when working with any high pressure cylinder.

- Always store your gas tanks in a secure and safe area where people without proper training can’t get to them. People without proper training should never handle or work with gas bottles.

- Cylinders should always be stored in an upright position and be chained to the wall or other firm points.

- The safety cap needs to be screwed on the head of the cylinder to protect its valve when it is not in use. If the valve gets damaged or broken off the cylinder will fly like a rocket all over the area and it can seriously injure people or worse. The material damage can also be great because it can destroy your shop and expensive equipment.

- The cylinder needs to be hydro tested regularly and in accordance with your local codes and standards.

- Store cylinders away from the work area and in a place where they can’t be over heated or damaged in any way. Be mindful of corrosion, electric or other area influences.

- The work area needs to have proper ventilation. The inert gasses like argon, co2 and others can cause suffocation if the welder is in a closed room while welding. Be mindful of this when transporting the cylinders as well. If the cylinders are placed in the vehicle make sure the windows are open.

- Use PPE at all times. Minimum you should use are safety glasses, gloves and steel toe shoes that can protect your foot if the cylinder would fall on your foot.

- There are many more important safety aspects of working with high pressure cylinders but this is to get you started. Make sure you know and abide by your area standards, laws and codes when working with pressurized equipment.

Conclusion

Welding gas tanks are quite simple really and especially once you get the hang of it. If you have any specific question that doesn’t fall in the realm of general knowledge like if you have specific welding applications, make sure to call your area’s gas supplier and they will definitely try to help you. After all, you are their future customer.

The most important things are to make sure that you can refill your tank or exchange it for a full one locally, get the right size, and abide by the safety standards.