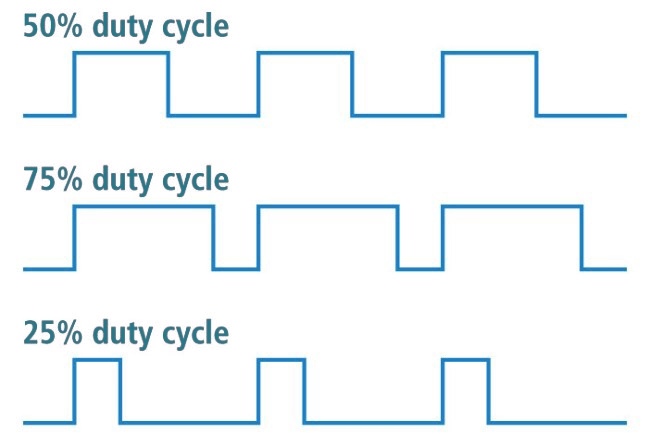

The duty cycle in welding is a percentage of a 10-minute time period showing how long the welder can output a specified amperage.

For example, a welder rated for a 30% duty cycle at 200 amps can weld non-stop for 3 minutes at a 200A output before it needs to cool down for another 7 minutes.

That was the whole story in a nutshell. But, there is much more to it than that. Duty cycles of welding machines depend on multiple factors, and we need to address the big elephant in the room. The quality of the machine. So, let’s discuss the duty cycle in more detail.

How to Calculate Duty Cycle in Welding

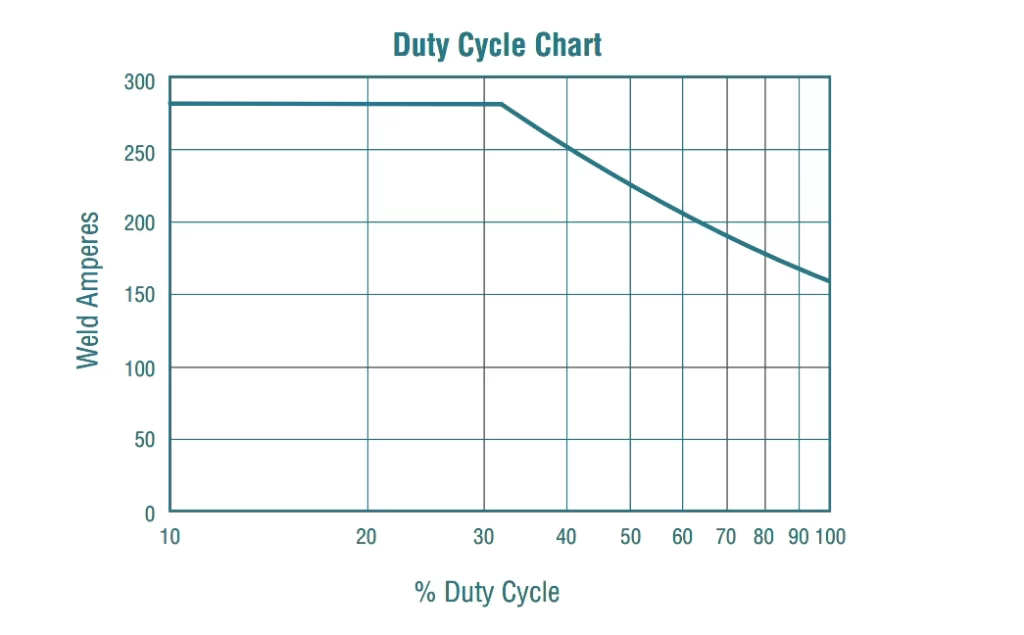

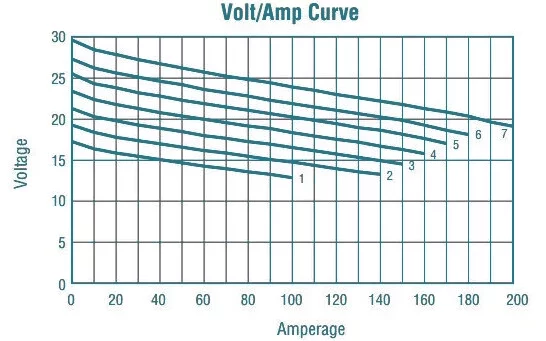

To calculate the duty cycle, you need to check the welding machine specification sheet or the specification plate at the back of the welder. You’ll see something like 20% at 140A, for example. Or multiple values. Some welders are rated for more output amperage settings, and some better brands provide an entire duty-cycle amperage curve diagram in the instruction manual.

The image above shows the duty cycle chart of the Hobart Ironman 240 MIG welding machine. If you look at the diagram, you can see that the 200A output horizontal line crosses just below the 60% duty cycle line. This means that the welder can output 200A at a 60% duty cycle.

Since the duty cycle is always rated for a 10-minute interval, this MIG welding machine can weld continuously for 6 minutes at a 200 amperage output.

What Is The Purpose Of a Duty Cycle Rating?

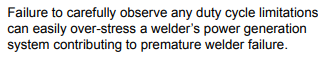

A duty cycle limit is placed on welding machines to prevent the sensitive internal components from heat damage. Most welders experience significant damage if their duty cycle is breached. This is true even if the machine continues to function as usual after it cools down.

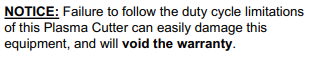

Every welding machine can breach its duty cycle many times before it breaks. But, many manufacturers place a dire warning in the instruction manuals saying that the duty cycle must not be breached. Sometimes continuously breaching the duty cycle limits will void your warranty.

The image shows a paragraph in the Titanium Easy Flux 125 instruction manual. This is common with many brands.

The image shows the warranty warning for the Titanium Plasma 45 plasma cutter. Losing a warranty for breaching the duty cycle limits is not very common, but it’s something to keep in mind.

Every welding machine has thermocouples inside it, which measure the internal temperature at the critical parts most prone to failure from overheating. If these temperature sensors sense high heat in these components, the welding machine will shut down to prevent damage.

The whole point of a duty cycle rating is to keep you welding in the acceptable internal temperature range.

Factors That Influence the Duty Cycle

Almost everything has an impact on the duty cycle. That’s why it’s challenging to perfectly match the welding machine duty cycle with real-life conditions. The actual welding time will vary slightly or drastically depending on several factors.

Ambient Temperature

All manufacturers rate their welding machines’ duty cycles at a specific ambient temperature. The industry’s gold standard is 104 F, 40C, but you should always check the instruction manual just in case.

But, if you weld at a higher ambient temperature than what the welder was rated for, you will get a lower duty cycle. The same goes in the opposite direction. If you weld in a cooler environment, you will get more welding time before the welding machine needs to cool down.

This is especially true when welding outdoors. That’s why it’s harder to hit the duty cycle limits in autumn/winter than in spring/summer. Hot climates like in California, Texas, and Florida, or even worse in Australia, take a toll on the welder. So, it’s always a good idea to buy a machine with a higher duty cycle if you plan to weld when it’s hot.

Amperage Output

The more power your welder outputs, the shorter the duty cycle. On the other hand, if you lower the amperage output, the duty cycle increases.

Some machines are rated with a 100% duty cycle at a lower amperage output. This means that you can weld indefinitely. Take a look at the Hobart Ironman 240 graph again. It can run at about 140A without any need to cool down. But, this again depends on the ambient temperature.

Nevertheless, if you wish to avoid hitting the duty cycle, lower the amperage below the welder is rated, and you will get more welding time.

Welder Quality

So.. What happens if those thermocouples are not placed near the sensitive components inside the welder? What if there is a delay between the moment the critical part breaches its maximum allowed temperature and when the thermocouple senses the heat and sends a signal to shut down the machine? Or what if the thermocouples are broken or missing from the welder?

Yep. You guessed it. That’s definitely not good.

That’s why you should buy welders from tried and tested brands. There is a reason why a random, import brand will die sooner than quality machines from Miller, ESAB, or Hobart. Better brands have more access to quality parts, and have qualified engineers to design heat management properly.

Do I Need a High Duty Cycle Welder?

You do not need a high-duty cycle welder unless you do high-volume welding. Even if you are a professional, you can manage with the low-duty cycle machine. It’s just that the duty cycle will be a bottleneck for your business.

It is always better to have a longer duty cycle, but it usually comes with a higher price tag. But, you will have less downtime.

Hobby welders don’t need more duty cycles. However, if there is a welder with a better duty cycle at the same price as the welder with a lower duty cycle, it’s better to go with the former.

How To “Extend” the Duty Cycle?

You can’t really extend the rated duty cycle, but you can help prevent the thermal overload. Keep the welding machine away from other objects and walls so that its ventilation openings are not obstructed. Additionally, ventilate the room you are welding in.

Of course, you will need adequate ventilation anyway because the welding fumes are dangerous. But, good ventilation also helps keep the machine cool. Avoid welding continuously unless necessary. The continuous operation doesn’t let the machine cool down between the welds, and the power supply will get hotter.

Duty cycle and MIG welding

To add to the previous point, the duty cycle is most important for the MIG welding machine. That’s because this welding process lets you weld without many pauses.

On the other hand, TIG welding and stick welding processes require frequent pauses to change the stick welding electrode or a filler metal rod.

So, these arc welding processes don’t weld continuously, or at least not unless a part of an automatic process.

The MIG operator, however, doesn’t need much off time. So unless you have a reasonable duty cycle, you should plan your welding ahead. Don’t make a continuous weld if it requires a high amperage that will hit the thermal overload protection. Instead, break it apart into smaller weld chunks.

Frequently Asked Questions

What is a 60% duty cycle?

The 60% duty cycle on a welder means that the machine can output the rated amperage for 6 minutes out of a 10-minute interval.

What does a 100% duty cycle mean on a welder?

The 100% duty cycle on a welder means that the welding machine can weld indefinitely at rated amperage.

Why should a welding machine never be overloaded?

The welding machine should never be overloaded because it can catch fire. This is dangerous, and you should ensure proper airflow at all times.

What is a good duty cycle?

A good duty cycle for welding is a rating that allows you to do your job with minimal interruptions. So, it depends on the kind of work you do and the volume of welding. But, the welding process also plays a major role. A TIG machine performs better than a MIG welder, for example. That’s because TIG welding is usually done on thinner materials, while MIG requires a higher amperage output.

Conclusion

The duty cycle percentage is a significant value to consider when buying your welding machine. If you weld often, especially at higher ambient temperature, it is necessary to have a much higher duty cycle than what hobbyist welders provide.

But, if you are a weekend warrior, most machines will get the job done. Just make sure you stop welding as the power source is approaching its limits.